-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2025 (1)

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Infographic

Achieving efficiency in manufacturing requires meticulous attention to pre-production processes, especially when managing temperature-sensitive operations. Pre-manufacturing thermal management is essential for maintaining product quality, ensuring equipment longevity, and improving overall operational efficiency.

The Role of Thermal Management in Manufacturing

Thermal management involves regulating temperature levels within machinery, materials, and environments to create ideal conditions for production. Excessive heat or improper cooling can compromise machinery performance and lead to defects in temperature-sensitive products. A robust thermal management strategy minimizes these risks, ensuring consistent outcomes and reducing downtime caused by equipment failure.

Industries such as electronics, pharmaceuticals, and aerospace often handle materials that demand precise thermal control. For instance, electronic components require steady temperatures during assembly to avoid warping or damage. Without adequate thermal management, manufacturers risk product recalls and damaged reputations.

Pre-Manufacturing Strategies for Temperature Control

Implementing a pre-manufacturing thermal management plan involves understanding your facility’s specific needs and employing the right tools to monitor and maintain conditions. Thermal analysis equipment is a key investment for businesses aiming to achieve optimal production outcomes. These tools provide detailed insights into how heat is distributed and managed throughout the production process, helping identify areas of inefficiency or potential failure.

Effective thermal management strategies also include proper ventilation systems, insulation, and advanced cooling technologies. Additionally, scheduling routine maintenance ensures that thermal management tools operate correctly, preventing unexpected disruptions during production.

The Long-Term Benefits of Optimal Thermal Management

Businesses that prioritize pre-manufacturing thermal control enjoy several advantages, including reduced operational costs, improved product quality, and extended equipment lifespans. By addressing thermal issues early, companies can avoid costly repairs, minimize energy consumption, and enhance workplace safety.

Furthermore, implementing thermal management measures aligns with sustainability goals, as efficient temperature regulation often reduces waste and energy usage, positively impacting the environment.

Pre-manufacturing thermal management is more than just a technical requirement—it’s a cornerstone of efficient and sustainable production. Investing in tools and prioritizing proactive strategies ensures businesses can meet high-quality standards while staying competitive in a fast-paced market.

Check out the accompanying resource below to learn more.

Efficient warehouse management is crucial for the success of any business. However, numerous challenges can hinder operations and impact overall profitability. Understanding these obstacles and implementing effective solutions is essential for optimizing warehouse performance.

Common Warehousing Challenges

Ineffective warehouse management practices, such as inadequate order and inventory management, can lead to significant inefficiencies and losses. Inaccurate data, inconsistent tracking, and insufficient space further exacerbate these issues. Additionally, erratic changes in demand and economic fluctuations can disrupt operations and make it difficult to maintain optimal inventory levels. Packaging wastefulness and design shortcomings can also contribute to increased costs and environmental concerns.

Optimizing Inventory Management

To address inventory management challenges, businesses should invest in advanced technologies and streamline processes. Implementing cloud-based inventory management platforms with demand forecasting tools and automated reordering systems can help optimize stock levels and reduce carrying costs. Utilizing mobile productivity tools allows for real-time inventory tracking and control, improving efficiency and accuracy.

Enhancing Warehouse Layout and Space Utilization

Maximizing warehouse space utilization is crucial for optimizing operations and reducing costs. Implementing a well-designed warehouse layout, incorporating storage solutions that maximize vertical space, and utilizing advanced warehouse management systems can help streamline workflows and improve productivity.

Leveraging Technology and Data

Technology plays a vital role in modern warehousing. Implementing barcode technology and system-directed pick/put-away procedures can significantly improve order fulfillment accuracy and speed. Digitizing documentation and utilizing data analytics can provide valuable insights into inventory levels, customer demand, and operational performance.

Addressing Packaging and Sustainability

Packaging waste and design shortcomings can impact both costs and environmental sustainability. Collaborating with pharma packaging machine manufacturers to optimize packaging design can help reduce waste and improve efficiency. Additionally, implementing recycling programs and using sustainable packaging materials can contribute to environmental responsibility.

Overcoming warehousing challenges requires a combination of strategic planning, technological advancements, and efficient processes. By addressing issues such as inventory management, space utilization, and packaging optimization, businesses can improve operational efficiency, reduce costs, and enhance customer satisfaction. The resource below provides a visual overview of common warehousing challenges and potential solutions.

The world is increasingly focused on sustainability, and the manufacturing sector is no exception. Consumers are demanding eco-friendly practices, and regulations are evolving to reflect this shift. This presents a compelling opportunity for manufacturers – by incorporating sustainability principles into the design of their machines, they can not only benefit the environment but also reap significant economic rewards.

The Benefits of Green Design

Sustainable manufacturing machine design offers a win-win scenario for businesses. By focusing on resource conservation and energy efficiency, manufacturers can significantly reduce their environmental footprint. This translates into a positive impact on the planet, aligning them with global sustainability goals. Additionally, sustainable design principles can lead to cost savings through minimized waste generation and lower energy consumption.

Beyond environmental and economic benefits, sustainable machine design can also enhance a company’s reputation. Customers today are increasingly conscious of eco-friendly practices, and a commitment to sustainability can be a major selling point. Furthermore, adhering to evolving environmental regulations becomes easier when sustainability is embedded into the design process from the very beginning.

Implementing Sustainable Design Principles

So, how can manufacturers translate these principles into action? A crucial step is integrating a life cycle assessment into the design process. This involves evaluating the environmental impact of the machine throughout its entire lifespan, from raw material extraction to disposal. This holistic approach allows engineers to make informed decisions about materials, manufacturing processes, and even end-of-life options.

Technology also plays a vital role in sustainable design. Advanced software tools like computer-aided design (CAD) can help engineers optimize both functionality and aesthetics, minimizing material usage and ensuring efficient operation. Additionally, simplifying design complexity can further reduce the environmental impact. Removing unnecessary components not only streamlines assembly but also minimizes energy loss during operation.

Material selection is another critical aspect of sustainable design. Opting for materials with lower embodied energy (the energy required to extract, process, and transport them) and those that can be easily recycled or reused can significantly reduce the environmental burden. For instance, utilizing high-efficiency, NEMA gearboxes, can not only improve overall system efficiency but also extend the lifespan of the equipment, reducing the need for premature replacements.

Safety plays a vital role not only for workers but also for the environment. Conducting thorough safety audits throughout the design process ensures the equipment operates safely and efficiently, minimizing the risk of accidents that could lead to environmental damage. Furthermore, integrating smart technologies like real-time energy monitoring and predictive maintenance systems empowers manufacturers to identify and address potential issues before they escalate into bigger problems.

Curious about the specific ways sustainable design can improve a machine’s environmental impact? The following infographic dives deeper into the benefits of sustainable manufacturing machine design, showcasing how each principle contributes to a greener future for the industry. By adopting these sustainable design principles, manufacturers can create machines that are not only efficient and productive but also environmentally responsible.

Downtime – the dreaded halt in production that can cripple a manufacturing operation. It’s more than just an inconvenience; it’s a hidden cost that can eat away at your profits. A recent study revealed that nearly 82% of businesses have experienced unexpected downtime in the past three years, with the average incident lasting four hours and costing a staggering $2 million. The impact goes beyond just financial losses – downtime can disrupt customer deliveries, delay critical projects, and erode trust with clients.

The Potential Culprits

One major factor is neglecting preventive maintenance. Regular servicing not only keeps equipment functioning smoothly but also allows technicians to identify potential problems before they snowball into major breakdowns.

Another hidden source is outdated equipment. Obsolete machinery can be a drag on your entire production line. Imagine a slow, malfunctioning piece of equipment holding up the entire process. This can put undue stress on other machines, leading to premature wear and tear, and ultimately, more downtime. Upgrading to newer, more efficient models can significantly improve production flow and reduce the risk of breakdowns. Outdated software can also be a culprit. Running outdated software can lead to compatibility issues with newer systems and leave your facility vulnerable to security breaches.

Beyond equipment and software, a lack of proper training for your workforce can also contribute to downtime. If operators don’t fully understand how a machine works, they might misuse it, leading to errors and breakdowns. Investing in comprehensive training empowers your employees with the knowledge and skills they need to operate machinery safely and efficiently, minimizing the risk of operator-induced downtime.

Finally, the importance of data tracking cannot be overstated. Keeping detailed logs of equipment issues and production hiccups allows you to identify recurring problems and implement preventative measures. Think of it as a historical record that helps you anticipate and address potential bottlenecks before they derail your production schedule.

Finding the Right Solution for You

The good news is that there are steps you can take to combat downtime and keep your production lines humming. Conducting risk audits to identify potential problems, installing sensors to monitor equipment health (like a torque transducer that detects excessive force on a rotating shaft), and implementing a comprehensive preventive maintenance program are all crucial steps in the battle against downtime.

Investing in employee training and partnering with reliable third-party service providers can further strengthen your defenses. By adopting a proactive approach to maintenance and addressing the root causes of downtime, you can significantly reduce disruptions and ensure your manufacturing operation runs smoothly and efficiently.

Want to learn more about the specific costs associated with different downtime causes? The following infographic breaks down the financial impact of various downtime triggers, helping you identify areas for improvement and optimize your production process for maximum uptime.

In today’s competitive business landscape, keeping labor costs under control is a constant concern. However, this pursuit of cost-efficiency must never come at the expense of safety. Here’s how businesses can strike a balance between these two priorities.

Standardization and Management

Standardized labor processes are the cornerstone of a safe and productive work environment. By establishing clear, well-documented procedures for each task, companies minimize confusion and errors, while also ensuring consistent quality. This translates to increased efficiency, reduced rework, and ultimately, lower labor costs.

Complementing standardized processes with a robust training program further strengthens this foundation. Comprehensive training, encompassing both initial onboarding and ongoing professional development, equips employees with the skills and knowledge necessary to perform their duties safely and effectively. This not only reduces the risk of accidents, but also empowers employees to identify and address potential issues before they escalate into costly problems.

Labor costs can be further optimized by taking a strategic approach to staff management. Reviewing staff schedules regularly and adjusting them based on actual workload can prevent unnecessary overtime and ensure employees are not overscheduled. Additionally, exploring options for part-time positions or flexible work arrangements can contribute to optimizing labor costs.

Technology and Lean Practices

Investing in automation technology can be a strategic move towards reducing labor costs while maintaining safety. Automated equipment can handle repetitive or hazardous tasks, freeing up employees to focus on more complex activities. This not only improves overall productivity but also reduces the risk of workplace injuries associated with repetitive motions or exposure to dangerous materials.

Lean manufacturing principles, which emphasize eliminating waste and maximizing value, can also offer significant cost savings. By taking a critical look at existing workflows and identifying areas for improvement, companies can reduce wasted time and resources, leading to a leaner, more efficient operation.

Choosing the Right Tools

The right tools for the job are not just essential for efficiency, but also for safety. For instance, opting for quality-assured scaffolding components like a ringlock modular system, compared to a cuplock system, can significantly impact labor costs in the long run. Ringlock systems generally require less assembly time, facilitating faster project completion and reducing labor hours. Furthermore, their robust design often translates to fewer repairs and maintenance needs, further reducing overall costs.

Implementing advanced software programs can also significantly improve various aspects of business operations, ultimately impacting labor costs. Digital tools can optimize scheduling processes, enhance production visibility, improve communication among teams, and streamline training programs.

The infographic below delves deeper into each of these strategies, providing a comprehensive roadmap to reducing labor costs while prioritizing safety. Remember, a safe and well-trained workforce is a productive one. By implementing these strategies and fostering a culture of safety and efficiency, businesses can create a win-win situation for both employees and the company’s bottom line.

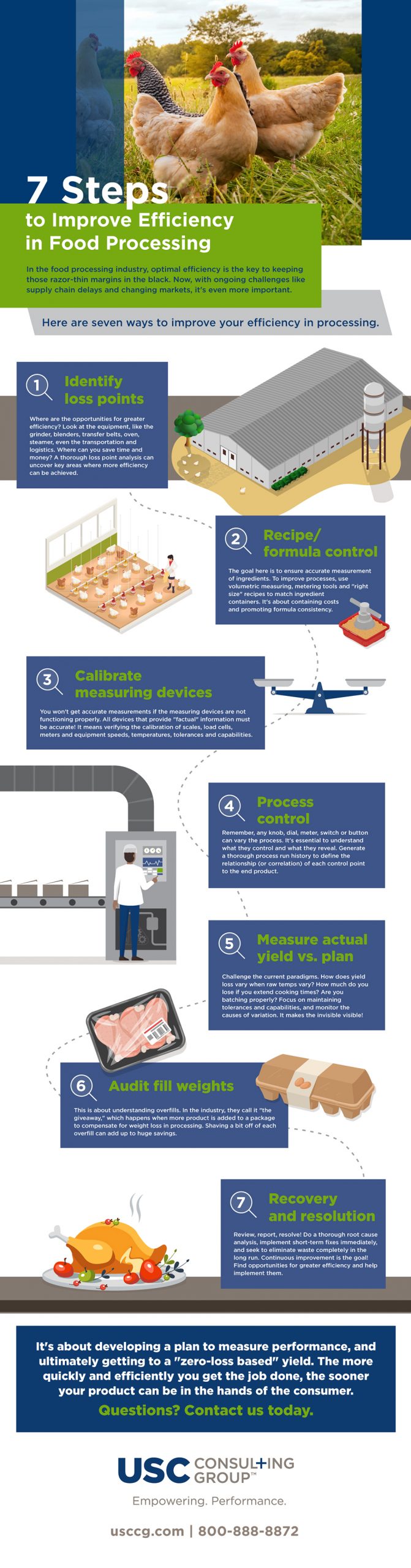

In the food processing industry, optimal efficiency is the key to keeping those razor-thin margins in the black. Now, with ongoing challenges like supply chain delays and changing markets, it’s even more important.

Efficient processes lead to reduced operating costs, improved yield and throughput, and more control over your management systems.

The following graphic provides seven ways to improve your efficiency in food processing:

1. Identify loss points

Where are the opportunities for greater efficiency? Look at the equipment, like the grinder, blenders, transfer belts, oven, steamer, even the transportation and logistics. Where can you save time and money? A thorough loss point analysis can uncover key areas where more efficiency can be achieved.

2. Recipe/formula control

The goal here is to ensure accurate measurement of ingredients. To improve processes, use volumetric measuring, metering tools and “right size” recipes to match ingredient containers. It’s about containing costs and promoting formula consistency.

3. Calibrate measuring devices

You won’t get accurate measurements if the measuring devices are not functioning properly. All devices that provide “factual” information must be accurate! It means verifying the calibration of scales, load cells, meters and equipment speeds, temperatures, tolerances and capabilities.

4. Process control

Remember, any knob, dial, meter, switch or button can vary the process. It’s essential to understand what they control and what they reveal. Generate a thorough process run history to define the relationship (or correlation) of each control point to the end product.

5. Measure actual yield vs. plan

Challenge the current paradigms. How does yield loss vary when raw temps vary? How much do you lose if you extend cooking times? Are you batching properly? Focus on maintaining tolerances and capabilities, and monitor the causes of variation. It makes the invisible visible!

6. Audit fill weights

This is about understanding overfills. In the industry, they call it “the giveaway,” which happens when more product is added to a package to compensate for weight loss in processing. Shaving a bit off of each overfill can add up to huge savings.

7. Recovery and resolution

Review, report, resolve! Do a thorough root cause analysis, implement short-term fixes immediately, and seek to eliminate waste completely in the long run. Continuous improvement is the goal! Find opportunities for greater efficiency and help implement them.

It’s about developing a plan to measure performance, and ultimately getting to a “zero-loss based” yield. The more quickly and efficiently you get the job done, the sooner your product can be in the hands of the consumer. Questions? Contact us today.

For more information about how Food & Beverage consultants can significantly reduce your operating costs and improve productivity, read this eBook:

What’s keeping manufacturing CEOs up at night? From supply chain disruptions to a disengaged workforce and growing skills gap, there are challenges aplenty plaguing leadership teams. Here are the top five manufacturing issues along with solutions from USC Consulting Group that will help them sleep a little easier.

Problem: Retiring workforce

My best shift supervisor is retiring next month! He knows everything there is to know about the line. How can I possibly replace him?

“The median age of manufacturing workers is 48 and continues to grow older.”

Solution: Capture that knowledge!

Before your seasoned vets retire, create mentorship programs, have roundtable discussions and update manuals with their hard-earned know-how.

Problem: Skills gap + Jobs gap

I have positions to fill but I’m not finding any qualified candidates! How am I supposed to get the job done?

“Manufacturers will have 2 million jobs to fill by 2030. But there’s a skills gap out there. A sea of open jobs and few skilled people to fill them is a one-two punch.”

Solution: Build training into your budget

Skill them up yourself! Invest in training for new hires and partner with a local trade school or community college to target new grads.

Problem: Disengaged employees

Are my employees happy? It’s like they’re just going through the motions. Are they going to quit?

“Only 36% of U.S. employees are engaged at work and 74% are actively looking for a new job at any given time.”

Solution: Walk the shop floor

Talk to the team, ask how things are going and how you can help. If they’re short-handed, roll up your sleeves! Also, promote from within and invest in career development! It’s a proven way to build morale and engagement.

Problem: Supply chain disruptions

My line was down AGAIN because our overseas supply was stuck at a port. Again! We have high customer demand but can’t meet it because we can’t get the supplies we need!

“A 400% increase in shipping costs from China and a 45% increase in ocean freight wait times is expected to continue for 6 to 12 months, if not longer.”

Solution: Reshoring

It has long been suggested as idealistic and beneficial for the country, yet unrealistic. That is, until now. It’s time. Reshoring is a way for U.S. manufacturers to invest in the country and claim valuable subsidies, while also shielding themselves from any potential global supply chain issues.

Problem: Inventory management

All of my departments have a different view on inventory management! Some want excess inventory. Others want it just in time. Do we have enough? Too much?

Solution: Sales, Inventory & Operations Planning (SIOP)

SIOP expands on S&OP by adding a crucial component: Inventory. It helps you wrangle your inventory management and achieve the optimal supply balance.

Want to learn more? Read What’s Keeping You Up at Night? The Main Concerns of Top Executives.

These aren’t the only challenges keeping CEOs up at night. At USC Consulting Group, we have more than 50 years of experience helping manufacturers find opportunities for greater efficiency and productivity. Call us today to talk about how we can help you get a good night’s sleep.

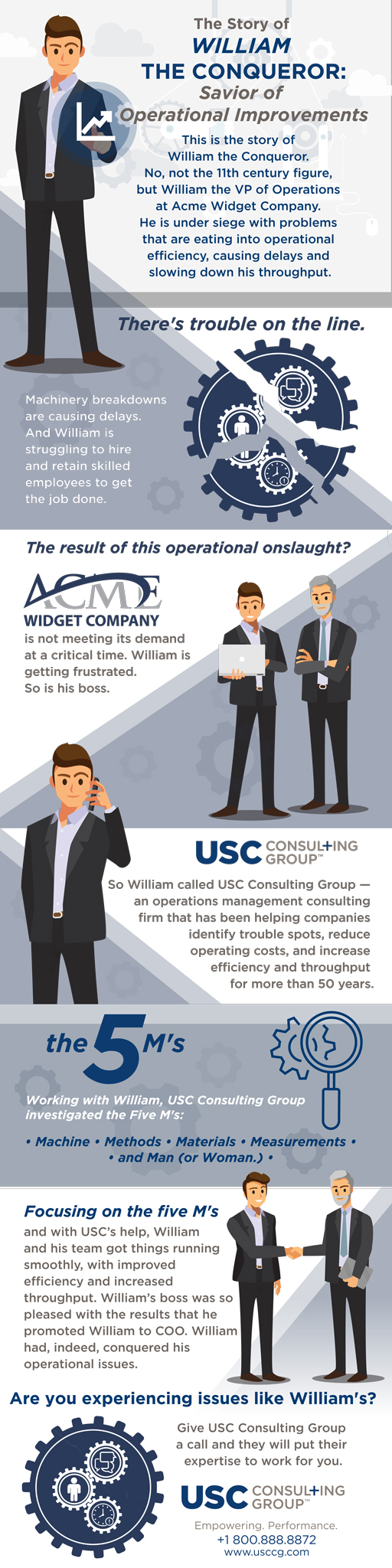

Everyday we set out to conquer life in various ways. We conquer fears, objections, and challenges. It is how we overcome these obstacles that defines are character and successes.

There was a famous historical figure with the moniker William the Conqueror who set out on a conquest which changed the face of history. While we are not conquering nations in the name of our country, we do find victories everyday for ourselves and our companies.

The following is a story illustrating one such victory overcoming operational issues that many others can also achieve themselves…

This is the story of William the Conqueror. No, not the 11th century figure, but William the VP of Operations at Acme Widget Company. He is under siege with problems that are eating into operational efficiency, causing delays and slowing down his throughput.

There’s trouble on the line. Machinery breakdowns are causing delays. And William is struggling to hire and retain skilled employees to get the job done.

The result of this operational onslaught? Acme Widget Company is not meeting its demand at a critical time. William is getting frustrated. So is his boss.

So William called USC Consulting Group — an operations management consulting firm that has been helping companies identify trouble spots, reduce operating costs, and increase efficiency and throughput for more than 50 years.

Working with William, USC Consulting Group investigated the Five M’s:

1. Machine (Does it need maintenance?)

2. Methods (Can you make processes more efficient?)

3. Materials (Supply chain bottlenecks?)

4. Measurements (Are we measuring the right things?)

5. Man or Woman power (Are your people skilled and trained?)

Focusing on the Five M’s and with USC’s help, William and his team got things running smoothly, with improved efficiency and increased throughput. William’s boss was so pleased with the results that he promoted William to COO*. William had, indeed, conquered his operational issues.

If you are experiencing operational issues like William, give USC Consulting Group a call today and we will put our expertise to work for you, too. *You may not be promoted to COO, but you will increase your operation’s efficiency.

Disruptive supply chains cause uncertainty. This leads to disjointed internal functions and frustration. And although there have been significant improvements with technology, supply chain disruptions are still managed by people.

Having good relationships with your strategic suppliers will help ensure someone will answer your call regarding delayed delivery dates, but that’s not enough to ensure supply continuity in our increasingly complex and disruptive supply chains.

There are five types of solutions supply chain managers can employ to decrease uncertainty and to improve reliability in their supply chain. We have compiled them into this infographic:

- TIME

- PRICING

- PRODUCTION

- INVENTORY

- INFORMATION

Each type of solution can be effective, however each has its downside to watch out for.

Time

Expediting freight or delaying order fulfillment are commonly used tactics.

What to watch for: If your customers have other options and low customer loyalty, delaying delivery dates can significantly reduce your revenues. If you have a low margin product, premium freight can wipe out profits.

Pricing

Prices for hard-to-get commodities skyrocket during times of uncertain supply, contributing to cost inflation.

What to watch for: If inflated material costs can’t be passed on to customers, margins suffer.

Production

Production solutions to supply disruptions include flexible manufacturing and quick changeover practices, having alternative suppliers and substitute materials, reducing quality rejects in order to have more saleable product, and improving the source, make, and deliver cycle times.

What to watch for: Production solutions often take time to develop, which is why they are effective during times of certain supply, but when dealing with surprising disruptions, they’re often too little, too late.

Inventory

Stocking up on inventory is a common response to disruptions, however warehouse and storage space can be a constraint requiring investment in facilities and equipment.

What to watch for: Excessive inventories drain cash and tie up working capital. A better practice is to use statistical analysis to evaluate how changing lead times are affecting the reorder points and order quantities in your ERP system.

Information

Uncertainty is caused by lack of information. Embed a strong SIOP process — Sales, Inventory, and Operations Planning. Conduct value stream maps to understand the tiered network of the supply chain. Implement strong supplier scorecards, and have a robust risk register process where there are early warning systems, contract optionality, and redundancies in the supply base.

What to watch for: Information solutions are sometimes viewed as expensive, however they are rarely more expensive than increasing investments in facilities and equipment, or habitually discounting obsolete inventory, or perpetually incurring premium freight.

If your company needs help reducing supply disruptions, turn to the supply chain experts at USC Consulting Group. We have been empowering our clients’ performance for over 50 years.