-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2024 (4)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: CMMS

Production involves different processes that run concurrently or independently, with operators and technicians handling several tasks at one go. They monitor the working conditions of machinery and the quality of products. As such, plant floors are ever busy, making safety a priority for companies. They establish and enforce safety regulations to enhance the consistency of processes, eliminate workplace injuries and minimize breakdowns.

Human error is among the leading causes of plant floor accidents leading to workplace injuries, equipment and product damage, pollution (non-compliance) and death. Human errors may arise from fatigue, slips and lapses, psychological stress, technical mistakes, or violation of safety regulations. Reducing human error and accidents on the plant floor goes beyond establishing a safety mindset among employees. Below are tips for reducing human errors and accidents on the plant floor.

1. Automate processes

There are several automation technologies for improving the consistency and accuracy of processes while minimizing human intervention. They range from basic control systems for starting, sequencing and stopping production to complex robots with artificial intelligence which perform repetitive tasks without fatigue. Conveyors and autonomous mobile robots replace forklifts for material handling, transporting large loads. Advanced robots have visual guides to enable them to navigate obstacles, thereby reducing plant floor collisions.

Automation systems are programmed to perform tasks following specific procedures, leaving no room for errors. They are equipped with automatic safety switches to stop processes when production conditions are violated. Automation reduces operator exposure to moving equipment parts and improves material handling.

Computerized Maintenance Management Systems (CMMS) are platforms for automating maintenance workflows. Companies upload equipment safety information, manuals and standard checklists that outline maintenance activities and intervals. Technicians navigate CMMS programs on mobile devices, allowing them to access accurate maintenance information promptly. CMMS solutions reduce maintenance mistakes and standardize operations, guaranteeing uniformity.

2. Develop standard operating procedures

The human factor in production means that individuals may skip or modify procedures to complete tasks faster. In some cases, the company provides mismatched safety and operational policies, breeding confusion during implementation. The incoherence of policies and ambiguity of procedures lead to more errors, more accidents and frequent production stops.

Companies need to compile all procedures in a single document, providing detailed instruction for accomplishing each task on the production floor. Standard Operating Procedures (SOP) increase the consistency of floor operations while leaving little or no room for errors. These documents use straightforward language to outline step-by-step guidelines, reducing the misinterpretation of policies.

Technicians de-energize production equipment when performing routine or emergency maintenance. To protect technicians and equipment, companies use equipment-specific lockout tagout (LOTO) procedures. They outline how to shut down processes, block energy sources during maintenance, tag equipment under repairs, startup procedures after maintenance and authorization protocols. In case of a technical mistake or unplanned re-energization of the system, lockout devices block the hazardous energy and signal technicians of impending danger. They halt the repair process and resume once they remove the hazard.

3. Audit facilities and perform conclusive root cause analysis

Equipment design and plant floor layout contribute to accidents. Proper arrangement of production equipment facilitates seamless continuity of processes while enhancing the safety of employees. When designing plant floor equipment, companies should consider ergonometrics. Equipment should be sized appropriately, fitted with protective safety guards and emergency switches. The plant floor should have adequate lighting, clearly marked walkways and visible safety signs.

Frequent facility audits enable companies to identify flaws on the production floor that escalate human errors. They inspect all machinery, check maintenance records and verify compliance of processes to internal and statutory regulations. Through facility audits, companies identify accidents that occur frequently and their causes. Insights from these audits facilitate future optimization plans, focusing on minimizing the impact of human errors in the production process.

Facilities may fail to investigate minor accidents since some operators or technicians underreport or disregard them. However, it is prudent that companies develop an accident reporting format that captures any incident irrespective of its magnitude. Accident reports enable companies to perform conclusive root cause analysis for the elimination of inherent hazards. Results of root cause analysis can be used to tailor safety training.

4. Conduct extensive staff training

Hiring a pool of skilled employees is not sufficient surety that human errors and accidents will happen. Over time, plant floor operations overwhelm the employees as they struggle to hit production targets amid other personal distractions. Companies upgrade machinery and adopt newer technologies as they strive to improve productivity and enhance compliance. Staff training is a continuous process that companies utilize to strengthen the technical capabilities of staff, introduce and explain safety policy changes and the consequences of non-compliance.

Through on-the-job maintenance training programs, technicians gain invaluable skills in troubleshooting and correcting equipment defects within a short time without errors. Technicians become aware of the safety procedures and understand how to exploit technological tools and protective equipment to eradicate plant floor accidents. Companies use training programs to equip operators with fundamental machinery diagnosis and care skills for identifying and correcting minor errors independently.

Final Thoughts

Reducing human errors on the plant floor is a collective responsibility that requires proactive action by staff and the management. The company provides correct work tools, trains staff, and guarantees the safety of facilities. Employees should follow safety regulations, report defects and accidents, use machinery correctly and adhere to standard operating procedures.

*This article is written by Bryan Christiansen. Bryan is the founder and CEO of Limble CMMS. Limble is a modern, easy-to-use mobile CMMS software that takes the stress and chaos out of maintenance by helping managers organize, automate, and streamline their maintenance operations.

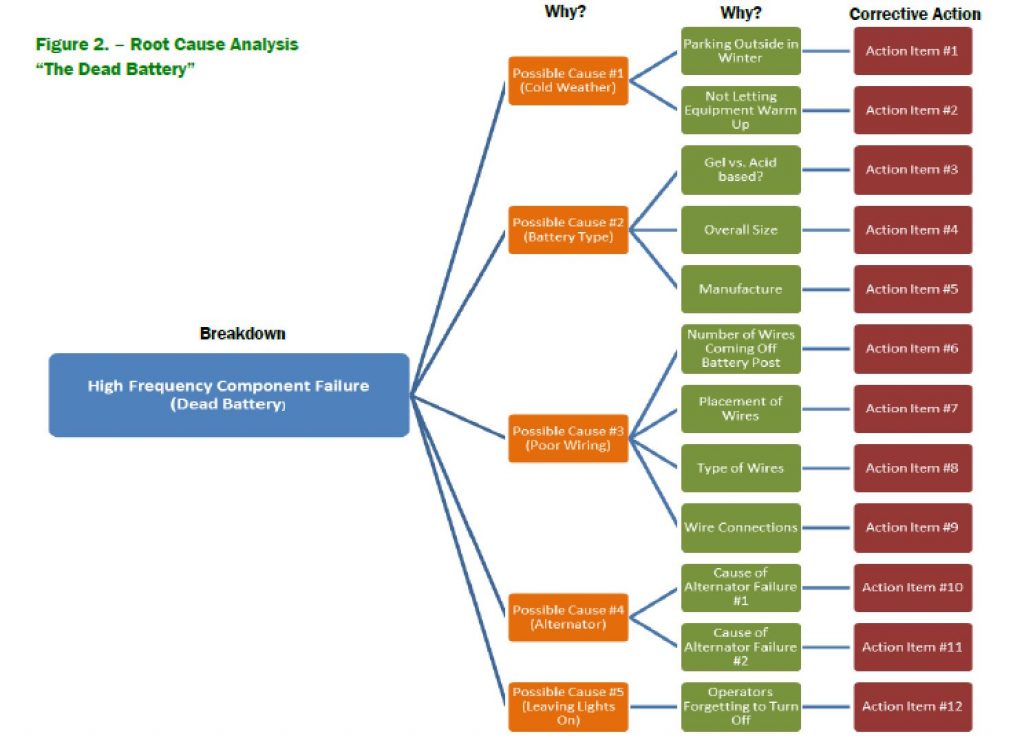

One of the most effective methods of analyzing operational breakdowns is to conduct a Root Cause Analysis (RCA). Some of the data needed in order to drive the analysis includes all of the unplanned failure work orders, which component required repair for each work order, and how long each work order took to complete. This analysis can be conducted on each individual piece of equipment, an entire fleet of the same type of equipment, an entire fleet of the same piece of equipment purchased in the same year, or the entire fleet as a whole. Each Computerized Maintenance Management Software (CMMS) will calculate these values in its own way. The more specific to each individual piece of equipment, the better; however, total fleet size and time constraints may not allow for each piece of equipment to be analyzed on an individual basis.

Frequency vs Severity

The objective of the RCA is to select a failure that is having a substantial impact on the equipment in question. This can either be based on frequency or severity. Frequency being the amount of times the failure occurs within a given period. Severity being the cumulative time it takes to make the repairs within a given time period. Ideally, one or more types of failures may have a high frequency and a high severity. Collecting this data alone may uncover some surprising results. For example, some quick and easy repairs that do not take long can add up very quickly if the frequency is high enough. This can come as a shock when the total time spent on this one repair is tabulated.

Take, for example, the case of the Dead Battery (Figure 2). This repair on average may only take between half an hour and an hour for a mechanic to complete, including mostly drive time and a quick battery boost. It is such a quick, straight forward solution that it may not have captured much of management’s attention. Nevertheless, when you consider how many times a dead battery has occurred in the last three months and total the hours involved in correcting this issue, it may show up as the number two consumer of the maintenance department’s human resources (mechanics labor hours). Management must be critical at this point of statements such “that’s just the work environment.” Questions need to be asked about what can be done to improve the failures that drain the greatest amount of the department’s resources.

An important element to consider is that there are always multiple root causes for any given failure. The intent of conducting the RCA is to uncover all of the individual root causes that may lead to the failure of the component in question. The true root causes are rarely uncovered at the first layer of asking “Why?” for the first time. Each answer provided must then be analyzed all over again, and this process must continue until all avenues have been explored and the group has arrived at a tangible end. It will often take five “whys” to uncover the true root cause of an issue. Once the session has uncovered all of the possible root causes of the failure in question, a solution must then be presented to address each one individually.

These solutions come in the form of action items which are reviewed at the end of the meeting by the management team, responsibility is assigned, expected completion dates are provided, and the method in which the solution will be accomplished is discussed.

After conducting a Root Cause Analysis, the management team will have a list of action items. All of which will have varying impacts on the equipment’s reliability. It is important that the management team takes the time to assess each item on two main criteria: how easy the item will be to complete and to what extent its effect is predicted to have on the equipment. Combining these two scales will provide a strong basis for prioritizing action items and deciding what to tackle first. The management team should begin with the high impact, easy to implement action items and leave the low impact, hard to implement action items for last.

RCA Action Item Generation

When considering what corrective actions can be taken in order to solve the root causes of the failure in question, keep in mind the areas or touch points where changes can be made to affect the equipment. Again, these can be simplified as:

► The Operator (how the equipment is used) – Change the process in which the equipment is used. Sometimes an operator is using equipment incorrectly or in a harmful way without knowing it. Added training will often improve these issues. It is common for operators to be required to inspect all equipment before use. This usually occurs in the form of a pre-use checklist. This checklist can be modified to draw the operator’s attention to certain areas of the equipment in which wear can be seen. Noting this wear, and informing maintenance, can prevent the component from failing during use.

► The Mechanic (how the equipment is repaired) – Sometimes the method in which repairs are made inside or outside of the shop will affect the way the equipment operates. If the equipment’s use is required at the time of breakdown, a mechanic may provide a “patch” to ensure it runs immediately. These “patches” however, will not always last until the next service date for the piece of equipment.

► The Service (how the cyclical services are conducted) – Consider the actual activities performed on the equipment during its regular preventative maintenance service. Can these activities be changed or include more that would prevent the root cause in question? Perhaps a specific component that is failing often needs to be cleaned during the service or inspected specifically for signs of wear.

► The Design (how the equipment is designed or modified) – In underground mining, equipment modifications are often required by law in North America before the equipment can even be commissioned. These modifications can vary depending on the type of underground mine. It is important to understand what impact these modifications have on the operation of the equipment. In the Dead Battery case example, maybe the equipment in question was outfitted with additional lights to make it safer to drive underground where it is pitch black. The addition of these extra lights places a larger strain on the battery and alternator. Have the battery and alternator been upgraded to keep up with this added strain as well?

These are the areas that the department has complete control over. An organization cannot control the weather, but they can understand what effects the weather has and correct them at their root. Winter brings cold temperatures; cold temperatures make it difficult for equipment to start.

The temperature cannot be changed, but where the equipment is parked can be. Can they be stored in a heated area? Could block heaters be installed at low cost? These are the kinds of questions that must be discussed in the Root Cause Analysis session with all stakeholders in the room.

Finding the root causes of operational hardships can minimize downtime and significantly boost productivity. With over 50 years of operations management experience, USC Consulting Group can troubleshoot any issues and establish preventative maintenance processes to enhance your asset management. Reach out today to learn more on how to set up an effective Root Cause Analysis.