-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2025 (1)

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Maintenance

Poor asset management can result in significant financial losses beyond the cost of replacement, with reputational damage, compromised data, and operational disruption a few of many risks involved. Effective asset management, on the other hand, is essential for businesses across industries, with advantages that include increased productivity, elevated asset utilization, and minimal downtime, The Enterprise World highlights. For organizations that aim to enhance their asset management process, the perfect balance of key strategies is a must — especially when the goal is to better manage the return and disposal of physical assets.

Preventative maintenance as a front line defense

For companies that manage assets like physical tech equipment, a strategy that focuses on maintenance is essential in order to maintain assets that are in optimal working condition at all times. Further advantages include asset longevity, reduced maintenance costs over time, and greater operational efficiency. Due to the value that preventative maintenance can bring, businesses must consider the strategy as a valuable front line defense in an asset’s life cycle.

While manual, routine inspections are crucial to an effective asset maintenance strategy, technology now plays an indisputable role in predictive maintenance and asset management as a whole. Artificial intelligence (AI) is just one technology that is gaining traction in asset management. For example, AI algorithms can process large amounts of data in order to predict maintenance issues and generate optimal schedules for maintenance — all the while factoring in an asset’s previous maintenance data. This can prove to be particularly beneficial for organizations that possess a significant number of assets (such as many laptop computers). When combined with efforts like manual asset tracking, businesses can rest easy in knowing that everything is accounted for, in good condition, and up-to-date on routine maintenance.

A streamlined return process

Effective equipment tracking is essential for any business with physical assets. Today, equipment management endeavors go well beyond a simple spreadsheet, and will typically involve the combined use of both physical tracking options (like barcodes or equipment tags). Software is another essential element, as asset management software provides a deeper look into the valuable details associated with physical assets. This technology will not only provide an overview of the assets that a business has, but details in regard to maintenance history and location (to highlight a couple of insights).

Businesses that have a well-defined asset tracking approach can easily overlook the complex nature of certain parts of the asset management process. For example, the return process can often involve several kinks along the way, such as employees that fail to send back company equipment, or inefficient shipping which can result in untimely delays. As such, effective equipment tracking does extend to a successful equipment return process. This is especially crucial for companies that routinely ‘loan out’ technology to their employees — a lost laptop is just one asset that can create a ripple effect for a business. In addition to lost productivity and the cost of replacement, the company may also have to shoulder the cost associated with a data breach, a factor that further underlines the importance of an effective return process. In addition to clear instructions, it’s essential that a business has a strategy in place to streamline the return. In addition to a trustworthy equipment management system and staying on top of paperwork (such as custom fees, etc.), aspects like consistent tracking updates throughout the shipping process can make a major difference.

Asset disposal can be a sustainable process

The integration of technology can elevate an asset management strategy by enabling businesses to continuously optimize maintenance schedules and elevate the return process. In turn, companies can minimize the downtime of assets, and benefit from equipment that will go the mile. When assets are truly no longer useful, however, businesses must abide by an effective disposal strategy. In many cases, there are sustainable approaches that can underline further advantages, such as environmental benefits or supporting the local community.

In some cases, a business may wish to donate old equipment (like computers, printers, etc.) to schools in order to support the local community. Businesses may wish to explore other options as well, such as the ability to refurbish and sell their equipment. Recycling old tech is another solution, and can be a sustainable option for equipment that is truly at the end of its life cycle. Before old tech leaves the hands of a business, however, it’s crucial to gain a full understanding of the laws, regulations, and the additional considerations that are involved. For example, businesses that wish to recycle their tech will need to comply with e-waste disposal laws. Other tasks are equally as necessary, such as a thorough asset inventory, the proper and secure destruction of any sensitive information (including GDPR compliance where applicable). Enlisting the help of a certified and professional Information Technology Asset Disposition (ITAD) provider can be a great option that can help guide a business through the process.

Poor management of physical assets brings to light a number of stark consequences for a business, from unnecessary financial losses to lessened efficiency overall. A balance between technology driven solutions and smart considerations, however, can make for an elevated management process even where asset return and disposal are concerned.

*This article is written by Lottie Westfield. Lottie spent more than a decade working in quality management in the automotive sector before taking a step back to start a family. She has since reconnected with her first love of writing and enjoys contributing to a range of publications, both print and online.

Over the next five years, mining and metals companies are expected to spend between $25 billion to $30 billion annually to maintain their assets.

Largely driven by efforts to improve operational efficiency, reduce downtime, immediately reduce costs, meet sustainability goals, and manage operational risks in an increasingly volatile market, mining and metals executives are motivated to start their asset management transformation now. Delaying this transformation could result in lost competitive advantages, higher operational costs, and increased regulatory or market pressures.

Over the next five years, the mining and metals industry is projected to invest heavily in the maintenance of fixed and mobile assets. Various reports indicate that the industry is expected to allocate a significant portion of its CAPEX to maintaining and upgrading its assets. A substantial part of this investment will be directed toward maintaining critical assets required to meet global demand for minerals essential for the energy transition. In a recent survey conducted by Global Data, 48% of the companies surveyed indicated they plan to increase investments in technologies like AI and IoT sensors for equipment upkeep over the next two years.

Investment in predictive maintenance is becoming a top priority for many mining operations. Companies are leveraging their EAM’s with advancing technologies like Digital Twins, AI and IoT, along with other reliability and planning applications, and significantly transforming asset management and the asset lifecycle. These advancements in technology are expected to reduce maintenance costs by 20-30%.

Mining and metals companies integrating Enterprise Asset Management (EAM), Computerized Maintenance Management Systems (CMMS), AI, and IoT are experiencing several quantifiable benefits, including:

- Improved Asset Reliability and Uptime: Utilizing a combination of AI, IoT sensors and Digital Twins provides continuous real-time monitoring of equipment health allowing companies to predict potential failures before they occur while reducing the reliance on reactive and scheduled maintenance – reducing unplanned downtime and fewer equipment breakdowns, increasing equipment availability and extending asset lifecycles.

- Cost Reduction: A predictive maintenance capability helps avoid costly emergency repairs and reduces unnecessary scheduled maintenance, saving on labor and spare parts. It also ensures that the right parts are available when needed, minimizing overstock and understock issues, which helps reduce capital expenditure tied to inventory. It optimizes the energy usage of equipment by adjusting operational parameters in real-time, leading to lower energy consumption.

- Scalability and Flexibility: Leveraging these technologies together, allows companies to scale their asset management strategies as they grow, adapting to changes in operational needs without significant disruptions. Maintenance scheduling based on asset condition rather than time-based intervals, ensures that resources are used effectively, reducing downtime and improving workflow efficiency. They provide a holistic view of all assets, enabling better coordination between teams while improving “wrench-time” productivity and the execution of maintenance and operational tasks. It delivers a single platform to access real-time data across the entire asset portfolio, improving visibility and control over operations for optimizing performance and recommendations for future operations.

USC partners with your organization and coaches your people to significantly impact performance outcomes and accelerate Operational Excellence

USC brings a tailored, structured, and disciplined methodology, along with a range of tools and techniques we apply collaboratively with client’s personnel. Whatever your challenge, we are the people who work with our clients to find full potential and unlock the hidden value.

USC help to identify waste, redundancies, and ineffective processes, and then rapidly recover the prioritized opportunities, and convert them to improvements in performance and operating profit. Further, our people embed with client teams to develop, enhance, prototype, validate and implement asset management strategies to drive, sustain and perpetuate improvements in asset lifecycles and equipment reliability, while changing how plans, schedules, and work is executed. In short, USC implements measurable, sustainable changes that drive asset performance and financial improvements.

- Increased Wrench Time (up to 25% improvement) – Reducing non-productive time through improved work-order generation and prioritization, maintenance teams spend less time searching for work-orders, tracking down parts or waiting for approvals.

- Reduction in Travel & Downtime (up to 20% time savings) – Optimizing the routing and scheduling of maintenance tasks and reducing travel time between jobs to maximize “time on tools”.

- Faster Work-order Completion (up to 30% efficiency gains) – Reducing delays in task assignment, approval and completion tracking, technicians can move quickly from one job to the next by ensuring all the necessary tools and parts are available at the work site, eliminating delays caused by missing resources.

- Optimized Spare Parts Management (up to 15% time reduction) – Faster access to parts and accurate spare part forecasting reduce time on sourcing, stocking and searching while ensuring tools & parts are available for tasks.

- Better Data-Driven Decision Making (up to 20% longer asset life spans) – Collecting and analyzing needed information provides actionable insights that support planning and allow for more informed and pro-active decision making, often delaying the need for capital-intensive replacements.

USC clients experience measurable operational and financial results that significantly improve both the efficiency and profitability of their operations. Benefits delivered may include a 10-20% increase in overall equipment availability due to reduced unplanned downtime and optimized maintenance schedules and a 10-15% improvement in equipment utilization as predictive maintenance reduces the time equipment is out of service.

USC Helps You Tackle Key Challenges

- Optimize maintenance strategies and increase equipment availability operational output

- Predict asset integrity and reliability needs and improve time on tools

- Mitigate risks through stronger stakeholder partnerships, while removing redundancies in the supply chain

- Overcoming cultural and communication issues with contractors, while ensuring quality expectations

Do you want to understand how prepared your company is to drive needed asset management performance and reliability improvements and what the key focus areas that will contribute to lower operating costs? Contact us today.

The world is increasingly focused on sustainability, and the manufacturing sector is no exception. Consumers are demanding eco-friendly practices, and regulations are evolving to reflect this shift. This presents a compelling opportunity for manufacturers – by incorporating sustainability principles into the design of their machines, they can not only benefit the environment but also reap significant economic rewards.

The Benefits of Green Design

Sustainable manufacturing machine design offers a win-win scenario for businesses. By focusing on resource conservation and energy efficiency, manufacturers can significantly reduce their environmental footprint. This translates into a positive impact on the planet, aligning them with global sustainability goals. Additionally, sustainable design principles can lead to cost savings through minimized waste generation and lower energy consumption.

Beyond environmental and economic benefits, sustainable machine design can also enhance a company’s reputation. Customers today are increasingly conscious of eco-friendly practices, and a commitment to sustainability can be a major selling point. Furthermore, adhering to evolving environmental regulations becomes easier when sustainability is embedded into the design process from the very beginning.

Implementing Sustainable Design Principles

So, how can manufacturers translate these principles into action? A crucial step is integrating a life cycle assessment into the design process. This involves evaluating the environmental impact of the machine throughout its entire lifespan, from raw material extraction to disposal. This holistic approach allows engineers to make informed decisions about materials, manufacturing processes, and even end-of-life options.

Technology also plays a vital role in sustainable design. Advanced software tools like computer-aided design (CAD) can help engineers optimize both functionality and aesthetics, minimizing material usage and ensuring efficient operation. Additionally, simplifying design complexity can further reduce the environmental impact. Removing unnecessary components not only streamlines assembly but also minimizes energy loss during operation.

Material selection is another critical aspect of sustainable design. Opting for materials with lower embodied energy (the energy required to extract, process, and transport them) and those that can be easily recycled or reused can significantly reduce the environmental burden. For instance, utilizing high-efficiency, NEMA gearboxes, can not only improve overall system efficiency but also extend the lifespan of the equipment, reducing the need for premature replacements.

Safety plays a vital role not only for workers but also for the environment. Conducting thorough safety audits throughout the design process ensures the equipment operates safely and efficiently, minimizing the risk of accidents that could lead to environmental damage. Furthermore, integrating smart technologies like real-time energy monitoring and predictive maintenance systems empowers manufacturers to identify and address potential issues before they escalate into bigger problems.

Curious about the specific ways sustainable design can improve a machine’s environmental impact? The following infographic dives deeper into the benefits of sustainable manufacturing machine design, showcasing how each principle contributes to a greener future for the industry. By adopting these sustainable design principles, manufacturers can create machines that are not only efficient and productive but also environmentally responsible.

Downtime – the dreaded halt in production that can cripple a manufacturing operation. It’s more than just an inconvenience; it’s a hidden cost that can eat away at your profits. A recent study revealed that nearly 82% of businesses have experienced unexpected downtime in the past three years, with the average incident lasting four hours and costing a staggering $2 million. The impact goes beyond just financial losses – downtime can disrupt customer deliveries, delay critical projects, and erode trust with clients.

The Potential Culprits

One major factor is neglecting preventive maintenance. Regular servicing not only keeps equipment functioning smoothly but also allows technicians to identify potential problems before they snowball into major breakdowns.

Another hidden source is outdated equipment. Obsolete machinery can be a drag on your entire production line. Imagine a slow, malfunctioning piece of equipment holding up the entire process. This can put undue stress on other machines, leading to premature wear and tear, and ultimately, more downtime. Upgrading to newer, more efficient models can significantly improve production flow and reduce the risk of breakdowns. Outdated software can also be a culprit. Running outdated software can lead to compatibility issues with newer systems and leave your facility vulnerable to security breaches.

Beyond equipment and software, a lack of proper training for your workforce can also contribute to downtime. If operators don’t fully understand how a machine works, they might misuse it, leading to errors and breakdowns. Investing in comprehensive training empowers your employees with the knowledge and skills they need to operate machinery safely and efficiently, minimizing the risk of operator-induced downtime.

Finally, the importance of data tracking cannot be overstated. Keeping detailed logs of equipment issues and production hiccups allows you to identify recurring problems and implement preventative measures. Think of it as a historical record that helps you anticipate and address potential bottlenecks before they derail your production schedule.

Finding the Right Solution for You

The good news is that there are steps you can take to combat downtime and keep your production lines humming. Conducting risk audits to identify potential problems, installing sensors to monitor equipment health (like a torque transducer that detects excessive force on a rotating shaft), and implementing a comprehensive preventive maintenance program are all crucial steps in the battle against downtime.

Investing in employee training and partnering with reliable third-party service providers can further strengthen your defenses. By adopting a proactive approach to maintenance and addressing the root causes of downtime, you can significantly reduce disruptions and ensure your manufacturing operation runs smoothly and efficiently.

Want to learn more about the specific costs associated with different downtime causes? The following infographic breaks down the financial impact of various downtime triggers, helping you identify areas for improvement and optimize your production process for maximum uptime.

Mining and metals companies are implementing a range of strategies to enhance asset management and equipment reliability.

In today’s market, many senior executives leading natural resource companies hesitate in making additional capital investment and instead focus on what can be done to squeeze higher performance out of current assets. Consequently, companies are increasingly looking for ways to improve performance and returns with existing infrastructure.

The key approach to this challenge lies in upgrading and improving asset management capabilities. Many organizations have failed to deploy optimal asset management practices. This is surprising given that asset spend frequently represents 30% to 50% of the overall operating expenses. Shifting to a best-in-class asset management program will consistently deliver improved plant or equipment performance, lower operating costs, extend asset life, and generate a higher return on capital. Most recently, companies have sought to implement a range of strategies such as:

- Implementing Asset Management Systems: Utilizing robust asset management systems to track equipment performance, maintenance history, and lifecycle costs, allowing for better decision-making regarding repairs, replacements, and upgrades. Digital technologies like IoT sensors, AI-driven analytics, and automation further optimize asset management.

- Enhancing Maintenance Practices: Implementing proactive maintenance strategies like conditioned-based monitoring and reliability-centered maintenance to address issues before they cause failures. Utilizing data-driven insights, mining companies can optimize “time on tools” by identifying patterns and trends in equipment usage, maintenance needs, and performance. This allows for more precise scheduling of maintenance tasks, reducing downtime and maximizing the time equipment is operational.

- Investing in Training: Providing comprehensive training programs for front-line management, maintenance and operations personnel to ensure equipment is used and serviced properly, reducing the likelihood of breakdowns due to human error and that access to equipment is available. Training personnel to utilize data-driven insights enables management to make informed decisions impacting “time on tools” and leading to improved equipment utilization and overall operational performance.

- Improving Supply Chain Management: Ensuring timely access to quality spare parts and materials to minimize downtime caused by equipment breakdowns and repairs. Some are adopting blockchain for transparent supply chain management and better tracking of assets throughout their lifecycle.

The level of performance improvement companies can realize by implementing key strategies such as enhancing proactive maintenance practices, investing in training to improve skills and capabilities, improving supply chain management, and leveraging digital technologies and data-driven insights varies depending upon factors like current operational efficiency, the scale of implementation, and industry conditions. However, many can expect significant improvements in:

- Safety: Proper training programs and proactive maintenance strategies contribute to a safe work environment by reducing risk of accidents and equipment failures.

- Productivity: Proactive maintenance and digital technologies can reduce downtime, increase equipment availability, and optimize process execution, leading to higher productivity levels.

- Cost Reduction: Efficient equipment usage and maintenance practices can lower operational costs by minimizing unplanned downtime, reducing repair and replacement expenses, and optimizing resource utilization.

- Quality: Improving the essential management skills and work place practices result improve the quality of maintenance execution.

Overall, these strategies can result in substantial performance improvements, enhancing competitiveness and profitability for mining and metals companies.

USC Consulting Group partners with your organization and coaches your people to significantly impact performance outcomes and accelerate Asset Management and Reliability Excellence.

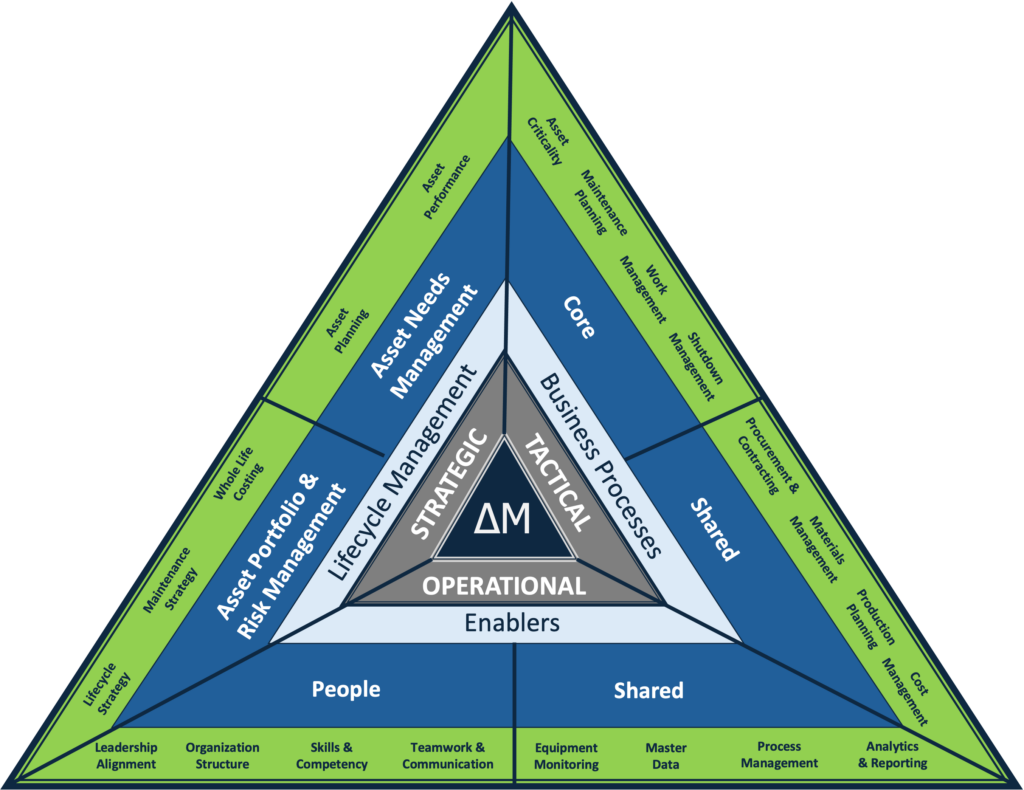

USC’s experience helping clients to shift asset performance by transforming and optimizing asset management capabilities and processes has repeatedly demonstrated the need to focus on the key levers and enablers to asset management and reliability excellence. Our asset management framework is designed to be pragmatic rather than conceptual, thereby leading to accurate, practical decisions about a client’s assets and aspirational outcomes.

The primary goal of USC’s asset management framework is to help our clients to implement and execute of a robust set of integrated processes and tools to manage and maintain their operational assets at the targeted service levels while optimizing life-cycle costs and asset life. This is accomplished by recognizing the needs to:

- Improve safe execution of work

- Increase asset life and reliability

- Improve productivity and cost performance

- Improve operational predictability

- Control material asset risks

- Develop competitive advantage

Our asset management and reliability framework helps clients identify an organization’s asset management maturity level and the areas and gaps that need to be addressed, by evaluating their strategic, tactical and operational levers and the enablers that comprise each.

Strategic (Lifecycle Management): A tailored maintenance program for each piece of equipment translates overall strategic objectives into executable plans for equipment upkeep. Our framework helps to structure and prioritize critical assets while defining a baseline operational ‘plan of action’ by determining strategies for maintaining equipment based on analysis of equipment capabilities, required performance levels, failure frequencies, and cost objectives. Optimal maintenance strategies are frequently a blend of preventative, predictive, operator-maintained, and run-to-fail options.

Tactical (Business Processes): Business processes bridge the gaps between the initial, ideal plan and the reality of ‘day-to-day’ operations, so the maintenance and reliability organization can make adjustments. Historically, many maintenance organizations have been poor utilizers of labor resources that result in low “time on tools” and excessive delays in repairing down or poor performing equipment.

Operational (Enablers): Enablers help to identify needed support to manage assets throughout their lifecycle in alignment with organizational aspirations. Leading asset management teams have also made changes in their organization structures and management practices to foster more action-oriented leadership that focuses on operational excellence, which usually requires a culture shift that must be relentlessly supported by the leadership team over the long-term. A heavy emphasis on management behaviors and company culture can help organizations make this difficult transition.

USC Helps You Tackle Key Challenges

- Optimize maintenance strategies and increase equipment availability operational output

- Predict asset integrity and reliability needs and improve time on tools

- Mitigate risks through stronger stakeholder partnerships, while removing redundancies in the supply chain

- Overcoming cultural and communication issues with contractors, while ensuring quality expectations

Do you want to understand how prepared your company is to drive needed asset performance and reliability improvements and what the key focus areas that will contribute to lower operating costs?

Want to find out more about how USC can help you uncover the hidden value lurking in asset portfolio?

For more information, let’s talk it through with a no obligation video conference call or a meeting with one of our executive team. Email info@usccg.com to arrange a call.

The energy and utilities industry is in the midst of change.

Businesses are facing pressure from the government and consumers alike for more renewable energy while also balancing that with grid reliability and traditional energy sources. Meanwhile, electricity demands are expected to skyrocket. Other wild cards are supply chain disruption, labor shortages and more.

But within those challenges, we always see opportunities. Let’s take a closer look into the outlook for energy.

Continued focus on renewables. The demand for clean energy will continue to rise. Governmental regulations are mandating the focus on clean energy and decarbonization, including enacting green-friendly legislation and incentives for companies to transition to cleaner sources like solar and wind. The industry made great strides in solar power and the energy storage it necessitates in 2023, but more is needed and the focus will continue in 2024 and beyond. Consumers are demanding it as well, with climate change among people’s top concerns. All of it has led many companies to push the timeline to cut carbon emissions by 80% from 2050 up to 2030.

Energy storage. The push for solar requires an enormous amount of battery storage capacity to, in very simple terms, store all of that energy for times when the sun’s not shining. It means innovation in battery technology, and 2023 saw much of that, with storage capability doubling in 2023 and set to nearly double again in 2024.

Electricity surge. According to industry sources, the demand for electricity is expected to triple by 2050. It means planning now for this increased load on what is likely aging infrastructure, resulting in costs to shore up that infrastructure to ensure grid reliability. It’s also necessary to consider expanding the grid to meet that demand.

Aging grids + extreme climate. We all saw the worst-case scenario play out in Texas when their grid failed when the state experienced a rare deep freeze. But weather extremes are becoming the norm, with heat, wildfires and drought on the one hand, floods and record snowfall on the other. The industry is modernizing the grid, and made progress in that area in 2023, but reliability is still a large concern.

Supply chain uncertainty. The recent geopolitical unrest in Ukraine and the Middle East has underscored the need to reshore this nation’s oil supply.

Labor shortages. Like many industries today, energy is battling a labor shortage and facing the double whammy of their most experienced workers retiring and taking institutional knowledge with them, and having too few younger people in the pipeline to pick up where they left off.

It’s a full plate for the energy sector in the coming years, that’s clear. But within these challenges, we see opportunities to bolster processes, making operations more efficient and guard against supply chain snafus. Reducing operating costs, improving productivity and increasing efficiency will help the industry navigate these challenging times.

This is where USC can help

Management Operating Systems. A solid Management Operating System is a must for efficiency, time savings, employee productivity and so much more. For a real-world example on how USC helped an energy producer save time and money by implementing an MOS, read “Energy Producer Generates Savings with Smarter Labor Practices.”

Reskilling employees. All of this innovation and growth in renewables, not to mention AI entering the mix, requires more workers with new skills. This can be very good news for your current employees, who can move up the food chain with new training, and the ability to attract highly qualified workers.

Resource planning. If you know anything about our company, you know we are great proponents of SIOP – Supply, Inventory and Operations Planning. It gives companies a roadmap to the future, so they’re not reacting to events, they’re anticipating them. With the exponential growth of the energy and utilities sector in the coming years, solid planning for the resources needed for that growth, like increased storage capacity and grid strength, is a must.

Bottom line, delivering reliable, affordable and sustainable energy is the goal for the energy and utility industry. It takes efficient operations, a handle on resources, and a clear eye toward the future. Contact us today to find out more about how USC Consulting Group can help.

Have you heard of a High Reliability Organization? The concept has been out there for several decades but it’s taking center stage again now. Let’s delve into what a High Reliability Organization is, why this concept is coming to the forefront again, and whether you should explore implementing the principles in your own organization.

Simply put, a High Reliability Organization (HRO) is a company that has a solid operating system of execution in place that emphasizes safety and strives to minimize risk across the business.

We’re talking about complex or hazardous industries like nuclear power, the Navy and other branches of the military, air traffic controllers and the mining industry.

The idea behind HRO is a basic one. Expect the unexpected. An HRO creates a number of operational systems and ways of working that promote consistency and keep the focus on achieving company goals while avoiding major errors. These systems not only make the HRO more nimble, responsive and functional than a non-HRO competitor, but they also deliver more efficiency and most importantly, safety.

Why being an HRO is vital today

The concept of HROs has long been a method of ensuring safety in hazardous industries, but it’s becoming more relevant today in mining and other industries because of a perfect storm of circumstances. The marketplace is changing dynamically. Shifting sands don’t exactly make for solid foundations. A few things happening now:

Natural disasters. We seem to be in a period of increased earthquakes, “storms of the century,” droughts, volcanic eruptions and more. It makes facilities vulnerable to disruption.

Cyber attacks. Another vulnerability. As the industry gets more dependent on technology, the vulnerability to hacking of control systems ratchets up.

Boomer retirements. The impact of this can’t be overstated. Baby Boomers make up nearly a third of the entire U.S. workforce. The U.S. Census Bureau projects that 4.4 million people will turn 65 (retirement age) every year from now through 2027. During the period from 2022 to 2030, 75 million Americans are expected to retire. Called the Silver Tsunami or the Great Retirement, it is the largest surge of retirement age Americans in history.

Loss of institutional knowledge. Those retiring Boomers represent your most experienced, knowledgeable workers. These are the people who have gotten the job done, and done safely, for decades. All of that know-how will walk out the door with them.

Lack of skilled workers. It’s a real problem for many industries, including mining. Talent acquisition and training is on the top of the list of concerns for mining CEOs, because when those Boomers retire, the mining industry needs skilled, experienced people to keep the operation moving.

Doing more with less. In this economy, it is incumbent on companies to do more with less, cut costs, trim staff and extend the lifecycle of equipment while also investing in AI.

All of these things are coalescing into a situation in which the mining industry is experiencing a great potential for increased risk. It’s easy to see why. Experienced people retiring en masse, less experienced people taking up the mantle but not having that deep institutional knowledge you just can’t get in a training course, and the need for constant cost cutting – it all adds up to risk.

And when you’re talking about operations in a mine, risk doesn’t just mean business disruption. It means people’s lives.

HRO core principles

It’s about more than just focusing more on safety. The core principles of HROs, specifically in the mining industry, include:

Preoccupation with failure. It’s vital to anticipate the potential for failure and put measures in place to stop a problem before it starts. Emergency response training, regular equipment inspections and maintenance, failsafe protocols. The goal here is to be ready to spring into action, to have that training kick in, when a potentially disastrous situation arises.

Sensitivity to operations. Everyone’s eyes need to be open, all the time. Much like the “see something, say something” campaign at airports, it means developing a culture of awareness among workers on the front lines and in the front office. Identifying processes and ways of working that can be optimized; or potential issues or risks that could lead to disruption in the future.

Resilience. The ability to roll with the punches. Redundancies need to be built in. Clear protocols for disruptions or sudden change responses need to be automatic.

Shared understandings. Everyone in the organization needs a shared understanding of HRO principles, the role they themselves play, and are operating with the same road map.

Respect hard-earned expertise. Those Boomers who are retiring? They know how to get the job done. They’re carrying your organization’s institutional knowledge – the part of the job that can’t be taught in a training class. This knowledge needs to be respected, especially when decisions get made.

Why being an HRO matters

Why should mines focus on high reliability? Here are a few of the benefits.

Safety. Since the first canary went down a coal mine, this industry has been implementing safety protocols. It can be dangerous for people working in a mine, period. Anticipating risks and putting safety protocols in place will save lives and reduce accidents and injuries.

Efficiency. The focus on asset management minimizes unscheduled downtime and process disruptions, while getting everyone on the same page streamlines operations. It all works together to increase efficiency.

Equipment lifespan. One of the challenges today is doing more with less, and that means keeping aging equipment on the job. The regular maintenance and inspection of equipment adds to its lifespan.

Hiring and retention. That lack of skilled workers? It’s causing stiff competition for the skilled workers who are out there. Being a High Reliability Organization shows new recruits that you’re committed to safety, value their contributions and knowledge. In short, it’s a powerful recruiting tool.

How USC can help: Anticipate the Unexpected

One of the most vital components of transforming into an HRO is the integration of a solid Management Operating System that breaks down siloes between areas of the organization like engineering, maintenance, procurement and operations.

The end goal: Constantly anticipating the unexpected and executing in a consistent manner.

When USC begins the process, we start with an assessment of current operations. Then we do a deep dive. Some, but by no means all, of the areas we focus on:

Identify operational disconnects. Is everyone on the same page to execute the plan? Are priorities between departments aligned? Has production prepared access to equipment to be maintained? Are shift managers setting work expectations in the same way? How are variances to the plan addressed?

Close the gaps. This is about breaking down silos and getting everyone looking in the same direction, working in the same way, and managing departmental operations with a common vision.

Build in buy in. Like many projects that require change at all levels of the organization, this requires buy in from the corner office to the depths of the mine. In many instances, this requires a culture change, with people being used to doing the job one way now asked to shift their operations.

Make it transparent. Change can’t be foisted on people in a vacuum. The new initiative on transforming into an HRO should be a full team effort, with full transparency from the top.

Implement measures and metrics. It’s also important to implement accurate measurements and targets. Still, one assessment rises above all others: addressing overall organizational health. Organizational health is the softer side of the business that is frequently dismissed because it is often viewed as both difficult to revamp and even more difficult to measure.

HRO Checklist

Do you need to focus on High Reliability Organization? Here’s a quick checklist to help you decide.

- Do you have an organization-wide sense of susceptibility to the unexpected?

- Does everyone feel accountable for organizational reliability?

- Are your leaders paying as much attention to managing unexpected events as they are to achieving formal organization goals?

- Do people at all levels of your organization value quality?

- Have you identified how your activities could potentially harm your organization, employees, other stakeholders and the environment at large?

- Do you pay attention to when and why your employees or other stakeholders might feel angry or disenfranchised?

- Do you have widespread agreement among the organization’s members on what shouldn’t go wrong?

Transforming into a High Reliability Organization doesn’t happen overnight, and many challenges exist in the process. It requires a cultural shift, training for both workers and management, investing in protocols, and commitment from the top.

But, in today’s volatile world, it’s a solid framework the mining industry can use to ramp up safety, increase efficiency, minimize risks and anticipate the unexpected. For help setting up your HRO, contact USC Consulting Group today.

In the dynamic realm of industrial operations, downtime is the arch-nemesis of productivity and profitability. Every minute lost to equipment breakdowns or maintenance activities translates into potential revenue losses, increased operating costs, and compromised competitiveness. Amidst this relentless pursuit of operational efficiency, the emergence of low or no maintenance industrial machinery heralds a transformative era for industries worldwide.

High maintenance equipment has long been a staple in industrial settings, requiring regular servicing, lubrication, and part replacements to ensure optimal performance. However, the inherent drawbacks of such machinery, including frequent downtime, escalating maintenance costs, and operational disruptions, have spurred a quest for alternative solutions.

Enter low or no maintenance industrial machinery—an innovation poised to revolutionize the industrial landscape. Engineered with durability, reliability, and longevity in mind, these advanced systems promise to mitigate the adverse effects of downtime and high maintenance requirements, ushering in a new era of seamless operations and cost savings.

The detrimental effects of downtime on industrial productivity cannot be overstated. Whether due to unexpected breakdowns or scheduled maintenance activities, every moment of idle machinery translates into lost production opportunities and diminished output. Moreover, the ripple effects of downtime extend beyond immediate financial implications, impacting supply chain dynamics, customer satisfaction, and overall business resilience.

In contrast, low or no maintenance components, equipment, and machinery offer a beacon of hope for industries grappling with the specter of downtime. By incorporating self-lubricating mechanisms, wear-resistant materials, and advanced monitoring technologies, these innovative solutions minimize the need for frequent maintenance interventions and extend operational uptime.

The benefits of adopting low or no maintenance industrial machinery are manifold. Beyond the immediate gains in productivity and cost savings, these systems promote a culture of efficiency, sustainability, and resilience within industrial ecosystems. By reducing reliance on traditional maintenance practices, industries can reallocate resources towards value-added endeavors, enhance worker safety, and contribute to environmental stewardship efforts.

In this infographic from FLEXIM, we delve into the profound impacts of downtime and high maintenance equipment on industrial operations, while illuminating the transformative potential of low or no maintenance machinery. Through compelling visuals and insightful analyses, we aim to empower industries with the knowledge and tools needed to navigate the evolving landscape of industrial maintenance and usher in a new era of efficiency and prosperity.

To learn more about best practices for asset management and reducing downtime, contact us to connect with our subject matter experts.

The automotive industry is driving automation by having the largest number of robots working in factories around the world — operational stock hit a new record of about one million units, according to the International Federation of Robotics (IFR). With the prevalence of automation rising in the automotive industry, the benefits associated with its use in manufacturing cannot be understated. With advantages that work to bring productivity and efficiency all around, advancements in technology such as the integration of artificial intelligence underline the many innovative applications to come.

Exploring the current advantages of automation

“The automotive industry effectively invented automated manufacturing,” notes Marina Bill, the President of the IFR. “Today, robots are playing a vital role in enabling this industry’s transition from combustion engines to electric power. Robotic automation helps car manufacturers manage the wholesale changes to long-established manufacturing methods and technologies.” The IFR goes on to highlight the recent density of robots in the automotive industry — in the Republic of Korea, 2,867 industrial robots per 10,000 employees were in operation in 2021, while Germany had 1,500 units followed by the United States with 1,457 units.

Automation plays a variety of roles in automotive manufacturing, including taking on tasks such as screw driving, windshield installation, and wheel mounting. Automate highlights one example of a valuable role that automation plays in the manufacturing process, via an automated vehicle floor plug insertion system developed by FANUC for General Motors. As a result, the system effectively helps relieve workers from “the ergonomic strain of the manual process and improves production time.” Apart from assembly, Robotics and Automation News notes additional uses for automation in manufacturing include car painting, welding, polishing and material removal, and quality inspection. Regarding the benefits, automation in automotive manufacturing is known to have a wide variety of advantages that heighten productivity in immense ways — including lowering costs, improving accuracy and safety, and amping up efficiency.

Increasing automation highlights a productive future

According to CBT News, automakers are “likely to introduce more robots and other forms of automation over time.” Currently, CBT notes that many robots on production lines are called ‘cobots,’ as they work alongside workers in order to complete tasks that are physically demanding or more challenging to do — Ford, for example, has “at least 100 of these cobots across two dozen of their plants around the world.” Automakers are already planning for increased automation in the future in order to achieve various goals. Tesla is a pioneer regarding factory automation and robots; Elon Musk, for example, has said that introducing more automated equipment at Tesla as part of a goal to cut the costs of making future models by 50%, according to CBT News.

To further underline the presence of automation in auto manufacturing, a 2021 article from The Korea Economic Daily Global Edition highlights the use of robots and artificial intelligence (AI) by Kia Corp., South Korea’s second-largest automaker. According to the article, the company had released a video “showing a highly automated production line of the all-electric mid-size crossover utility vehicle (CUV) at a smart factory powered by artificial intelligence and robot technology.” Crossovers have risen in popularity in the US, with the vehicle featuring an SUV-style body based on a car (rather than a truck platform), therefore using unit-body construction. Today’s crossovers offer a variety of features, with top-rated crossovers offering those such as a spacious interior and a smooth engine.

Innovation foreshadows advancements to come

In addition to simply expanding automation efforts throughout auto manufacturing, ‘smart manufacturing’ employs technology in addition to automation. Also called Industry 4.0, RT Insights notes that data-driven decision-making and predictive maintenance are just the beginning of the advantages associated with smart manufacturing, with benefits extending to areas such as energy efficiency and supply chain optimization. “The resulting factors of having a smart manufacturing set-up are efficiency, production optimization, trackability, quick turnaround during downtime, safer working conditions, and responsible manufacturing,” notes Mobility Outlook.

AI and machine learning (ML) are both components that are driving the future of smart manufacturing, with Mobility Outlook explaining that AI systems analyze data sets and historical records of Internet of Things (IoT) devices. As a result, AI can identify patterns and trends which would otherwise go unnoticed by workers. ML algorithms, on the other hand, can “learn from data, make predictions, and make suggestions to improve manufacturing processes.” Predictive maintenance can also make a major difference in the future of automotive manufacturing, with the analysis of data allowing for minimized repair costs and proactive maintenance. Furthermore, Mobility Outlook highlights the value of quality control systems powered by AI — with this technology, defects can be detected in real-time, allowing for waste reduction and improved product quality across the board.

Automation brings a variety of benefits to automotive manufacturing. While automakers are already making use of the technology, technological advancements like AI are driving the future of ‘smart manufacturing,’ effectively foreshadowing a range of advantages to come.

*This article is written by Lottie Westfield. Lottie spent more than a decade working in quality management in the automotive sector before taking a step back to start a family. She has since reconnected with her first love of writing and enjoys contributing to a range of publications, both print and online.