-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2024 (4)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Process Management

As organizations today have become ever more reliant on networks and other systems that run using 21st century data-driven technology, one way in which they can maximize their potential is through the implementation of a management operating system.

What is a management operating system (MOS), and what can one do for my business?

According to CEO Magazine, an MOS allows for an organization to “better control the flow of work and production, driving higher outcomes in customer service, quality and cost.” At a minimum, these systems make use of tools that allow organizations to create plans for future work in certain operations, carry out that work, and then measure the work performance data to suggest future improvements that could be needed.

In short, an MOS is a set of tools, processes, and frameworks by which an organization’s employees operate. It is responsible for gathering data and then using the garnered information to inform decision making that fosters continuous improvement to address issues as they occur. These issues can range from production shortfalls to those related to worker safety; as such, companies that use production lines or have other types of hazardous workplace environments commonly employ management operating systems.

A MOS is a set of processes and resources by which businesses operate that drive the decision making of important organizational figures.

One way that an MOS can be described is that it is a set of processes and resources by which businesses operate each day that in turn drive the decision making of important organizational figures.

An effective MOS should be able to identify and quantify inefficiencies in an operating system and shift any reactive data-gathering methods towards those based in data analysis. This ensures that any adjustments can be made so operations are not adversely affected. An MOS should also use real-time feedback so an organization can safely direct operations, funding and other resources to maximize return on investment.

Organizations can observe some notable benefits after they implement an MOS, including cost savings, waste reduction, and increased product quality. Among other benefits, an MOS can help organizations identify and close workflow gaps, find ways to improve efficiency, or monitor operations to see if they are in compliance with company or government regulations and policies.

After an organization has implemented a management operating system, it may see the following benefits:

- Increases production cycle efficiency through the elimination of any bane to an organization’s workflows, such as unnecessary overtime or any operational and/or financial surprises.

- Ensures that key products such as raw materials are readily available at all times to meet any production requirements or needs

- Maximizes the potential of available workspace, equipment, inventory, and human resources

- Reduces excessive inventory and can help avoid any defective or outdated products from getting to customers

Human-run MOS still important in the impending age of automation

Some have argued that the MOS has become obsolete with the rise of automated data-driven decision making and the ongoing replacement of human beings in certain occupations with robots and artificial intelligence, according to CEO Magazine. That being said, the article’s author David Hand also argues that this view does not consider reasons that management operating systems were required in the first place, citing a few major points. In particular, Hand predicts that management operating systems will continue to be used wherever there are human beings employed instead of robots. Sectors reliant on human resources that have grown the fastest are the healthcare and professional services such as information technology and engineering, notably among others.

While organizations are able to reduce costs by making use of technology rather than humans, the article notes that cost is only one of two aspects that a customer requires to make a purchase, the other two being service delivery and quality. As a result, organizations that place too much of an emphasis on cost reduction amid a “new wave of innovation” related to technology use have been found to get away with poor customer service and product delivery. To avoid this dilemma, MOS principals such as short interval control and management of variance are important for any enterprise, no matter how big or small.

“Organizations must not be complacent. The struggle to remain competitive and to improve service delivery is unrelenting and a willingness to confront process shortfalls that drive customers away is vital,” Hand writes.

Adherence to an MOS and related principals can also have a positive impact on employees such as knowledge workers with regard to delivering better outcomes. Deadline commitment is the single most effective MOS principal that a knowledge worker can follow, Hand argues, and despite the stress of meeting deadlines, the practice can often result in large dividends.

How can my business best use an MOS, and what are the benefits?

In particular, owners of business operations can employ business management systems not only to bolster their bottom lines, but also to prepare themselves for planned growth or unexpected downturn. Forest Admin’s Thomas Didier concludes that while most businesses it has observed use different methods in their management operating systems, they center around four main components: processes, systems, roles, and structures.

When designing processes, businesses must be sure that they are safe, secure and clear for employees to understand and tools are used to support operations — never are they to be used in ways not dictated by the overall structure. This means that users should not use tools in inappropriate ways, especially those that could simply automate their inefficient methods. An effective MOS uses well-designed systems upon which their employees and processes are reliant to achieve goals, which means they should run smoothly and do not reduce established efficiency. Roles within a MOS should adhere to clearly defined job descriptions that require certain skill sets, and when combined with a business’s processes and systems can best utilize talents. Finally, the best-run management operating systems always establish a business-wide structure upon which the different roles within the company interact. This is usually done last because it ensures that the processes do not dictate the entire established structure and cause further issues.

“Many factors…can have an impact on the definition of your structure. As a result, it is unlikely that two companies with the same processes, systems, and roles will end up with the same structure,” Didier explains.

How to realize benefits when after implementing or improving an existing MOS

Businesses that do not make full use of a management operating system can undoubtedly improve the efficiency and overall profitability of their operations if they are able to create ones that effectively suit their needs. Regardless of whether an organization has an insufficient MOS already in place or does not use one at all, the development of a new one is a process that requires a great deal of investment and commitment from different organizational figures and departments. For example, some older production plants may have become reliant on relatively outdated production line methods and need to reduce observed downtime and inefficient processes in order to cut costs.

Regardless of whether an organization has a poorly planned MOS already in place or doesn’t use one at all, the development of a new one requires a great deal of investment and commitment from different key figures and departments.

Without an MOS in place, those responsible for the plant’s operations should first find a way in which to quantify key performance indicators related to products, assets and even everyday routines; there are different tools and methods that can be used to find out which information needs to be quantified, including those used by consulting services. As a result, conclusions drawn from the former can allow employees to operate more efficiently. This translates into a better understanding of the causes of production downtime, which can drive proactive and accurate decision making. Departmental training should be required with any future changes to a MOS to ensure that it still remains effective.

Rather than come up with the most basic of KPIs as a solution, organizations that use an MOS and aren’t seeing desired results need to reevaluate their methods of quantifying the information upon which they rely. For instance, one scenario might be that a major operation has become reliant on data collection methods that overlook key information explaining the causes of operational delays or unrealistic production deadlines and expectations. With the ability to see how workload expectations relate to overall productivity, a well-run management operating system can help an organization hit its numbers without worry each quarter.

When it comes to important areas in business operations such as the success and cost of a project or the safety and productivity of employees, knowing how to garner the right information and put it to good use is essential.

USC Consulting Group can help enhance your existing MOS or implement an entirely new one using its Client Technology Solutions like LINCS Lean Information Control System. Contact USC Consulting Group today to see how we can help your organization achieve desired outcomes.

In life, bottlenecks crop up from time to time; moments where we’re stuck and can’t push through a problem. Patience may be the only remedy. In the manufacturing sector, however, bottlenecks can be a serious drain on productivity, revenue, efficiency, and asset utilization.

What does a bottleneck mean in manufacturing terms?

When people think casually of “bottlenecks,” they might think of forced congestion, like traffic on a multi-lane highway pinched down to a single lane for construction or emergency reasons. Traffic would be an apt metaphor, as bottlenecks on the road and those in a manufacturing plant are both concerned with throughput and achieving continuous flow.

However, in manufacturing, bottlenecks have their own clear-cut definition as well. According to the Institute of Industrial and Systems Engineers, bottlenecks occur when:

- A process step exceeds 100 percent utilization

- Capacity drops below or equals takt time

- Capacity drops below or equals demand

To identify bottlenecks, plant managers ought to utilize operational data and tighten their focus on steps in assembly that meet these specifications or come close. However, seasoned plant employees and equipment operators may be able to sense and point out potential bottlenecks without crunching the numbers.

What do bottlenecks look like on the plant floor?

For some manufacturing processes, bottlenecks are easy to spot. For instance, if asset operators in a bottling facility – to continue with today’s theme – notice visible accumulation of goods clogging a labeler, chances are the labeler is the issue, so long as all other operations appear to be functioning to capacity.

“One common indicator of a bottleneck is inventory overabundance.”

Other times, bottlenecks are not as readily apparent, but misbehaving processes ancillary to production may clue plant managers into trouble elsewhere. One common indicator of a bottleneck is inventory overabundance. When manufactures have aligned inventory needs against demand properly, inventories should remain relatively lean. Materials overflow in that context, therefore, would signal capacity issues somewhere in production. All that’s left to do is hunt them down and sort them out.

How can manufacturers overcome bottlenecks?

Once plant managers locate their bottleneck, they must perform three basic functions to formulate a solution. First, they must temporarily reduce the capacity of the entire process, carefully watching how a bottleneck functions for any observable performance problems.

Second, upon gathering a few notions as to what may be creating a bottleneck, plant managers must then conduct root cause analysis on each. Root cause analysis involves tracing the conspicuous bottleneck issue back to its true catalyst. Perhaps it’s as simple as a mechanical failure, or maybe as comprehensive as accidental overproduction.

Finally, after arriving at the bottleneck’s root cause, plant managers should assess whether it is a long- or short-term concern. Long-term concerns may require organizational change to correct the issue once and for all, but may require scheduled maintenance or production downtime to finalize the fix.

Short-term concerns generally correct themselves with little to no intervention. However, in the meantime, plant managers may feel more secure in their operations by decentralizing capacity over multiple employees or machinery. That way, should an out-and-out failure occur, manufacturers minimize the effect of downtime on productivity.

Trade advisory consultants at Vigilant Global Trade Services, a turn-key solutions provider for every aspect of global trade management, configured a detailed infographic illustrating how to avoid bottlenecks in your supply chain:

Contact us today to learn more about how you can avoid manufacturing bottlenecks and optimize your operations.

Continuous improvement — this is the dream for forward-thinking shop floor stakeholders across all industries. However, few manage to facilitate such sustained advancement. In fact, more than 40% of the business leaders who spearhead continuous improvement efforts find themselves overseeing failing programs, according to research published in Harvard Business Review. There are a number of common contributing factors, including lacking daily practice. Yes, reinforcing continuous improvement through everyday exercises is essential to success. But how exactly can leaders promote this kind of necessary daily rededication? Embracing the Kaizen methodology ranks among the best options.

Organizations in virtually every sector leverage this Japanese philosophy, which emphasizes operational transformation through incremental optimization. Both formalized and impromptu ideation and root-cause analysis exercises are key to achieving these outcomes. Business leaders who want to implement continuous improvement initiatives that work would be wise to adopt the Kaizen approach and work with employees at all levels to make pragmatic, enduring change.

Mapping the emergence of Kaizen

Kaizen and lean manufacturing occupy the same theoretical orbit. This makes sense considering that they both emerged from the same location: the original Toyota Motor Company production plant located in Toyota, Japan. It was here that management consultant Masaaki Imai collaborated with former Toyota Chairman Shoichiro Toyoda to develop shop floor processes that facilitated continuous improvement or “change for the better,” the literal Japanese translation of Kaizen. These workflows empowered workers to address deficiencies in real time, Quartz contributor Melody Wilding reported. The automaker directed production teams to stop work and collaborate to find solutions for assembly process problems, quotas be damned. This approach reduced error occurrence and wastage and boosted efficiency, helping Toyota evolve into the biggest vehicle manufacturer on Earth.

Imai cataloged, organized, and formalized the strategies deployed at Toyota and published them in his landmark 1986 book, “Kaizen: The Key to Japan’s Competitive Success.” He established the Kaizen Institute one year later, which he has since used to promote the Kaizen approach.

Unpacking the Kaizen methodology

Kaizen centers on five foundational principles. These include:

- Knowing the customer: Understand what customers want and develop positive experiences that appeal to them.

- Let it flow: Eliminate waste wherever possible and focus on value creation on every organizational level.

- Go to gemba: Seek out continuous improvement where value creation happens — the production areas.

- Empower people: Give employees the agency, tools, and support they need to pursue continuous change.

- Be transparent: Leverage accessible performance metrics to propel operational decision-making.

These core concepts underlie all the actionable frameworks and tools that facilitate Kaizen application. Actually implementing the philosophy necessitates coordination and commitment, as only business leaders who adhere to overarching event schedules and agendas can uncover the kinds of shop floor insights that lay the groundwork for sustainable organizational advancement. As mentioned above, Kaizen methodology emphasizes internal collaboration, ideation, and problem solving through formalized sessions. While these gatherings do not generally occur daily, the more consistent and focused cooperation that unfolds, the more likely positive change is to happen.

All Kaizen events have the same goals: getting stakeholders in one place, reviewing existing processes, improving existing processes, and ensuring buy-in. However, these sessions do not share identical frameworks — the strategy allows for variation. Here are some of the most common types of Kaizen events in use now:

- Blitz: Here, personnel completely deconstruct a specific process and reassemble it in an effort to achieve improvement.

- Burst: This event, which happens over the course of three to five days, focuses on rapid process improvement and empowers staff to develop and deploy quick changes with big impact.

- Workshop: During a five-day period, team members conceive production improvements, implement them, and then measure shop floor performance to determine their efficacy.

While there are numerous other Kaizen session types — businesses that have adopted the philosophy over the years have also helped expand it — the collaborative formats mentioned above are typically considered canon.

Coordinating an effective Kaizen event

Kaizen events are immense productions. Internal stakeholders from different departments mingle with external consultants, executive team members depart their corner offices and make appearances, and in the end everyone unites to flip the switch on fresh production processes. With so much involved, impeccable coordination is absolutely essential. Fortunately, there are a good number of formalized event management best practices available to business leaders hosting their first Kaizen sessions. Here are some of the many variables that those involved in Kaizen event planning should address to facilitate success:

- Location: While improvement implementation will obviously unfold on the shop floor, participants must have access to a space within which they can collaborate effectively.

- The agenda: Freewheeling brain storming is not an option within the confines of the Kaizen approach, meaning all events must come with clear-cut agendas.

- The sponsor: Kaizen events typically have high-level internal sponsors who use their clout to green-light operational changes and generally lend support.

- The attendees: Individuals who attend Kaizen events are expected to contribute by mining their specific expertise and experience, a reality that makes attendee selection key.

- The objectives: Kaizen events are meant to spur immediate action that leads to measurable and planned production improvement.

- Information access: The Kaizen approach as a whole emphasizes the use of data during decision-making. Attendees must therefore have access to any internal insights they need.

- Decision-making: Determining how final decisions are made is critical to Kaizen event success.

These are just a handful of the many factors that Kaizen adherents take into account when planning internal events, as continuous improvement often unfolds as a consequence of strong coordination.

Generating ROI the Kaizen way

Kaizen ranks among the most popular strategies for achieving continuous improvement — and for good reason. With roots in Toyota and Japan’s immensely well-respected industrial culture, the strategy easily holds up to scrutiny and can give business leaders the power to transform their companies, should they follow best practices. Of course, even stakeholders who fully embrace Kaizen can encounter difficulties stemming from the significant coordination requirements. Fortunately, these professionals have a place to turn for assistance: USC Consulting Group. We have been helping enterprises of all sizes embrace the agents of continuous change, including the Kaizen methodology.

Connect with USCCG today to learn more about are services and wide breadth of experience.

“It is just not the right time.” Business leaders bring out this all-too-common excuse when confronted with the notion of process improvement, often pairing the statement with promises of future operational advancement initiatives. Why? There are several common reasons. For instance, a good number of executives operate with the impression that frontline employees, including those in managerial positions, do not want change.

Back in 2016, leadership coach and New York Times bestselling author Mark Murphy surveyed approximately 2,100 business leaders and found that more than 37 percent believed that all employees preferred sticking to the status quo rather than pursuing change. Other executives are reticent to devote company resources to process improvement efforts whose results could vary, depending on implementation and long-term follow-through. These and other rationales give decision makers in the c-suite all the ideological ammunition they need to push off shop-floor optimization indefinitely.

In all, these business leaders are not detached from reality. Employees do fear change – Murphy discovered that 45 percent were more comfortable maintaining existing workflows – and haphazard spending can lead to significant budgetary damage. However, the risks that accompany operational stagnation are much greater than those associated with internal resistance and aggressive budgeting.

The modern marketplace dictates that organizations across all sectors seek out improvement wherever and whenever possible. Those that cling to the status quo typically find themselves suffering losses as a consequence of unyielding operational rigidity, losing ground to forward-thinking competitors, or grappling with mass customer attrition as past patrons seek out new product or service providers that can more effectively meet their increasingly intense expectations. Here are some of the reasons why now is always the right time for process improvement:

1. Changing marketplace conditions

The global marketplace never stops evolving due to the arrival and departure of overarching economic and technological developments. The emergence of protectionist trade policy, particularly in the U.S., is perhaps the most consequential event affecting the market. In April 2017, the Trump administration instituted sweeping tariffs on Canadian softwood lumber imports, per The New York Times. The Department of Commerce, at the behest of the White House, imposed tariffs of between 3 percent and 24 percent on the wood in retaliation over what the DoC deemed underhanded trade practices. Leaders within the commercial and residential construction and development sectors reacted with disappointment, claiming that the action would ultimately increase home prices and hurt consumers. This predicated outcome ultimately came to pass, as builders passed on their increased overhead expenses to buyers, The Times reported.

A similar scenario unfolded in May 2018, when the Trump administration called for increased duties on imported aluminum and steel, according to The Wall Street Journal. DoC officials imposed duties of 10 percent and 25 percent on aluminum and steel, respectively, a major move that sent shock waves across numerous industries – most notably, the automotive space. While domestic automakers normally source the metal used to make vehicle frames from American mills, these entities leverage large amounts of imported aluminum and steel to create ancillary components. As a consequence, the overhead costs associated with the production of these parts rose significantly following the implementation of the duties, increasing vehicle prices by hundreds and, in some cases, thousands of dollars.

Marketplace shifts of this nature are immensely disruptive to enterprises across countless industries and occur with regularity. However, businesses can mitigate the financial fallout and keep their footing by exploring and implementing process improvements that facilitate organizational scalability and ultimately allow them to make the best out of bad situations.

2. Increasing competitor capabilities

The emergence of sophisticated yet reasonably priced information technology services and solutions has leveled the operational playing field, lending small- and medium-sized companies the shop floor capabilities needed to carve out a considerable market share, even among larger, more established competitors. An estimated 43 percent of businesses worldwide have allocated more resources to digitization efforts in 2019, intent on putting into place the latest enterprise technologies, including artificial intelligence, business intelligence, and internet of things solutions, according to the Enterprise Mobility Exchange.

Of course, executives are not putting their faith in technology alone, as approximately 42 percent are supplementing new IT infrastructure with major process improvement efforts meant to bolster efficiency and boost revenue gain, per research from Red Hat. In short, organizations everywhere are pursuing operational advancement at scale, via multiple means.

Executives sitting on the outside looking in on this widespread push for improvement have no choice but to embrace progress and search for strategies that might make their respective companies more viable. Even those overseeing veritable industrial empires should take this approach, as marketplace fragmentation can bring down the biggest players.

3. Rising customer demands

Modern consumers are notoriously demanding, a phenomenon most analysts pin on both the emergence of advanced consumer technologies and the ecommerce revolution. Unfortunately for businesses, these buyers become more emboldened with each passing year, continually raising their expectations.

For instance, shoppers are no longer content with mobile application access or stock delivery services, researchers for JDA found. They expect retail companies to maintain robust on-the-go shopping experiences that feature seamless payment and data security components, while also offering accelerated shipping services in line with Amazon Prime. Businesses in the food and beverage industry are experiencing similar pressures, as buyers push them to adopt all-natural ingredients and provide food labeling with exhaustive ingredient lists. And, once these organizations meet such demands, consumers will undoubtedly come up with more.

Pursuing process improvement is perhaps the only way organizations can keep up with customer expectations, remain relevant, and ultimately find sustainable success.

All of these variables – marketplace change, competition, and customer demand – never stop evolving, which means the right time for process improvement could conceivably be “always.” Embarking on such programs is, of course, no easy task. In fact, most businesses need external assistance of some kind to get the job done. Here at USC Consulting Group, we have been helping companies optimize their operations for decades, leveraging proven techniques and tools that ease change and lay the foundation for growth and continuous improvement.

Contact us today to learn more about our work.

Professionals who ascend to the heights of their respective industries often develop healthy egos on their way up. An inflated sense of self-confidence can be an asset in certain situations, like when company leaders are looking to inspire staff – an important executive capability that 70 percent of professional development experts believe is critical to C-suite success, according to researchers from Harvard Business School.

But corporate egoism can also cause problems. In fact, many executives who suffer serious career failures can link these collapses to unhealthy pursuits of power or status, Entrepreneur reported.

Collaborating with consultants is perhaps when most business leaders flex their well-developed egos to the detriment of the organization. Even while they suffer from operational deficiencies, business leaders often balk at the idea of taking advice from external parties, including those with decades of experience and demonstrable successes. This prideful approach can start leaders down the path toward greater dysfunction and even organizational failure. To cultivate strong relationships with third-party consultants, executives must check their egos at the door. How? Here are some tried-and-true techniques:

1. Know the signs of egoism

Having the ability to identify the point at which confidence unravels into arrogance is key to tamping down egotistic tendencies. Leaders who effectively work with outside experts know the signs of unbridled egoism, including constant complaining and an overwhelming urge to intervene in projects just to take credit, according to The Business Journal. If these inclinations sound familiar, it’s time for leaders to take a step back, evaluate and correct their behavior before things get out of hand.

2. Model the ideal collaborator

Few professionals enjoy working with narcissists. Many executives today probably remember a time when they worked for or with an egomaniac, but have since lost sight of the damaging power of egoism as they climb up the corporate ladder. Some even take on the qualities of the executive despots they once detested.

Business leaders who find themselves in such positions can reverse the damage by going back to basics and modeling positive collaborative behavior, Inc. contributor and Voray CEO David Olk found. Olk himself learned that by avoiding defensive, self-centered action and focusing on relationship building, he could accomplish more as a leader. These and other similar strategies ultimately make for fruitful collaborations with third-party consultants.

3. Take a step back and support

Consultants enter partnerships with one primary objective: helping the business address its operational pain points. They do not function in the service of executives. But leaders sometimes act as though this is the case, attempting to lord over external contributors by questioning decisions with which they do not agree, which can hurt the organization when it’s at its most vulnerable. The advice of experts goes unbidden, and without buy-in from top brass, their efforts for operational improvements never materialize.

Business leaders looking to improve their organizations with help from consultants must revert to a supporting role and focus solely on the company for optimal results. How? Maintaining an open mind and asking questions are two good places to start. Additionally, leaders who accept that they have blind spots are usually more open to ego-less collaboration and therefore more likely to facilitate consulting success.

Executives who are considering bringing in outside operational experts would be wise to embrace these techniques and strive for improvement, ego-free. Here at USC Consulting Group, we’ve spent the past 50 years helping companies achieve sustainable growth through the implementation of strategies centered around supply chain, operational excellence, and more. Connect with us today to learn more about our experience and how we can help your business find firmer footing in the marketplace.

This holiday season, American consumers are expected to spend more than $720 billion, an increase of nearly 5 percent over sales figures from 2017, according to the National Retail Federation. But as buyers bolt to malls to take advantage of last-minute deals and purchase gifts online, manufacturers here and abroad are navigating a holiday rush all their own.

During peak season, businesses in the manufacturing space – especially those that serve brick-and-mortar and online retailers – pour all available resources into ambitious shop-floor initiatives centered on facilitating optimal output and service delivery.

Finding success during peak season is, of course, no easy task. As competition increases, more production roadblocks materialize. This is why manufacturing organizations must develop and deploy specific operational strategies designed to achieve favorable results during peak season. When they do, their clients can keep their shelves stocked, customers get the products they want and company coffers grow. What exactly are these peak season manufacturing best practices?

Keep an eye on manpower

Worker absenteeism is an acute year-round problem that only grows worse during peak season. According to research from the Society for Human Resource Management, an estimated 72 percent of American businesses said that workers take unplanned time off around the holidays, reducing staff levels and making it harder for businesses to hit production targets.

Manufacturers can fight back against these operational roadblocks by planning ahead and introducing innovative solutions such flexible shifts, which can bolster employee engagement and retention. Moving forward with ambitious hiring initiatives is another proven option, as this allows firms to cultivate corps of willing workers prepared to work to embrace the holiday rush.

Address the supply chain

As customer demand reaches its zenith, supply chain operations become even more critical. Manufacturers that plan for this eventuality set themselves up for success. According to The Wall Street Journal, in autumn 2017, Nintendo began ramping up supply chain processes for its new Switch video console, which had suffered from logistical issues, making it harder to acquire after its release date earlier that summer. Pre-holiday planning allowed the company to meet customer demand during peak season and laid the groundwork for historic sales, according to Polygon. Manufacturers can find similar peak season success by anticipating the effects of heightened demand, safeguarding against issues and ensuring supply chain efficiency ahead of the holiday shopping season.

Prepare for marketplace changes

With every peak season comes unique economic challenges. Manufacturing businesses must take steps to mitigate shop-floor issues stemming from recent marketplace developments. Many companies looking for success in the final weeks of 2018 have begun putting into place processes designed to address the trade war unfolding between the U.S. and China, a conflict that has complicated raw material procurement practices, Logistics Management reported. Some have decided to secure materials and components from China as early as possible, thus beating the implementation of the tariffs. Others are biding their time, developing backup plans and hoping the countries come to an agreement that doesn’t include tariffs.

Manufacturers that implement these and other peak season best practices can end the year strong and make out like so many of the bargain hunters out shopping for holiday sales. That said, implementing these strategies alone might prove difficult for some teams. USC Consulting Group is here to help, leveraging decades of consulting experience to assist manufacturers intent on optimizing their operations and boosting the bottom lines. Contact us today to learn more about our work in the manufacturing space.

No matter how you define it, diversity is important to every company, and every team within every company, looking to succeed.

Cross-functional groups, which typically consist of stakeholders from different departments, ensure equal representation at the table when decisions are made and changes are plotted. Ultimately, they serve to streamline internal operations and bolster efficiency, productivity, and quality – or, at least, they do when they’re effective. And not many are.

Only a small number of cross-functional teams actually manage to achieve these aims, according to research published in Harvard Business Review. Stanford University Management Science and Engineering Professor Behnam Tabrizi collaborated with fellow academics and consultants to assess the performance of almost 100 cross-functional teams at more than two dozen leading corporations. Tabrizi and his colleagues discovered that three-quarters of these teams failed to meet customer expectations, align with organizational goals, and adhere to established budgets, timelines and project specifications.

So why did these teams fail? Tabrizi linked the dysfunction to a lack of accountability and clearly defined metrics for performance evaluation. To turn this situation around, these and other struggling cross-functional teams must first figure out how to assess their efficacy. Here are some proven and actionable strategies for keeping such diverse working groups in check and ensuring they reach their potential:

1. Make success the primary objective

This may seem like an obvious strategy, but it often falls by the wayside because of the very nature of cross-functional teamwork. Since members hail from different departments, they often have discrete and sometimes conflicting priorities, which can undermine collaboration and set them up to fail. Organizations can prevent this outcome by encouraging team members to place the success of the project above their individual interests. What’s more important is ensuring decisions don’t adversely affect their departments in ways that co-workers from other departments might not notice until it’s too late.

2. Establish project milestones

While quality of output is certainly the most important metric for cross-functional performance, using this indicator alone can also increase the likelihood of dysfunction and failure. Businesses that focus solely on the quality of the end result tend to not track project progress in real-time and address collaborative or operational friction as it arises. This is why experts advise companies to establish milestones that measure progress at each stage of the project. With this multiphase assessment strategy in place, business leaders can not only effectively monitor team performance but also intervene to stabilize projects about to tip over the brink of failure.

3. Mandate peer reviews

Cross-functional teams are only as strong as the individual contributors that staff them. Consequently, it is critical that companies looking to assess the effectiveness of these groups also evaluate how individual members perform. Of course, such groups often work in isolation, meaning external parties cannot observe team dynamics and compile feedback on specific members.

Peer reviews are a valuable option here, but enterprise leaders must be careful when using this information to drive improvement. Organizations that have management present peer review results should ensure that the feedback is constructive and framed in a positive way, as studies show that professionals do not respond well to overly negative feedback.

4. Involve outside team members

Cross-functional team members are best equipped to measure holistic success, as they live and breathe project execution. For this reason, many forward-thinking businesses allow these individuals to participate in the design of performance measurement systems for assessing the effectiveness of cross-functional collaboration, according to HBR. Teams can offer unique insights into how these groups should function on a microscopic scale and help build out key performance indicators that accurately contextualize outcomes at every stage of the project. However, business leaders should still provide some oversight and ensure that macro measurements comport with larger business goals.

5. Consider expert assistance

Sometimes operational leaders are ill-equipped to assess the performance of cross-functional work groups. Many shop floor supervisors and business leaders simply do not have enough time to build out effective measurement frameworks. Others lack the expertise needed to execute such tasks. In these scenarios, calling in an external partner can provide a much-needed outside opinion from an expert who has seen firsthand how cross-functional teams fail and how they reclaim what they lost.

Here at USC Consulting Group, we’ve been working with organizations across numerous industries for over 50 years, helping them transform their operations and adapt to marketplace shifts of all kinds. Connect with us today to learn more about our experience in team performance assessment, process improvement, and change management.

Businesses seeking to improve internally often focus considerable energy on trying to transform shop-floor operations through the introduction of new equipment, production processes or software. While such additions can surely lay the groundwork for change, these modifications alone cannot catalyze true operational transformation. The employees responsible for managing mission-critical production workflows must change as well. Tools are only as effective as the professionals who wield them.

To bolster worker performance and thereby meet internal improvement goals, organizations must drive behavioral change by promoting innovative workplace practices that pair well with new and improved processes and production assets. Here are the five secrets to driving such change:

1. Start from the top

Executives shape company culture through their actions, providing the behavioral blueprint for employees in every department. Enterprises embarking on internal improvement efforts should utilize this top-down approach to behavioral osmosis by leveraging influential leaders within the initiatives accompanying significant change on the shop floor. In fact, studies show that this is necessary for sustainable, organization-wide behavioral change. According to a study from Harvard Business Review, 70 percent of enterprise transformation efforts fail. And a lack of senior leadership is often why these businesses cannot bring about the cultural changes necessary to innovate their practices well. How can businesses avoid this unwanted outcome?

Leaders must examine their own behaviors and pinpoint conduct that undermines organizational flexibility and innovation. For instance, many executives are guilty of transferring inapplicable experiences from their past to make decisions about the future. Others prevent growth by engaging in personal perfectionism, attempting to cultivate unimpeachable executive narratives by avoiding situations that might result in failure. When business leaders identify and root on these behaviors, they open themselves up to change, setting the stage for behavioral transformation across the business and facilitating true internal improvement. Learn more about personal behavioral change in INPLCenter’s article on why simple behaviors seem impossible to change.

2. Embrace technology

Enterprise technology is often framed as a product of behavioral change. This, of course, is an accurate perception. A significant number of companies launch internal initiatives aimed at reconditioning staff and providing them with the knowledge they need to embrace newer processes centered on the latest hardware and software.

But technology is sometimes employed to support change management activities prior to the unveiling of any large-scale organizational shifts, according to CIO. Many platforms facilitate behavior change by providing leaders valuable information about how employees function during day-to-day operations, lending these decision-makers the baseline data they need to implement changes that help workers get the most out of new operations. Some solutions leverage neuroscience to help professionals grapple with amended production best practices. Employees using these advanced tools can access training modules that break down complex operational subjects into digestible instructional exercises that promote behavioral change.

Cutting-edge information technology offerings of this kind can do a lot for organizations searching for actionable tools that can support behavior change across the businesses and prepare workers for new shop-floor workflows.

3. Market innovation internally

Marketing teams often launch and oversee internal initiatives aimed at promoting behavioral change. A majority of these campaigns are designed to promote regulatory compliance or raise morale, but businesses can leverage similar promotional programs to encourage behavior change, which, in the context of operational improvement, means embracing new processes and tools.

Incubation campaigns take this approach a step further, calling workers to get involved in organizational transformation by providing professional insights and offering up potential solutions to pressing problems. Inward-facing marketing initiatives of this kind can spark behavior change among professionals in all departments, showing them that their superiors are interested in growing the business through their talent and experience.

4. Search for operational issues

Sometimes, employees are unable to adopt more innovative behaviors because of systematic roadblocks. No matter how forward-thinking the professionals trapped within these workflows may be, the surrounding workplace structures make it impossible for these individuals to act on their innovative urges. This is why businesses looking to prompt behavioral change and unlock improvements that improve their bottom lines must work to streamline operational frameworks that might prevent employees from contributing meaningfully to wider cultural change.

5. Work with external collaborators

While businesses can achieve behavioral change on their own, many may encounter stumbling blocks that require outside expertise and a fresh perspective. Here at USC Consulting Group, we’ve been working with organizations across numerous industries for more than 50 years, helping them transform their operations and adapt to marketplace shifts of all kinds. Connect with us today to learn more about our experience in process improvement and change management.

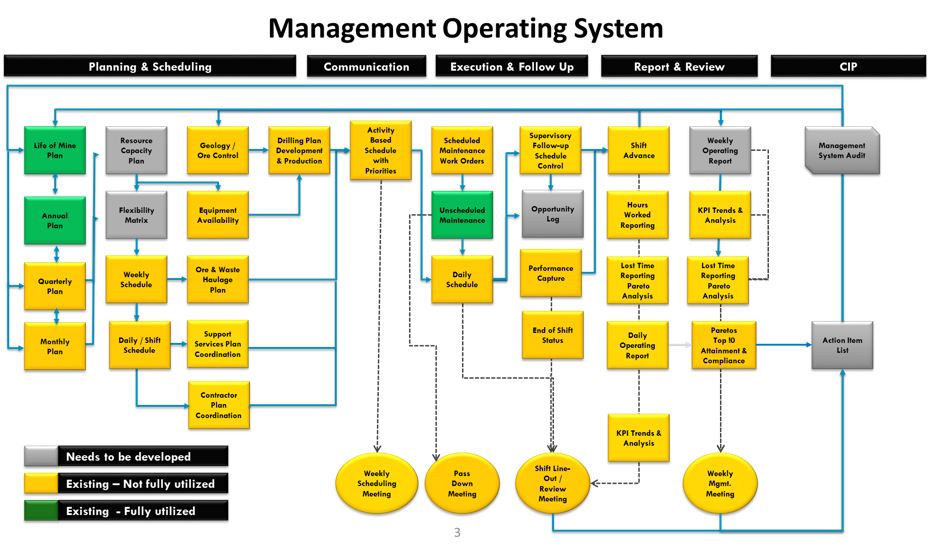

Define your mine management operating system and close the gaps in productivity and workflows.

Mines are sprawling operations. Companies have to monitor large and numerous assets, from employees to equipment and minerals. Given the scale of these operations, many organizations have turned to data to inform their decision-making, initiatives and communications.

At the center of such plans is a Mine Management Operating System (MMOS). Without it, management may have trouble realizing gains and expectations. Yet with a clearly defined MMOS, mines can be become proficient in tactical, technical and technological responses.

With a structured MMOS, organizations can:

- Identify and close gaps in workflows.

- Discover opportunities for improved efficiency, effectiveness or optimization.

- More closely monitor operations for compliance.

To learn more, download our ebook “The Mine Management Operating System: A Foundation for Success” today.

Organizations of all sizes now leverage continuous improvement programs to make the most of their workflows. Initiatives centered on revolutionary shop floor methodologies, such as lean and Six Sigma, are everywhere, as firms look to optimize their resources and generate growth without investing in expensive, time-consuming capital improvements.

Most of these efforts depend upon internal improvement teams, which use the latest technology and operational expertise to pinpoint and eliminate process-based roadblocks that inhibit production. But not all of these internal groups see success. Many businesses don’t invest enough in their improvement teams and find themselves grappling with constant production issues as a result. The experts at USC Consulting Group regularly assist enterprises in this unfortunate position, enhancing their internal improvement teams and setting the table for success.

Upon entering an operation that lacks strong performance from its improvement team, we normally encounter at least one of three common scenarios:

- Overwhelming work demands: Internal improvement groups simply have too many tasks to complete and cannot get out from underneath their workloads, preventing them from making meaningful improvements or developing long-term strategic plans.

- Flawed operational objectives: Internal improvement teams are focusing on the wrong goals.

- Reactive workflows: Instead of implementing improvements that reduce the likelihood of serious production holdups, internal improvement teams spend the bulk of their time responding to surface-level incidents rather than their respective root causes.

How do our improvement specialists go about tackling these issues? Here are some of the strategies we regularly employ:

Bolstering communication channels

A significant number of businesses operate a network of facilities spread across perhaps hundreds of miles. In most cases, these sites maintain disparate internal improvement teams. This regional strategy works, so long as these groups communicate with one another and attempt to collaboratively address production problems across the entire organization. Unfortunately, many businesses fail to foster such connections and, in doing so, isolate their internal improvement teams. In response, these groups dive into the minutiae of the everyday workflows they encounter and forgo more wide-reaching, standardized initiatives.

We address this problem by helping companies develop lines of communication that allow internal improvement teams across numerous sites to unite under sets of common goals and facilitate organization-wide progress.

Trading observation for actionable data

It is easy for internal improvements teams to focus on readily observable issues and act reactively. After all, skilled operational stakeholders can easily address problems as they unfold before their eyes during daily walkthroughs. However, in many cases, these difficulties are symptoms of larger issues that a tour of the shop floor won’t necessarily reveal. In such cases, internal improvement teams must collect and analyze quantifiable production data, then use this information to both combat large-scale obstacles and formulate forward-looking goals.

Our experts facilitate this kind of transition by helping organizations adopt key performance indicators that move the focus off reactive activities – which, ideally, maintenance teams should tackle – and onto overarching exercises centered on macro improvements that drive growth and revenue.

Implementing auditing, documentation and training programs

Administrative tasks such as process auditing, document creation and training development are the backbone of effective internal improvement programs. These activities ensure continuity across the enterprise and the adoption of best practices. Many businesses are in good shape when it comes to training. For instance, firms in the manufacturing space have long facilitated instructional programs designed to increase efficiency and productivity. According to research from the Manufacturing Institute, on average, industrial businesses spend about $1,000 per year per employee on skills training. One in ten invests more than $5,000 per employee annually.

However, when it comes to auditing and documentation, businesses tend to fall behind. Additionally, while companies may offer consistent training, such programs are not always aligned with effective best practices, meaning workers end up learning how to navigate substandard processes. Our improvement specialists work with internal improvement teams to build out effective shop floor best practices and correlate those to easy-to-deploy training efforts. On top of this, we then assist these team in developing auditing and documentation workflows that validate and evolve more effective processes.

Using these methodologies, the experts at USCCG enhance internal improvement teams and empower them to make strategic change throughout the organization. This, in turn, facilitates flexibility, which, in the lean area, often has a more tangible impact than capital investment.

Is your organization interested in bolstering its internal improvement teams? Contact us today to discuss your project and learn more about our portfolio and how USCCG can provide horsepower to your internal efforts. Our expertise spans numerous industries, from food and beverage to mining to transportation and logistics, and focuses on all areas across the supply chain.

Keep reading more insight from our subject matter experts by subscribing to our blog in the upper right side of this page.