-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2025 (1)

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Change Management

At USC Consulting Group, we’ve been empowering performance for more than 50 years. What does that mean?

It means we’re an operations management and process improvement firm that empowers your people and processes to achieve operational excellence.

The below graphic lays out our experience and the areas we specialize in:

Let’s look in more detail at how USC partners with you to accelerate and augment your process improvement efforts.

What we focus on

Operational excellence. We help clients define and implement a strategic approach to achieving and maintaining the highest levels of operational performance. It’s about eliminating waste, improving quality and ramping up productivity.

Process improvements. We look at your processes through the lens of efficiency and effectiveness. We identify bottlenecks that might be slowing down your workflow, assessing the “we’ve always done it this way” processes that every business has. We find that a fresh set of eyes on these types of long-held processes can yield more effective ways to achieve results.

Optimal efficiency. This is about the “well-oiled machine” factor. Everyone knows what that is, although it’s different for every company. It’s when you’re cooking and booking, churning and burning, and achieving the maximum throughput for your efforts.

Supply chain optimization. In the post-Covid era, we’re still seeing supply chain disruption and the headaches they cause. We help companies analyze their supply chain networks and spot inefficiencies and bottlenecks. Is there a supplier closer to home? Is it time to reshore? Can we improve procurement or logistics?

Change management. Many of the process changes we recommend involve new ways of doing things – perhaps significant changes. With training and development, strong communication and getting feedback and input from stakeholders, we can help companies embrace change for the better.

Asset Performance Management. At USC, we focus on getting the most out of the assets you already have. Heavy investments in new technology is not always necessary, especially if your old workhorses just need some care and feeding. Applying predictive maintenance to reduce unplanned downtime, usage that doesn’t cause more wear and tear than necessary, and processes to extend the lifecycle of the tools you rely on.

EBITDA improvement. This refers to a company’s Earnings Before Interest, Taxes, Depreciation and Amortization. Sounds like your worst day in the accountant’s office, right? But it’s really about helping clients look for cost-savings opportunities, revenue enhancement, and more. It’s also about everything else we do – productivity improvement, asset management, operational efficiency, cost reduction and more.

How we do it

How do we enhance our clients’ operations? We’re experts in process improvement methodologies and tools, like:

Lean Six Sigma. LSS is a combination of two powerful methodologies, Lean, which focuses on limiting waste in a process, and Six Sigma, which focuses on increasing quality.

Sales, Inventory, and Operations Planning (SIOP). In a nutshell, SIOP aligns sales, inventory and operations planning functions to improve demand forecasting, efficiency, supply chain performance and more.

Employee Involvement Prototype Process. One of the cornerstone techniques USC uses to validate and measurably implement changes to elements of the MOS with full client personnel engagement. Your employees are the most vital components to every project, especially the workers in the trenches on the shop floor or production site. We involve them every step of the way.

System Reviews. We do a comprehensive analysis of your systems, processes, procedures and more. System Reviews tell the story of a company’s process and depicts the future state MOS with the deficiencies from current state corrected. It shows the flow of data, actionable information and decision-making points in a closed loop environment.

LINCS advanced reporting tools. The Lean Information Control System (LINCS) is a state-of-the-art software application that facilitate fact-based decision making from the shop floor to the boardroom. It includes modules for advanced planning, manufacturing and logistics, value stream mapping, scheduling, inventory analysis and more. Operators are able to see and evaluate their work as it takes place, while executives and managers are better equipped to prioritize activities based on accurate, actionable information.

AI, Machine Learning, and Predictive Analytics. Much like Netflix’s use of predictive analytics created a seismic shift in consumer expectations, this new technology is transforming operating procedures and processes. Predictive analytics helps companies better understand what’s occurring in any given process, refine and optimize processes, and more. But, it also needs the human touch. People aren’t getting replaced by the bots in this area any time soon. To learn more, download our free eBook: AI and Machine Learning: Predicting the Future.

Our 55-plus years of experience covers a wide variety of industries, including:

- Mining & Metals

- Food & Beverage

- Manufacturing

- Building Products

- Automotive

- Pulp & Paper

- Life Sciences

- Oil & Gas

- Utilities & Energy

- …And many more

We have a defining principle to our approach that guides every project. We do not swoop in and tell companies how to do it better.

We are partners in the process. We work with your team to implement the changes at the point of execution.

We listen to what makes your company tick, observe your current operations, get a handle on the issues, involve your frontline employees in the process, and implement a plan for change.

We play the long game, delivering results our clients can maintain for years to come. We don’t have our 98% customer satisfaction rating for nothing.

That’s how USC Consulting Group empowers YOUR performance.

When you hire a consulting firm, you expect recommendations, changes, process improvements and a healthy return on your investment. In short, you want your company to be more efficient and profitable when the consultants walk out the door than it was when they walked in. Right? That should be a given.

But, what happens when the project is finished, when the consultants are not there to guide the process going forward? The answer to that question is process improvement sustainability and is a key element USC Consulting Group specializes in.

The aftermath: Preparing clients for sustainability

At USC Consulting Group, operations consulting is what we do. Companies bring us in to look at their operations with a fresh set of eyes, leveraging best practices we’ve learned in our half century (and counting) in the business. We’re not party to office politics and other company red tape, and as such, we’re able to make recommendations for necessary changes, process improvements, and operating and management system overhauls to get the company functioning optimally.

Increasing throughput and yield, reducing excess costs, identifying and eliminating waste — these are some of our areas of expertise. But, at USC, there’s one thing we DON’T do. We do not set it and forget it.

That’s one aspect of our approach that sets us apart from our competitors out there. We play the long game. We don’t swoop in, offer solutions and swoop out, leaving clients on their own. We deliver results that our clients can maintain. We make sure the positive changes we’ve helped companies enact will stick, long after we’re not walking through the door every day. It’s the whole “give a man a fish vs. teach him how to fish” philosophy. It’s our goal to give clients the tools to keep it going. Here’s how we do it:

1. Employee involvement. This needs to start from Day One. It’s hard to overstate how critical employee involvement is while the project is happening, and after it’s complete. We use “daily huddles” with team members to engage on things like scheduling, production, maintenance, quality, project status and much more. We do best practice skills. We review KPIs. The whole idea is to give team members the tools to continue successful operations and maintain the results we’ve achieved together.

2. Action items. Throughout our process, we will regularly identify action items, steps that need to take place going forward. We’ll get agreement on these and hold people accountable for success. It helps set them up for continued success after the project is finished.

3. Managing change management. We say it often — we can effect all the change in the world. But if we don’t manage that change correctly, none of it will stick. We’ve become experts in effective change management over the years. A few pearls of wisdom we’ve picked up along the way: Operational changes require behavioral changes. Employees, especially longtime employees, don’t necessarily love that. People need reassurance their jobs aren’t disappearing. Also, it’s extremely useful to recruit “advocates” on the front lines who can champion the changes we’re implementing. And it’s vital to be clear on the “why” of any changes put forth. Read more about it in “8 Change Management Best Practices to Ensure Sustainability” on our blog.

4. General training. We develop education and training for “in the field” work for team members, supervisors, leads and managers to support the Management Operating System changes being made by the team as well as supporting behavioral change management — also a critical part of the process. People need to do their jobs differently. Sometimes radically differently. And it can be a stumbling block for employees who may be resistant to change. The training gives them the skills to keep progress going.

5. Lean Six Sigma training. It’s a pretty safe bet you don’t have a Lean Six Sigma Master Black Belt on your staff currently. No problem. We do. One of the most effective ways to create lasting process improvements out there, Lean Six Sigma is the combination of two manufacturing methodologies, Lean, which is focused on eliminating waste and reducing process lead times and Six Sigma, which focuses on cutting down on defects and improving quality. But it takes a lot of study to get it right. That’s why we choose team members to train in this highly effective tool so our efforts using it to increase efficiency and decrease defects are sustainable. Read all about Lean Six Sigma in our eBook, “Lean Six Sigma: Do You Really Know These Methodologies?”

6. Toolkit. This is a playbook of what we’ve done on the project, successes we have achieved, steps forward, sustainable practices and more. It’s a detailed, workable plan that outlines how to go forward and build on that success.

All of these tactics work in tandem to ensure process improvement sustainability, so companies remain firing on all cylinders now and into the future. But, that’s not all. We may not be on site every day after a project is completed, but we’re always just a phone call away. We play the long game with our clients and perform audits to ensure sustained results. Setting and forgetting isn’t part of our playbook. Never has been. Never will be.

It’s a problem plaguing companies across most, if not all, industries: the loss of institutional knowledge when a seasoned vet retires. The person you’ve had on the job for decades gets their gold watch, has a retirement party and walks out of your door for the last time… and takes everything they’ve learned on the job with them. That knowledge is gold to companies, and the loss of it can be devastating. According to the Association of Equipment Manufacturers, the lack of knowledge transfer when an experienced worker retires can cost individual companies $47 million per year “due to time wasted, missed opportunities, frustration and delayed projects.”

Manufacturing is especially hard hit by this, because its workforce is aging and younger people aren’t coming in to fill in those ranks. IndustryWeek reports that 54% of U.S. manufacturers are finding it difficult to attract skilled workers to get the job done. That’s up from 38% before the pandemic. But, it’s not just a manufacturing issue. By 2030, one in five Americans will be 65 or older. That’s a lot of great employees looking at retirement.

All of that said, the loss of institutional knowledge isn’t just an age issue. It’s also a generational turnover rate issue. Compared to Boomers, younger workers are on the job for a nanosecond before moving on. The average millennial tenure on the job is 2.9 years. For Gen Z, it’s even less: 2.3 years. The “Great Resignation” following the pandemic didn’t help matters, when people who could leave the workforce, did. They still are. In February 2023, 4 million people left their jobs. The one-two punch of older workers retiring and high turnover rate among younger workers has created a knowledge gap crisis.

The solution? Companies need to have rock-solid foundational training that covers key processes in their operations, written on stone tablets if necessary. It requires a shift in a company’s learning curve, and many simply don’t know where to start. That’s where USC comes in.

How USC helps companies shift the learning curve

Those are the stats and facts about the loss of institutional knowledge. We’ve seen it play out on the shop floor in many of the companies we partner with. Companies that didn’t have simple, well-documented processes lost capability, capacity and quality as their experienced workforce left. It resulted in companies playing catch-up in terms of time, money and employee turnover.

This doesn’t just affect the shop floor. Junior and mid-level managers lost mentors and leaders who might have been there to show them the ropes. We’ve seen frustrated, disengaged, underdeveloped employees leave companies as quickly as they’re hired.

It has resulted in USC developing a closed loop Training Management process that documents and maintains standardized operator work instructions, quickly ramps and levels employee knowledge, encourages employee engagement, and promotes leadership development.

The objectives? Here’s what we’re looking to accomplish:

- Document operator level processes and standard work using a closed loop system that facilitates change management and training.

- Implement a training management system to keep track of who is and who is not trained.

- Retain employees through leadership engagement and demonstrating your investment in their performance and development.

Deliverables include all of the above, along with a detailed timeline for standard operating procedures development and training.

Our approach is designed to accelerate and deliver sustainable change while engaging your people and bringing focus, clarity and transparency to organizational effectiveness.

It includes a Rapid Assessment Analytics Phase and an Implementation Phase. Here’s how it works:

Learn and Collaborate

With leadership, we explore key issues and opportunities in order to articulate the vision of the project.

Engage

In this stage, we find the gaps and align with leadership on goals.

Solution Design

With key players, we develop a roadmap and a detailed execution plan. We determine the changes we need to implement and do triage to knock out quick wins to move the project along.

Execute and Sustain

This is where the rubber meets the road. We mobilize stakeholders and implement the solution. It requires ongoing training and coaching, weekly reviews, and a study of ROI and benefits.

As with every project we undertake, our training management approach does NOT include us swooping in and making pronouncements of how things should be. Instead, we engage with your people to create a blueprint that’s unique to your company.

Training Management Project Approach

We aim to drive significant value on two fronts, the “just do it” phase to drive immediate value, and the “change the game” phase to drive sustainable outcomes and long-term value. It includes

- Employee engagement: If people don’t buy into the process, it’s never going to stick.

- Leadership engagement: Involvement with HR, Ops and Training managers is critical.

- Leadership training: We’re not going to be onsite forever. Leaders need to become trainers for this to sustain. We empower people but provide ongoing support.

Yes, a lot of this can sound like “consultant-speak.” What it boils down to, in plain English, is keeping your operations humming along on all cylinders even if every experienced employee on your line suddenly walks out of the door. It’s about identifying your core processes and procedures — what needs to happen to keep the place running. Documenting those procedures, and then creating and providing solid training to employees and higher ups. Sometimes that can involve getting to the heart of what IS NOT in any training manual, those invaluable nuggets of institutional knowledge your people have developed over years on the job.

To learn more about how you can shift your learning curve to retain your employees, give us a call today.

A little goes a long way. It’s an old adage, but one we’ve seen play out, day after day, during our 55-plus years in the consulting business. It’s the notion that what may seem like small changes actually produce big results. At USC Consulting Group, one of our specialties is the “detective work” we do to find hidden opportunities for greater efficiency. Acting on those opportunities can create great change.

Here are some ways a “little” can go a long way for our clients.

Outage management

Most industries that have 24/7 operations — manufacturing, mining & metals, and others — need to do planned outages, or work stoppages, for regular maintenance. It’s a practice we enthusiastically recommend. Planned outages prevent unplanned crises when a machine breaks down unexpectedly. Managing planned outages correctly is vital, because any time the operation is shut down for maintenance, that time is money.

Intricate detail and planning go into planned outages. That was the case with one of our recent clients in the mining industry. They approached USC to assist in planning and executing an upcoming plant-wide outage. Because of cost and schedule overruns year in and year out, the plant was given an ultimatum from its parent company — make the upcoming outage successful or close the plant down.

Through careful planning and execution, we shaved one day off of their planned outage. You might be thinking, just one day? That “small” improvement saved the company upwards of $1 million. The outage was successful, and the plant stayed open.

Food processing

The commercial food industry has a tough nut to crack (pardon the pun) when it comes to processing and bagging their product to send to grocery stores or other end-clients that sell to consumers. Getting the most of their raw materials is all about improving yield, but it’s not easy to achieve the right balance. Let’s take the beef industry for an example. In processing beef into burger, there is a loss of moisture. That’s why when you start off with a pound of beef you don’t get a pound of burger. But, as a consumer, when you’re buying what is labeled a pound of burger, you can expect a pound — by law. To achieve that, the industry compensates for the loss of moisture and adds more ground beef into each unit. Better to pack a little too much than too little, right? It’s what the industry calls “the giveaway.” It’s essentially overpacking.

Just a little more? How big a problem is this, really? If a company is processing, say, 30,000 pounds of ground beef into burger every day, adding a smidge more into each package can be a very big problem indeed. One recent client of USC came to us when they realized they were giving away over 1.5 million pounds of beef yearly.

With process improvements, equipment fixes and increased speed and throughput, we were able to help our client strike the right balance, decreasing that overpack from 2% to 1%. Just a 1% savings? That’s a pretty small number on the face of it… until you see it resulted in a savings of $84,000 per month. That’s huge.

Change management

Not every “small” change can produce hard numbers like the examples above, but we see the benefits time and time again when we’re helping clients with change management.

We’ve learned that we can effect all the change we can muster — make the line more efficient, increase throughput, get the operation lean and mean, whatever else is needed — but none of it will stick without managing the change correctly. This part of the job isn’t about numbers, planning or complex methods. It’s about people.

Whatever the change you’re making, it’s going to involve people behaving and working in a different way. So at its core, effective change management requires helping people transform their behavior. As we all know, people don’t necessarily love that, especially if they’ve been getting the job done one way for the duration. Research shows 62% of people don’t like leaving their comfort zone.

We find that small changes really go a long way here. It’s about the CEO taking some time to walk the shop floor and talk with frontline workers about the changes that are coming down the pike. It’s about us involving those workers in the process of change from the get-go, asking for their ideas for improvements, their thoughts about what the problems are that need solving. That way, the change that we’re implementing won’t be happening to them. They will be a part of it, champion it, and make that change stick every day on the line.

One other bonus to this tactic? It creates employee engagement and loyalty. Just 36% of U.S. employees are engaged at work, and 74% are actively looking for new jobs, according to a Gallup survey. 94% of employees say they’d stay at a company longer if it invested in their career development, LinkedIn reports. With manufacturing looking at 1 million unfulfilled jobs and the cost of replacing an employee as much as twice their annual salary, those small changes can mean big numbers on your balance sheets.

This is one part of our process that doesn’t take advanced degrees, engineers or Lean Six Sigma black belts to achieve. It just takes a little time and some people skills.

Get in touch today if you’d like to talk about how USC can help your company become more efficient and effective. One small conversation can go a long way to improving your operations.

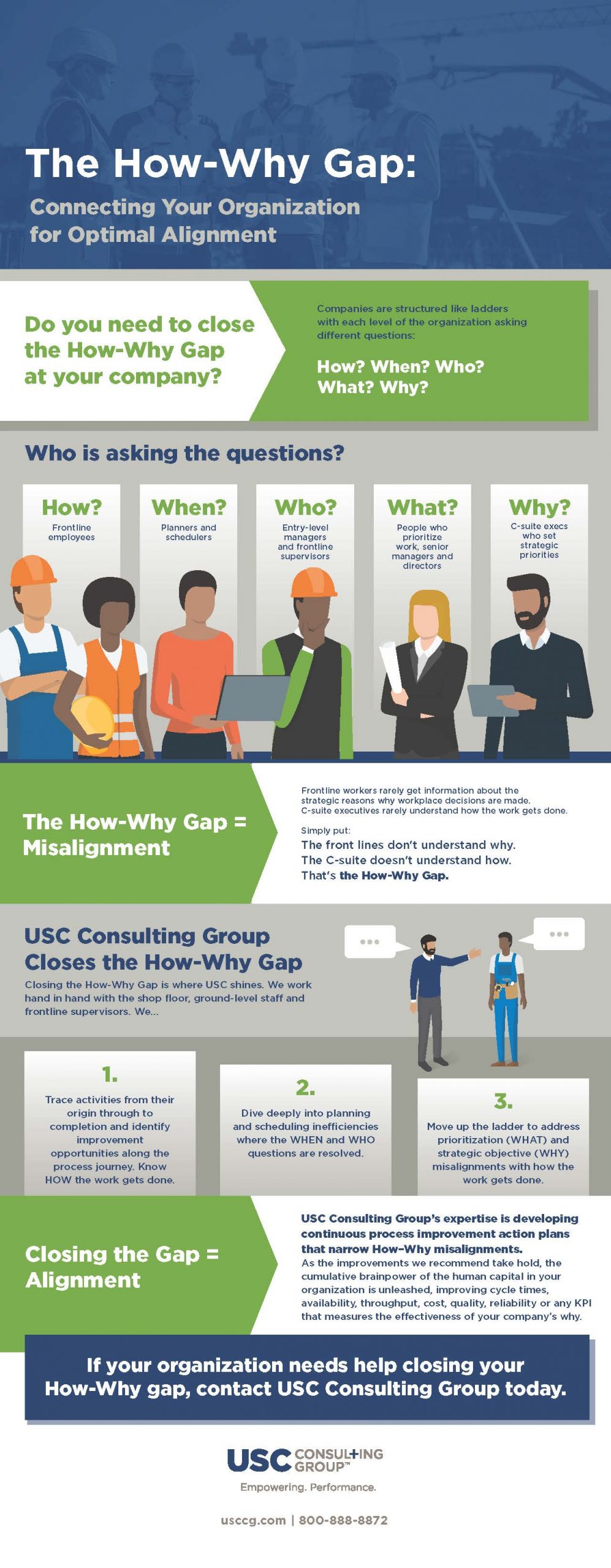

Asking the question, “What’s your why?” has become fashionable to the point of cliché. The intent is to explore purpose and personal meaning. In the workplace, companies are structured like ladders with each organizational layer asking (and ideally solving), “How, When, Who, What and Why” questions. Companies with work execution problems must resolve their “How–Why” gap to achieve organizational alignment.

Breaking Down The How-Why Gap

So what is the How–Why gap? Employees who ask a lot of “how?” questions are most likely working at the ground level – where the work gets done; making journal entries, receiving and shipping goods, or producing widgets. Employees who ask “when?” and “who?” questions, are likely planners / schedulers, front-line supervisors or entry level managers. People who ask “what?” questions are people who prioritize work – Senior Managers and Directors. At the pinnacle of the organization, members of the C-suite often find themselves asking a lot of “why?” questions to set strategic priorities and the purposes of the organization.

“The frontline often does not understand why, and the Executives often don’t understand how.”

When front-line employees venture to ask why questions amongst themselves in the breakroom, they often lack insight into the forces that drive the why strategies. By the same token, it is rare for Executives to understand how the work gets done. Simply put, the frontline often does not understand why, and the Executives often don’t understand how. The greater the misalignment between the why actions taken by the C-Suite and the how execution on the shop floor, the stronger the cultural cognitive dissonance throughout the organization. I call this the “How-Why” gap. Scott Adams, the creator of the workplace cartoon “Dilbert” became famous by satirizing the “How–Why” gap between Dilbert and the Pointy-Haired Boss.

Aligning the How, the Why and everything in between

Reconciling the “How–Why” gap is where USC Consulting Group shines. Many consultants offer Executives ideas on emerging strategies, but few consulting companies get to the how of a company’s point of work execution problems. USC does this by working hand in hand with shop floors, ground level staff and front-line supervisors. We trace activities from their origin through to their completion and identify improvement opportunities along the process journey.

But USC doesn’t stop at understanding how the work gets done, we move up the work ladder to address misalignments with the Who and When, the What and the Why challenges facing the organization. Once insight is gained into the current state, we dive deeply into planning and scheduling inefficiencies where who and when questions are resolved. As one of our senior partners is keen to remind us, USC stands for the “Universal Scheduling Company.” Not only is master scheduling and resource capacity planning our heritage, but it is literally part of our name.

Getting answers to what questions can be among the most challenging because these questions demand prioritization. Managers and Directors who are embroiled in answering what questions are often battling for limited resources (budget and headcount), trying to keep their personal initiatives high on the priority list. This rung of the ladder is where most corporate politics are fought out.

USC Consulting Group’s expertise is developing continuous process improvement action plans that narrow How–Why misalignments. As the improvements we recommend take hold, the cumulative brainpower of the human capital in your organization is unleashed improving cycle times, availability, throughput, cost, quality, reliability, or any KPI that measures the effectiveness of your company’s why. Front line employees can answer “how do we execute our why?” Managers can answer “who will execute our why and when will we do it? Directors can answer, “what initiatives need to be prioritized to execute our why?” and Executives can effectively map the strategic course to answer, “what is our organizational why?”

This detailed infographic illustrates the importance of each role and how to achieve optimal organizational alignment:

If your company needs help with organizational alignment and closing your How-Why gap, please contact us today.

Change management – how do you define it and why is it such a popular term these days? The BNET Business Directory calls change management “the coordination of a structured period of transition from situation A to situation B in order to achieve lasting change within an organization.” That’s a mouthful. Accurate? Technically, yes. But we think there’s more to it than that. Successful change management is an art form.

At USC Consulting Group, we’ve been effecting change in organizations for more than 50 years, and if we’ve learned one thing, it’s the importance of managing that change correctly. It really is the key to the whole thing. That’s because you can go into a company and effect all the change you want — make the line more efficient, increase throughput, get the operation lean and mean, whatever else is needed — but none of it will stick or do the good you envision it will do without managing the change correctly. The bad news: Change management is not intuitive or easy. The good news: We’ve developed several change management best practices along the way.

Change management best practices

Here’s some of the secret sauce we put into our change management recipe for success.

Remember, it’s about human behavior

When we go into a company, our goal is to identify gaps in performance and rectify whatever is impeding the operation. But when it comes right down to it, everything revolves around behaviors. Whatever the change you’re making, it’s going to involve people behaving and working in a different way. So at its core, effective change management requires helping people transform their behavior. And as we all know, people don’t necessarily love that, especially if they’ve been getting the job done one way for the duration. Research shows 62% of people don’t like leaving their comfort zone. As Operations Manager Chris Smith says, “It takes time and it takes a lot of intent.”

Generations are different

Effecting change within a company isn’t a one-size-fits-all proposition. Boomers have one set of expectations. Millennials look at things differently. And Gen Z has its own lens. “You have to take into account who you’re coaching and what they’re willing to put up with,” Smith advises.

Reassure people their jobs aren’t going away

This is one of the biggest misconceptions about consultants — that we’re going to swoop in, slash and burn, and paper the shop floor with pink slips. That couldn’t be further from the truth. We never go into a company intending to cut jobs. Just the opposite. We believe people are a company’s biggest and most important asset. Making the operation more efficient might mean people’s jobs change, but it’s not our tactic to boost the bottom line by cutting staff. Still, people seem to have a universal suspicion that change is going to usher them right out the door. Let them know their jobs are safe and you’ll get less resistance to whatever change you’re proposing.

Involve people at all levels

We can’t overstate how important this is to the process of change. It’s crucial to involve people at all levels of the organization, from the C suite right down to the people getting the job done on the line. Not only will you get a wealth of ideas by listening to all of them, the buy-in that comes from getting people involved at the outset is crucial. That way, the change that you’re implementing won’t be happening to them. They will be a part of it. With that kind of mindset, you’re setting yourself up for success.

Recruit advocates

Of the employees who are part of the process, ask some of the more enthusiastic and excited among them to spread the word about what you’re doing and why it will be a positive step. Consider leveraging your informal leaders to weigh in. Making it their idea goes a long way toward acceptance among the rest of your working group.

Be clear on the “Why”

While it’s crucial to involve people at all levels, you’re not going to be able to involve everyone. For those who are not a part of the process, it’s important they understand why the change is happening. It could be that the company’s throughput is lagging. Or profits are down. Or supply chain disruption is grinding things to a halt. Whatever it is, identifying the problem is a big step toward getting people on board with the solution.

Communicate early and often

“Transparency” is a big buzzword these days. But all it really means is telling people what’s going on. Don’t work in a vacuum or people will wonder what you’re doing, why, and if their jobs are on the line – if you don’t provide information your employees will likely make up their own. Let people know what’s happening, what you’re finding and what they might expect.

Stay the course

This is one of the biggest differentiators between USC and the other guys. We don’t simply hand upper management a file of recommendations for change, pat them on the back and walk out the door. We stay on site to help implement the changes we’ve recommended, iron out any glitches along the way and make sure everything’s running smoothly. We’re a true partner for our clients.

Utilize these change management best practices to ensure the process improvements you make last. Get in touch today if you’d like to talk about how USC can help your company become more efficient and effective. We’ll help you manage that change, guaranteed.

Supply chain disruption. Layoffs. The Great Resignation. Hiring wars. The past few years have not been smooth sailing for the manufacturing industry. Dealing with ongoing challenges can take more time out of your day than simply getting the job done.

So, how do manufacturers survive in this tumultuous business climate? Our subject matter experts here at USC Consulting Group have identified and examined six challenges as the most common issues bedeviling manufacturing right now, along with the strategies we offer to our clients to tackle them.

Manufacturing challenges include:

- The ongoing hiring wars

- The skills gap

- Creating a better frontline worker experience

- Digital transformation

- Supply chain disruption and inventory management

- Change management

Dive deeper into each one of these issues and learn the solutions to overcome them in our free white paper “The Consultant’s Guide to Overcoming Today’s Manufacturing Challenges.”

1. The Ongoing Hiring Wars

Like most other industries these days, manufacturing is grappling with the most challenging hiring market in decades. IndustryWeek reports that 54% of U.S. manufacturers are finding it difficult to attract skilled workers to get the job done. That’s up from 38% before the pandemic.

2. The Skills Gap

The hiring wars and the skills gap are giving manufacturing a one-two punch. Not only is it incredibly challenging to fill open positions, but filling them with people who have the skills and experience to get the job done right is proving to be nearly impossible. Hence, the skills gap.

3. A Better Frontline Worker Experience

Just 36% of U.S. employees are engaged at work, and 74% are actively looking for new jobs, according to a Gallup survey. With all of the hiring challenges and shortages of skilled workers, it’s more important than ever to focus on your frontline workforce.

4. Digital Transformation

Digital transformation has been an industry term for several years now. What it means, at its core, is utilizing digital technology to make processes faster, easier, safer and more efficient. The pandemic kicked digital transformation up a notch for manufacturers.

5. Supply Chain Disruption and Inventory Management

Supply chain and inventory management issues have long been a challenge for manufacturers, made worse by the pandemic. These are separate issues, but two sides of the same coin.

6. Change Management

All of these challenges represent and require some degree of organizational change. The term “change management” may seem like the jargon of the moment, but really, it’s about laying the groundwork for change to be successful in your organization.

Learn about each of these challenges in more detail and how to overcome each issue by downloading our white paper:

The Consultant’s Guide to Overcoming Today’s Manufacturing Challenges

If you’re grappling with any of these manufacturing challenges, USC Consulting Group is here to help. We are a global operations management consulting firm that has been helping organizations through more than 50 years of challenges. It’s our specialty. Give us a call today to talk about how we can help you.

The competition has become sky-high and relentless across all major industries. Pricing is a race to the bottom, resources are harder than ever to come by, and new protocols and regulations constantly disrupt processes and add to manufacturing costs. The still-struggling economy doesn’t help matters.

Operations managers have their work cut out for them: Creating and maintaining smooth, high-functioning processes in this climate is a challenge. Preparation, a constructive attitude, and informed decision-making are required in spades. Here’s USC Consulting Group’s take on how operations managers can remain competitive and, indeed, thrive in the digital era:

1. Keep your customers front and center

Metrics like cycle time and the operations profit margin are important. They show you how well your operations processes are doing. They don’t, however, determine your net profitability – your customers do. As such, while it’s important to tweak your operations processes, satisfying your customers’ various needs and expectations is more so. Some ways to make customers – B2B or otherwise – happy is to focus on end-to-end transparency, automation, timeliness, accessibility, and user-friendliness.

2. Train your employees

Processes are more than machines, automation, and technology – they are the people that run them. Your employees can be your biggest asset and resource. Cultivating them – especially the ones in key roles on the floor – can net you massive gains across the board. Consider investing in employee training and education programs. Spend plenty of time with your workers, exchange feedback, and create a culture of honesty, accountability, and pride in a job well done. Every manager needs people skills to be successful, says ESRI.

3. Embrace change

Change is rapid and swift in this day and age, thanks to the onset of Industry 4.0, globalization, and constantly shifting market conditions and associated employee turnovers. Even iconic brands like Motorola – once the biggest name in the cellphone industry – can go out of business at the drop of a dime. A process being profitable today is no guarantee of it being profitable tomorrow. Also, what you did to find and keep good employees yesterday may not work anymore. Don’t be averse to change – it’s one of the more common small business management mistakes. Instead, see it as a good, necessary thing. Don’t be afraid of restructuring, reshaping, and overhauling if you need to.

4. Utilize the latest technology

Technology is resource-intensive but it can pay you back multifold. Researching the newest technologies and updating your processes to match can assist in several ways. With real-time data gathering you can make informed operations decisions on the fly. Using IoT, you can keep tabs on multiple processes, worksites, and employees remotely. With automation, digital reality, AI, and blockchain, you can speed up and optimize your supply chain end-to-end. With inventory tracking, you can keep your customers in the loop. It’s a good idea to study how the biggest manufacturers operate – like Toyota – for inspiration.

5. But don’t use technology too much

As important as technology is, it’s not the answer to all your problems. Industry 4.0 is a relatively new phenomenon and the apps or software you’ll be using will typically be a work in progress. Automating every process just because can and will backfire. Technology is excellent for number crunching, simple machine operations, and data gathering. It can’t replace skilled human labor for complex operations and is never a substitute for a well-oiled, streamlined work process.

Analyze every process thoroughly and assess if technology is going to help or hinder before the implementation. Finally, consider the long-term costs of maintaining, updating, and integrating the technology. Not all technology plays well together. Strike a balance.

Conclusion

The secret to success for sustainable operations management is to constantly keep improving and evolving. The biggest manufacturers in the world, like Volkswagen, didn’t become successful overnight, as Translate Media can attest. They focused on innovation, quality, a culture of excellence, and – most importantly – keeping customers happy. They led change instead of shying away from it.

*This article was written by Dean Burgess. Dean runs Excitepreneur, which celebrates the achievements of entrepreneurs. He understands that there are many types of entrepreneurs, and strives to provide helpful information to assist them in achieving their particular idea or goal.

Nobody knows the job better than your frontline employees. So, when you’re instituting new efficiencies to improve the processes and procedures that they use on the job every day, one vital key to success is getting their buy-in from the get-go.

At USC Consulting Group, helping companies find process improvements is what we do. We work with companies in industries like manufacturing, mining and metals, oil and gas, food and beverage, transportation and logistics, and others to become more efficient, effective and in the end, profitable. We strive to empower your performance and help you reach your highest potential by uncovering greater operating excellence across the entire supply chain. It’s about identifying and eliminating wasteful practices and procedures.

One big difference between us and the other guys is how we go about doing that.

We sell our methodology and our process, not just a solution

Nine times out of ten, when companies come to us, they already have a pretty good idea of what their challenges are. So we don’t go into a client engagement telling them what we think they should do. We have over 50 years in this industry behind us, but all of that experience doesn’t mean we provide cookie-cutter solutions. Most of our clients are looking to us to break bottlenecks in their operation, find out if they can do more with what they have, or even do more with less. But every one of our clients is unique. Every one of those bottlenecks has a different cause. The only way to find the best road that will lead to more process efficiencies is not to rest on our laurels and do what worked for the last client, but to roll up our sleeves, get into your operation and see what’s going on.

A big part of that is listening to your frontline people.

Your frontline employees are the key to the success of the project

We don’t simply sit in your boardroom and pontificate with your C-suite about how to do things better. At USCCG, we believe it’s about effecting change at the point of execution. That means we involve your frontlines. Ferreting out new processes and solutions that can increase efficiencies starts with the people actually doing the job. It’s the only way it’s going to work. Here’s why:

A single source of truth. By talking to your frontline employees, we get the lowdown on what’s happening in your operation day to day. We hear what’s going right, and at times, what’s going wrong. They often can see what the problems are, but not know how to fix them. We can get the single source of truth from your frontlines and implement plans to fix the issues and improve productivity. It’s crucial to finding where efficiencies can happen.

From resistance to change… We get it; change is difficult to accept. More than that, it can be threatening. Frankly, it’s completely counterproductive to swoop in and tell people that the way they’ve been doing their jobs for years is inefficient at best and wrong at worst. You’ll lose their cooperation. They’ll be resistant to any new ideas, because those new ideas mean the way they’ve been working has been wrong. If you don’t get their cooperation, it can be difficult to implement any sort of process changes. And if you have their opposition, it can be downright impossible.

…to drivers of change. That’s why involving your employees in the process from the start is so important. It ensures they’ll feel listened to and respected. It won’t be something that’s happening to them. Positioning this process as a way to harvest their wealth of frontline information in order to make the company more effective and efficient is the key to making it work. We involve employees from the get-go, and time and time again, we’ve seen them become the drivers of change.

Making the changes stick. Initial buy-in is only the beginning of the importance of your employees to this process. It goes further than that. It’s about making sure those changes stick. Your employees need to feel invested in the process changes in order for them to stick to them, on the job, every day. That’s why we don’t come in and hand them a new playbook. They’ll help write it. And that’s crucial to the success of implementing change.

At USC Consulting Group, we understand how important employees are in the process of change. We will respect them, listen to their institutional knowledge that only years on the job day after day can provide, and create a collaborative approach to finding the hidden opportunities for greater efficiency in your operation.

For more information about how we work during this time of COVID, download our free eBook Times have Changed – USCCG Can Help You Adapt.