5 Steps to Reducing Supply Chain Costs

A colleague was relating a conversation he had with a CFO of a $1 billion business, he was talking about how the company reduced waste in manufacturing by 12%, the CFO then added, “… but what we really need next is a way to reduce the cost of the materials and services we buy”.

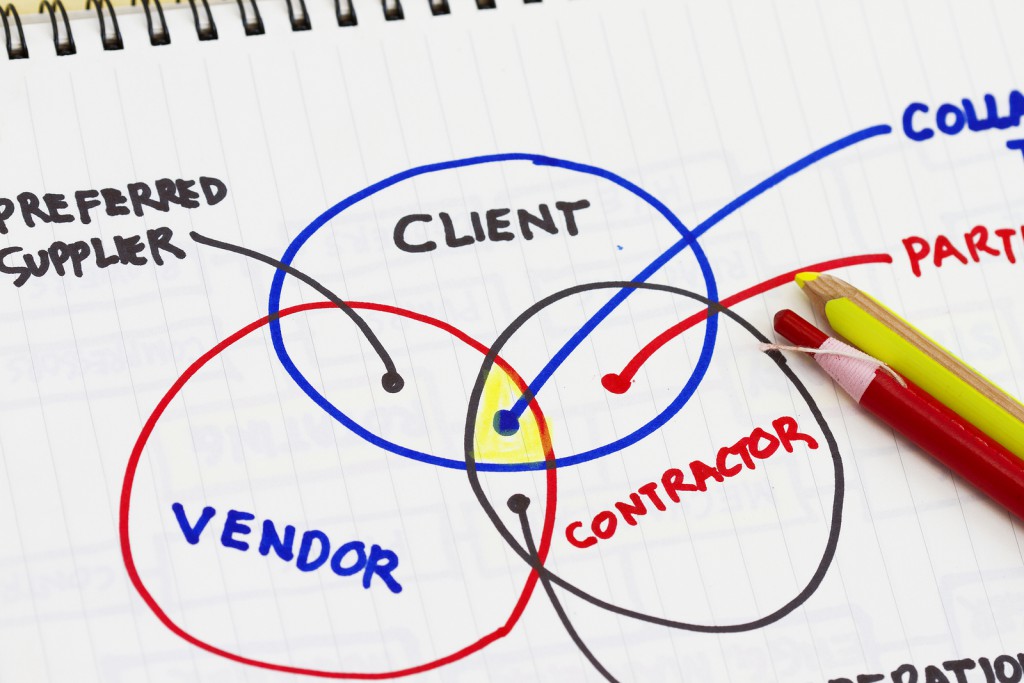

He was talking my language! He was talking about Supplier Relationship Management, or SRM.

SRM applies to both direct purchases i.e., materials used in manufacturing products and providing services (e.g., parts) and indirect costs such as uniforms, insurance, catalogs, or waste hauling. Even Freight is a great opportunity to reduce indirect costs in your supply chain! Often these costs have not been managed holistically, and offer a significant opportunity to save. SRM can be a complicated process but I’ve tried to break it into the following five-steps:

- Create Visibility. You need an enterprise-wide view of all spending separated into categories. This lets you see where the money is being spent and prioritize them to address in the Supplier Relationship Management process.

- Understand your Supply Chain and the Supply Market. You need to know and understand your available supplier options in order to reduce cost.

- Engage Your Organization. It’s a team effort to determine what supply chain spend reduction strategy would be most effective with each category. Create cross-functional teams that include operations, procurement, quality, engineering, and finance in the development of the category strategy.

- Provide the Resources. Dedicate the necessary manpower to implement the SRM process. This is key; the process falls apart if you cannot dedicate the resources to making the strategies happen.

- Monitor and Measure. Develop the dashboards and metrics to allow you to measure the results and monitor them over the long-term to ensure continuous savings.

A common misconception about Supplier Relationship Management is that it is simply about finding alternate suppliers with a lower cost. While this could be one of your strategies, it goes beyond that. Consider not only cost, but improvements in delivery, quality, service, etc. You may be pleasantly surprised to find a new supplier that provides all those and more at a lower cost.

Also, be sure to look at your product offering. Have you engineered unnecessary complexity into it? Are there a proliferation of SKUs resulting in more POs and excessive inventory? Re-examine your requirements and you may find easy savings.

Keep in mind that a good SRM program can typically deliver cost reductions from 8% – 30% or more, often in a very short period of time!