-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2025 (1)

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Management Operating System

There is one element of an organization that holds significantly more value than any other aspect and yet many companies overlook it.

Focusing on this critical piece of your business leads to increased productivity, improved efficiency and safety, and higher customer satisfaction.

This essential asset… your employees.

At USC Consulting Group, we understand the value of your people and why it is so vital to empower them to be the best they can be.

One key to our success is a strategy we call the Employee Involvement Prototype (EIP) process. This gets to the heart of what makes companies tick.

The EIP process is one of the cornerstone techniques USC uses to validate and measurably implement changes to a company’s management operating system. The secret of it all is getting onto the shop floor at the point of execution and talking to employees to obtain their feedback and insights.

But change is hard

We’ve been in the consulting business since 1968 and have learned a few things about change in that time. When we go into a company, it’s because something isn’t working and needs to be tweaked, optimized or even overhauled. That usually involves changing the way things are done, day to day. But here’s the thing about change. It’s difficult and people don’t love it, especially if it’s coming from a consultant.

In the end, when we’ve finished our work and the company is functioning more efficiently and effectively, like a well-oiled machine, people are happy with the changes we’ve implemented. But it can get pretty dicey when you tell a shift boss who has been on the job for decades that the “way they’ve always done it” can be improved upon. It messes with their sense of competency, job satisfaction and know-how.

That’s why the EIP process is such a powerful ally.

Why the Employee Involvement Prototype process works

The Employee Involvement Prototype process is a method of introducing change on a small scale that involves the people who do the work. You can’t change the whole plant at once, we need a good point to start.

First, together we pick an area that has a need to improve and is open to change. An area where we can start to fill in the gaps and address the issues we have observed. Then, design or enhance the needed tools and demonstrate our techniques. We have open dialogue between USC, the employees and on up to management with daily meetings. These meetings are held on the floor, in the area where the work takes place.

We spend time observing how things are currently done. We talk to the employees on the front lines and ask for their input.

- What did they observe?

- What are the logjams and impediments to them getting the job done?

- Are they happy with the way things currently are?

- How do they think things might be improved for tomorrow?

- Is there a better way?

The answers to these questions become employee identified opportunities for improvement.

And it’s not just us out there. We involve the top brass at the company and encourage them to walk the shop floor with us.

Along the way as we’re rolling out changes, we have daily EIP meetings. The key agenda points are:

- What did we like?

- What didn’t we like?

- What do we need to do differently?

You find a lot of wisdom on the shop floor from people who have spent years, even decades, doing the job.

It allows us to identify the root cause of operating problems and implement permanent solutions.

This simple tactic works on many levels. Here’s how and why:

Employee buy-in. When change is foisted on people, they don’t like it. They might even fight against it and undermine it. But when you involve employees in creating change, that creates ownership, pride and ultimately, buy-in. They become the champions for the change.

Demonstrates the USC difference. Employees can be quite skeptical of outside consultants. The EIP is a very rapid and concrete way for the company leadership to show their employees that this effort is different. They have likely never seen their managers and executives in the workplace striving to fix issues. We spend the shifts in the area, seeing the process in action and demonstrating that we are interested in what is really going on.

Quick results. We call the EIP a starting point, a “pilot” in which we begin with one machine or in one area of a plant where we can start to engage the client in the change process, the tools we use, and how it all works. It allows us to start small, and if something isn’t working, we can correct it quickly.

Bottom line, it’s all about involving employees in the changes we’re making. In the end, they’re the ones whose day-to-day will change, so they should be part of the team that uncovers the problems and finds solutions.

For more info into what USC Consulting Group does and how we do it, read “How USC Consulting Group Accelerates Your Process Improvement Efforts.”

By integrating their Management Operating Systems (MOS) with AI and IoT, mining and metals companies can significantly enhance their operational capabilities, leading to better asset management, increased productivity, and ultimately, improved financial performance.

Utilizing IoT devices, such as sensors and connected equipment, to continuously collect data on various aspects of their operations, including equipment performance, environmental conditions, and production metrics, this real-time data is fed into the MOS, providing a comprehensive and up-to-date view of operations. The collected data is then analyzed by AI algorithms within the MOS to generate insights, identify patterns, and predict outcomes, allowing for proactive management of assets and operations, such as predicting equipment failures or optimizing production schedules.

A key aspect of any MOS is to assist management in decision making. Integrating AI with MOS enables real-time decision support, where AI provides recommendations or automates decision-making processes based on the analysis of IoT data. This helps managers make more informed decisions quickly, improving responsiveness to changing conditions. Additionally, AI allows the MOS to simulate different operational scenarios and predict their outcomes. This capability helps managers evaluate the potential impact of different decisions before implementing them, reducing risks and optimizing outcomes.

By focusing on operational efficiency, AI models integrated into the MOS can optimize processes in real-time by adjusting operational parameters based on current conditions and historical data, leading to improvements in ore and metal recovery, energy efficiency, and overall productivity. AI can also be used to analyze data on resource usage and availability, helping the MOS to optimize the allocation of resources such as labor, equipment, and materials, leading to cost savings and improved operational efficiency.

When approaching enterprise asset management and predictive maintenance models, integrating AI and IoT with the MOS, companies can enhance their predictive maintenance capabilities. AI algorithms analyze sensor data from IoT devices to predict when maintenance is needed, helping to prevent unexpected equipment failures and reduce downtime. This assists the MOS to automatically schedule maintenance activities based on AI predictions, ensuring that maintenance is performed only when necessary and that it is coordinated with other operational activities.

The use IoT and AI integration helps the MOS to optimize inventory levels by predicting demand for spare parts and materials based on operational data, thus reducing inventory costs and ensuring that critical components are available when needed. By having AI analyze data across the supply chain, assisting the MOS to optimize logistics, reduce lead times, and minimize costs associated with the procurement and transportation of materials.

Integrating Management Operating Systems with AI and IoT in the mining and metals industry offers substantial benefits, but it also comes with several challenges and potential pitfalls.

USC partners with your organization and coaches your people to significantly impact performance outcomes and accelerate Operational Excellence

For more than 55 years, USC has been working with clients to address the challenges and avoid the pitfalls when developing, enhancing and deploying their management operating systems.

As technology enablers, like AI and IoT, are deployed, we help clients to address the challenges through careful planning and a strong focus on change management, including employee involvement. By proactively identifying and mitigating the pitfalls, mining and metal companies can successfully integrate AI and IoT with their MOS, unlocking the full potential of these technologies for improved asset management and operational efficiency.

Integrating AI and IoT into MOS often requires close coordination across different departments, such as IT, operations, and maintenance. Misalignment or lack of communication between these departments can lead to project delays and failures. The complexity of integrating AI and IoT, projects can often experience timeline and budget overruns. Effective project management is critical to keep the implementation on track and within budget.

Mining and metal operations often have data scattered across different systems and departments. Integrating this data into a unified MOS that can effectively leverage AI and IoT is challenging, particularly if the data is stored in incompatible formats or is not standardized. AI systems require high-quality, accurate data to function effectively. Inconsistent, incomplete, or inaccurate data can lead to poor AI performance, resulting in unreliable predictions or insights. Ensuring that data from IoT devices is processed in real-time is crucial for effective AI-driven decision-making. However, high latency in data transmission or processing can lead to delays, reducing the effectiveness of AI in making timely decisions.

Many companies often face a skills gap when it comes to AI, IoT, and data analytics. There may be a shortage of in-house expertise required to manage and maintain these advanced technologies effectively, so having a partner can assist in compressing the time it normally takes cleanse data and align MOS processes. Employees accustomed to traditional methods may resist adopting new technologies, especially if they perceive AI and IoT as threatening their jobs or making their roles redundant. Effective change management and training programs are essential to address this issue.

Companies that have integrated their Management Operating Systems with AI and IoT are experiencing several quantifiable benefits across various aspects of their operations. These benefits are often measurable in terms of improved safety (30-50% reduction in safety incidents), cost savings (10-40% reduction in maintenance costs), and an increased productivity (5-15% increase in productivity and 10-20% improvement in operating efficiency), just to name a few. By leveraging these technologies effectively, mining and metal companies can achieve substantial improvements across their entire value chain.

USC helps you tackle key challenges

- Ensure the right resources are at the right place to minimize lost time – enabling safe and disciplined execution

- Optimize mine planning and scheduling across all planning horizons – delivering detailed and accurate plans

- Identify potential roadblocks proactively during mine planning and solve complexity during the planning process

- Control quality of work at the point of execution by identifying off specification and enabling in-shift correction

- Enhance your ability to cluster & centralize scarce human expertise, allowing all sites to benefit from their expertise

Do you want to understand how a MOS can integrate your mine and operational planning, while helping you to safely increase performance site wide? Contact us today.

A robust MOS is vital for mining and metal companies to navigate the challenges of today’s market.

Management operating systems (MOS) are making significant impacts to performance goals and outcomes for mining and metals companies by providing a structured and systematic approach to managing the business across the value chain. Companies have a strong need for robust MOS in today’s market to ensure safety and compliance, improve efficiency, and achieve sustainable growth, given the safety of workers is a top priority across the mining industry; the global demand for minerals and resources is rising, leading to increased competition; mining operations are inherently complex; the industry is facing significant cost pressures from fluctuating commodity prices and rising operational costs; and the adoption of new technologies requires an integrated approach to managing operations.

Performance is improved by providing a structured framework for planning, monitoring, and controlling operations. MOS can help through:

- Safety and Compliance – ensuring that safety protocols and regulatory compliance are integrated into daily operations, while minimizing the risk of accidents and legal issues, promoting a safer working environment.

- Enhanced Planning and Scheduling – creating detailed and realistic operational plans and schedules, ensuring that resources are allocated efficiently and that production targets are met without unnecessary delays. Potential bottlenecks can be identified and addressed during the planning process – “Planned work is safer and more productive than unplanned work.”

- Real-Time Monitoring and Control – tracking operations in real time, allowing for quick in identification and in-shift resolution of issues, while reducing downtime and safeguarding that operations run smoothly.

- Improved Communication and Coordination – standardizing processes and providing clear protocols, MOS enhances communication and coordination among different departments and teams, leading to more cohesive and efficient operations.

- Data-Driven Decision Making – providing and analyzing comprehensive data on various aspects of the operations to identify trends, inefficiencies, and opportunities for improvement and leading to more informed decision-making.

- Cost Control and Efficiency – optimizing resource use and reducing waste, while aiding in cost control and improving operational efficiency.

Supporting mining and metal companies to stay competitive and adapt to changing market conditions, MOS fosters a culture of continuous improvement by regularly reviewing processes, identifying areas for improvement, and implementing changes.

MOS in mining and metal operations are significantly enhanced by today’s technological advancements. By leveraging these advancements, MOS becomes more robust, responsive, and efficient. This not only enhances operational performance but also ensures better safety, sustainability, and profitability.

USC partners with your organization and coaches your people to significantly impact performance outcomes and accelerate Operational Excellence

USC brings a tailored, structured, and disciplined methodology, along with a range of tools and techniques we apply collaboratively with client’s personnel. Whatever your challenge, we are the people who work with our clients to find full potential and unlock the hidden value.

USC identifies waste, redundancies, and ineffective processes, and then rapidly recover the prioritized opportunities, and convert them to improvements in performance and operating profit. Our consultants achieve this by improving the skills sets of all levels of the client’s management and employees.

Our people embed with client internal teams to develop, enhance, prototype, validate and implement management operating system (MOS) element improvements to drive, sustain and perpetuate change in how the business budgets, plans, schedules, assigns work, executes, follow-up, reports, analyzes and improves. In short, USC implements measurable, sustainable changes that drive operational and financial improvements.

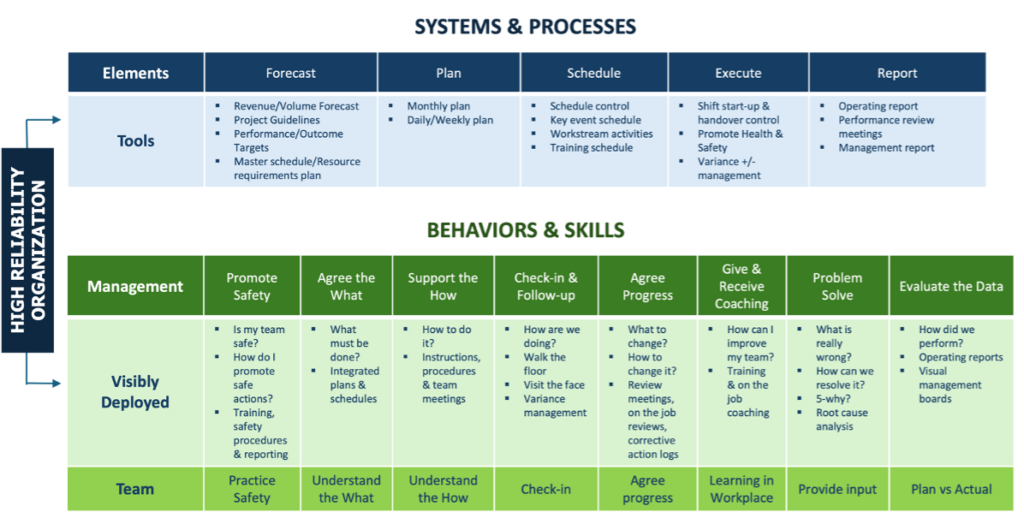

Our Management Operating System (MOS) Essentials Framework is designed to be pragmatic rather than conceptual – thereby leading to accurate, practical decisions about your operations and outcome aspirations. The key, that many miss, is the linkage process execution with management behaviors. MOS is about “managing differently” using visibly deployed management and supervisory behaviors. Consistent execution of the right behaviors at the right time creates certainty in the workplace, driving performance improvement and sustainable new ways of working.

Client performance goals and outcomes are realized through:

- Integrated safety protocols and compliance requirements into daily operations., leading to a safer work environment and fewer accidents.

- Reduced operational costs, including minimized waste, optimized equipment usage, and reduced energy consumption.

- Optimized workflows and resource allocation, leading to increased efficiency and higher production rates.

- Effective maintenance planning and real-time equipment monitoring, MOS reduces unexpected breakdowns and downtime.

- Alignment of daily operations with strategic objectives, ensuring that all activities contribute to the company’s long-term goals.

- A culture of transparency by providing clear performance metrics and regular reporting while driving better performance and tracking progress towards goals.

USC Helps You Tackle Key Challenges

- Optimize mine planning and scheduling across all planning horizons – delivering detailed and accurate plans

- Identify potential roadblocks proactively during mine planning and solve complexity during the planning process

- Ensure the right resources are at the right place to minimize lost time – enabling safe and disciplined execution

- Control quality of work at the point of execution by identifying off specification and enabling in-shift correction

- Evaluate performance and identify opportunities for improvement, enabling continuous improvement mindset

Do you want to understand how a MOS can integrate you mine and operational planning, while helping you to safely increase performance site wide?

Want to find out more about how USC can help you uncover the hidden value loitering in your operations?

For more information, let’s talk it through with a no obligation meeting with one of our executive team members. Email info@usccg.com to arrange a call.

The energy and utilities industry is in the midst of change.

Businesses are facing pressure from the government and consumers alike for more renewable energy while also balancing that with grid reliability and traditional energy sources. Meanwhile, electricity demands are expected to skyrocket. Other wild cards are supply chain disruption, labor shortages and more.

But within those challenges, we always see opportunities. Let’s take a closer look into the outlook for energy.

Continued focus on renewables. The demand for clean energy will continue to rise. Governmental regulations are mandating the focus on clean energy and decarbonization, including enacting green-friendly legislation and incentives for companies to transition to cleaner sources like solar and wind. The industry made great strides in solar power and the energy storage it necessitates in 2023, but more is needed and the focus will continue in 2024 and beyond. Consumers are demanding it as well, with climate change among people’s top concerns. All of it has led many companies to push the timeline to cut carbon emissions by 80% from 2050 up to 2030.

Energy storage. The push for solar requires an enormous amount of battery storage capacity to, in very simple terms, store all of that energy for times when the sun’s not shining. It means innovation in battery technology, and 2023 saw much of that, with storage capability doubling in 2023 and set to nearly double again in 2024.

Electricity surge. According to industry sources, the demand for electricity is expected to triple by 2050. It means planning now for this increased load on what is likely aging infrastructure, resulting in costs to shore up that infrastructure to ensure grid reliability. It’s also necessary to consider expanding the grid to meet that demand.

Aging grids + extreme climate. We all saw the worst-case scenario play out in Texas when their grid failed when the state experienced a rare deep freeze. But weather extremes are becoming the norm, with heat, wildfires and drought on the one hand, floods and record snowfall on the other. The industry is modernizing the grid, and made progress in that area in 2023, but reliability is still a large concern.

Supply chain uncertainty. The recent geopolitical unrest in Ukraine and the Middle East has underscored the need to reshore this nation’s oil supply.

Labor shortages. Like many industries today, energy is battling a labor shortage and facing the double whammy of their most experienced workers retiring and taking institutional knowledge with them, and having too few younger people in the pipeline to pick up where they left off.

It’s a full plate for the energy sector in the coming years, that’s clear. But within these challenges, we see opportunities to bolster processes, making operations more efficient and guard against supply chain snafus. Reducing operating costs, improving productivity and increasing efficiency will help the industry navigate these challenging times.

This is where USC can help

Management Operating Systems. A solid Management Operating System is a must for efficiency, time savings, employee productivity and so much more. For a real-world example on how USC helped an energy producer save time and money by implementing an MOS, read “Energy Producer Generates Savings with Smarter Labor Practices.”

Reskilling employees. All of this innovation and growth in renewables, not to mention AI entering the mix, requires more workers with new skills. This can be very good news for your current employees, who can move up the food chain with new training, and the ability to attract highly qualified workers.

Resource planning. If you know anything about our company, you know we are great proponents of SIOP – Supply, Inventory and Operations Planning. It gives companies a roadmap to the future, so they’re not reacting to events, they’re anticipating them. With the exponential growth of the energy and utilities sector in the coming years, solid planning for the resources needed for that growth, like increased storage capacity and grid strength, is a must.

Bottom line, delivering reliable, affordable and sustainable energy is the goal for the energy and utility industry. It takes efficient operations, a handle on resources, and a clear eye toward the future. Contact us today to find out more about how USC Consulting Group can help.

Have you heard of a High Reliability Organization? The concept has been out there for several decades but it’s taking center stage again now. Let’s delve into what a High Reliability Organization is, why this concept is coming to the forefront again, and whether you should explore implementing the principles in your own organization.

Simply put, a High Reliability Organization (HRO) is a company that has a solid operating system of execution in place that emphasizes safety and strives to minimize risk across the business.

We’re talking about complex or hazardous industries like nuclear power, the Navy and other branches of the military, air traffic controllers and the mining industry.

The idea behind HRO is a basic one. Expect the unexpected. An HRO creates a number of operational systems and ways of working that promote consistency and keep the focus on achieving company goals while avoiding major errors. These systems not only make the HRO more nimble, responsive and functional than a non-HRO competitor, but they also deliver more efficiency and most importantly, safety.

Why being an HRO is vital today

The concept of HROs has long been a method of ensuring safety in hazardous industries, but it’s becoming more relevant today in mining and other industries because of a perfect storm of circumstances. The marketplace is changing dynamically. Shifting sands don’t exactly make for solid foundations. A few things happening now:

Natural disasters. We seem to be in a period of increased earthquakes, “storms of the century,” droughts, volcanic eruptions and more. It makes facilities vulnerable to disruption.

Cyber attacks. Another vulnerability. As the industry gets more dependent on technology, the vulnerability to hacking of control systems ratchets up.

Boomer retirements. The impact of this can’t be overstated. Baby Boomers make up nearly a third of the entire U.S. workforce. The U.S. Census Bureau projects that 4.4 million people will turn 65 (retirement age) every year from now through 2027. During the period from 2022 to 2030, 75 million Americans are expected to retire. Called the Silver Tsunami or the Great Retirement, it is the largest surge of retirement age Americans in history.

Loss of institutional knowledge. Those retiring Boomers represent your most experienced, knowledgeable workers. These are the people who have gotten the job done, and done safely, for decades. All of that know-how will walk out the door with them.

Lack of skilled workers. It’s a real problem for many industries, including mining. Talent acquisition and training is on the top of the list of concerns for mining CEOs, because when those Boomers retire, the mining industry needs skilled, experienced people to keep the operation moving.

Doing more with less. In this economy, it is incumbent on companies to do more with less, cut costs, trim staff and extend the lifecycle of equipment while also investing in AI.

All of these things are coalescing into a situation in which the mining industry is experiencing a great potential for increased risk. It’s easy to see why. Experienced people retiring en masse, less experienced people taking up the mantle but not having that deep institutional knowledge you just can’t get in a training course, and the need for constant cost cutting – it all adds up to risk.

And when you’re talking about operations in a mine, risk doesn’t just mean business disruption. It means people’s lives.

HRO core principles

It’s about more than just focusing more on safety. The core principles of HROs, specifically in the mining industry, include:

Preoccupation with failure. It’s vital to anticipate the potential for failure and put measures in place to stop a problem before it starts. Emergency response training, regular equipment inspections and maintenance, failsafe protocols. The goal here is to be ready to spring into action, to have that training kick in, when a potentially disastrous situation arises.

Sensitivity to operations. Everyone’s eyes need to be open, all the time. Much like the “see something, say something” campaign at airports, it means developing a culture of awareness among workers on the front lines and in the front office. Identifying processes and ways of working that can be optimized; or potential issues or risks that could lead to disruption in the future.

Resilience. The ability to roll with the punches. Redundancies need to be built in. Clear protocols for disruptions or sudden change responses need to be automatic.

Shared understandings. Everyone in the organization needs a shared understanding of HRO principles, the role they themselves play, and are operating with the same road map.

Respect hard-earned expertise. Those Boomers who are retiring? They know how to get the job done. They’re carrying your organization’s institutional knowledge – the part of the job that can’t be taught in a training class. This knowledge needs to be respected, especially when decisions get made.

Why being an HRO matters

Why should mines focus on high reliability? Here are a few of the benefits.

Safety. Since the first canary went down a coal mine, this industry has been implementing safety protocols. It can be dangerous for people working in a mine, period. Anticipating risks and putting safety protocols in place will save lives and reduce accidents and injuries.

Efficiency. The focus on asset management minimizes unscheduled downtime and process disruptions, while getting everyone on the same page streamlines operations. It all works together to increase efficiency.

Equipment lifespan. One of the challenges today is doing more with less, and that means keeping aging equipment on the job. The regular maintenance and inspection of equipment adds to its lifespan.

Hiring and retention. That lack of skilled workers? It’s causing stiff competition for the skilled workers who are out there. Being a High Reliability Organization shows new recruits that you’re committed to safety, value their contributions and knowledge. In short, it’s a powerful recruiting tool.

How USC can help: Anticipate the Unexpected

One of the most vital components of transforming into an HRO is the integration of a solid Management Operating System that breaks down siloes between areas of the organization like engineering, maintenance, procurement and operations.

The end goal: Constantly anticipating the unexpected and executing in a consistent manner.

When USC begins the process, we start with an assessment of current operations. Then we do a deep dive. Some, but by no means all, of the areas we focus on:

Identify operational disconnects. Is everyone on the same page to execute the plan? Are priorities between departments aligned? Has production prepared access to equipment to be maintained? Are shift managers setting work expectations in the same way? How are variances to the plan addressed?

Close the gaps. This is about breaking down silos and getting everyone looking in the same direction, working in the same way, and managing departmental operations with a common vision.

Build in buy in. Like many projects that require change at all levels of the organization, this requires buy in from the corner office to the depths of the mine. In many instances, this requires a culture change, with people being used to doing the job one way now asked to shift their operations.

Make it transparent. Change can’t be foisted on people in a vacuum. The new initiative on transforming into an HRO should be a full team effort, with full transparency from the top.

Implement measures and metrics. It’s also important to implement accurate measurements and targets. Still, one assessment rises above all others: addressing overall organizational health. Organizational health is the softer side of the business that is frequently dismissed because it is often viewed as both difficult to revamp and even more difficult to measure.

HRO Checklist

Do you need to focus on High Reliability Organization? Here’s a quick checklist to help you decide.

- Do you have an organization-wide sense of susceptibility to the unexpected?

- Does everyone feel accountable for organizational reliability?

- Are your leaders paying as much attention to managing unexpected events as they are to achieving formal organization goals?

- Do people at all levels of your organization value quality?

- Have you identified how your activities could potentially harm your organization, employees, other stakeholders and the environment at large?

- Do you pay attention to when and why your employees or other stakeholders might feel angry or disenfranchised?

- Do you have widespread agreement among the organization’s members on what shouldn’t go wrong?

Transforming into a High Reliability Organization doesn’t happen overnight, and many challenges exist in the process. It requires a cultural shift, training for both workers and management, investing in protocols, and commitment from the top.

But, in today’s volatile world, it’s a solid framework the mining industry can use to ramp up safety, increase efficiency, minimize risks and anticipate the unexpected. For help setting up your HRO, contact USC Consulting Group today.

All roads are leading most industries to adopt increasingly more sustainable practices. The pressure for manufacturers to go green is growing in the face of climate change, supply chain challenges and especially consumer preferences.

A report from the Roundup, “Environmentally Conscious Consumer Statistics,” paints a pretty clear picture.

- Products marketed as sustainable grew 2.7x faster than those that were not.

- 78% of consumers feel that sustainability is important.

- The sale of carbon labeled products (such as those with 1% For the Planet or Climate Neutral Certification) doubled in one year, reaching $3.4 billion in 2021.

- 62% of people say they “always or often” seek products to purchase because they are sustainable, which is up from just 27% in 2021.

Consumers are opting for products that are sustainable, but that’s not the only headline for manufacturers. Because, it’s not just products. It’s the companies, too. Some 29% of consumers said they are “often or always” influenced by a company’s commitment to adopting more sustainable practices.

Sustainability challenges: It’s not easy being green

Many in the manufacturing industry are undoubtedly feeling some kinship to Kermit the Frog these days. Despite the pressure to adopt more sustainable practices, as the Muppet so famously lamented: “It’s not easy being green.”

It’s all well and good to work toward shoring up the environment (and we need to) but it’s a challenging lift for manufacturers. Some obstacles include:

High upfront costs. New technologies, processes and materials come at a price. It’s especially tough for manufacturers in industries like food and beverage, which has razor-thin margins.

Long wait for return-on-investment. ROI from major expenses can take years to come to fruition.

Supply chain challenges. Even if your company has shifted to more sustainable practices, what about your suppliers?

Skilled labor shortage. It’s difficult enough to find warm bodies to work on the line. But new technologies come with new skills requirements.

Opportunities are emerging

At USC Consulting Group, we help companies look for the opportunities within challenging situations. We always find the silver linings. Here are a few:

Cost reduction. Yes, there are upfront costs. But sustainable practices can lead to reduced energy and water consumption, the possibility of lower regulatory compliance costs, and lower materials costs by using recycled materials.

New partners, suppliers and revenue streams. The sustainable marketplace is an ecosystem all its own. It’s possible to find new partners, customers and even suppliers.

Attract and retain top talent. Yes, there is a labor shortage. But the companies with strong sustainable practices are attracting the best people out there. Companies that care for the environment also find their employees are more engaged and involved.

Governmental tax breaks. The government is committed to rewarding companies for adopting more sustainable practices with tax breaks and other financial incentives.

Strategies for manufacturers

One of the best ways to adopt more sustainable practices is to first look in the mirror. It’s not necessarily about investing in new technologies and turning the world upside down. First, look at your processes and operating systems. You’ll likely find efficiencies you didn’t even know were there. Places to start:

Minimizing waste. Lean Six Sigma methodologies can find hidden wastes and lead to more efficient operations. Not only will it save you considerable money, but minimizing waste is a key principle in sustainability. That’s a win-win.

Operations improvements. How efficient are your operations? A solid management operations system, which is a structured approach to your operations, creates much greater efficiency. The best MOS focus on processes, systems, roles and structures to map out how the job gets done, and by whom. Learn more about it in our short video, Stop the Firefighting Mentality to Improve Your Bottom Line.

Sales, inventory and operations planning. You’ve heard of S&OP. We added the “I.” We find inventory to be a key piece of the operations puzzle. When doing sales forecasting and planning for demand and supply, adding inventory elevates the process a notch. It makes inventory a strategic tool. Learn more about it in our free eBook, “Sales, Inventory and Operations Planning: It’s About Time.”

Training. About that skilled labor shortage. A way to combat that is by training and upskilling your people. And solid training for not just employees on the line but managers, too, will get everyone on the same page, creating greater efficiency organization-wide.

By moving toward more sustainable practices, manufacturers can ultimately reduce costs, find greater efficiencies, attract both consumers and employees and help the planet in the process. But it’s not easy. At USC Consulting Group, we’re the experts on helping companies become more efficient, effective and profitable. With more than 55 years behind us, we’ve seen trends come and go. The key is turning challenges into opportunities. Get in touch to find out more.

With Halloween just around the corner, we started thinking about nightmares that can occur to manufacturers. Is something bedeviling your productivity leading to more tricks than treats? Is there a ghost in the machine? Here are some of the most common “monsters” that haunt manufacturing managers, and ways to banish them from your operation for good.

Things that go bump in the night (or day). Every manufacturing plant on the planet has experienced an “unexpected shutdown” that seemingly comes out of nowhere. Something broke, wore out, went awry or otherwise seized up, causing production to grind to a halt. These unexpected dark periods, whether they last an hour, a day or longer until the problem is resolved, are extremely costly in lost productivity and revenue, delays in shipments and deliveries, and more.

Banish it! Regular shutdowns for maintenance need to be an essential part of your yearly calendar. Yes, these planned maintenance periods still mean downtime, but the point is, you build them into your schedule and plan accordingly for shift scheduling, delivery and other variables.

Zombies on the line. Unmotivated teams can bedevil companies in any industry. From the Great Resignation to Quiet Quitting, employee morale has taken a tumble since the pandemic. People are just going through the motions out there. Couple that with some spooky stats: According to a Gallup survey, only 36% of U.S. employees are engaged at work and 74% say they are actively looking for new jobs. Low morale costs companies in just about every way possible — increased absenteeism, dips in quality and efficiency, and rock-bottom motivation levels among them.

Banish it! There are many spells you can cast to break that zombie curse. Invest in training and development for your employees. Hold listening sessions to get ideas for improvements on the job. Walk the floor and talk to your people regularly, something management just doesn’t do enough. Build a promotion pipeline from your front lines. All of these will help increase employee engagement and get their heads back in the game.

Process poltergeists. Are you constantly putting out fires that seem to combust without warning? Human errors, unforeseen backups, supply chain bottlenecks, inventory imbalances (too much or too little), glitches on the line. It can feel like you have a firefighting mentality, and it’s counterproductive to, well, productivity. When you’re in a constant state of troubleshooting, you’re not efficient at doing the job today or laying the groundwork for tomorrow.

Banish it! A solid Management Operating System, which is a structured approach to your operations, will help stop trouble before it starts. This allows you to make adjustments and otherwise pivot so your operations aren’t adversely impacted. The best management operating systems focus on processes, systems, roles and structures to map out how the job gets done, and by whom. To learn about MOS in more detail, watch our short (and dare we say fun) video, Stop the Firefighting Mentality.

“20% of each dollar is wasted in manufacturing due to inefficient processes each year”

Wasting disease. Waste can hide on your shop floor like a monster under the bed. It hides where you least expect it, like time, energy, employee talent, productivity and more. Here’s a figure that will keep you up at night: 20% of each dollar is wasted in manufacturing due to inefficient processes each year, adding up to $8 trillion globally.

Banish it! Waste is such an enormous problem in manufacturing, Toyota (or Henry Ford, depending on who you ask) created a process methodology about it. Lean is all about identifying and eliminating waste in manufacturing operations. The classic Seven Deadly Wastes (we think it’s eight, but let’s not split hairs) include overproduction, waiting, transporting, processing, inventory, motion and defects. (People is our eighth.) Lean is the process to minimize or eliminate those, boosting your bottom line. Read more about it by downloading our eBook, “Lean Six Sigma: Do You Really Know These Methodologies?”

The invisible man (or woman). The loss of institutional knowledge happens when your best workers vanish (retire or quit) and take all their hard-earned, on-the-job know-how with them. It’s the tips, tricks and tactics that aren’t in the employee manual. The loss of this irreplaceable knowledge is a growing issue for manufacturing, because the workforce is aging, and there is a lack of skilled younger workers to take their place.

Banish it! Capture that knowledge before your seasoned pros retire or otherwise leave the workforce. Create mentorship programs pairing older workers with younger ones, ask those older employees to participate in roundtable sessions that can focus on “what’s not in the manual” knowledge, and solicit their advice on how to do the job better.

While this is a lighthearted look at manufacturing problems, these issues are no joke. They can seriously hamper your efficiency, productivity and ultimately, your bottom line. At USC Consulting Group, we’re the experts in helping companies reach operational excellence. If you’d like to learn more, please give us a call.