-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2025 (1)

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Safety

The world is relying more than ever on automation and robots to get the job done. How do these human-less machines improve efficiency? Here are seven innovations reshaping manufacturing and related industries.

1. V2X Communication

Vehicle-to-everything (V2X) communication is integral to the development of self-driving cars. With V2X capabilities, the car sends and receives information from other vehicles, energy grids and smartphones. Automobiles have yet to reach SAE level 5 autonomy, though V2X has already benefited manufacturers in existing vehicles.

For example, it can warn cars of nearby emergency vehicles and help them avoid collisions. V2X has another role in efficiency by improving fuel economy and reducing wait times. With enabled devices, manufacturers can implement automated platooning to minimize drag and consume less diesel. Communicating with the grid also informs vehicles about roads to avoid when jams occur.

2. Autonomous Ships

While research on self-driving vehicles focuses on the road, other experts have concentrated on autonomous ships. When deployed, these crewless boats can operate alone and without human intervention. Maritime professionals can control the vessel if needed, but autonomous boats leverage IoT sensors and other technologies to avoid collisions.

Autonomous ships have yet to become widespread, though some organizations have conducted trials in short voyages. Maritime experts say these crewless vessels could benefit the industry through advanced safety and efficiency. With autonomous systems, ships can optimize routes further and operate continuously. They also use data analytics for predictive maintenance and optimized shipping routes.

3. Delivery Robots

The timely arrival of goods is vital for order fulfillment and customer satisfaction. How can robots help companies reach their clients? Delivery robots are another example of autonomous innovation that improves efficiency. These machines take over the last mile and bring goods to the destination. While popular for restaurants, delivery robots have spread to other businesses.

Due to widespread use, the delivery robot market is expected to be worth $3.2 billion by 2032. Companies have incorporated them into their operations because they can reduce labor and fuel costs.

4. Drones

Drones are another significant autonomous innovation used across industries. These machines can access hard-to-reach areas and provide quality information, thus saving time. When deployed on construction sites, drones operate as flying security cameras on building sites and protect equipment. They can also track progress and recognize safety issues before they hurt employees.

Manufacturers have used drones to streamline processes and reduce waste. For instance, BMW deploys these crewless aircraft to check inventory and improve accuracy. General Electric (GE) has developed autonomous drones to inspect wind turbines, aircraft engines and other essential equipment. Manufacturers also benefit from drones when emergencies arise and rapid deployment is necessary for mitigation.

5. Brick-Laying Robots

Monotonous work can take time and energy away from more important jobs. Experts say nearly half of workers spend most of their time doing repetitive tasks. How can autonomous technology remove the time-consuming, monotonous tasks? In construction, industry professionals are turning to brick-laying robots.

Automating masonry is vital when building houses and office buildings. These machines can outpace humans in brick-laying without needing a break, thus reducing construction timelines and costs. Hadrian X is among the pioneers in brick-laying robots, and this technology recently arrived in the U.S. Reports indicate the machine had a sustained rate of 300 blocks per hour in testing.

6. Farming Equipment

Agriculture is crucial to the global economy, as it feeds communities and provides jobs. The world’s increasing population necessitates autonomous technology to meet demand while maintaining sustainability in the sector. In recent years, research and development has introduced driverless tractors, harvesters and planters to reduce labor needs and improve production.

Autonomous tractors benefit farms by working longer than humans and increasing precision in crop fields. Professors from the University of Missouri said this farming equipment could extend agricultural careers if farm owners have mobility or age-related issues. Other prominent features of autonomous tractors include GPS tracking, LiDAR and sensors for monitoring soil health.

7. Cleaning Robots

Devices like Roomba and iRobot have eased the cleaning burden in homes and smaller facilities. However, autonomous innovation has powered larger machines for manufacturing and industrial settings. These robots help janitorial staff clean more efficiently, thus reducing labor costs and improving hygiene. With continuous operations, they can clean overnight and support production schedules.

Autonomous cleaners have become versatile and efficient thanks to LiDAR, infrared sensors and similar technologies. These features help the robots detect obstacles, understand their surroundings and determine what needs cleaning. Recent innovations like the compact X4 Rovr assist manufacturers by fitting into small spaces and using AI-powered navigation technology.

Using Autonomous Technology to Build the Future

Industries are racing toward automation because of its efficiency opportunities. While challenges exist, companies have embraced these technologies because of heightened safety and sustainability. These machines and small devices can operate with minimal breaks, thus increasing output and reducing labor costs. From automotive to agricultural settings, autonomous innovations are rapidly changing the manufacturing landscape.

*This article is written by Jack Shaw. Jack is a seasoned automotive industry writer with over six years of experience. As the senior writer for Modded, he combines his passion for vehicles, manufacturing and technology with his expertise to deliver engaging content that resonates with enthusiasts worldwide.

A robust MOS is vital for mining and metal companies to navigate the challenges of today’s market.

Management operating systems (MOS) are making significant impacts to performance goals and outcomes for mining and metals companies by providing a structured and systematic approach to managing the business across the value chain. Companies have a strong need for robust MOS in today’s market to ensure safety and compliance, improve efficiency, and achieve sustainable growth, given the safety of workers is a top priority across the mining industry; the global demand for minerals and resources is rising, leading to increased competition; mining operations are inherently complex; the industry is facing significant cost pressures from fluctuating commodity prices and rising operational costs; and the adoption of new technologies requires an integrated approach to managing operations.

Performance is improved by providing a structured framework for planning, monitoring, and controlling operations. MOS can help through:

- Safety and Compliance – ensuring that safety protocols and regulatory compliance are integrated into daily operations, while minimizing the risk of accidents and legal issues, promoting a safer working environment.

- Enhanced Planning and Scheduling – creating detailed and realistic operational plans and schedules, ensuring that resources are allocated efficiently and that production targets are met without unnecessary delays. Potential bottlenecks can be identified and addressed during the planning process – “Planned work is safer and more productive than unplanned work.”

- Real-Time Monitoring and Control – tracking operations in real time, allowing for quick in identification and in-shift resolution of issues, while reducing downtime and safeguarding that operations run smoothly.

- Improved Communication and Coordination – standardizing processes and providing clear protocols, MOS enhances communication and coordination among different departments and teams, leading to more cohesive and efficient operations.

- Data-Driven Decision Making – providing and analyzing comprehensive data on various aspects of the operations to identify trends, inefficiencies, and opportunities for improvement and leading to more informed decision-making.

- Cost Control and Efficiency – optimizing resource use and reducing waste, while aiding in cost control and improving operational efficiency.

Supporting mining and metal companies to stay competitive and adapt to changing market conditions, MOS fosters a culture of continuous improvement by regularly reviewing processes, identifying areas for improvement, and implementing changes.

MOS in mining and metal operations are significantly enhanced by today’s technological advancements. By leveraging these advancements, MOS becomes more robust, responsive, and efficient. This not only enhances operational performance but also ensures better safety, sustainability, and profitability.

USC partners with your organization and coaches your people to significantly impact performance outcomes and accelerate Operational Excellence

USC brings a tailored, structured, and disciplined methodology, along with a range of tools and techniques we apply collaboratively with client’s personnel. Whatever your challenge, we are the people who work with our clients to find full potential and unlock the hidden value.

USC identifies waste, redundancies, and ineffective processes, and then rapidly recover the prioritized opportunities, and convert them to improvements in performance and operating profit. Our consultants achieve this by improving the skills sets of all levels of the client’s management and employees.

Our people embed with client internal teams to develop, enhance, prototype, validate and implement management operating system (MOS) element improvements to drive, sustain and perpetuate change in how the business budgets, plans, schedules, assigns work, executes, follow-up, reports, analyzes and improves. In short, USC implements measurable, sustainable changes that drive operational and financial improvements.

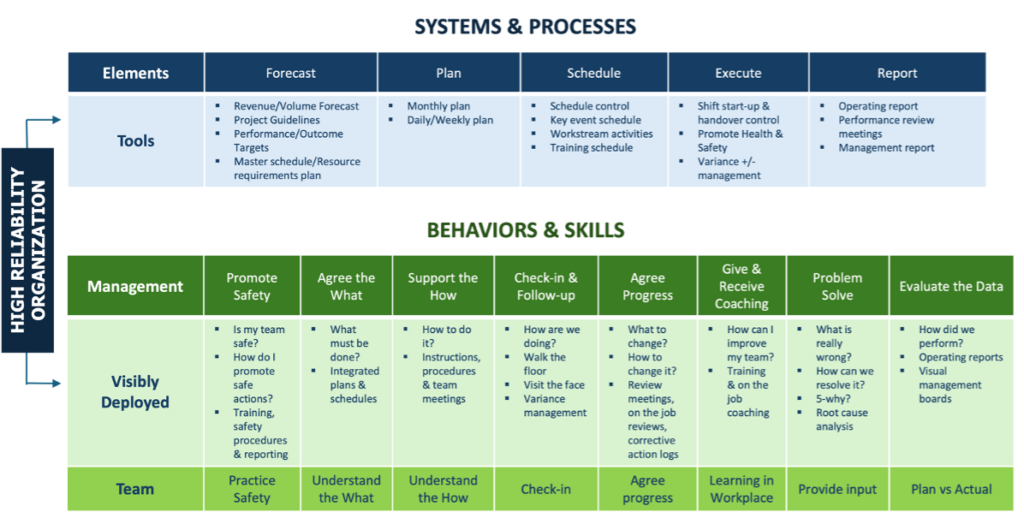

Our Management Operating System (MOS) Essentials Framework is designed to be pragmatic rather than conceptual – thereby leading to accurate, practical decisions about your operations and outcome aspirations. The key, that many miss, is the linkage process execution with management behaviors. MOS is about “managing differently” using visibly deployed management and supervisory behaviors. Consistent execution of the right behaviors at the right time creates certainty in the workplace, driving performance improvement and sustainable new ways of working.

Client performance goals and outcomes are realized through:

- Integrated safety protocols and compliance requirements into daily operations., leading to a safer work environment and fewer accidents.

- Reduced operational costs, including minimized waste, optimized equipment usage, and reduced energy consumption.

- Optimized workflows and resource allocation, leading to increased efficiency and higher production rates.

- Effective maintenance planning and real-time equipment monitoring, MOS reduces unexpected breakdowns and downtime.

- Alignment of daily operations with strategic objectives, ensuring that all activities contribute to the company’s long-term goals.

- A culture of transparency by providing clear performance metrics and regular reporting while driving better performance and tracking progress towards goals.

USC Helps You Tackle Key Challenges

- Optimize mine planning and scheduling across all planning horizons – delivering detailed and accurate plans

- Identify potential roadblocks proactively during mine planning and solve complexity during the planning process

- Ensure the right resources are at the right place to minimize lost time – enabling safe and disciplined execution

- Control quality of work at the point of execution by identifying off specification and enabling in-shift correction

- Evaluate performance and identify opportunities for improvement, enabling continuous improvement mindset

Do you want to understand how a MOS can integrate you mine and operational planning, while helping you to safely increase performance site wide?

Want to find out more about how USC can help you uncover the hidden value loitering in your operations?

For more information, let’s talk it through with a no obligation meeting with one of our executive team members. Email info@usccg.com to arrange a call.

The manufacturing industry keeps society ticking, but it consists of people. As technology advances, using it to improve worker safety reigns paramount, protecting the individuals who move the machines that create the products society uses daily. Keeping abreast of the latest developments to improve industrial health and safety helps owners and managers improve working conditions and processes.

Such improvements span every aspect of the industrial process, from producing the products to warehousing them and delivering them to customers. Responsible parties can draw inspiration from the innovations below to improve industrial hygiene and safety for a healthier and happier workforce.

Warehousing Procedures

Warehouses combine multiple workers and machines in a single small space, increasing the risk of accidents. Injuries can result from equipment misuse, failure to follow safety procedures or overuse stemming from repetitive motions. For example, approximately half of all workers at certain warehouses experience an injury within their first three years. Facilities have begun to implement the following innovations to decrease accident risk.

1. Warehouse Management Systems

These advanced computer programs boost efficiency by optimizing travel routes and times to streamline picking and putting away procedures. They can prevent “traffic jams” in aisles and decrease fall risk by keeping moving equipment like forklifts out of areas where workers are using ladders or scaffolding.

2. Robotics

Robots reduce repetitive motion injuries by taking some of the heavy lifting off human hands. Additionally, they can reduce fall risk by retrieving items on high shelves. Such technology also empowers warehouse managers to make better use of vertical space instead of increasing their facility’s footprint.

3. Appropriate Safety Gear

Relying on workers to supply PPE can result in the most vulnerable going without or investing in inferior protection to meet company requirements. Providing gloves, facial protection, hearing protection, steel-toed boots and reflective vests protects workers against sudden traumatic injuries while reducing some of the wear and tear of daily work on their physical selves.

Lockout/Tagout

Lockout/tagout procedures protect against electrocution and other traumatic events, such as crushing injuries when a piece of equipment goes down and multiple workers must coordinate their efforts to correct the problem. OSHA guidelines cover proper measures for controlling energy from electrical, mechanical, hydraulic, pneumatic, chemical and thermal sources. Compliance with these standards saves an estimated 120 lives yearly.

Here, too, technological improvements enhance worker safety. For example, video surveillance ensures workers apply the appropriate lockout devices to equipment before service work begins. Sensors can alert workers to energy remaining trapped in the system or sound the alarm if a stray body part enters the restricted area. Improved equipment testing ensures refurbished equipment meets lockout regulation standards before operators put it to use.

Heavy Equipment

Improvements in heavy equipment also increase safety in industrial environments. Electric forklifts produce fewer emissions than previous models, sparing workers’ lungs, and their narrower bodies and smaller turning radius prevent accidental collisions in crowded warehouses. They’re also quieter, reducing noise pollution. Approximately 18% of industrial workers have a hearing impairment, which lowers their life quality and may increase dementia risk.

Forklifts aren’t the only heavy equipment going electric. Many facilities have begun to outfit their organization with full electric fleets, and even bulldozers are joining this technical revolution. Electric vehicles typically have less complicated engines, leading to fewer malfunctions and opportunities for injuries to occur as crews scramble to find workarounds.

Fall Prevention

Falls from heights are the number one cause of workplace death in the UK and lag behind only transportation and workplace violence in the United States. The term “fall from height” is somewhat misleading, as many of the fatalities involved falls from lower levels, not towering skyscraper beams.

Improved safety technology and procedures work in tandem to prevent falls. For example, requiring harnesses for work involving ladders and scaffolding can reduce the risk of injury if the standing structure falls or an accidental bump sends it tumbling. Providing additional training is another safeguard, as advances in computer technology allow workers to remediate as needed instead of waiting for a single group training to refresh their knowledge.

Worker State of Mind

Improvements in technology won’t go as far as they can in increasing industrial hygiene and safety without the buy-in of the workers running operations. One of the simplest yet most effective methods of bringing up safety scores is to simply slow down. While this mindset goes against the obsession with productivity and metrics typical of many facilities, it’s a rebalancing of modern reality with human ability.

Consider an experiment on seminary students asked to give a speech on “The Good Samaritan” parable. Researchers told one group their participants were already waiting, creating a hurry. The second group was told they had just enough time, and the third was told they had more than enough. Even given the topic of the speech, only 10% of the hurried participants stopped to render aid to someone in need as they crossed campus, while 63% of the unhurried students paused.

Technology has increased overall productivity but has also added responsibilities for workers without a corresponding drop in working hours or adequate time to absorb new information and procedures. Exhaustion and burnout can lead to mistakes that cause injuries and cost lives.

Recent legislation to shorten the average workweek, if passed, could reduce the burnout many feel, improving workplace safety. In the meantime, site leaders can emphasize quality over quantity and stress safety over metrics in determining raises and bonuses to decrease the temptation to cut corners to make numbers.

Improving Industrial Hygiene and Safety

Workplace injuries cost countless lives and disrupt operations. Improving industrial hygiene and safety demonstrates a commitment to a strong, healthy and thriving workforce.

Site owners and supervisors should periodically review the latest updates to improve their operations. Keeping workers safe decreases liability, enhances workflow and results in a happier, more productive environment.

* This article is written by Jack Shaw. Jack is a seasoned automotive industry writer with over six years of experience. As the senior writer for Modded, he combines his passion for vehicles, manufacturing and technology with his expertise to deliver engaging content that resonates with enthusiasts worldwide.

Mining and metals companies are implementing a range of strategies to enhance asset management and equipment reliability.

In today’s market, many senior executives leading natural resource companies hesitate in making additional capital investment and instead focus on what can be done to squeeze higher performance out of current assets. Consequently, companies are increasingly looking for ways to improve performance and returns with existing infrastructure.

The key approach to this challenge lies in upgrading and improving asset management capabilities. Many organizations have failed to deploy optimal asset management practices. This is surprising given that asset spend frequently represents 30% to 50% of the overall operating expenses. Shifting to a best-in-class asset management program will consistently deliver improved plant or equipment performance, lower operating costs, extend asset life, and generate a higher return on capital. Most recently, companies have sought to implement a range of strategies such as:

- Implementing Asset Management Systems: Utilizing robust asset management systems to track equipment performance, maintenance history, and lifecycle costs, allowing for better decision-making regarding repairs, replacements, and upgrades. Digital technologies like IoT sensors, AI-driven analytics, and automation further optimize asset management.

- Enhancing Maintenance Practices: Implementing proactive maintenance strategies like conditioned-based monitoring and reliability-centered maintenance to address issues before they cause failures. Utilizing data-driven insights, mining companies can optimize “time on tools” by identifying patterns and trends in equipment usage, maintenance needs, and performance. This allows for more precise scheduling of maintenance tasks, reducing downtime and maximizing the time equipment is operational.

- Investing in Training: Providing comprehensive training programs for front-line management, maintenance and operations personnel to ensure equipment is used and serviced properly, reducing the likelihood of breakdowns due to human error and that access to equipment is available. Training personnel to utilize data-driven insights enables management to make informed decisions impacting “time on tools” and leading to improved equipment utilization and overall operational performance.

- Improving Supply Chain Management: Ensuring timely access to quality spare parts and materials to minimize downtime caused by equipment breakdowns and repairs. Some are adopting blockchain for transparent supply chain management and better tracking of assets throughout their lifecycle.

The level of performance improvement companies can realize by implementing key strategies such as enhancing proactive maintenance practices, investing in training to improve skills and capabilities, improving supply chain management, and leveraging digital technologies and data-driven insights varies depending upon factors like current operational efficiency, the scale of implementation, and industry conditions. However, many can expect significant improvements in:

- Safety: Proper training programs and proactive maintenance strategies contribute to a safe work environment by reducing risk of accidents and equipment failures.

- Productivity: Proactive maintenance and digital technologies can reduce downtime, increase equipment availability, and optimize process execution, leading to higher productivity levels.

- Cost Reduction: Efficient equipment usage and maintenance practices can lower operational costs by minimizing unplanned downtime, reducing repair and replacement expenses, and optimizing resource utilization.

- Quality: Improving the essential management skills and work place practices result improve the quality of maintenance execution.

Overall, these strategies can result in substantial performance improvements, enhancing competitiveness and profitability for mining and metals companies.

USC Consulting Group partners with your organization and coaches your people to significantly impact performance outcomes and accelerate Asset Management and Reliability Excellence.

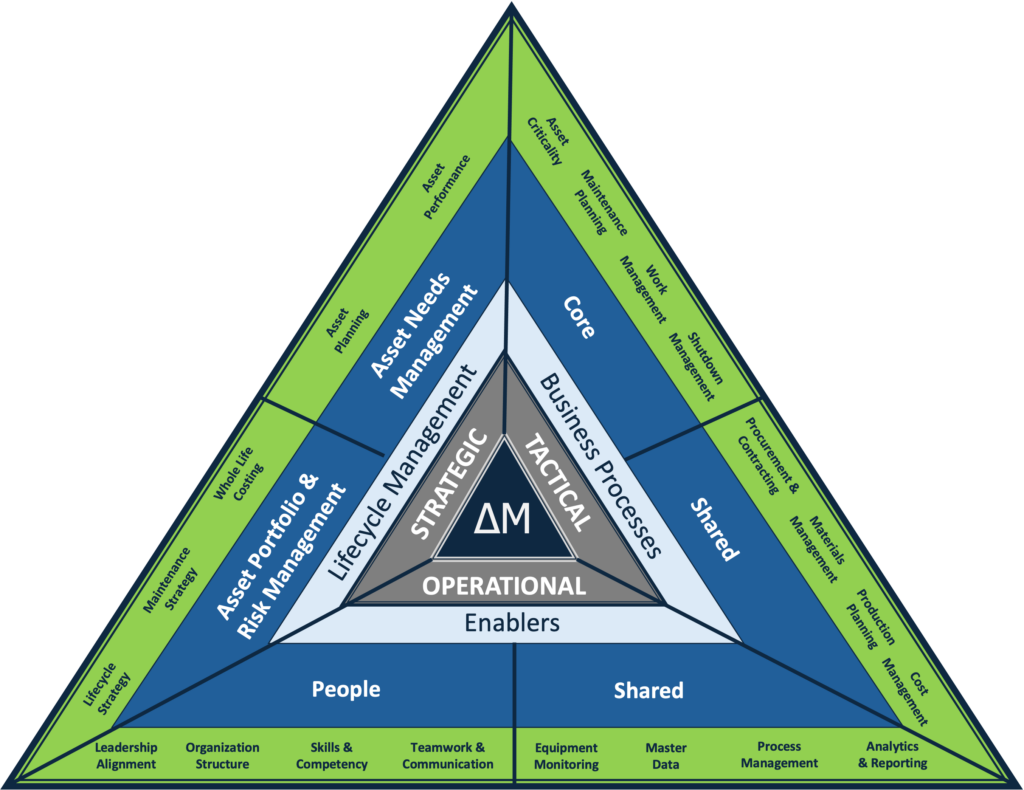

USC’s experience helping clients to shift asset performance by transforming and optimizing asset management capabilities and processes has repeatedly demonstrated the need to focus on the key levers and enablers to asset management and reliability excellence. Our asset management framework is designed to be pragmatic rather than conceptual, thereby leading to accurate, practical decisions about a client’s assets and aspirational outcomes.

The primary goal of USC’s asset management framework is to help our clients to implement and execute of a robust set of integrated processes and tools to manage and maintain their operational assets at the targeted service levels while optimizing life-cycle costs and asset life. This is accomplished by recognizing the needs to:

- Improve safe execution of work

- Increase asset life and reliability

- Improve productivity and cost performance

- Improve operational predictability

- Control material asset risks

- Develop competitive advantage

Our asset management and reliability framework helps clients identify an organization’s asset management maturity level and the areas and gaps that need to be addressed, by evaluating their strategic, tactical and operational levers and the enablers that comprise each.

Strategic (Lifecycle Management): A tailored maintenance program for each piece of equipment translates overall strategic objectives into executable plans for equipment upkeep. Our framework helps to structure and prioritize critical assets while defining a baseline operational ‘plan of action’ by determining strategies for maintaining equipment based on analysis of equipment capabilities, required performance levels, failure frequencies, and cost objectives. Optimal maintenance strategies are frequently a blend of preventative, predictive, operator-maintained, and run-to-fail options.

Tactical (Business Processes): Business processes bridge the gaps between the initial, ideal plan and the reality of ‘day-to-day’ operations, so the maintenance and reliability organization can make adjustments. Historically, many maintenance organizations have been poor utilizers of labor resources that result in low “time on tools” and excessive delays in repairing down or poor performing equipment.

Operational (Enablers): Enablers help to identify needed support to manage assets throughout their lifecycle in alignment with organizational aspirations. Leading asset management teams have also made changes in their organization structures and management practices to foster more action-oriented leadership that focuses on operational excellence, which usually requires a culture shift that must be relentlessly supported by the leadership team over the long-term. A heavy emphasis on management behaviors and company culture can help organizations make this difficult transition.

USC Helps You Tackle Key Challenges

- Optimize maintenance strategies and increase equipment availability operational output

- Predict asset integrity and reliability needs and improve time on tools

- Mitigate risks through stronger stakeholder partnerships, while removing redundancies in the supply chain

- Overcoming cultural and communication issues with contractors, while ensuring quality expectations

Do you want to understand how prepared your company is to drive needed asset performance and reliability improvements and what the key focus areas that will contribute to lower operating costs?

Want to find out more about how USC can help you uncover the hidden value lurking in asset portfolio?

For more information, let’s talk it through with a no obligation video conference call or a meeting with one of our executive team. Email info@usccg.com to arrange a call.

In September of 2022, autonomous aerial robot systems pioneer Exyn Technologies engaged USC Consulting Group to perform an independent evaluation of the AL4 Autonomy being utilized in the ExynAero underground drone.

The detailed study focused around one main objective; to gain practical exposure to the use of this technology by the survey team, while surveying active headings.

The ExynAero uses a LIDAR unit mounted to the drone in order to perform cavity mapping surveys inside of open stopes.

Over the course of a two-day visit USCCG was able to observe surveyors mapping live stopes utilizing the new drone technology on the ExynAero in comparison to the traditional boom and scanner CMS method. The observations yielded immensely positive results including:

- 45% faster surveying times underground

- 24% more volume realized in the same cavities as compared to traditional CMS

- Added safety by increasing distance between working area and the brow from 1-3ft to 50+ feet

- Reduced physical strain in set-up / take-down of equipment

As a follow-up to the evaluation of mining’s top innovations, USC Consulting Group worked with both Northern Star Resources Limited’s Pogo Mine and Exyn Technologies to prepare a white paper detailing these findings. This free white paper is available for download below:

Mining Benefits

There were many benefits that were observed during the study, which included improved safety, survey quality, and time savings.

“It (ExynAero) is infinitely safer to use… we’re nowhere near the brow now, doing jobs around the corner in some cases. The safety aspect is definitely one of the driving factors to why we purchased the gear.” – Chief Mine Surveyor, Pogo Mine

Working at or around the brow is widely regarded as one of the most hazardous places in any mine. The National Institute of Safety and Health (NIOSH) still lists it as one of the top five major causes of lost time injuries in underground mining, accounting for almost 10% of reported injuries.

Read the full report of benefits in our white paper: ExynAero vs Traditional CMS: A Study of Mining’s Top Innovations

If you want to learn more about this study or you’re interested in speaking with one of our Mining experts, please contact us.

*Photo credit: Richard Bishop

An ancillary component to all mining operations, perhaps more so than any industry, is mining safety. Everything mine workers and their foremen do throughout their day-to-day itinerary should include extra attention to adhering to mining safety standards and improving on them wherever possible.

Though the U.S. Department of Labor’s Mining Safety and Health Administration reported workplace fatalities have plummeted over the last 40 years from around 250 annually in the late 1970s to under 50 in 2014, securing employees against risk protects them as much as the business itself. After all, time spent recovering from an injury chips away at a mining company’s productivity. In the end, it’s in everyone’s best interests to increase minig safety and prevent harm for both medical and financial reasons.

Taking extra precautions need not complicate the task at hand – safety and efficiency aren’t mutually exclusive. In fact, foremen and managers seeking to optimize processes and improve the quality of their risk prevention can do so by simply focusing on improving efficiency in target areas.

Fragmentation

As the first step to the mining process, fragmentation can have an incredible impact on mine development and even auxiliary operations. Proper fragmentation can align ore extraction with daily objectives, which subsequently allows workers and engineers to utilize mining and transport equipment at peak efficiency. It’s important every load sent to the surface doesn’t fall short of its predicted capacity, otherwise mine operators unnecessarily expend fuel, pay staff to work longer hours, and wear down machinery, all for a less-than-anticipated return. As such, implementing an intelligent, data-driven approach to fragmentation that consistently provides adequate resources helps everything after and beyond flow smoothly.

A clean, controlled explosion can help miners perform their duties with greater efficiency.

With all that in mind, we are talking about explosions, however controlled they may be. Luckily, some of the greatest mining safety tools also promote efficiency. According to a study by the Department of Mining Engineering at the Federal University of Technology in Akure, Nigeria, to protect workers from inefficiency, as well as safety hazards like fly rocks, miners should pay closer attention to rockmass and blast parameters. Just as a well-executed fragmentation sets up workers for ideal extraction conditions, a comprehensive assessment of rock density and placement of explosives enhance the effectiveness of the fragmentation. Additionally, competent adjustments to blast hole diameters and borehole depth reduces overburden and minimizes extraneous equipment use, which again, cuts down on energy, wear-and-tear, and time spent on-site that detracts from extraction.

When an occupation includes handling high explosives as part of the job description, it can feel as though a piece of everyday operations will be left to chance. However, mining professionals know that’s far from the truth. Businesses can takes steps toward calibrating their fragmentation, fine tuning it until it maximizes production and mining safety.

“Without ample attention paid to communication services, miners and engineers can lose productivity and decrease mining safety.”

Signal strength

Communication in the mining industry remains a multifaceted issue with a variety of considerations. Mining is one of the rare instances of workers performing 12 to 14 hour shifts over many consecutive days. In this business model, foremen and managers get the most out of their teams, which keeps production moving and on quota. That said, without ample attention paid to communication services, miners and engineers can lose productivity and the resources they need to stay safe.

Network communication provider Globecomm broke down mining communication into two basic hemispheres: reachback and mine site communication. Reachback communication connects the quarry with the outside world via telecommunications and Internet, typically used as a means for connecting “boots on the ground” with headquarters. However, as the Internet continues to grow in popularity as a source of entertainment, a reliable Wi-Fi or wired connection for workers to use during downtime keeps spirits high after intense physical labor. Moreover, during the workday, reliable web services and telecommunications also allow miners to perform research, supplying them with the information they need to do their jobs safely and efficiently.

To that same end, high-quality communication between workers can not only keep continuous processes in full swing, but at a blast site that uses explosives and industrial equipment to rend solid rock, it can also save lives in an industry. Workers should always have a reliable channel of communication to prevent accidental injuries. Additionally, as mining technology continues to advance, companies will also begin integrating more data-powered machinery, which will also require a strong network connection on which to transmit information.

Foremen, miners and engineers understand mining safety is not an option in their line of work, but a necessity, one that doesn’t have to be leveraged against filling orders on time and at allocation. By employing mining safety measures as a means to highlight areas of operation in need of an efficiency boost, these workers can have the best of both worlds.