-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Supply Chain Management

The nature of supply chains has evolved over the years, with new technologies and many players in the middle making logistics highly complicated and expensive. A report by PwC indicates that logistics and supply chain costs account for approximately 10% of the organization’s total expenses. This is the most costly issue businesses struggle to minimize in their supply chain operations.

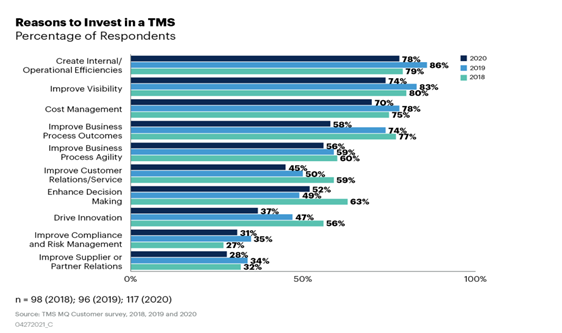

Managed transportation systems (MTS) address this problem, providing an organized way of consolidating logistics and eliminating waste. According to Gartner, the transportation management systems (TMS) market is expected to grow by 60%. This boom exemplifies the role of MTS in adapting to the prevailing dynamics of supply chain management.

This article will define MTS within the supply chain, reveal its operational and financial advantages, and explain how companies can embed them within their current structures and processes without disruption.

Benefits of Using Managed Transportation Systems

Managed transportation systems (MTS) go beyond optimizing shipping routing and data analysis management. They help manage logistics, allowing companies to concentrate on their primary business operations. Outsourcing the transportation management systems promotes professional development within the organization. It also enhances efficiency by eliminating wastefulness and saves costs in the long run.

The following are key benefits of using MTS in your supply chain processes:

Risk Management

Risk management has become more crucial now than ever because disruptions are bound to impact a company’s performance in its logistics industry. A managed transportation system can reduce risk by controlling carrier relationships and fine-tuning supply chain networks while using data-driven predictive tools to prevent delays or inefficiencies.

Cost Savings

Managed transportation systems assist organizations in selecting appropriate carriers and routes. This helps marketers cut transportation costs. In fact, companies that use data-driven insights can make well-organized decisions geared toward saving and managing costs effectively in the long run.

Simplified Day-to-Day Operations

If your company outsources logistics management, it can concentrate on its core business activities, such as developing new products and servicing customers. MTS providers manage logistics complexities, from booking shipments to addressing issues that may arise, so internal resources can be focused on core operations, increasing operational efficiency.

Enhanced Data and Insights

MTS analytics helps businesses monitor where logistics failed in real time. These insights allow businesses to make timely decisions, reduce delivery time, and optimize supply chain operations. Research indicates that data analytics helps cut costs and improve service levels.

Achieving Cost Efficiency with Managed Transportation Solutions

To stay competitive in the logistics market, your business must focus on reducing the cost of operations. But how do we achieve this? It’s pretty simple: Integrate managed transportation systems into your business.

Here are some vital hands-on ways to guarantee cost-effectiveness with MTS.

Carrier Optimization

Cost efficiency starts with choosing the appropriate carrier. MTS providers are not always out to settle on the cheapest rates but instead aim to optimize carrier selection by balancing cost and service performance. This guarantees timely deliveries and reduces transport costs.

Route and Mode Optimization

MTS helps companies find an optimum route and transport mode, resulting in huge cost savings. Increased route planning and mode selection for faster transit times help save on fuel consumption.

Data-Driven Decision Making

Data analytics are essential tools in minimizing a company’s costs. MTS vendors gather information from multiple systems and provide organizations with intelligence regarding logistics activities. Predictive and prescriptive analytics help forecast demand, anticipate disruptions, and make informed decisions that drive long-term cost savings.

Harnessing Data-Driven Insights for Superior Supply Chain Management

As supply chains grow more complex, data and analytics have become more than an optional add-on; they have become enablers of efficiency and resiliency. With the situation becoming even more complicated due to global disruptions, regulatory demands, and changing market conditions, data-driven approaches can bring a paradigm shift in supply chain management.

Here’s how businesses can capitalize on data-driven capabilities to improve the efficiency of their supply chain.

Supply Chain Data Management

Effective data management is the backbone of survival in the modern supply chain. There is an increasing reliance on advanced analytic tools for managing large volumes of data, which warrants quick insights and quicker actions.

According to KPMG’s Future of Supply Chain report, 39% of global supply chain professionals say they will invest in digital technologies to strengthen their data analysis capabilities. The readily available data enables an organization to anticipate interruptions, enhance visibility, and support efficient actions that maximize costs and service.

AI-Enabled Supply Chain Planning

Traditionally, demand planning is frequently carried out across departments using antiquated methods. This always leads to slow and less accurate forecasts. Fortunately, using AI-powered supply chain planning, the gaps between internal and external data can now be eliminated by leveraging unique machine learning models that link disparate types of information into a much more accurate forecast.

Generative AI in Supply Chain

Generative AI (GenAI) can transform supply chain management by making automation and decision-making easy. Examples of Gen AI use cases are translating complex data, summarizing legal documents, and analyzing customer feedback in real time.

Gen AI helps supply chain leaders more easily spot early warning signs, such as disruptions in supplier countries. It also supports faster response due to its capacity for handling huge amounts of information.

Best Practices for Leveraging Managed Transportation Systems in Your Business

A managed transportation system is a significant step and must be planned accordingly. Some best practices can help guide the process and ensure business gain from these systems.

1. Evaluate the Specific Needs of Your Business

Each company has different logistics requirements, and there may not always be a one-size-fits-all answer. When choosing a managed transportation provider or system, map your specific needs and see if they align with what they have—this is key. Shipment volume, frequency, and where you operate your business are some things to reflect on.

2. Monitor Key Performance Indicators (KPIs)

Measuring success for managed transportation system metrics begins with setting KPIs as they provide the capability to formulate results and track ongoing progress. Some metrics to monitor in your LSP are on-time delivery rates, transportation cost per shipment, and how fuel-efficient they run. Frequent monitoring of these KPIs will help determine the probable areas where the system could be improved to deliver desired outcomes.

3. Focus on Continuous Improvement

The logistics industry is ever-changing, and what works today may not work tomorrow. Businesses should be proactive agents, constantly assessing their managed transportation system and making informed course corrections based on data intelligence and performance metrics.

While this explanation can be more in-depth, businesses that embrace these best practices will have a smoother deployment of their managed transportation system and the operational as well as cost-saving results they expect.

Conclusion

There are many benefits of using managed transportation systems for businesses trying to improve supply chain efficiency and cost savings. MTS gives companies the tools needed to modernize logistics by delivering real-time visibility, route optimization, and data-driven decision support so that carriers can gain a competitive advantage in an increasingly complex supply chain. By deploying these systems, businesses can reduce costs and improve compliance and overall customer satisfaction.

*This article is written by Sheer Logistics. Sheer Logistics provides technology-driven supply chain solutions that empower businesses with visibility, efficiency, and agility across their logistics operations. With a focus on transparency and strategic partnership, Sheer Logistics helps clients optimize their supply chains and drive sustainable growth.

When cargo theft occurs, the entire supply chain suffers. Manufacturers must be aware of these recent trends occurring and act accordingly to protect their assets. With smart planning, businesses can adequately thwart thieves and safeguard their employees. Here are considerations for manufacturers to move in the right direction.

1. Understanding the Most Significant Risks

First, companies should understand the specific threats to which they are most vulnerable. The most immediate danger could be trucks in unsecured areas where thieves can quickly access them. In other instances, manufacturers may see organized crime targeting highly valued goods. Regardless, business owners need to acknowledge their weaknesses.

Researchers have investigated risk influential factors (RIFs) to determine the most damaging aspects. A 2022 study published in Reliability Engineering and System Safety developed a data-driven Bayesian network model to predict and diagnose cargo theft. The experts said product category, year, region, location type and modus operandi are the most significant RIFs. Therefore, manufacturers should be aware of these guidelines.

2. Leveraging Advanced Algorithms

Improving cargo security has become more challenging due to increased attack surfaces and opportunities for outside threats. In response, manufacturers must leverage advanced technologies like artificial intelligence (AI) and machine learning (ML) to protect their assets. Algorithms are excellent tools for business owners because they reduce the theft risk when transporting goods on the road.

A 2024 study published in Computers and Industrial Engineering used a physical internet-based analytic model to combat rising cargo theft. The researchers used real-world scenarios in their experiments to understand the benefits and drawbacks. Their model determined the risk of different product types based on their specific routes, allowing them to better understand the threshold where shipments become vulnerable to criminal organizations.

3. Using the Internet of Things (IoT)

IoT devices are critical for management operating systems (MOS) because they enhance software and hardware capabilities. With these gadgets, manufacturers can improve productivity and financial performance. IoT research is also critical for securing cargo through each step of transit. For instance, GPS technology provides real-time knowledge of each shipment.

Manufacturers should take advantage of IoT because it can be present with the device and around the facility. Smart cameras are an excellent example because business owners can remotely monitor the feeds and promptly take action. Advanced technology also lets manufacturers take extra steps to protect their cargo. Smart locks with biometric recognition are a vital safeguard against thieves.

4. Improving Cybersecurity Practices

Cargo theft increased by 46% in the first quarter of 2024 compared to the same time in 2023. CargoNet reported 925 incidents in the quarter, emphasizing the need for heightened security tactics. While physical barriers are necessary, manufacturers should also improve their cybersecurity practices. Internet crime is equally damaging to companies and could be more challenging to predict.

Ransomware attacks are among the most pivotal for manufacturers, considering their frequency. A 2022 IBM report found that 23% of these incidents affected manufacturing, making it the most targeted industry. Preventing ransomware attacks entails basic to advanced cybersecurity tactics, such as multifactor authentication, anti-malware software and software updates.

5. Selective Supplier Partnerships

Some manufacturers outsource specific tasks to reduce overhead and strengthen their bottom line. In addition to these partners, companies must watch other links in the supply chain. Businesses should monitor supplier relationships to ensure security — otherwise, they risk lost revenue and downtime while fixing errors.

Supplier relationships start with background checks and regular audits. Manufacturers must ensure these partners do their best to detect and address vulnerabilities. Business owners should find companies with pertinent industry certifications like C-TPAT if applicable. Monitoring should continue throughout the relationship with consistent communication and key performance indicators (KPIs).

6. Properly Training Employees

While suppliers can be security liabilities, it’s equally essential for manufacturers to monitor their employees. Workers may willingly or unknowingly contribute to cargo theft through their actions, so businesses should protect them from themselves. First, company leadership should train employees on best security practices, such as reporting procedures and proper loading.

Then, the company should focus on internal theft from its workers. Experts say over 75% of employees have stolen from their employer at least once. Therefore, robust internal measures should be in place to prevent theft. Mitigating employee stealing includes restricting access control and using biometric scanners. Business owners could also encourage workers to be vigilant of suspicious activity.

7. Controlling Supply Chain Aspects

Ultimately, it’s up to manufacturers and business owners to control as many supply chain aspects as possible. Internal audits are a valuable tool because they reveal gaps in shipments and where theft has potentially occurred. Once a company understands its insufficiency, leadership teams can act accordingly. Businesses should audit their inventory, security and other critical business features.

Supply chain professionals should also regain control in areas they may consider less secure, such as transit. Highways and oceans provide plenty of unknowns, so businesses must protect their cargo before, during and after the route. Besides GPS devices, forward-thinking companies wield electronic seals, telematics devices, light sensors and other tech.

Tackling Theft and Protecting Assets

The rise in cargo theft should alarm manufacturing professionals and business owners. Outside threats have become more sophisticated through physical and cybersecurity risks. While crimes have increased, manufacturers should proactively combat thieves. Leadership teams should scrutinize suppliers, employees and other aspects of the supply chain to ensure safety.

*This article is written by Jack Shaw. Jack is a seasoned automotive industry writer with over six years of experience. As the senior writer for Modded, he combines his passion for vehicles, manufacturing and technology with his expertise to deliver engaging content that resonates with enthusiasts worldwide.

How’s your supply chain running these days? If you’re like most manufacturers, you’re still experiencing challenges. Big challenges. The pandemic threw the worldwide supply chain into chaos and it hasn’t yet recovered, but the truth is, there have always been supply chain issues bedeviling the industry. The pandemic just exacerbated what already had the potential to go wrong and uncovered new problems lurking just below the surface.

Just-in-time strategies, which were (and continue to be) popular methods of having just the right amount of inventory on hand at any given time, left manufacturers vulnerable to supply chain disruptions. The increasing complexity of global supply chains didn’t help the situation, nor did the pervasive lack of visibility into supply chains themselves.

What are manufacturers facing this year in terms of their supply chain? Let’s take a look at these issues, and examine some ways USC can help.

Manufacturers supply chain challenges for 2024

Materials shortages. Global instability, the lingering effects of the pandemic and other factors are leading to shortages of raw materials and components. Production delays, increased costs and unhappy customers are the result. And speaking of costs…

Rising freight costs. As fuel prices ride the same roller coaster we’re all seeing at the gas pump, and labor shortages and ongoing congestion at ports collide, it means costs to get those components and materials are going up, eating into your profits. And speaking of labor shortages…

Labor shortages. This problem is ongoing, and we have to say, it’s one thing that wasn’t caused by the pandemic. Manufacturing workers are aging and retiring, and there isn’t a large pipeline of younger people with the skills to replace them. It means reduced output and productivity, dwindling motivation and drive, and the loss of institutional knowledge.

DRIP. It stands for data rich, information poor. When you’re talking about the supply chain, it means you need to use data to its fullest. Outdated inventory systems won’t cut it.

Tactics that can help

Diversifying supply chains. Having too many eggs in one basket has proven costly when that basket falls apart. Reliance on any one supplier, especially if that supplier is overseas, is becoming yesterday’s strategy that is just not working in today’s market.

Reshoring. Supply chain disruption, ongoing global instability, higher costs (including higher labor costs in China), increased lead times and more hassles are leading companies to reconsider foreign sources. Many are already doing it. Yahoo Finance reported in June 2023 that 80% of manufacturers are now considering or acting on reshoring some or all of their production. A couple of quick examples: General Motors invested $7 billion in production facilities in Michigan to not just manufacture electric vehicles but the batteries that power them. Intel invested $20 billion in a new semiconductor manufacturing plant in Ohio, and is investing $30 billion for a similar facility in Arizona. Some manufacturers are “nearshoring,” bringing production closer to home, from China to Mexico, say. Not only will this reduce lead times, improve quality control and leave companies less vulnerable to global unrest, it will also create jobs here at home.

SIOP. We laud this tactic often because it really does improve efficiency, but in the age of supply chain disruption, it’s crucial. Sales, Inventory and Operations Planning (SIOP) is a collaborative process that aligns all departments. It involves using inventory as a strategic tool, demand management and supply planning, giving you the ability to capture, analyze, integrate and interpret data to give you a strategic advantage.

Learn more about SIOP in our free eBook, Sales, Inventory and Operations Planning: It’s About Time.

Solid training. The labor shortage isn’t going away, and we’re finding that many manufacturers are investing in training, ensuring that everyone is doing the job the same way, with rock-solid operating procedures. It’s a powerful way to keep institutional knowledge within your facilities, instead of losing it when people retire.

At USC Consulting Group, we have over 55 years of experience helping manufacturers ramp up their efficiency, production and operations. It’s especially crucial to be firing on all cylinders during challenging times… and we’re in them, right now. Give us a call and let’s talk about how we can help.

Effective inventory management is often a challenging task for businesses to undertake. While some factors may be similar across organizations, predicting inventory demand can vary significantly depending on the industry or business model. One of the most common problems affecting various industries is a lack of inventory visibility.

Inventory visibility issues have become increasingly prevalent with the rise of online shopping. The additional steps and expediency demands of this now preferred process can make tracking an item even more complicated. This often results in invisible inventory, where materials or products are unaccounted for in the system.

To address these issues, many companies are turning to supply chain visibility (SCV) technologies to remain competitive. These advanced systems provide real-time tracking, monitoring, and notification of each item in the supply chain. By utilizing responsive supply chains, a company can increase transparency within its inbound/outbound processes and other daily activities.

Another innovative solution is cloud-based POS systems and e-commerce management software. This technology integrates every aspect of a business for greater efficiency and offers a range of benefits. Companies can use it to track sales and customers, exercise better point of sale control, automate inventory replenishment, and generate reports with detailed analysis of gross margin ROI.

By utilizing modern technology to improve inventory visibility, businesses can stay ahead of the competition and provide better customer satisfaction. To discover strategies for staying ahead in inventory management, we encourage you to explore the resource provided below. It offers valuable insights to help you tackle this crucial aspect of your business operations.

Invisible Inventory from Celerant, a bike shop pos system company

If you need assistance with your inventory management, contact USC Consulting Group today.

The B2B supply chain is changing in this tech-forward world. Like so many other things, if you’re not getting on board with smart business tech, you could be missing out on important successes. That starts with your supply and integrating tech to reduce human error and track things more clearly.

As a B2B business owner, you already know that transactions tend to happen within the supply chain. Whether you’re a wholesaler or retailer, if you’re not using tech to keep track of your supply and your sales, your business might not be able to keep up with those who are integrating different types of tech – including cloud-based technology.

Let’s take a close look at how smart business tech is optimizing the B2B supply chain, and what steps you can take to implement more sophisticated technology into your management strategy.

Why Smart Tech Matters

Tech innovations aren’t just important for manufacturing purposes. They are extremely beneficial for every step in the B2B supply chain. If you’re a supplier, integrating smart tech into your supply chain strategy can help with things like:

- Compliance

- Cash flow

- Efficiency

- Accuracy

- Speed

You’re also reducing the risk of human error throughout the process, especially when it comes to processing and fulfillment. Integrating smart technology as a part of your risk management plan makes it easier to reduce risk and put plans in place for fast recovery if disaster does strike within your supply chain.

Additionally, when you use things like automation and AI, you’ll actually end up freeing up many of your employees so they can focus on other tasks while improving efficiency. Your business can grow, your employees can move up the ladder, and you can move more product safely and quickly.

What You Can Do Today

Although technology is quickly advancing, there is plenty of technology you can start implementing into your B2B supply chain strategy immediately. For example, Enterprise Resource Planning (ERP) software will help you overcome existing challenges you might face within supply chain management, including:

- Customer acquisition

- Retention

- A global shift toward e-commerce

- Time constraints

With this kind of software, you’ll enjoy seamless data transfer from system to system. This offers another opportunity to reduce human error while optimizing your efforts because you won’t have to rely on manual data entry. Instead, you’ll have a consistently-updated clear picture of your efforts.

You’ll also be able to take advantage of automated workflows and accurate shipment tracking while offering greater confidence in fulfilling orders on time.

Integrating ERP software into your existing system should be just the beginning when it comes to what you’ll be able to do in the future with smart business tech. As you continue to grow, take advantage of existing technology that is becoming more widely available to small businesses and enterprises alike.

Preparing for the Future

As our globe becomes inundated with fossil fuels, every business needs to do its part in reducing its footprint to succeed in the future. Luckily, our world has combined the power of technology and sustainability, and nowhere is that more evident than in solar power technology. In the last decade alone, the limits of solar technology have broken down significantly. Today, solar power has been used for a variety of purposes, including transportation, military defense, and even space exploration.

When it comes to harnessing solar power for your B2B supply chain, it can be utilized almost anywhere you’re currently relying on traditional forms of energy. You can take advantage of solar energy-powered transportation by integrating it into your fleet. Not only will it help to reduce your overall reliance on fossil fuels and reduce your budget for fuel, but it can shed a positive light on your business practices and help with client acquisition

In addition to solar technology, you should also be looking into 5G for the future of your supply chain. Integrating 5G into your existing supply chain tech will help to reduce disruptions and improve optimization efforts. Things like smart sensors can be placed on your fleet trucks to track product location or determine the cause(s) of delays in real time. Shipments can be tracked electronically to prevent cargo from getting lost. Again, the risk of human error will be greatly reduced this way. 5G makes it much easier to implement AI and automation into your strategy without having to worry about network lags or lapses in connection.

Many people look at the supply chain industry and automatically assume it’s outdated. Others think if it’s not “broken,” it shouldn’t be fixed. But, smart technology is already optimizing the B2B supply chain, and the businesses that don’t jump on board will experience greater losses, delays, and burnt-out employees for years to come. Consider some of the tech solutions you can implement now and in the future, and you’re likely to see greater success and more streamlined production.

*This article is written by Ainsley Lawrence. View more of Ainsley’s articles here.

Supply chain technology has come a long way in the past few years. Improvements in AI technology and deep learning programs can help supply chain managers accurately predict shortages, adapt to current conditions, and operate more efficiently.

Supply chain technology can also be used to improve the customer journey. Effective supply chain management leverages the Internet of Things (IoT) to give consumers greater control over their orders. Emerging technology can also be used to reduce human error, increase operational efficiency, and improve security.

These breakthroughs in technology improve the customer experience and ensure that consumers get the products they want when they need them.

CX and SCM

At first glance, consumer experience (CX) and supply chain management (SCM) seem unrelated. However, as senior sales executive Sven Esser points out “the relationship between CX and SCM is symbiotic.”

Esser goes on to explain that effectively mapping the customer journey is an important facet of effective CX and SCM. Predicting consumer behavior ensures that supply chains are operating as efficiently as possible and that consumers have accurate information about shipping and order fulfillment before they check out.

Esser advocates for a model of SCM that gets to know consumers and uses AI analytics to accurately map and predict the typical consumer journey. This will help businesses connect with consumers’ personal needs and help supply chain managers shift to a more “customer-focused effort.”

Businesses can use AI analytics to map the consumer journey and improve their SCM through Google Analytics (GA4). GA4 is typically used by marketers who want to improve the materials. However, GA4 can also be used to track users from the referral page to the conversion or exit page.

Supply chain managers can work with marketing to get a better picture of the consumer journey and typical behavior. GA4 can be particularly useful for businesses that use the IoT to place orders or improve CX.

The IoT

The Internet of Things (IoT) is revolutionizing industries around the world. Consumers and businesses can use the IoT to link devices and create “smart” networks between products and machines.

The IoT can also improve the efficiency of supply chains by giving businesses an up-to-date assessment of inventory and potential problems. For example, a business that runs an IoT-integrated warehouse will be aware of issues like faulty equipment and disrupted supply lines earlier than competitors who do not leverage the IoT.

IoT-integrated supply chains can improve the consumer journey directly, too. IoT technology makes it easier for customers to place and edit orders. For example, folks who utilize smart home devices like Google Nest or Amazon’s Alexa can place and edit orders with a simple voice command.

Human Error

Emerging technology like AI software and the IoT is designed to improve operational efficiency and streamline the consumer journey. However, human error still threatens to derail business operations and supply chains.

Supply chain managers can reduce the risk of human error in the workplace by automating relevant processes. This is particularly important in warehouse management, where human error may result in injury due to repetitive motions or dangerous working conditions. Automated machines in smart factories and warehouses can take humans out of the firing line and ensure that customers have their orders fulfilled with minimal delays.

Supply chain technology can also improve post-sale communication with consumers. Consumers who have ordered expensive goods want regular updates on the status of their products. Businesses can send out automated emails when the customer’s product has passed production phases and is ready for shipping. Automated communication improves the customer journey by alleviating worries about order fulfillment without derailing operational efficiency.

Operational Efficiency

Operational efficiency is at the heart of a successful customer journey. Customers can tell when all departments are working in unison and will benefit from quicker order fulfillment due to higher efficiency in the workplace.

Maximizing operational efficiency is particularly important for businesses that use Just-in-time (JIT) inventory management. JIT inventory management relies on accurate consumer forecasts and robust supply chain management to ensure that businesses get the inventory they need just when they need it. This can result in major savings, which can be passed onto the consumer or used to otherwise improve the customer journey.

However, for inventory management methods like JIT to work, businesses need to hyperautomate their operations. Hyperautomation allows businesses to “rapidly identify, vet, and automate as many business and IT processes as possible.” Hyperautomation relies on deep learning programs that can successfully capture and utilize massive data sets. This will improve the customer journey, too, as the same data sets can be used to present personalized adverts and products to consumers.

Conclusion

Emerging technology like the IoT can have a direct impact on the customer journey. Consumers today can place, edit, and receive orders using a network of machines and devices that are connected by AI algorithms. Recent upgrades to supply chain technology can also improve operational efficiency and reduce the risk of human error in factories and warehouses. This ensures that consumers receive their orders with minimal delay and at a lower cost.

*This article is written by Ainsley Lawrence. View more of Ainsley’s articles here.

In many industries, globalization has resulted in the consolidation of suppliers and increasingly interdependent Supply Chains. Globalization has increased efficiencies and economies of scale, but it has led to decreased diversity of sourcing and supply options.

Increasing geopolitical tensions, pandemic related lockdowns, and ideological polarizations have increased supply chain disruptions for many products and materials.

Supply Chain Risk Management System

An active Supply Chain Risk Management System cannot ensure continuity of supply, however, it can provide a playbook with options when sources of supply are threatened.

Download our free eBook “The Supply Chain Risk Management Playbook: Navigating Through an Uncertain Supply Chain Future” as we advise how to identify and respond to the unique risks that affect your business.

This Playbook details the various concepts that will secure your operations, including:

- Planning the Risk Management assessment

- Conducting the Risk Management assessment

- Checking your findings

- Acting on your findings

Planning the Risk Management Assessment

During the planning stage you will define the project charter and assess your organization’s Risk Tolerance.

Conducting the Risk Management Assessment

Once management has defined success and risk tolerances, it’s time to take action and conduct the assessment.

Check your findings

This step must be tailored to the risk being assessed. Here you will build the risk models and validate the assumptions with your stakeholders.

Act on your findings

Once all appropriate stakeholders have agreed to the change, put the risk mitigation strategy into action.

For full details on each of these critical stages, download the complete Playbook below:

Installing a well-functioning Supply Chain Risk Management Operating System is a journey, not an event.

Enhancing responsiveness to risk provides competitive advantages, especially in industries where competition for key vendors, access to resources, and logistics constraints are prevalent.

USC Consulting Group’s Supply Chain experts have over 50 years of industry experience with the latest risk management practices and can help you with your unique challenges. Contact us to remove the risks and start driving operational improvements in your business.

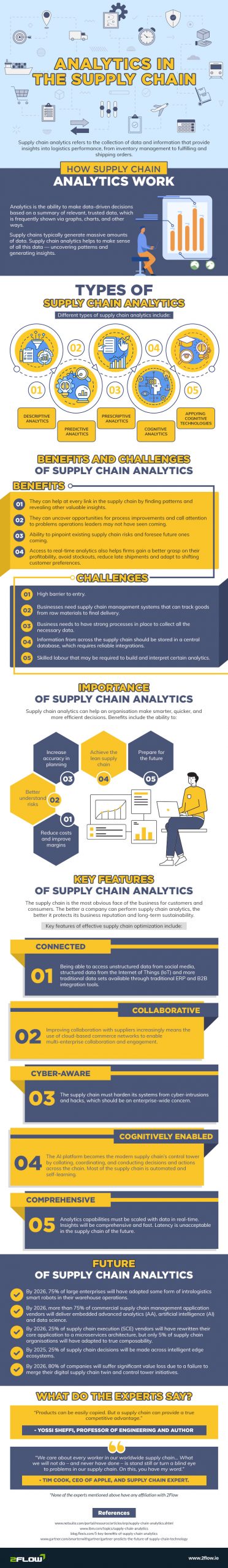

Supply chain analytics refers to the collection of data and information that provide insights into logistics performance, from inventory management to fulfilling and shipping orders.

How Data Analytics is Changing the Supply Chain Landscape

The ever-increasing reliance on big data is altering the landscape of supply chains as we know them. Historically, the majority of supply chain management was dependent on intuition and experience. However, with the introduction of powerful data analytics technologies, supply chains are now guided by data-driven decision making.

The ever-increasing availability of data is driving this transition. Previously, data was dispersed across numerous silos inside a business, making it difficult to provide a comprehensive perspective of the supply chain. Organizations, on the other hand, may collect and store data from all areas of the supply chain in one central location owing to data warehouses and data lakes. This enables supply chain managers to see the entire picture and make data-driven decisions to increase efficiencies and performance.

The rising availability of strong data analytics tools is another factor pushing the change to data-driven decision making. To examine data in the past, supply chain managers had to rely on manual procedures or limited software tools. However, a wide range of powerful data analytics technologies is now available to assist managers in making sense of massive data sets and uncovering hidden patterns and trends. The transition to data-driven decision making is reshaping the supply chain landscape and has far reaching implications for how businesses function.

Organizations may improve the efficiency and performance of their supply chains by leveraging the power of data, providing them with a competitive advantage in the marketplace.

The Advantages of Data Analytics in Supply Chain Management

Data analytics can aid in the smooth and effective operation of supply chains. Supply chains can uncover patterns and trends in past shipments by examining data from previous shipments. This can help them minimize disruptions and stock-outs while also improving inventory management. Furthermore, data analytics can assist supply chains in optimizing their routes and schedules, as well as tracking their success over time.

Here are some of the primary advantages of employing data analytics in supply chain management:

- Reduced Inventory Costs

- Optimized Production Plans

- More Efficient Cargo Shipments

- Reduced Risks

- Cross-Functional Cooperation

Check out the following infographic by 2Flow which takes a deep dive into ‘Analytics In The Supply Chain’.

Supply chain analytics are guiding managers into the future with data-driven decision making. If you need assistance properly analyzing your data and setting up your supply chain management for success, contact USC Consulting Group today.

The automotive industry outlook shows it travelling down the road toward another challenging year. The global supply chain is still reeling from COVID-era issues resulting in slow manufacturing times. Reduced consumer demand for traditional vehicles is impacting the industry, and the gasoline crisis amid the Russia-Ukraine tensions is keeping people off the roads. Despite these challenges, there is great reason for positivity. Brighter skies are on the horizon.

One especially bright spot: Electric vehicles. EVs have taken the market by storm, with many manufacturers worldwide making pledges for increased production and utilization of this emerging technology. Along with that comes increased need for things like batteries and charging stations to support widespread EV use. It’s exciting to see the increased need for the infrastructure and tools required to go electric!

In this article — with information from The Economist Intelligence Unit’s (EIU) comprehensive Automotive Industry Outlook 2023 — we will highlight key trends to be aware of in the industry for the coming year.

Gas Uncertainty

As long as the tensions between Russia and Ukraine persist, gas prices and availability will remain a question mark — but it’s a trend that started long before those tensions erupted. It began with the COVID pandemic.

Beginning in March of 2020, demand for gas plummeted when the majority of the U.S. was put on forced isolation. People just weren’t commuting. The highways were like ghost towns. Midway through the pandemic, folks started wondering when was the last time they filled up their gas tanks. They might not have been able to remember, but the industry certainly did. It caused many of the oil refineries in the United States to stall or close their doors for good.

While refinery numbers are slowly creeping back up, challenges still exist. According to the Refinery Capacity Report from the U.S. Energy Information Administration (EIA), this past June saw a refining shortage of roughly one million barrels of oil a day compared to pre-pandemic numbers. Add that to the ongoing tensions in Eastern Europe, and the market has many questions to answer in regards to supply and refinement capabilities.

Supply chain shortages

While the global supply chain is rebounding from the unprecedented COVID-era delays, there is still work to be done and shortages of supply.

One of the most prominent concerns for the automotive industry is the status and availability of semiconductors. EIU anticipates that additional capacity for this essential piece of equipment won’t come until 2024 — and the shortages of essential minerals such as steel, aluminum, nickel and lithium won’t just impact the semiconductor market, but the production of EV batteries as well.

To combat this, many countries are taking action to increase local production and mineral extraction. The United States, for example, recently passed the CHIPS and Science Act of 2022. According to the White House briefing, the act will drastically increase domestic semiconductor research and production, and “strengthen American manufacturing, supply chains, and national security, and invest in research and development, science and technology (…) including nanotechnology, clean energy, quantum computing, and artificial intelligence.”

It remains to be seen if this can supplement the semiconductor shortage for 2023, but it is certainly a step in the right direction for future availability.

Stalled sales

After a rise in both new and used vehicle prices in 2022, sales for traditional automobiles are set to decline in 2023. The reasons include a perfect storm of reduced commuting time for people who continue to work from home, continued high gas prices and the aforementioned supply chain issues and semiconductor shortages, which caused a massive increase in cost for both new and used vehicles. The result? People are putting off buying new vehicles as their cars sit in their garages. One of the biggest culprits is simply the rising prices of new cars. Consumers paid $3,462 more on average for a new vehicle in 2022 than the previous year.

Slowly but surely, as the supply chain issues are repairing and more supply enters the market, sales and prices are set to decrease in the upcoming year. The EIU predicts that new car sales will decrease by 2.4% in North America… but estimated global vehicle sales of $79 million will continue to fall short of the pre-pandemic $88 million in sales.

“The total EV investment among automotive suppliers and manufacturers is set to reach $526 billion between 2022 and 2026.“

The EV wave

The shining star of the automotive industry in 2023 and beyond is the continued production and implementation of electric vehicles and charging stations.

While electric vehicles only accounted for 8% of global sales in 2021, production and market share is set to explode to an estimated 33% of global sales by 2028, and as high as 54% in 2035, according to Reuters. Not only that, but the total EV investment among automotive suppliers and manufacturers is set to reach $526 billion between 2022 and 2026, nearly double the investment from the beginning of the decade.

The EIU confirms that optimism, predicting that the sales of electric vehicles will grow by roughly 25% in 2023, to almost 11 million units. The ongoing tax breaks and subsidies provided by countries around the world are seemingly propelling this growth, with more incentive now than ever to join the EV automotive revolution.

We can help to navigate uncertainty

While the automotive industry outlook is set for a challenging year in 2023, there is still light at the end of the tunnel for manufacturers to get back on track and capitalize on new trends.

At USC Consulting Group, we are always ready to help your organization stay on top of the automotive industry. Give us a call today to ensure successful operations in the upcoming year and the foreseeable future.

Since Covid people who never heard the term “supply chain” have become painfully aware of what it means and how deeply it impacts their lives. It doesn’t take a viral pandemic to create supply chain disruptions. A factory fire, a natural disaster, or resource scarcity — everyday occurrences — can all lead to items disappearing from shelves.

The recent formula shortage was largely due to a single factory being temporarily shut down.

Product shortages can be a significant hardship for families all around the world. In this article, we talk about how data mining can add stability and predictability to supply chain management.

First, What is Data Mining?

Data mining is the practice of looking at large quantities of information already stored in a database to retrieve new insights from it. Basically, it’s the process businesses use to create actionable knowledge. In the context of supply chain management, the data could pertain to anything from consumer habits, transportation routes, product development, or resource excavation.

Every single action that takes a raw resource out of a mine or jungle and turns it into a product on your shelf creates information. More information than any human (or, for that matter, any room of humans) could ever examine in two lifetimes.

With data mining, data processing, and data analysis, that information can be tamed and channeled toward productive means.

Supply Chain Threats

What variables currently threaten supply chain management? Because there are so many steps taken to turn raw material into a physical product, many variables can interrupt the process. Perhaps there is a storm that halts excavation. A viral outbreak that pauses work at a factory.

Disruptions in the transportation sector. Maybe the demand for a product is so much higher than anticipated that it becomes impossible to manufacture it at an appropriate pace.

All of these scenarios can lead to supply chain disruptions. Through data mining, however, many of them can be mitigated or avoided outright.

Understanding Supply

Let’s say (with unfortunate accuracy) that there is a recession projected to sweep through the country in the not-so-distant future. Naturally, financial downturns can have a significant impact on the way people shop.

But how can stores and supply chain managers use this information to make sure that there is plenty of the things people need and a relatively modest amount of things that will go largely ignored?

Data!

Using historic shopping data, supply chain managers can get a vivid forecast of how people are likely to behave during the next recession. This might mean deemphasizing the production and supply creation of luxury items and focusing more on putting staples on the shelves.

Fleet Management

The transportation industry is an enormously important component of supply chain management. Using IoT (internet of things) and data, fleet managers now enjoy unprecedented control over their routes. Maps, even GPS-driven maps, tend to be relatively limited in how granular they get. Route recommendations mostly factor in distances. Even programs that account for speed limits, etc. do so for the benefit of personal vehicles.

Trucking is a different animal. Does this route include a short overpass that the truck will need to detour to get around? Maybe the road winds, requiring a large vehicle to slow down to a crawl.

With historical route data, mined through telematics technology (sensors, mostly) fleet managers now get automated reports that recommend the best routes for their trucks. These recommendations not only factor in arrival times, but can also be calibrated to make recommendations most likely to preserve the condition of the vehicle.

Transportation companies run more efficiently. Products arrive at their destinations on time. It’s a win for everyone.

Adjusting the Chain

In a post-Covid world, one needn’t stretch their imagination to imagine a scenario where something could go wrong within a supply chain. Delays and shortages can happen after only a single break in the chain.

With data, supply chain managers can make reasonable forecasts about potential disruptions, and plan accordingly. Already, the supply chain management industry has moved toward keeping a healthy supply of alternative production lines — often closer to home — so that they can pivot immediately into new solutions when problems arise.

With robust access to data, supply chain managers can receive quicker insights as to when they should reach for these solutions.

The result? Fewer disruptions, and significantly more consumer stability. No more months and months of waiting for a new refrigerator or oven.

*This article is written by Andrew Deen. Andrew has been a consultant for startups in almost every industry from retail to medical devices and everything in between. He implements lean methodology and is currently writing a book about scaling up business. You can follow him on Twitter @AndrewDeen14.