-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Planning and Scheduling

A robust MOS is vital for mining and metal companies to navigate the challenges of today’s market.

Management operating systems (MOS) are making significant impacts to performance goals and outcomes for mining and metals companies by providing a structured and systematic approach to managing the business across the value chain. Companies have a strong need for robust MOS in today’s market to ensure safety and compliance, improve efficiency, and achieve sustainable growth, given the safety of workers is a top priority across the mining industry; the global demand for minerals and resources is rising, leading to increased competition; mining operations are inherently complex; the industry is facing significant cost pressures from fluctuating commodity prices and rising operational costs; and the adoption of new technologies requires an integrated approach to managing operations.

Performance is improved by providing a structured framework for planning, monitoring, and controlling operations. MOS can help through:

- Safety and Compliance – ensuring that safety protocols and regulatory compliance are integrated into daily operations, while minimizing the risk of accidents and legal issues, promoting a safer working environment.

- Enhanced Planning and Scheduling – creating detailed and realistic operational plans and schedules, ensuring that resources are allocated efficiently and that production targets are met without unnecessary delays. Potential bottlenecks can be identified and addressed during the planning process – “Planned work is safer and more productive than unplanned work.”

- Real-Time Monitoring and Control – tracking operations in real time, allowing for quick in identification and in-shift resolution of issues, while reducing downtime and safeguarding that operations run smoothly.

- Improved Communication and Coordination – standardizing processes and providing clear protocols, MOS enhances communication and coordination among different departments and teams, leading to more cohesive and efficient operations.

- Data-Driven Decision Making – providing and analyzing comprehensive data on various aspects of the operations to identify trends, inefficiencies, and opportunities for improvement and leading to more informed decision-making.

- Cost Control and Efficiency – optimizing resource use and reducing waste, while aiding in cost control and improving operational efficiency.

Supporting mining and metal companies to stay competitive and adapt to changing market conditions, MOS fosters a culture of continuous improvement by regularly reviewing processes, identifying areas for improvement, and implementing changes.

MOS in mining and metal operations are significantly enhanced by today’s technological advancements. By leveraging these advancements, MOS becomes more robust, responsive, and efficient. This not only enhances operational performance but also ensures better safety, sustainability, and profitability.

USC partners with your organization and coaches your people to significantly impact performance outcomes and accelerate Operational Excellence

USC brings a tailored, structured, and disciplined methodology, along with a range of tools and techniques we apply collaboratively with client’s personnel. Whatever your challenge, we are the people who work with our clients to find full potential and unlock the hidden value.

USC identifies waste, redundancies, and ineffective processes, and then rapidly recover the prioritized opportunities, and convert them to improvements in performance and operating profit. Our consultants achieve this by improving the skills sets of all levels of the client’s management and employees.

Our people embed with client internal teams to develop, enhance, prototype, validate and implement management operating system (MOS) element improvements to drive, sustain and perpetuate change in how the business budgets, plans, schedules, assigns work, executes, follow-up, reports, analyzes and improves. In short, USC implements measurable, sustainable changes that drive operational and financial improvements.

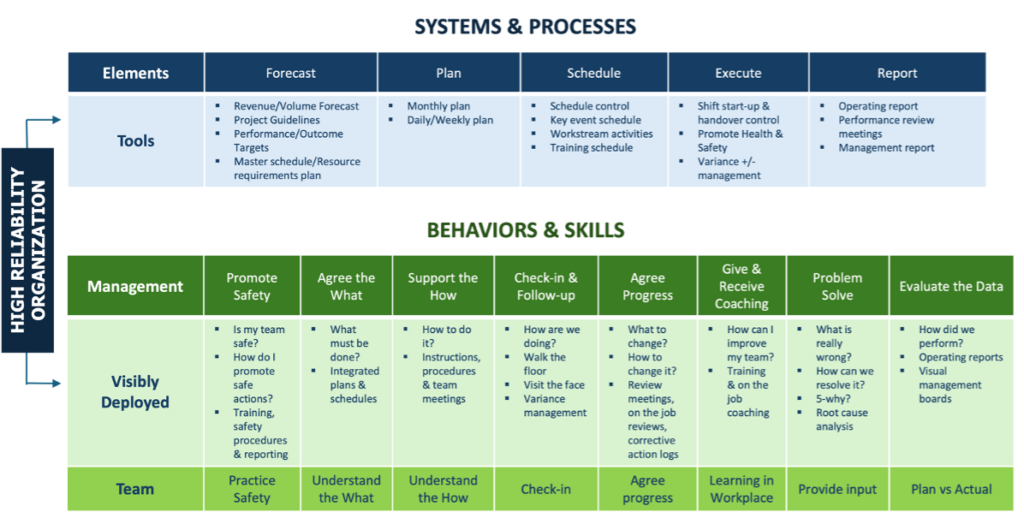

Our Management Operating System (MOS) Essentials Framework is designed to be pragmatic rather than conceptual – thereby leading to accurate, practical decisions about your operations and outcome aspirations. The key, that many miss, is the linkage process execution with management behaviors. MOS is about “managing differently” using visibly deployed management and supervisory behaviors. Consistent execution of the right behaviors at the right time creates certainty in the workplace, driving performance improvement and sustainable new ways of working.

Client performance goals and outcomes are realized through:

- Integrated safety protocols and compliance requirements into daily operations., leading to a safer work environment and fewer accidents.

- Reduced operational costs, including minimized waste, optimized equipment usage, and reduced energy consumption.

- Optimized workflows and resource allocation, leading to increased efficiency and higher production rates.

- Effective maintenance planning and real-time equipment monitoring, MOS reduces unexpected breakdowns and downtime.

- Alignment of daily operations with strategic objectives, ensuring that all activities contribute to the company’s long-term goals.

- A culture of transparency by providing clear performance metrics and regular reporting while driving better performance and tracking progress towards goals.

USC Helps You Tackle Key Challenges

- Optimize mine planning and scheduling across all planning horizons – delivering detailed and accurate plans

- Identify potential roadblocks proactively during mine planning and solve complexity during the planning process

- Ensure the right resources are at the right place to minimize lost time – enabling safe and disciplined execution

- Control quality of work at the point of execution by identifying off specification and enabling in-shift correction

- Evaluate performance and identify opportunities for improvement, enabling continuous improvement mindset

Do you want to understand how a MOS can integrate you mine and operational planning, while helping you to safely increase performance site wide?

Want to find out more about how USC can help you uncover the hidden value loitering in your operations?

For more information, let’s talk it through with a no obligation meeting with one of our executive team members. Email info@usccg.com to arrange a call.

S&OP is a business management process that involves sales forecast reports, planning for demand and supply, and other factors. The goal is to help companies get a better, more clear look at their operations and create better-informed strategy decisions, allowing them to deliver what clients need in the most profitable way.

It’s a useful process, but we’ve found a lot of our clients do not include inventory as a strategic tool in their S&OP process. Therefore, they leave the “I” out of SIOP.

“A key to SIOP is to emphasize inventory as a strategic tool to help offset variation in either demand or production issues,” explains David Shouldice, senior vice president and managing director of USC Consulting Group’s global mining and metals practice. “One lever of control in the SIOP process is to make inventory harder working as a strategic tool.“

Adding inventory into the mix is just one additional step, but we find it can be the key to the whole process. When you’re focusing on inventory, it requires more careful planning and elevates the entire planning process up a notch. When your inventory is optimized, which is not an easy mark to hit in these days of supply chain disruption, things tend to fall into place. With SIOP, you can make your inventory work harder for you.

Download our free eBook “Sales, Inventory and Operations Planning: It’s About Time” to discover the SIOP process, how it works, and the benefits of including inventory into your strategic planning process.

You will learn the principles of SIOP that include:

- In-depth definition of what is SIOP

- SIOP’s core components

- The benefits of implementing SIOP

- How it works in practice

- Real-world example case study

The Sales, Inventory and Operations Planning process assists USC Consulting Group in helping our clients become more efficient, profitable and competitive. If you’d like to find out more, contact us today.

The planning and forecasting process has always been a vital part of manufacturing, but now, after a roller coaster of a year, it’s becoming clear to many in the industry that this process needs to be bulletproof — and in many cases, it isn’t. The good news? A little tweaking and refining can shore up your planning process and help protect your operation against any kind of uncertainty, or disruption, that may come down the pike in years to come.

Problems in planning

You already know that accurate planning and forecasting is designed to anticipate demand and determine how much to produce to meet that demand, including shoring up adequate, but not too much, supply. We find that for a number of our clients, that works out to a “tons per hour” measurement of what they can realistically produce on any given day.

But, snags that manufacturers encounter in their planning process tend to come from the “it’s the way we’ve always done it” files. Here are just a few that we’ve seen lately:

Data is old by the time the plan actually goes into effect. Does this sound familiar? You start planning at the beginning of the month. By the end of the month, you’ve got a plan to hold yourself accountable. Great! But, the problem is, you’re using month-old data to start their planning process, so at the time the plan goes into effect, you’re using two-month-old data.

Data is not uniform. If manufacturers have multiple locations, odds are that they’re not all walking in lockstep when it comes to planning and forecasting. You may have plants doing their own thing, how they’ve always done it in regard to efficiencies, so there is no single source of truth on efficiencies and capabilities companywide.

Vetting time. If manufacturers are taking too much time to vet the plan, it delays the accuracy and immediacy of their data.

Unforeseen circumstances. We all know now, all too well, how unforeseen circumstances can throw a wrench into operations.

Refinements that can solve those problems

We’ve found that for many of our clients, some tweaks and refinements to their planning process can make all the difference. Here are a few problem-solvers that our clients are implementing.

A rolling calendar structure. We recommend instituting a 24-month rolling calendar, so when one month drops off, another is added on the back end. Here’s how it looks in practice:

- The first third of the month. Look back and assess how you performed vs. the plan in the previous month. If you fell short, how can you get better?

- Middle third: Continuous improvement. Develop action items to make the planning more smooth.

- Final third: Actually do the planning. Instead of having two-month-old data, you’ll be working with at most 10- to 15-day-old data.

Compromise on perfection in favor of immediacy. Don’t write those 24 months in stone. The plan might change multiple times between the start of the plan and 24 months down the line because of unforeseen circumstances. Being OK with this might require a huge shift in mindset for some people.

Flexibility. The forecasting and planning process has to be flexible enough in manufacturing to roll with the tides that might shift at any given moment in time.

SIOP. We focus on Sales, Inventory and Operations Planning, a holistic process that integrates customer-focused demand plans with production, sourcing and inventory plans, resulting in improved tactical and long-term business decision-making capability. The purpose of SIOP is making sure the business is having the right conversations about the right things at the right time. Steps in the plan include:

- Sales forecast

- Inventory considerations

- Planning

- Executing the plan

- Reporting and reviewing

- Analyzing and improving

Uniform efficiencies across all plants. If you have multiple locations, get everyone on the same page in terms of planning.

Bottom line, more accurate planning and forecasting is going to make your manufacturing operations more efficient and ultimately more profitable. At USC Consulting Group, we’re dedicated to helping our clients get there.

For an inside look into how we helped a national construction materials supply company refine their planning process, read “Building Materials Supplier Lays Groundwork with SIOP.”

These past several weeks have been a whirlwind for pretty much the entire world. The novel coronavirus – which has led to more than 3,020,000 deaths globally and has infected nearly 142 million people, according to John Hopkins University – has turned virtually everything on its head. In less than a month’s time, the U.S. economy went from being healthy to being forecasted to enter a recession, as over 25 million Americans have filed for unemployment benefits and over 700,000 jobs were lost in March, according to government data. This has led many Americans to lose confidence in the economy’s vibrancy; just 25% of respondents in a recent LIMRA survey believe it to be in good shape, down from 56% as recently as January. Fully 50% of Americans indicate that their financial situation is becoming worse, according to newly released polling from Gallup. That represents the highest percentage of respondents who have felt as much in the more than 20 years that the polling agency has been asking such a question. This comes after numerous monthly economic reports from the Department of Labor indicated unemployment nationwide was at a 50-year low and consumer spending was trending higher.

The suddenness of the economic downturn has many people – especially business leaders – wondering: Was the writing on the wall as to the extent of the adverse effects COVID-19 would have on supply chains? In other words, could it have been forecasted? No, according to Eric Wilson, director of thought leadership at the Institute of Business Forecasting & Planning. What the pandemic did do, however, is re-emphasize why it’s so important to plan for worst-case scenarios.

“50% of Americans indicate that their financial situation is headed downhill.”

Many businesses at risk

Businesses in the private sector have felt the affects of reduced consumer spending, constrained operations and supply chain challenges. In a survey performed by the U.S. Chamber of Commerce, a majority of small businesses – 53% – said they were less than six months away from shuttering permanently due to the economic downturn resulting from the nationwide shutdown.

These findings align with the Institute of Business Forecasting & Planning’s findings, which found that a strong plurality of mid-to-large-sized companies in the U.S. did not have a plan in place for a sudden economic downturn, Supply Chain Dive reported. Evidence of this was the fact that over 60% of respondents said they experienced delays in receiving orders from China, an issue that may have been avoided by dual sourcing.

The fluidity of the coronavirus situation and the timeline of when the threat first came to light has many people questioning what red flags, if any, were missed. Of course, no one can see things coming in the future, certainly not a novel virus.

However, given that approximately three-quarters of supply chains have been adversely affected due to the pandemic, according to survey research from the Institute for Supply Chain Management, it’s clear that everyone could have done a better job at contingency planning.

This starts by ensuring there’s more transparency within the supply chain, advised Subodha Kumar, professor of marketing and supply chain management at Temple University’s Fox School of Business. Speaking to Supply Chain Dive, Kumar warned that the biggest lesson to take away from the pandemic is becoming more effective in supply chain management so disruptions can be curtailed. The coronavirus serves as “a wake up call for all the companies, that this is the time to change the whole supply chain, and create transparency in the system where any changes at the store level are transmitted to all the partners in the supply chain – and as quickly as possible.”

In other words, companies of all sizes must do more to create transparency so it allows for smarter and smoother proactive contingency planning techniques.

What’s the difference between forecasting and contingency planning?

Forecasting and planning are terms that are often used interchangeably. While they undoubtedly have similarities, the key distinction is in regard to expectations. In other words, whereas forecasting is predicting a specific event to transpire, contingency planning is rooted in what behaviors and strategies should be employed to overcome disruptions, even if you don’t predict all, or even one, may actually happen.

A classic example of successful contingency planning consists of restaurants that prioritized their delivery channels prior to COVID-19. Because of the highly contagious nature of the virus, virtually all restaurants have closed their dining rooms and offer only takeout and delivery. Whether by partnering with delivery apps like UberEats and DoorDash or hiring personnel who can drive orders to customers’ houses, eateries have been able to effectively pivot and maintain incoming revenue. The restaurant sector has undoubtedly been hard hit by the shutdown, with businesses forced to lay off or furlough much of their staff. But companies that had delivery already in place were in a better position to adapt to sudden changes to business as usual.

The same can be said for those who use dual sourcing strategies. Particularly popular among manufacturers, dual sourcing serves as a smart fallback because it ensures that if one supplier is unable to deliver a particular product, the alternative likely can. As noted by IndustryWeek, dual sourcing usually entails utilizing suppliers from that are geographically diverse, such as one that is overseas and another that’s local or national. This more effectively balances supply-side or demand-side impacts

Data is critically important

What’s the best way to plan? Those who have been in the trenches say data plays a key role. Dustin Deal, director of North America business operations for telecommunications firm Motorola, noted during a recent town hall hosted by IBFP that the company’s ability to track, catalog and obtain data has enabled it to better adapt to how COVID-19 has affected its operations in many different countries.

“There’s so many data points coming at you from all over: the health industry, the government, financial markets,” Deal said, according to Supply Chain Dive. “[We] constantly look at the variables and try to figure out how that’s going to shape our markets.”

While many aspects of the pandemic are unclear and confusing, one thing is certain: the effects of the virus will be long-lasting. You may not be able to change the course of events, but there’s a lot you can do to develop a planning playbook so you’re more capable of adjusting and modifying your operations should similar local or federal emergencies happen again. USC Consulting Group can be your partner in arms in this effort and provide you with the education and strategies that fuel efficiency and adaptability. Contact us today to learn more.

The story of the manufacturing industry has been one of progress. Few manufacturers continue to produce the same products as they did in their infancy years. In order to remain competitive, manufacturers must continue to evolve their products to meet the demands of the marketplace. But meeting consumer demand is only half the battle — the other half is staying up to speed with industry advancements.

New technology brings a host of changes that manufacturers must recognize. For example, increasing dependence on automation leads to the need for more skilled workers who understand these advanced systems. If workers cannot adapt successfully, organizations could find themselves struggling to keep up with the rest of the industry.

To remain competitive in this dynamic environment, organizations should have several tools at their disposal that go beyond the physical equipment and technology innovations used in their facilities. These tools are ideas manufacturers can keep in their toolbox and use to produce next-level productivity. For instance, one tool can be an investment in regular maintenance, which can ensure that machinery stays in service for as long as possible. This results in higher productivity and fewer costly downtime periods.

There’s more than one kind of tool necessary for success in manufacturing. Check out this infographic containing twelve important concepts and ideas manufacturers should have in their toolbox to yield higher productivity and become more efficient overall.

As you can see there are many areas for opportunity to boost your manufacturing productivity levels. Tackling these initiatives in stages, however, is the way to go. This will help to avoid overwhelming your team as well as ensure success at each phase. A third-party operations management consultant can be a guide in the process by providing a playbook for obtainable and sustainable results and accelerate process improvements. To ramp up your operations contact USC Consulting Group today.

Sales, Inventory & Operations Planning (SIOP) is a dynamic process in which the company’s operating plan is updated on a regular monthly or more frequent basis. The plans take into account projections made by the sales and marketing departments, the resources available from manufacturing, engineering, purchasing, and finance, and are directed toward hitting the company’s objectives. Sales, Inventory & Operations Planning is done on an aggregate or family level, and covers a sufficient span of time to make sure that the necessary resources will be available. Any difficulties in supporting the sales plan are worked out. The approved aggregate plans drive the individual departmental detail plans. Each month, the representatives meet again to determine whether the overall company plan is on course, and to adjust for changes in the marketplace and changes or problems within the company.

Another contribution of Sales, Inventory & Operations Planning is that it enables the company to fine-tune its long-range strategic plan and annual business plan. The strategy must answer such vital questions as:

- What is our business (products, and services)?

- To whom do we sell (markets, customers)?

- What resources are required (people / skills, technology, plant and equipment, distribution, etc.)?

- What is the measure by which we compete (quality, delivery, price, service)?

- What is our financial strategy (profit, growth, ROA, ROI)?

- Any additional strategies (make or buy, market share, flexibility)?

Sales, Inventory & Operations Planning offers another key benefit to companies striving for the competitive edge: it enables them to operate Manufacturing Resource Planning (MRP II) at its full potential. When Sales, Inventory & Operations Planning is the driver in an MRP II system, the results are likely to be a Class A performance, which in turn means better customer service, more reliable performance, reduced costs, and greater profits.

Objectives of Sales, Inventory & Operations Planning

- Support and measure the business plan. Sales, Inventory & Operations Planning helps to determine whether your original financial expectations (budget), current sales plan, and operations plan are in sync with each other. It does this through monthly reviews of the marketplace and updates of the company’s operations plans. The updated plans must be in tune with the marketplace.

- Ensure that the plans are realistic. The key players from each department participate in formulating the new plans to make sure that all recommendations can be realistically supported. Since all of the numbers and assumptions are out on the table throughout the process, each department has more time to evaluate its resources and capabilities in the context of the company-wide plan. The result is a solid set of department plans that are based on real numbers and capabilities.

- Effectively manage change. The ability to carry out Sales, Inventory & Operations Planning is synonymous with being able to manage change, to substitute controlled and appropriate responses for knee-jerk reactions.

- Better manage finished goods inventory and / or backlog to support customer service. Maintaining the right level of finished goods inventory for make-to-stock families is essential for good “off the shelf” customer service. Operating at too high an inventory level results in extra costs, while operating at too low a level creates too many back orders. In a similar manner, controlling backlogs for make-to-order products is also essential for good customer service. If actual backlog becomes too large, delivery times stretch out, which eventually will cause customers to go elsewhere. By contrast, insufficient backlog can incur extra operating costs.

- Measure performance. Sales, Inventory & Operations Planning incorporates performance measurements to identify whenever actual performance is deviated significantly from the plan. The two main purposes of this are to separate those activities that are in control from those that aren’t, and to quickly bring the out-of-control situation to the surface so that an evaluation can be made and, if necessary, corrective action taken.

- Build teamwork. A key element of Sales, Inventory & Operations Planning is that it gives each department an opportunity to participate in the overall planning process. Each executive brings his experience and skills, which add insights to the matter of making changes to the current plans. These same talents can respond to proposed changes in terms of consequences and alternatives.

Prerequisites for Performing Sales, Inventory & Operations Planning

- Each department must gain an understanding of the Sales, Inventory & Operations Planning process.

- The company must commit the time and resources to the process

- The company must define product groupings or families

- The company must establish an adequate planning horizon

- The company must establish and manage time fences.

Understanding How to Operate

For SIOP to be effective, there can be no “black boxes” in the process; all participants must understand how it works and what it is designed to achieve. When people understand that sharing information does not mean giving up control and they see that the exchange actually leads to gaining control, they will be more willing to work in concert with their fellow departments toward the larger objectives of the company.

Commitment and People

Embarking on the Sales, Inventory & Operations Planning process is like making a lifetime commitment.

A suggested list of participants is as follows:

Company President, Vice President Sales & Marketing, Vice President Operations, Director of Logistics, Vice President Engineering, Vice President Finance, Vice President Information Systems, Vice President Human Resources

Optional Participants:

Products Managers, Materials Manager, Manufacturing Managers, Distribution Managers, Customer Service Manager

Defining Families

SIOP is carried out at the aggregate level. By “aggregate” we mean product groupings or families rather than individual products or items. The idea is to get effective input and control from management. This comes about by managing families, not items, and managing rates, not specific work orders.

Planning Horizon

The term “planning horizon” refers to how far ahead you need to establish your plans. Everyone recognizes that Sales, Inventory & Operations Planning is long-term, but the word “long” needs to be quantified. The SIOP plan must extend far enough into the future to ensure the availability of all resources. Thus, whichever resource – material, equipment, people – takes the longest determines the length of the planning horizon.

Time Fences

All departments must recognize in their SIOP process that changes in the plan are time-dependent; that is, the closer the change, the more costly or impossible it may become to make the changes in the plan. For every product family, there are “time fences” – guidelines that demarcate when changes are feasible. The fences reflect the realities of each business.

Sales, Inventory & Operations Planning as an Ongoing Process

A critical aspect of SIOP is that it not a one-time event during which production levels are established. For each Sales, Inventory & Operations Planning cycle, the key players from each department compare actual results to plan, evaluate their performance, and prepare updated plans for the current period.

Sales, Inventory & Operations Planning meetings should take place at least once per month. A month is usually a sufficient period of time to differentiate a trend from a minor variation or “blip,” but it is not so long that corrective action is no longer possible. Still, there are occasions when SIOP meetings must be held more frequently than once a month, depending on the nature of the company and the volatility of the marketplace. Companies that sell seasonal items, for example, might have to meet weekly prior to and during their peak selling periods.

Another cause for meeting more frequently or on a special basis is abnormal demand. When demand is suddenly noticeably higher or lower than normal, sales and marketing must decide if the demand represents real change or just a temporary anomaly. The key point is that decisions about how to handle abnormal situations must be made in a timely fashion at the appropriate management level.

Developing a proactive strategy that syncs up all divisions across a company enables flexibility and improves overall production. For help optimizing your Sales, Inventory & Operations Planning process, contact the company that was established over 50 years ago as Universal Scheduling Corporation (USC) and has been excelling clients’ processes ever since.

And to learn why inventory is the key to the whole process and why we identify it as SIOP and not S&OP, download our eBook below:

Maintaining a sustainable manufacturing facility is no ordinary task. At times, the difficulty of it can seem like a high-wire act. In fact, were manufacturing processes not primarily carried out within the confines of a warehouse, the Big Top would be a fitting replacement, as pulling it all together requires the balance of a trapeze artist or Cirque Du Soleil performer.

But accomplish it they do, and while the feat may not always be easy, it can be made simpler through sales and operations planning, or S&OP. What is S&OP? What are the steps involved and who are the actors that contribute to this all-hands-on-deck effort?

What is S&OP?

From a process standpoint, manufacturing is primarily composed of two elements: supply and demand. The goal is to produce at a rate that’s roughly in line with the rate at which a product or service is consumed. Sales and operations planning is designed to marry those factors so that they align with a business’ long-term strategic goals from a standpoint of profitability. The American Production and Inventory Control Society (APICS) puts sales and operations planning a bit more succinctly, describing it as “the function of setting the overall level of manufacturing output and other activities to best satisfy the current planned levels of sales.”

Furthermore, as APICS defines it, S&OP involves the recognition of general business objectives as they pertain to the supply chain, such as profitability, customer lead times, and inventory management. For instance, to diminish backlog, manufacturing facilities may seek to consolidate resources to produce more efficiently and reduce waste. S&OP lays out how this will take place and what steps are involved in the process.

While manufacturing facilities may deploy sales and operations planning for different business purposes or goals, each process is composed of a few central pillars. They include the following:

Gather data

To get a sense of how supply and demand are working relative to one another and are harmonious with your company’s objectives, you must have something to measure. That’s what the first step is all about. Whether it’s inventory, recent sales, or cash on hand, data is gathered and aggregated to identify trends and see how they align with corporate goals. It’s important that this data be as accurate as possible, as the process moving forward hinges on what the facts are on the shopfloor. In short, the outcome at the end largely depends on what information is available at the very beginning.

Assemble key stakeholders

“The data that’s compiled will largely dictate the stakeholders to assemble.”

Manufacturing companies are multilayered, involving personnel in many different divisions, such as fabrication, customer service, processing, delivery, quality control as well as research development. Since the goal of S&OP is ensuring supply and demand aligns with the company’s long-term goals, representatives from each division should be represented during S&OP meetings to interpret the data that’s complied. The data that’s compiled will largely dictate the stakeholders to assemble. The frequency of these meetings is also contingent on what’s being assessed, such as sales, production, development or customer satisfaction.

Examine demand

As its name implies, demand is the focus in this phase of S&OP. Virtually every aspect of demand is examined here. For example, questions may include how a particular product sold during a given period of time (e.g. monthly, quarterly, yearly), if the demand was in line with expectations or what actions may be needed to increase the desirability of a product if demand was weak.

Examine supply

Supply and demand are the ultimate pairing: Each is heavily contingent on the other. Here, supply issues are reviewed both as they currently exist, what happened previously and how it will look in the days ahead. For example, if demand were to improve, would the facility have the requisite needs to produce at a higher rate to avoid shortages? What will the costs be? What processes need to be honed to ensure efficiency? These are just a few of the questions asked in this portion of sales and operations planning.

Reconcile and assign

The last step in S&OP is putting it all together so the collective goal is put into motion. For example, if stakeholders need to be reassigned or new responsibilities are required, what that actually looks like is fleshed out in this phase. Additionally, if stakeholders have questions or issues, they would make mention of them so everyone is on the same page.

As the old saying goes, a failure to plan is a plan to fail. Sales and operations planning provides the roadmap for developing a harmonious strategy that can help you achieve success. Manufacturing involves many working parts. Depending on your company’s size, you may only interact with the individuals that are within your department. S&OP allows stakeholders from each unit to see how everyone else is doing so the appropriate modifications can be made. And at USC Consulting Group, we can help you make S&OP more than mere meetings, but productive meetings of the minds. Regardless of the challenge you face, we can offer strategic insight to help you reach your operational goals.

Please contact us to learn more and experience the USC Consulting Group difference.

Learn more about project management best practices.

Every organization with major assets has different initiatives or projects it wants to pursue such as shutdowns, turnarounds, outages or other large scale capital projects. However, managing all the details that go into those efforts — from team coordination to stakeholder communication — requires a dedicated strategy. Furthermore, avoiding schedule overrun and staying within or under budget is critical. That’s where project management comes in, which helps leaders better monitor, control and execute projects by emphasizing:

- An established scope of work and delivery schedule.

- Different methodologies for different projects.

- Progress tracking and win sharing.

Want to learn more? Download our eBook “Getting Down to Business: The Essentials of Project Management.”

Planning an upcoming project? Contact us today to speak with our subject matter experts about your initiative.

Supply Chain Management encompasses many facets from acquiring raw materials to delivering to the consumer and each component is as important as the next in the process. When looking to optimize your operations you must take into consideration the entire supply chain.

So how do we end the disruptions and take on such a massive undertaking? Start at the front end with planning and scheduling, inventory management, and strategic sourcing. These stages in the process set up the foundation for an optimized system.

Next, the focus shifts to the manufacturing of products and how to increase throughput while reducing costs and maximizing yield. Utilize real-time data analysis and reporting tools to improve productivity and enhance maintenance programs.

From there, identify the most cost-effective distribution and logistics options to further enhance your supply chain management.

Optimization is in sight, but many may encounter stumbling blocks that require outside expertise and a fresh perspective. Here at USC Consulting Group, we’ve been working with organizations across numerous industries for 50 years, helping them transform their operations and optimize their supply chain.

To learn more about how USC Consulting Group can improve your supply chain operations, contact us today.