-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: RCM

Heavy production assets are ubiquitous across numerous industries, from residential construction to mining. Keeping this mission-critical equipment up and running is among the top priorities for modern industrial organizations. It is why the average firm devotes almost 10 percent of its facilities budget to maintenance activities, according to researchers from Plant Engineering.

Virtually all of these entities leverage either predictive or preventive maintenance methodologies, both of which materialized in recent years due to widespread enterprise digitization. But how exactly are businesses deploying these strategies to ensure heavy production assets maintain peak performance? Here is an industry-agnostic look into the state of predictive and preventive maintenance best practices for heavy asset optimization:

Unpacking the preventive approach

An estimated 80 percent of maintenance teams employ preventive maintenance techniques, per survey data from Advanced Technology Services and Plan Engineering. The proactive approach centers on one operational goal: reducing production downtime. There are several associated best practices that guide preventive maintenance implementation and management.

Relinquishing the reactive approach to asset maintenance is the most impactful of these exercises. Unfortunately, it is also the hardest to adopt, Modern Materials Handling reported. Maintenance specialists that have traditionally listened for the cacophony of mechanical collapse and responded in turn must change their mindsets and instead focus on implementing piecemeal adjustments to mitigate the wear and tear that causes asset failure.

Making this cultural switch is no easy task – neither is reassessing all production and maintenance policies and procedures, and drafting new ones to comport with key performance indicators and company goals. However, four-fifths of maintenance teams have managed to execute these and the other preventive best practices on the way to transformation, including groups responsible for overseeing heavy assets.

Industrial organizations that excel at heavy machinery maintenance and effectively address small mechanical errors before they devolve into downtime-causing kinks focus on developing and sustaining routine asset optimization schedules, according to Reliable Plant. Through consistent check-ups and slight tweaks, maintenance teams responsible for bulky equipment can ensure these key production tools are always in good condition and ready to perform. Usage monitoring is also key, as heavy assets that are misused, either intentionally or unintentionally, typically break down the fastest.

How does usage monitoring unfold within an actual production workflow? A construction company preparing to excavate a new worksite might assess the climate and the soil to determine which backhoe digging attachment is not only best suited for the task at hand, but also the least likely to cause mechanical stress. These and other techniques make preventive maintenance possible, even with heavy assets in play.

Unpacking the predictive approach

When investments in heavy machinery began climbing dramatically more than a half decade ago, equipment manufacturers advised industrial companies to adopt asset tracking solutions to ensure that the multimillion-dollar tools they were deploying were actually required, The Wall Street Journal reported. At the same time, an innovative approach to maintenance, which also happened to be based on data analytics, was emerging.

This methodology, called predictive maintenance, would allow organizations to harness the power of advanced information technology to monitor mission-critical machinery in real-time, calculate the potential for future downtime and make improvements to avoid shutdown. In the years since this strategy materialized, many businesses have embraced it. In fact, 47 percent of industrial firms attest to deploying predictive maintenance processes and tools, per Advanced Technology Services and Plan Engineering.

Perhaps the most well-publicized and successful predictive maintenance programs have unfolded within organizations leveraging larger production assets. For example, construction equipment giant Caterpillar was among the first asset producers to manufacture products meant for use in predictive maintenance workflows, Forbes Magazine reported. The company began building bulldozers, dump trucks, excavators and other common equipment with pre-installed wireless sensors designed to transmit usable performance insights to maintenance leaders. Caterpillar customers have seen significant efficiency gains and cost reductions as a consequence of this forward-thinking equipment and the accompanying software.

Harley-Davidson is another early adopter that propelled predictive maintenance to new heights. Starting back in 2010, the automotive giant began outfitting the decades-old equipment in its York, Pennsylvania plant with wireless sensors configured to monitor mechanical operations and measure physical variables such as component vibration to assess asset performance, The Journal reported. These tools and the predictive maintenance program they facilitated led to drastic shop floor improvement, as Harley-Davidson watched production throughput times and costs decrease.

While impressive, these outcomes merely represent the initial stages of the predictive maintenance approach, according to PricewaterhouseCoopers. The rise of deployable enterprise artificial intelligence technology is expected to have an immense impact on this strategy, lending industrial firms the ability to monitor more data points across larger pools of equipment, including heavy assets.

That said, there is ample ground to cover before AI-propelled predictive maintenance workflows become industry standard. Most organizations inhabit the second position on the predictive maturity scale, per PwC, and therefore still depend on instrument inspections and other manual means. However, a significant number have entered stage three and now leverage real-time condition monitoring tools. Far fewer are in stage four, where expansive data-driven workflows capable of handling massive amounts of asset information are the norm.

In any case, predictive maintenance holds immense potential for teams assigned to heavy assets and, as the survey data from Advanced Technology Services and Plan Engineering indicates, a good number of the teams overseeing large machinery today have at least embraced some processes and tools associated with the strategy.

Implementing preventive and predictive maintenance strategies centered on heavy equipment can seem like an overwhelming task, especially for smaller industrial firms or those with particularly intense production demands. For businesses in these positions, external assistance could be all but necessary. USC Consulting Group has been helping organizations optimize their maintenance operations for decades, leveraging proven techniques and tools that accelerate change and lay the foundation for sustainable growth.

Connect with us today to learn more about our work and how we can help your company reduce heavy asset-related downtime.

The Trump administration recently published its 2019 budget proposal, which includes deep spending cuts totaling hundreds of billions of dollars. The budget request also calls for the elimination of several federal oversight bodies, including the U.S. Chemical Safety Board, according to Bloomberg. Created in 1990 as part of the Clean Air Act, the independent watchdog leverages $11 million in annual funding to investigate industrial incidents stemming from the mismanagement of caustic chemicals. While the elimination of the CSB seems, on the surface, an ideal development for industrial organizations, some industry leaders and workplace safety experts have expressed skepticism.

Modern manufacturers are deeply invested in protecting their employees, and support the work of bodies such as the CSB as they establish new workplace safety paradigms centered on innovative strategies and technology. Current CSB Chairperson Vanessa Allen Sutherland has received praise from industry leaders for streamlining the agency’s investigation workflows and collaborating more effectively with businesses. Despite these positive developments, however, the agency has been put on the chopping block as part of a wider push for government deregulation.

How would the abolition of the CSB impact firms developing new safety and reliability programs?

Addressing chemicals in the workplace

Chemical compounds are among the most serious safety hazards found within industrial work environments, according to the National Safety Council. Manufacturers and other businesses leverage hundreds of different substances in everyday workflows and produce significant amounts of equally dangerous chemical residue. Workers who encounter these materials can suffer serious or sometimes fatal injuries. In fact, approximately 268 American employees died in 2016 because of such exposure events, according to research from the Occupational Safety and Health Administration. Firms in the industrial space are well aware of the dangers that their workers face, which drives them to develop safety and reliability programs that prevent injuries.

Oversight bodies like OSHA and the CSB are heavily involved in these efforts, working with industry stakeholders to create enforceable policies that keep employees safe, even as they encounter risk while performing everyday duties. In 2016, the CSB conducted seven major investigations, including an inquiry into the 2013 explosion at the West Fertilizer Company plant in West, Texas, that killed 15 workers and injured more than 260 others. Through these investigations, the CSB developed best practice recommendations so industrial businesses do not repeat the errors of their less fortunate peers. OSHA adds another dimension by approaching the subject of chemical management from the position of the worker and formulating safety standards that keep employees safe. While businesses in the industrial space have traditionally butted heads with OSHA, they have had a productive relationship with the CSB, which many leaders credit for revolutionizing chemical handling practices here and abroad. Its investigations have resulted in the creation of new guidelines that not only keep workers safe but also reduce costs associated with employee injury.

Considering operations after CSB

If Congress embraces the Trump administration’s budget and authorizes the elimination of the CSB, then industrial organizations would have to seek out new external partners and refocus their efforts in order to ensure vigilance in an environment with little federal oversight. The critical insight the agency once provided would be gone, increasing the likelihood of catastrophic events caused by small operational lapses. The West fertilizer plant resulted in more than $230 million in damages to the local community. Without the CSB, another similar situation may develop.

USC Consulting Group can help chemical manufacturers with operating efficiency by developing effective safety and reliability programs for addressing chemical usage in the workplace. Furthermore, our consultants can establish asset performance management programs to ensure facilities are properly maintained with scheduled maintenance and well-planned outages, resulting in their employees staying safe from avoidable mishaps.

Is your organization considering how it might operate in a world without the U.S. Chemical Safety Board? Connect with USC Consulting Group today to learn more on how to improve safety in the workplace.

Truly innovative asset management covers all aspects of monitoring, analyzing, and maintaining capital equipment. Does your business have all its bases covered?

Now recovering from economic instability over the last decade, companies in asset-intensive industries have begun to invest in new and recommissioned equipment. In turn, these decisions ignite a fervent interest in improving uptime quality through optimized workflows, reliability-centered maintenance, and proactive decision-making.

Download our latest e-book “Asset Management: The Rise of Reliability” to discover asset management best practices from our team of experienced operational experts. Here are the seven points examined and discussed therein.

1. Work management

A work order is more than just a slip of paper. Its life cycle extends further than most businesses realize and should include information valuable to future successes in asset management.

2. Downtime tracking

If you fail to understand the nuance of downtime tracking, you will fail to sustainably decrease it.

3. Preventive and predictive maintenance

Reward awaits those facilities that understand what these two cutting-edge maintenance methodologies entail and how to execute on them properly to achieve new heights.

4. Asset criticality review

Are you allocating your resources to the machinery that matters most to your business? Align your goals with your actual asset management processes with a comprehensive ACR.

5. Equipment history capture and analysis

Those who ignore history are doomed to repeat it. Do you know what sorts of data you should capture about your assets today in order to make informed decisions tomorrow?

6. Root cause failure analysis

Assets fail for any number of reasons, but they boil down to three basic types of failure. Learn these as well as tips for digging below the surface when failures strike.

7. Operator equipment care

Line operators can work wonders for an innovative asset management program – if only their leaders know how best to utilize them.

Asset-intensive industries have cautiously maintained their commitment to present and future major capital investments in the wake of the 2008 economic collapse. Total capital expenditure, which includes the purchasing of both equipment and structures, has grown without pause since 2009, according to a recent report from the U.S. Census Bureau.

But ventures today are not the same as they were before 2008. They now come with new perspectives on how best to improve reliability across the business with tightening margins, ensure throughput or productivity by reducing downtime and preserve mission-critical assets effectively, intelligently, and affordably throughout their life cycles. To some degree, all industries with large-scale assets cared about these principles in the past, but now many – energy, oil and gas, process industries, telecom – must do so in the face of trends rapidly transforming their sectors.

Considering major capital investments? Here’s how enterprise asset management and maintenance can save you from dire financial straits.

Are you caught in an asset utilization trap?

Industries with heavy assets owe it to themselves to develop innovative and more robust asset management practices, lest they fall victim to an endless cycle of profligate capital spending.

Let’s use an example industrial businesses have no doubt experienced: how to respond to low asset utilization. A mining company crunches the data on month-over-month utilization for its fleet of articulating vehicles. Asset management metrics return a utilization rate of around 45 percent, same as it’s been for more than a year. Utilization has plateaued, so company stakeholders decide that increased capital investment on newer trucks will resolve their issue with stagnant asset-related revenue generation.

Chances are good that it won’t, definitely not if low utilization stems from maintenance and scheduling. An ill-prepared asset management program in charge of a larger fleet will only exacerbate the utilization problem, not fix it.

If this mining company, or any other asset-reliant business for that matter, truly believes in the doctrine of continuous improvement, they will turn their attention to the real culprit: underdeveloped asset management operating systems and reliability-centered maintenance. Here’s how to build out these areas and create an asset support network that drives higher utilization:

Get granular with preventive or predictive maintenance

All industries that rely on heavy equipment or high-tech plants must gradually, but assuredly, move toward a proactive versus reactive stance on enterprise asset management. Repairs and calibration must either happen on a time-based cycle (preventive maintenance or PM) or through advanced sensors and preemptive failure detection (predictive maintenance or PdM).

However, these are very broad recommendations asset management teams will probably already understand the value of. What specific details should PM and PdM adopters lock onto if they want to boost utilization?

Pinpoint ideal KPI metrics: Find the measurements that align best with your mission as an organization and can report capably on issues surrounding asset utilization, then automate the acquisition and visualization of those measurements so you understand them in real time.

Investigate data hygiene: Key performance indicators must be accurate to serve operators, technicians, and supervisors. Review where your data comes from, who handles it, and what may adversely affect its veracity.

Standardize cross-functional transparency: Businesses that democratize information allow their workers to contribute to and analyze all data related to asset health. Build visibility into the entire asset management operating system – reporting, inspecting, scheduling, repairing, confirming, and documenting – and leave no area of your business in the dark.

Devote more resources to root cause failure analysis

Are mechanical failures on critical assets really the result of something mechanical? You’ll never know without comprehensive root cause failure analysis (RCFA).

Although deficiencies or outright failures may present as technical glitches, best-in-class asset management processes must dig below the surface to reveal what’s actually causing asset functionality – and ultimately utilization across the board – to drop.

Returning to the hypothetical mining company from before – perhaps utilization rates were low because heavy trucks require a lot of maintenance. What kind of maintenance? Technicians report back that the most common work order is repair or replacement of shock absorbers. To the untrained eye, this appears rational given the rough terrain and capacity requirements of the job. But practitioners of thorough root cause failure analysis don’t stop there. They ask the following:

- Are these universal issues experienced by competitors?

- Are these failures caused by the roads we drive on?

- According to the manufacturer’s specifications, are we overloading these trucks?

- Is a lack of communication between operators and maintenance professionals to blame?

Immediate remediation of one, some, or all of these concerns will improve the reliability and availability of assets, raise utilization rates, and may even deter unnecessary capex and opex spending. In order to achieve this high level of awareness over the condition of capital investments, however, asset-intensive businesses must first invest their time and effort into fleshing out RCFA.

Want to learn more about how to improve asset utilization through asset management and proactive maintenance? Contact USC Consulting Group to speak to an operations management consultant today.

What areas should transportation divisions look to that could both hide wasteful processes and, if maintained properly, significantly optimize processes?

Transporting goods, as a subdivision of a company’s logistics department, has transformed from an ancillary service to one of the most valuable resources in modern commerce.

Though the value of transportation logistics varies across different supply chains and might be difficult to ascertain cumulatively, a William Blair & Company study found third-party logistics companies constitute a more than $500 billion global venture with only 10 percent of the logistics market share. As evidenced, the power of an intelligently managed fleet can yield exciting revenue growth and truly define a business at its core.

That said, operational deficiencies can also turn the best logistics providers on their proverbial ears. Supply chain networks subsist on the fast execution or pertinent tasks and abhor waste in all forms. Depending on where it occurs along the supply chain, even the smallest inconsistency can offset processes down the line and cause subsequent harm, costing several companies considerable revenue all at once.

Best practices always encourage logistics providers to implement verifiable methods of improving operations when it comes to transportation management. In many ways, this is easier said than done. However, what areas should transportation divisions look to that could both hide wasteful processes and, if maintained properly, significantly optimize processes?

Reliance on technology necessitates repair management

As more and more advanced equipment make their way into all levels of the supply chain, manufacturers expand their potential for accelerated growth and enhanced productivity in granular increments to complement positive scalability. However, once any process becomes heavily dependent on technology, it can just as easily fall victim to its limitations. Machinery doesn’t last forever, and eventually businesses utilizing advanced equipment will need to dip into their repair and maintenance allocations. That is, after all, total cost of ownership.

Big trucks cost big bucks to maintain.

Unfortunately, these R&M costs are not fixed and will require foresight to avoid exorbitant fees. According to a study conducted by the American Transportation Research Institute, the average R&M costs per mile for a single truck grew by 7 percent between 2012 and 2013. When multiplied over an entire fleet and compounded by overall industry growth with expanded services, these operational costs truly stack up. Moreover, the ATRI study also stated fluctuating petroleum prices can impact the cost of tires, an integral and unavoidable resource for ground travel.

On top of all that, these costs don’t even consider the most important ones of all: downtime-related revenue losses. This multifaceted issue affects all aspects of business performance and can ruin profitability across all. Downtime loses companies customers, stifles on-site and off-site productivity, leads to expensive overtime pay for workers, hurts a brand’s image and could possibly even lead to expensive litigation. Though trying to assign a set number value to downtime casts a wide net, Gartner places the figure around $5,600 per minute – or more than $300,000 an hour – on average.

Companies who take their R&M schedule into their own hands can undermine these risks. Logistics providers should be sure to develop strategies that log relevant data pertaining to things like vehicle wear and tear. This can allow logistics managers to address necessary maintenance before the equipment breaks down and the serious costs start piling up. Moreover, this regiment creates an operational framework that accounts for repairs rather than responds to them as best it can.

Closing the skills gap

To maintain a competitive edge, the transportation industry requires a competent workforce knowledgeable about on-site operations, as well as overarching trends in the field. However, many problems stand in opposition of this, ultimately stemming from negative public opinion about the transportation industry and those who are needed to assume its mantle in the coming years.

For example, a study by the Economic Modeling Specialists International found more than half of all truck drivers in Houston, Texas, are 45 years old or older. This is not an isolated issue. Given the size of the baby-boom generation, as these workers retire, others will need to fill the void. Not anyone will do – as stated earlier, transportation has undergone a digital age makeover as of late. With Big Data and the Internet of Things redefining logistics operations, new hires must possess ever-increasing technological knowledge. Ironically, many young people in search of their first careers have been and will continue to be swayed by the incorrect notion that logistics and manufacturing are strictly about manual labor.

To ensure any enhancements to long-term productivity, transportation and logistics providers should never underestimate the value of public relations. Additionally, these organizations should develop new training tools that facilitate an accelerated process that doesn’t glance over the necessities, but provide job candidates with resources that complement their tech-savvy lives and minimize downtime between incoming and outgoing employees.

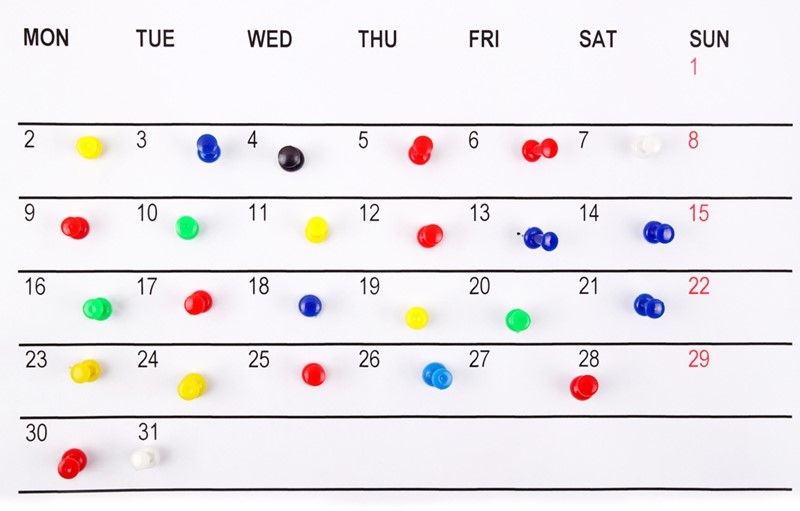

Regularly scheduled repairs on capital-intensive assets are the cornerstone of any preventive, predictive, or proactive maintenance strategy in the industrial sector. By preempting outright equipment failures and counteracting small, nearly unnoticeable deficiencies in performance, businesses save cycle time, maintain product/service quality, optimize labor costs, prevent waste, keep operators safe, and preserve the lifespan of their most valuable machinery.

All these benefits aside, planned asset maintenance programs require plant managers and decision-makers to coordinate with technicians as to customizing a maintenance agenda that comports with the business at hand, whose operations may differ vastly from others. However, a few considerations are universal and enhance maintenance scheduling no matter where or how one works.

Consider capacity always

In the industrial sector, nothing should be more valuable to a business than production or service. To that end, companies dependent on advanced machinery rely on scheduled asset maintenance programs, first and foremost, to sustain uptime. Planned maintenance or tune-ups minimize the impact offline equipment has on the business’s bottom line.

Depending on the number of assets under a given planned maintenance program, it is possible to lose this edge because of –believe it or not – poor planning in regard to capacity. Let’s say you own a fleet of 100 delivery trucks and, on an average day, you need 90 up and running to accommodate your customers. Any maintenance schedule, therefore, could only address one-tenth of the fleet on any given day, otherwise, the work would compromise availability.

Capacity, unfortunately, is never that cut and dry. Maintenance management teams should always consider backlog, upcoming product/service changes, or seasonal demand metrics which may affect operations and respond intelligently.

Planned maintenance can deliver incredible value, so long as you’re doing it the right way.

Factor in labor costs

Reactive maintenance, or responding to failures after they occur, can cost a business significantly through emergency labor. A study by Maintenance Phoenix found businesses can spend nearly 20% of the total replacement cost for a given machine to remedy a single reactive maintenance event. Comparatively, proactive maintenance events generally cost just 1.4% of the same variable.

Expenses that low don’t happen automatically, so maintenance management teams should keep a few things in mind. First, it is almost always better to spread larger maintenance orders over a few shifts rather than tackling everything all at once. This leaves room in technicians schedule for other things that may crop up.

“Don’t let overtime negate the margin of savings reclaimed by switching to a planned program.”

Second, overtime expenses should be a major factor in planning, regardless of whether businesses employ in-house repair professionals or outsource. Typically, initiating a preventive, predictive, and proactive asset maintenance program involves hiring a few additional technicians. Scheduled maintenance during overtime hours may, therefore, negate the margin of savings reclaimed by switching to a planned program in the first place.

Prioritize work orders

Another benefit to scheduled maintenance is the ability to rank work orders in a low-risk environment. Reactive maintenance forces organizations to respond to situations as they arise, leaving little to no time to respond to anything else. Since planned maintenance catches failures before they happen – usually through embedded sensors and telemetry monitoring internal changes in temperature or vibration – the organizations that adopt such programs may be allowed windows of opportunity to handle repairs before experiencing the repercussions of leaving them unattended.

With that in mind, an asset-heavy company should not only create an actionable list of all their equipment and components, but rank those assets according to importance based on their respective business objectives. These lists should update after every major tech investment to ensure prioritization accurately reflects current operations. Advanced computerized maintenance management software (CMMS) could be a welcome addition to maintenance management system and help businesses develop both a master asset list and real-time asset hierarchies.

Making the change to scheduled asset maintenance delivers many competitive advantages, so use these tips to develop a more robust and effective program.

Process mapping allows businesses to chart out steps in a given system to understand them more fully. Virtually every process in any industry can and should be mapped, in order to conceptualize exactly where bottlenecks may exist, wasteful actions occur and, where emergency detours might be necessary to preserve production or service uptime.

As any cartographer will tell you, there are right and wrong ways to construct maps. While process mapping might not have been what map-makers like the ancient explorers had in mind, similar rules apply. We’ve collected a few best practices for creating valuable process maps that deliver results and hone operations.

“Process mapping works best with concrete tasks.”

1. Tangible processes map best

Almost any process materializes well onto a process map. It is, however, worth noting the small category of those that don’t: highly abstract processes. Process mapping works best with concrete tasks that include appreciable and quantifiable objectives.

If process map-makers find it keeps failing to address all the concerns that led them to begin the project in the first place, that may be a sign the prospective map ought to be broken down into smaller chunks, a set of process maps within a greater process map. The road to the top of the mountain is beaten by many footsteps, so don’t attempt to leap there in a single bound.

2. Know where you’ve been and where you’re going

Since it is a tool commonly attributed to an agenda of continuous improvement, process mapping exists within a time continuum. Perhaps an organization has used process mapping since its inception, or maybe it’s part of a new operational excellence initiative. In either case, the use of this resource represents a single moment in an organization’s unending commitment to changing for the better. As such, process mapping should exploit the context of time any way it can.

“Treating process maps like historical documents can provide valuable insight.”

Process mapping can provide valuable insight as to how a company’s performance has improved or declined – a great metric for change management – as well as what sorts of process maps might be worthwhile in the future. Concise documentation is always needed to flesh out the story around the map: the reasons for updating, iterations of experimentation with process changes or shifts, or whether the team reached its goals at that time in history.

These notes will be informed by legacy and, in turn, inform future mappers. After all, process changes may pave the way for whole new avenues of possibility. Most of all, meticulousness ensures no step in the process goes unheeded and operations have the highest potential to succeed.

3. Strive for simplicity

All that said, these notes should be supplementary to process mapping and not exist on the map itself. Process maps should clearly and succinctly outline a system in the order it should be performed, with careful attention paid to visual simplicity. Save the extra documentation for planning meetings, but leave it off the map itself to prevent confusion or worse: non-use.

4. Try cross-functional mapping – but only when you’re ready

While all process maps are subject to time, only some are subject to a single department. In many instances, process mapping is most beneficial when it goes beyond a single silo. However, cross-functional process mapping adds a new dimension of complexity, as different departments may be subject to requirements, regulations, customs and, other kinds of checks and balances.

Gain some experience with a few simpler processes before tackling organization-wide process mapping challenges. Cross-functional maps can bring about significant improvements, but only if they’re established and implemented with speed and accuracy honed through experience.

“Every step from beginning to end should result in some tangible value.”

5. Distinguish value at every turn

Process mapping is very much a value-based activity. Every step from beginning to end should result in some tangible value for the organization and/or its customers, even if the benefit is simply a more optimized system. But to accomplish this, the map-maker must examine what value means for their organizations – and their organizations alone – as it pertains to each component of their process maps as well as the “big picture” objective.

Say a manufacturer wants to create a process map for an equipment changeover that includes a recently established standardized method operators have been asked to perform. Although the overarching reason for standardization might be to improve lead times, each step within the process map should demonstrate a quantifiable time management improvement over past operations:

Has the location of the equipment components necessary for changeover moved so they’re physically closer to the operator? Does the asset need to be equipped with different resources like raw materials or packaging? If so, how with a process mapping change factor into reloading?

However, the value in a single step doesn’t necessarily have to align with the process map’s general objective. So long as it’s of benefit to either the business or the client, the process map succeeds.

Comprehensive preventive maintenance and asset management ensure both the functionality, and efficiency of high-value equipment at a given business throughout its lifecycle. Yet, without an equally comprehensive auditing and optimization strategy for the ancillary processes around enterprise assets, businesses may accidentally overextend their operating budgets in unnecessary, preventable ways.

How can manufacturers, process industries, energy providers and other asset-intensive sectors optimize their preventive maintenance programs without hurting their productivity?

Reduce preventive maintenance schedule variance

When it comes to preventive maintenance, no matter how beneficial it may be to enhancing the performance of enterprise assets, it is possible to have too much of a good thing.

Is your maintenance schedule overbooked, underbooked, or just right?

Uneven scheduled downtime, for instance, could hike up operational costs in one of three ways:

- When preventive maintenance occurs too frequently, maintenance labor costs outweigh the threat posed by machine deficiency or outright failure. Balancing these costs is crucial to getting everything a business needs from its PM, but not overpaying for superfluous maintenance.

- Spacing scheduled preventive maintenance too far apart has its obvious consequences, like unintentionally allowing a small deficiency to exacerbate unnoticed.

- Choppy preventive maintenance schedules that vary hinder managers from planning strategically over the long term, both in an operational sense and financially.

Moreover, as The Maintenance Phoenix pointed out, scheduling variance could be the result of uncalibrated enterprise asset management software like computerized maintenance management systems (CMMS). Variance could also occur when maintenance professionals assigned repairs don’t carry out work orders within a tight timeframe. To cut down on preventive maintenance variance, businesses should assess their operational data, determine whether their maintenance programs suffer from any of these issues and take the needed corrective steps.

Minimize spare parts inventory management and costs

Traditionally, spare parts management follows along the same vein as asset management. In fact, there is considerable overlap between the two. Both preserve asset availability and mitigate the impact of downtime when it strikes.

That said, businesses must constantly work toward honing their spare parts inventory as much as possible without compromising the insurance these components provide asset uptime. Accomplishing this involves a two-pronged approach to spares: analysis and adjustment.

When a particular component within an asset breaks, an inventory of spare parts on hand accelerates the repair process. However, spare part inventory growth inexorably leads to cost increases, sometimes to the tune of as much as 20 percent or more of company expenditures, according to Life Cycle Engineering. Instead of adding a new batch of spares to the pile whenever assets appear to require them, it might be more cost-beneficial to perform root cause analysis on the “bad actor.”

For example, if a manufacturer spends $2,000 per month stocking fan belts for an asset integral to production, perhaps spending a little more on a one-time RCA cost may uncover why the asset churns through fan belts in the first place. A successful RCA, followed by corrective maintenance, could effectively eliminate the recurring cost entirely.

After tackling spare parts inventory, businesses should then be sure to adjust procurement plans accordingly so they represent the new optimized operations precisely and cut costs.

For spend managers at these organizations hoping to push their enterprise into the 21st century, what value could be achieved by concentrating spend where it’s needed most?

Enterprise spend management stresses the value of smart budgeting with a tight focus on maximizing ROI, optimizing processes, and expanding businesses in meaningful and sustainable ways. One may think the chemical processing and refining industry wouldn’t need to worry too much about how it spends, given how its products permeate as much as 96 percent of the supply chains for all manufactured goods, according to a recent study.

However, the success of the chemical industry as a whole is built on a foundation comprised of companies of all shapes and sizes looking to invest practically in their own prosperity. For spend managers at these organizations hoping to push their enterprise into the 21st century, what value could be achieved by concentrating spend where it’s needed most?

Reliability-centered maintenance

Direct spend management strategies tend to take top billing over indirect spend management. Direct spend management centers around equipment purchases, software integration and other physical assets a company can purchase. Indirect spend management, like coordinating spend on a sound on-site maintenance program, may not be as viscerally appealing as state-of-the-art assets, but can be just as valuable to a chemical processing plant, if not more so.

Reliability-centered maintenance strategies utilize vast stores of data to analyze how plant equipment functions. In doing so, supervisors can track productivity and deficiencies which may evolve into failures over time. Maintenance personnel then address these issues before they exacerbate. From a spend management perspective, this practice undeniably adds value. Proactive maintenance hits on several crucial concepts the chemical processing industry has been moving toward reinforcing: environmental accountability, strengthening employee safety, securing asset availability and uptime, and overall process optimization.

“Asset owners can use maintenance spend to gauge the financial viability of a replacement.”

Furthermore, an updated maintenance plan could guide organizations toward making more intelligent direct spend management decisions. If one asset continues to underperform despite several rounds of proactive maintenance, its owners can use maintenance spend as a metric to gauge the financial viability of a replacement.

Driving out commoditization with R&D investment

Growing commoditization of chemical goods increasingly prevents businesses in the industry from investing in innovation.

In his book Winning at New Products: Creating Value Through Innovation, author Robert G. Cooper explains that although the average time-to-market across all manufacturing sectors has trended downward since the turn of the century by more than 42 percent, new product sales decreased over that same period of time by 15 percent. Many investors cannot justify the “risks” of R&D, like steep upfront costs and long lead time, when highly specialized chemicals already in market favor perform so well.

Desire for a quick buck has officially overridden the urge to innovate, but from a spend management perspective, this narrow mindset offers little in the way of long-term financial sustainability. The chemical industry shouldn’t be afraid to expand its horizons by investing healthfully into a diverse product portfolio, but must do so with tact. For instance, chemical companies should only room in the budget for prospective products that fulfill an explicit objective valuable to their enterprise. In addition, technological investments should serve more than a single purpose, lest they go to waste on the off chance a new product fails to capture the market’s attention.

Can smarter asset management and maintenance strategies address mining issues of today, as well as those on the horizon?

When they supply manufacturing and other process industries with the minerals they need to service their customers, the U.S. mining industry also performs an incredible service to the stability of the nation. The mining industry processes hundreds of billions in minerals each year, and once delivered to other sectors, the materials added more than triple their worth to the economy, according to the National Mining Association. Mining is the fuel for the engine of production.

An industry so valuable to the economic integrity of the U.S. requires reliability-centered maintenance initiatives to protect and preserve mining assets over their entire life cycles. By investing in regular, data-driven repairs, mining assets have the potential to last longer, and their owners avoid cost increases related to inefficient operation, downtime and replacement, among others. But mining is an industry like no other, one with its own set of unique challenges.

Long hours of operation take their toll on mining assets

So long as there are minerals left to mine, a mining company’s extraction process will continue to be lucrative. But while mine workers and equipment operators in the U.S. average just over 44 hours weekly, according to the U.S. Bureau of Labor Statistics, the assets they utilize on the job may virtually never really stop running. According to literature published by the state of Illinois detailing a day in the life of a coal miner, many mines operate 24 hours per day. So, while workers might come and go according to their shift schedules, on-site assets function around the clock.

“Operation without end increases an asset’s susceptibility to inefficiency and breakdowns.”

These conditions present two problems for mining assets and the legacy maintenance strategies used to protect them: First, running machines constantly for long hours obviously puts an incredible amount of physical strain on the equipment in question. Operation without end increases an asset’s susceptibility to inefficiency and breakdowns. Furthermore, when assets run on a 24-hour operations schedule, any downtime – planned or unplanned – detracts from site efficiency.

That said, planned downtime as part of a reliability-centered maintenance strategy can take advantage of data communicated between machine and managers to reduce time to repair. If mining telemetry effectively predicts machine deficiencies capable of spiraling into full-blown failures, maintenance crews can plan downtime to address these smaller concerns rather than waiting for a big, expensive breakdown. The ability to schedule maintenance in advance delivers benefits all its own. If a mine has any off hours, even a handful a day, maintenance can devote that time to their work orders accordingly.

As mining demand rises, so does the significance of uptime

If the previous points didn’t stress the importance of asset reliability and continuous production, hikes in mining demand will. Industrial and technological trends have added pressure to the mining industry, compounding the need for maintenance programs designed specifically to enhance uptime.

By the NMA’s assessment, the average computer chip contains upwards of 60 different minerals and elements, all requiring mining operations. Moreover, the latest technological advancements may involve expanded mining operations to extract new metals – in 2011, Technology Review discussed how the U.S. is the largest consumer of cobalt while, at the time, mining none of mineral itself. That has since changed.

“As businesses move back stateside, procurement will need to follow suit.”

Additionally, reshoring may also increase mining demand in the U.S. According to the Reshoring Initiative’s 2014 data report, America went from losing 140,000 manufacturing jobs per year to overseas companies to gaining 10,000 per year in the last decade. As businesses move back stateside, procurement will need to follow suit, lest they undermine the cost efficacy of relocating to the U.S. by sourcing abroad.

Reliability-centered maintenance for mining assets keeps equipment availability high and mines in operation. As heightened demand pushes productivity to the limit, every machine extracting or transporting minerals will require support from a maintenance plan working alongside asset management best practices to secure availability.

The prosperity of future mining operations depends on the industry’s ability to respond to forecasted demand, so why not use the same principle to enhance asset functionality? With reliability-centered maintenance, mine workers and machine operators turn asset data into actions, thereby reducing maintenance costs, eliminating large-scale failure events, improving safety and throwing their full weight behind value-added operations.