-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2025 (1)

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: KPIs

Industry standards serve as essential benchmarks, establishing a baseline for operational excellence and competitive differentiation. They guide organizations in implementing best practices, ensuring compliance, and maintaining quality. However, merely adhering to these standards is insufficient; businesses must translate them into actionable strategies with measurable goals to foster continuous improvement and drive growth. In fact, some goal-setting statistics indicate that setting challenging but achievable goals leads to 90% better performance.

Turning standards into strategies involves a systematic approach, where organizations identify specific objectives aligned with industry benchmarks. These objectives should be quantifiable, allowing for the monitoring of progress and outcomes. By doing this, your organization can track its performance, make informed decisions, and pivot when necessary.

Leveraging tools and frameworks is critical to effectively achieving these measurable goals. They provide a structured implementation methodology, including data collection, analytics, and performance tracking techniques. Utilizing these resources ensures your strategies are well-defined and adaptable, ultimately elevating operational practices and driving sustainable success.

Beyond Standard Operating Procedures: Going Further

While most businesses use standard operating procedures (SOPs) to ensure consistency and compliance within an organization, they are not enough to propel a company toward continuous improvement and innovation. SOPs outline how tasks should be performed; however, without measurable goals, your organization may lack defined targets for assessing performance and driving enhancement. Measurable goals create benchmarks that enable teams to identify areas for improvement and innovate beyond established practices.

Leadership plays a crucial role in this process. Leaders must establish clear, actionable goals that align with industry standards while inspiring their teams to embrace a culture of excellence. By setting these objectives, you can empower your staff to take ownership of their performance and contribute to the organization’s strategic vision.

Continuous feedback loops foster improvement, motivating teams to pursue innovative approaches to meet and exceed established benchmarks. Ultimately, bridging the gap between SOPs and measurable goals, guided by proactive leadership, can position your business for sustainable growth and adaptability in a dynamic marketplace.

Collaborative Tools for Defining and Achieving Goals

Online brainstorming tools are powerful platforms for teams to visualize and organize their goals effectively. These tools enable real-time collaboration, allowing team members to share ideas, feedback, and insights in an interactive space. This collective input fosters creativity and ensures that diverse perspectives are included when defining objectives.

Mind mapping is a specific technique within these tools that helps teams outline their goals visually, linking related ideas and priorities. By creating a graphical representation of thought processes, your team can identify connections between objectives, ensuring a cohesive understanding of strategic direction. This clarity promotes strategic alignment, making prioritizing tasks and allocating resources easier.

Collaborative brainstorming sessions further enhance this alignment by encouraging open dialogue among team members, leading to innovative solutions. As teams engage in structured discussions, they refine their goals, making them more measurable and actionable. The combination of mind mapping and collaborative brainstorming ultimately drives measurable results by providing a framework for continuous improvement and keeping everyone focused on shared objectives.

Tracking Progress: Measuring Success

Regularly tracking progress toward goals is crucial for ensuring alignment with business objectives and fostering a culture of accountability. It can allow your organization to identify successes, address challenges, and make informed decisions for continuous improvement.

Performance dashboards are powerful tools that provide real-time insights into key performance indicators (KPIs). They enable businesses to monitor their status against established goals. By visualizing metrics through dashboards, your team can quickly assess performance trends and take necessary action.

To maintain accountability, your organization should implement regular check-ins and performance reviews, fostering an environment of open communication among team members. Establishing clear KPIs that are specific, measurable, attainable, relevant, and time-bound (SMART) ensures that everyone understands their roles in achieving these milestones.

Performance data must guide decision-making when adjustments are needed. Encouraging your team to remain flexible and responsive can enhance adaptability, allowing businesses to pivot strategies based on real-time information. Overall, a structured approach to tracking progress and embracing a culture of transparency drives sustainable growth and success.

Conclusion: Driving Success with Strategy and Measurement

Transforming standards into strategic initiatives is essential for achieving sustainable success in today’s competitive landscape. By establishing clear, measurable goals, your business can enhance alignment, boost accountability, and foster continuous improvement. Leveraging tools like performance dashboards enables organizations to monitor progress in real time, while regular check-ins promote open communication and adaptability.

To thrive, your organization must prioritize implementing structured strategies that cultivate a culture of measurable success. We encourage businesses to take proactive steps: define your standards, develop actionable goals, and utilize performance tracking tools. Embrace transparency and adaptability as cornerstones of your operational framework.

Committing to this approach will elevate your business practices and empower your team to drive innovation and achieve extraordinary results. Start today and make measurable success a cornerstone of your strategy.

*This article is written by Ainsley Lawrence. View more of Ainsley’s articles here.

In a landscape that shifts with every digital innovation, understanding your customers in the present moment is more than a goal—it’s the foundation for impactful decision-making. Real-time insight into customer desires and preferences has the power to reshape how businesses engage, adapt, and deliver value. The result? A customer relationship that’s not only data-informed but deeply responsive, a differentiator in a competitive world. Real-time KPIs provide a clear path to these insights, creating a bridge between raw data and actionable, strategic change.

Start with a Real-Time Data Platform

A customer data platform that works in real time offers a wealth of benefits, allowing businesses to capture, analyze, and act on customer information as interactions happen. This approach supports more accurate segmentation and enables immediate adjustments to marketing strategies—all of which contribute to highly relevant, timely customer engagements. Here’s a possible solution that also adapts to today’s privacy-focused digital landscape, supporting a transition into cookieless marketing for effective targeting and engagement. Using this kind of system, brands can tap into data from direct interactions, prioritize consent-driven data gathering, and integrate advanced identity solutions, crafting personalized customer journeys that meet stringent privacy standards.

Zero In on Key Customer Interactions

To effectively gather real-time data for developing Key Performance Indicators (KPIs), it’s crucial to first identify your business’s main customer touchpoints. By doing so, you can concentrate on the interactions that have the most potential to yield valuable insights into customer behavior. Leveraging digital tools can help you track these interactions, transforming raw data into actionable intelligence. This approach not only enhances your understanding of customer journeys but also allows you to predict trends and make informed adjustments to your engagement strategies. By focusing on pivotal touchpoints, you ensure that your KPI development is rooted in data that truly reflects real-time customer experiences.

Achieve Clarity with Automated Data Systems

To maintain a continuous and precise flow of customer data from diverse channels, it’s crucial to implement automated data gathering systems. These systems streamline the data collection process, reducing the manual workload and errors typically associated with data management tasks. By doing so, you can achieve real-time data access, enabling more accurate insights into customer behavior across all touchpoints. Investing in the right technologies is not just an option; it’s a necessity to stay competitive in a rapidly evolving digital landscape.

Set Standards for Real-Time Engagement Success

To effectively gauge the success of real-time customer engagement, establishing precise criteria is essential. You should focus on tracking specific metrics that capture both the quality and quantity of interactions, including customer satisfaction and response times. For instance, as Sprinklr explains here, you can monitor metrics like customer self-service rates and digital engagement effectiveness. Additionally, combining these quantitative metrics with qualitative feedback from customers can paint a comprehensive picture of interaction efficiency. By integrating both sources of data, you can refine your strategies, ultimately enhancing customer satisfaction and boosting loyalty.

Bridge Data for a Holistic Customer View

In an era where customer insights are pivotal, deploying data integration tools that synthesize real-time data from various sources is essential for gaining a complete understanding of your clientele. These tools empower you to collect and analyze dynamic customer information, which is often described as volatile, untidy, and fleeting, from multiple channels into a cohesive whole. By effectively simulating integration processes and handling data streams in parallel, you ensure a seamless flow of information across your organization. Furthermore, planning for potential system failures and packaging data streams for insightful analysis are crucial steps to leverage these systems fully.

Transform Dashboards into Decision-Making Hubs

To effectively present real-time KPIs, dashboards must be designed with efficiency and clarity. You should focus on integrating 8-12 key performance indicators that are immediately relevant to your business objectives, ensuring that these metrics are easily comprehensible through the use of simple and consistent visual layouts. Including interactive elements such as dynamic filters and alerts can further enhance decision-making by allowing you to delve deeper into the data as needed, all while maintaining up-to-date information through automated updates. Training your team to engage with these dashboards regularly ensures that the insights provided are consistently leveraged in decision-making processes.

Enhance KPI Accuracy with Predictive Technology

By utilizing machine learning algorithms, you can significantly enhance your ability to predict customer needs and improve the precision of key performance indicators (KPIs). These algorithms employ techniques like linear regression and recurrent neural networks to analyze historical data and identify emerging trends, enabling businesses to anticipate market shifts and consumer demands more accurately. In the retail sector, for instance, machine learning can analyze sales data and customer behaviors to provide more personalized recommendations, boosting both customer satisfaction and sales performance. Integrating these predictive models into your KPI framework makes them more dynamic and adaptable, aligning closely with your strategic goals.

Embracing the tools and strategies for real-time insight isn’t just about keeping pace with change; it’s about transforming your ability to predict, adapt, and connect on a level that resonates. By continuously refining your approach to KPIs and real-time data, you align with the rhythms of your customers and deepen your capacity to serve them in meaningful ways. As this approach evolves, so does your potential to lead in an environment where agile, informed decisions are the hallmark of sustained success.

Adapt to changing times and enhance your competitive edge with USC Consulting Group — your partner in driving operational excellence and sustainable growth since 1968.

*This article was written by Dean Burgess. Dean runs Excitepreneur, which celebrates the achievements of entrepreneurs. He understands that there are many types of entrepreneurs, and strives to provide helpful information to assist them in achieving their particular idea or goal.

There’s a popular phenomenon being shared online at the moment: “Instagram vs. Reality.” It’s two photos, side by side. One is doctored and photoshopped and filtered to look perfect. The other is what it looks like in reality. More often than not, there’s a big difference. Perfection is a far cry from reality, and not just on Instagram.

It got us thinking about operational excellence. Some operational excellence consulting firms might tell you their goal is to deliver optimal perfection in which your organization is running on all cylinders 24/7. But in our experience, reality is a lot more complicated than that. We find that operational excellence is a process. And sometimes it’s a moving target. It can change and morph, affected by myriad factors that may be out of your control, like the economy, supply chain issues, hiring problems and snafus, your best leader on the line quitting with a moment’s notice. The list goes on.

As an operational excellence consulting firm, we contend that operational excellence is a process of continuous improvement, not something static and perfect that stays that way in perpetuity. Does it exist? Absolutely. But it doesn’t stay the same.

What is operational excellence consulting?

The textbooks will tell you operational excellence is a process for improving a company’s effectiveness and efficiency — two things we happen to specialize in. The goals of operational excellence consulting read like a playbook of our typical projects: Improving productivity and throughput, reducing waste, focusing on quality and reducing defects, optimizing shifts, updating processes.

Often an end goal of Lean Six Sigma (LSS), operational excellence is a moving target. Striving for operational excellence means continuously improving, rolling with unforeseen circumstances, adapting to ever-changing tides. Here are some effective strategies we’ve honed in the pursuit of operational excellence that you can apply in your operations today.

Strive for process optimization

The cornerstone of LSS, process optimization means finding opportunities to ramp up efficiency, eliminating bottlenecks and waste, enhancing productivity, reducing defects and glitches in both the product and the process, and the whole nine yards of LSS. To read a deep dive into LSS and what it can do for your organization, download our eBook, “Lean Six Sigma: Do You Really Know These Methodologies?”

Get the right people in the right jobs…

Is everyone from the front lines to the corner office in the right jobs? Assess skills, provide training if necessary and listen to feedback so your team is ready to tackle their roles with a great work ethic and enthusiasm.

…and then empower them to do the job right

Many times, the people who work on the shop floor know a lot more about the job than the people in the C-suite. Give them the power to do their jobs and to act quickly when unforeseen situations arise.

Develop KPIs

If you’re not already establishing and monitoring key performance indicators and metrics, get on that. It helps your people know what’s expected of them, and helps you evaluate the quality of the work they’re doing. They also show opportunities for improvement.

Develop standards

Hand in hand with KPIs, standardized operating practices and procedures can ensure you’re getting the consistent results you need.

Manage by the numbers

It’s an oft-used phrase here at USC. Decisions need to be driven by data and hard numbers, not what’s “always worked in the past.” The data can tell you where to improve, what’s working and what needs to change.

Keep the customer in focus

Sometimes, companies can get so caught up in process improvements they lose sight of the end customer. By keeping their needs, expectations and wants in the forefront, you can be assured you’re hitting the mark.

Encourage a culture of continuous improvement

Culture change is easier said than done, but it’s a necessary component to operational excellence. Encourage innovation and ideas for improvement, and reward employees for finding ways to do their jobs better.

Above all, remember it’s a process, not a single achievement. Yes, you may have achieved operational excellence… today. What about tomorrow?

Enjoy the article? Subscribe to our blog to receive the latest news and content.

The supply chain refers to all activities involved in converting raw materials to finished products and getting the finished products to the final consumer, forming a vital cog in the business wheel. A successful business depends on the success or efficiency of its supply chain. Thus, the need to constantly monitor the various supply chain stages, from raw material sourcing to delivery to the final consumer, ensuring smooth operations for maximum returns.

To achieve this, you need to constantly measure the performance of your supply chain using various Key Performance Indicators (KPIs). For instance, a shipping line from China to UAE is most likely to measure the speed of delivery as a KPI while a retail store measures the number of cash sales or customer service as a crucial aspect of the business that success relies on.

Thus, supply chain KPIs are a set of measurable metrics that tell you about the efficiency of your supply chain over a while and help you identify the weak areas of the supply chain where improvement is needed for better performance. They also help monitor the overall business efficiency in cost, value service, and waste generated and measure the progress in achieving its goals. Thus, the importance of KPI in supply chain.

There are several KPIs that a company can choose to measure depending on the crucial aspects of the business that it focuses on. This article will expose you to some top KPIs common among businesses and industries that can be used to measure supply chain efficiency.

Top supply chain KPIs to focus on

Supply chain KPIs are measures of supply chain performance, helping improve business productivity and customer satisfaction. The following are top supply chain performance metrics that aid supply chain managers measure and work towards achieving these objectives.

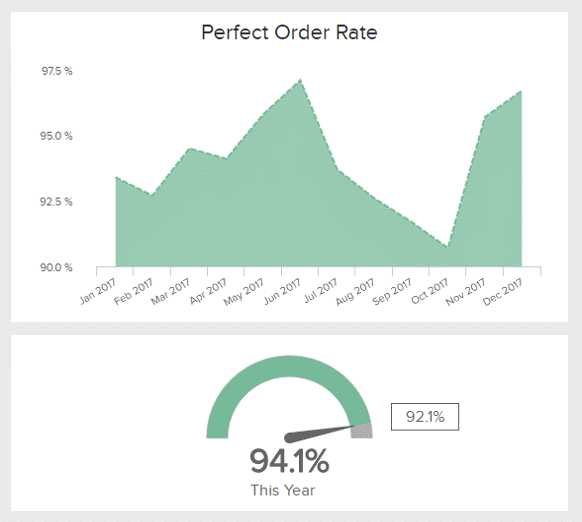

Perfect order

Copyright: www.datapine.com

This is crucial to measuring supply chain efficiency and comprises various other smaller metrics. It also gives you an insight into the efficiency of your order fulfillment and helps track storage and delivery options, as well as cost and customer satisfaction. Perfect order comprises

- On-time delivery: A measure of the percentage of delivery that got to the customer at the desired time

- In-full delivery: A percentage of the correct delivery made to the right customer

- Damage-free delivery: This calculates the ratio of goods delivered to the customer in good condition, without any damage.

- Accurate documentation: This gives an insight into the percentage of deliveries made with correct documentation such as invoices, packing lists, labels, etc.

A low value for these KPIs depicts low customer satisfaction, which can lead to loss of sales and poor business yields. In addition, it also gives an insight into the cost incurred by inefficient order fulfillment. The formula for calculating perfect order is

[(total number of orders – number of orders with errors)/ total number of orders] x 100

- The number of orders with errors can be any of the four smaller components of perfect order KPI.

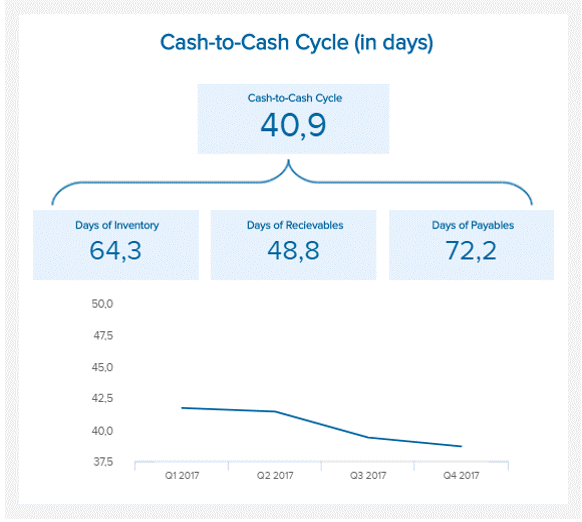

Cash to cash time cycle

Copyright: www.datapine.com

This measures the time it takes to receive cash for an inventory purchased. It is the time between when you pay for inventory and when you receive money from the sales of that inventory or the time taken to convert resources to cash flows. A low figure for this KPI means that your inventory doesn’t spend much time in your warehouse before selling them and is great for the business.

On the other hand, a high value means that goods are spending too much time in the warehouse and can be improved by better forecasting and stocking faster-selling goods. Although this metric seems more like a financial one, it is a vital tool for determining your supply chain efficiency. The formula for calculating cash to cash cycle is

Inventory outstanding days + Sales outstanding days – Payables outstanding days

Freight Bill Accuracy

This is essential to measure the accuracy of shipments from the supplier and to the end customers. Shipping is a critical part of business logistics and must be carried out with utmost precision as a slight error can affect business profitability and lead to poor customer experience. Therefore, the need to maintain billing accuracy in the supply chain.

Tracking this KPI will help you identify negative trends in billing accuracy, helping you improve this metric and increase business profitability and growth. The formula for this KPI is

(Error-free bills – total number of bills) x 100

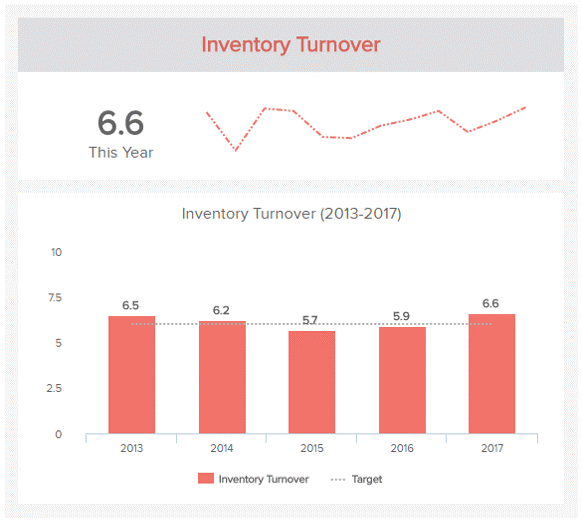

Inventory turnover

Copyright: www.datapine.com

This KPI gives an idea of the frequency of selling your entire inventory over a given period. A high value for this KPI indicates efficiency in production planning, fulfillment abilities, sales and marketing strategy, and process strategy. Calculating this KPI will also give you an idea of where you stand among your competitors when you compare your value with theirs.

Inventory turnover measures the efficiency with which you turn your working capital into business profits, and you can improve this KPI by working on your sales and marketing strategy and other areas of your business that affects your business turnover such as fulfillment operations and production processes. The formula for this KPI is

Cost of goods sold/ [(Opening stock – Closing stock)/2]

Inventory velocity

This is a measure of the speed at which inventory is sold. It shows how much inventory is expected to be sold during a given period and how much inventory is left, facilitating better inventory planning and management. A good value for this KPI signifies optimized warehouse operations and inventory planning and helps reduce the risk of overstocking and outdated inventory while also increasing customer satisfaction.

Inventory can be classified as fast-moving (75% – 80%), slow-moving (< 60%), or continuously-moving (60% – 70%) items according to their inventory velocity determined by monthly sales, the number of items leftover in the warehouse, or margin percentage. This will help you identify goods that sell fast and invest more in them.

The formula for this KPI is (Opening stock/ Next period’s Sales Forecast)

Conclusion

No matter the nature of the business, all businesses in the manufacturing industry have a common feature of receiving raw materials and processing them into finished goods delivered to the customer. As such, the need for an efficient supply chain system to manage the supply chain operations optimally. Identifying various KPIs critical to business performance and measuring them will help achieve this efficiency.

Organizations can also employ executive dashboards that use various supply chain metrics to provide real-time information that can help in decision-making. Whether calculated manually or with the use of executive dashboards, keeping track of these KPIs and many others is critical to ensuring supply chain efficiency and ultimately business success and profitability.

*This article is written by Danielle Gregory. Danielle is a writer and marketing expert who is currently working for QAFILA. Danielle’s writing relates to a range of subjects such as logistics and IoT. Besides writing, she enjoys traveling, cooking, and riding.

When businesses begin to scale, many of the challenges they face result from added operational complexity and lack of visibility. As organizations start investing more in their business’s functional components, such as inventory production, warehousing, logistics, and order management processing, communication silos and departmental disconnects begin to appear, blurring certain efficiency lines across the company as a whole.

To combat these operational challenges, many companies often rely on Key Performance Indicators (KPIs) to help them make informed decisions about their business as a whole. However, operational data in itself isn’t always useful in its raw state. Organizations typically need to take additional steps to make their system data informative and actionable. This is where data mining comes in.

What is Data Mining?

According to Consumer Notice, data mining is the process of turning raw data points into useful and actionable information. By collecting, sorting, and analyzing large amounts of data from various sources all at once, data mining helps companies discover valuable patterns and trends in their business operations.

Discovering and refining these data points manually across multiple systems would be time-consuming and inefficient for most businesses. Data mining simplifies the process exponentially and provides organizations with the unified data transparency they need to reduce their costs, improve client relationships, reduce operational risks, and increase revenues.

How Does Data Mining Work?

Much like the refining processes of metals and materials, data mining involves several stages before a final product can be achieved. When applying data mining in business analytics, the method uses the following six stages of progression:

- Business Understanding — Identification of business goals and recognize the overall outcome of the data mining process the organization wants to achieve.

- Data Discovery — The implementation of tools and solutions designed to understand all raw data formats and sources for the business and their relevance in the data mining process.

- Preparation — A key part of the “refining” process, often using AI-driven tools to convert unstructured raw data formats into forms that people can understand and quantify.

- Modeling — Several techniques are used to quickly and efficiently sort through several large databases simultaneously, identifying relevant trends and correlation analysis patterns.

- Evaluation — A series of human and machine-driven quality control processes to ensure data is properly mapped and accurately compiled.

- Deployment — Raw data has been fully refined and is now formatted to be used in near-limitless applications, whether represented as metrics, reports, or other digestible and actionable forms.

Data mining plays a fundamental role in business intelligence platforms and will continue to drive the future of data analytics as a whole. As businesses rely more and more on fast, actionable data to inform decisions around their growth and sustainability, data mining solutions will continue to be more readily adopted by all industries. In fact, data mining technology itself has already created roles within organizations such as data analytics specialists and data scientists who dedicate their professions to extracting and presenting new information to the business.

Data Mining in Supply Chain Operations

Management of a supply chain can be a daunting task for organizations of any size. Whether it’s running production facilities, coordinating shipping and logistics, managing inventory across multiple warehouses, or processing and tracking large volumes of orders, supply chains are made up of many individual components, each of them needing their own calibration efforts.

One area of supply chain management that heavily impacts business operations is product transportation. This is especially the case in the current landscape of remote business operations, now heavily reliant on shipping services and efficient vehicle routing. However, while the need for streamlined and profitable logistics coordination efforts has never been higher than it is now, many companies still use outdated and disconnected processes to keep things running.

Legacy logistics planning and tracking processes are often made up of many manual processes and riddled with routing problems that need solving. Some of these problems include inefficient shipping planning that leads to missed deadlines, a lack of visibility between shipment origin and destination, and unknown volumetric capacity or maintenance statuses of vehicles. With so much of these logistics processes disconnected from other critical components of the business, streamlining this data collection with other key business metrics is essential to ensure long-term business sustainability.

The data mining process does this by helping organizations create a unified view of all areas of the business. This is achieved through actionable reports highlighting key performance indicators, giving them the insight they need to improve how they manage product sourcing, efficient execution of their transportation network, and streamline all supporting workflows in and outside of the office.

The use cases of data mining are nearly limitless and can be applied to all business areas. However, by mining for data in supply chain operations, organizations can achieve the visibility they need to balance business efficiency, compliance, and profitability all in one place. This leads to a much more scalable business growth path and ensures long-term sustainability down the road.

*This article is written by guest author Beau Peters. View more of Beau’s articles here.

In the ongoing pursuit of operational excellence, do you feel like it’s 1st and goal or 4th and long? The challenges you encounter in business can feel like you’re in the middle of the game with the clock ticking down. The moves you make and steps you take determine whether you’ll score the touchdown or come up a few yards short. But with the right mindset, plays, and strategy, you and your teammates can come through in the clutch.

Operational Excellence applies to your entire team in the organization – from the top business executives to the shop floor employees. Each player recognizes the flow of value to the customer and have a strategic plan in place to fix that flow should it experience a disruption. In other words, your employees have the ability to call an “audible” to correct abnormal conditions.

Here are six plays that can take you past the red zone and into the end zone:

- Recruit the right players and promote a strong work ethic — Instilling a culture of operational discipline is critical to victory.

- Know the X’s and O’s — Map out how operational excellence manifests itself in the office, factory, or shop floor, and determine your strategy.

- Trust your roster — Empower your workers with a game plan so when abnormal conditions arise they can call the audible for proper corrections

- Review the game film — Establishing and monitoring key performance indicators help you evaluate the quality of performance and what needs correction.

- Play to the whistle — Even when you reach your goal, you can’t let up; operational excellence revolves around continuous improvement.

- Support your fans — Understanding your customers and what it takes to satisfy their needs provides direction and value proposition.

USC Consulting Group has the keys to winning the game of operational excellence for your business. We can coach you to victory. Contact us today before time runs out.

A proper Asset Performance Management (APM) plan ensures that your critical revenue-producing assets operate smoothly, efficiently, and at or near their rated capacity.

Asset Performance Management is the broad, systematic planning and control of a physical resource throughout its operating life. It includes the specification, design, construction, operation, maintenance, modification, and ultimately, disposal. Its principles apply to any industry with mission-critical assets, and is best implemented with support from the top-down and bottom-up. The entire organization should be involved, and supportive to ensure that it is executed properly.

Methodologies used in APM

- Asset Reliability – The process of ensuring that assets continue to do what they are needed to do, when they are needed to do it.

- Reliability-centered Maintenance (RCM) – Used to determine the activities necessary for the asset to operate properly by focusing on maintenance tasks that mitigate against the consequences of failure.

- Maintenance Management – Adherence to a benchmark of world-class maintenance standards and practices.

Key Performance Indicators (KPIs) and Enabling Technology

A vital step in implementing an APM plan is establishing, tracking, and analyzing KPIs. This is what takes a maintenance plan from reactive to proactive. The close management of leading and lagging Key Performance Indicators helps increase the likelihood of driving measureable results without significant capital investment.

Important KPIs include:

- % of planned maintenance work, and completed.

- % of unplanned/emergency maintenance work.

- Proactive work as % of planned maintenance work.

- Actual maintenance hours vs. planning estimate.

- Overall equipment effectiveness.

Having the right technology tools are needed to measure and analyze this data. USC Consulting Group has helped clients optimize their existing tools or install computerized maintenance management systems (CMMS), ERP systems, and USC’s own proprietary Lean Information Control System (LINCS) to ensure that this data is used effectively.

Benefits of Asset Performance Management

In addition to increased uptime, shorter turnaround times, greater throughput and lower maintenance costs, organizations have seen improvements in their EBITDA by 15-25%.

Learn more about how APM can improve the performance of your revenue-producing assets by downloading our eBook Asset Management: The Rise of Reliability.

Continuous improvement — this is the dream for forward-thinking shop floor stakeholders across all industries. However, few manage to facilitate such sustained advancement. In fact, more than 40% of the business leaders who spearhead continuous improvement efforts find themselves overseeing failing programs, according to research published in Harvard Business Review. There are a number of common contributing factors, including lacking daily practice. Yes, reinforcing continuous improvement through everyday exercises is essential to success. But how exactly can leaders promote this kind of necessary daily rededication? Embracing the Kaizen methodology ranks among the best options.

Organizations in virtually every sector leverage this Japanese philosophy, which emphasizes operational transformation through incremental optimization. Both formalized and impromptu ideation and root-cause analysis exercises are key to achieving these outcomes. Business leaders who want to implement continuous improvement initiatives that work would be wise to adopt the Kaizen approach and work with employees at all levels to make pragmatic, enduring change.

Mapping the emergence of Kaizen

Kaizen and lean manufacturing occupy the same theoretical orbit. This makes sense considering that they both emerged from the same location: the original Toyota Motor Company production plant located in Toyota, Japan. It was here that management consultant Masaaki Imai collaborated with former Toyota Chairman Shoichiro Toyoda to develop shop floor processes that facilitated continuous improvement or “change for the better,” the literal Japanese translation of Kaizen. These workflows empowered workers to address deficiencies in real time, Quartz contributor Melody Wilding reported. The automaker directed production teams to stop work and collaborate to find solutions for assembly process problems, quotas be damned. This approach reduced error occurrence and wastage and boosted efficiency, helping Toyota evolve into the biggest vehicle manufacturer on Earth.

Imai cataloged, organized, and formalized the strategies deployed at Toyota and published them in his landmark 1986 book, “Kaizen: The Key to Japan’s Competitive Success.” He established the Kaizen Institute one year later, which he has since used to promote the Kaizen approach.

Unpacking the Kaizen methodology

Kaizen centers on five foundational principles. These include:

- Knowing the customer: Understand what customers want and develop positive experiences that appeal to them.

- Let it flow: Eliminate waste wherever possible and focus on value creation on every organizational level.

- Go to gemba: Seek out continuous improvement where value creation happens — the production areas.

- Empower people: Give employees the agency, tools, and support they need to pursue continuous change.

- Be transparent: Leverage accessible performance metrics to propel operational decision-making.

These core concepts underlie all the actionable frameworks and tools that facilitate Kaizen application. Actually implementing the philosophy necessitates coordination and commitment, as only business leaders who adhere to overarching event schedules and agendas can uncover the kinds of shop floor insights that lay the groundwork for sustainable organizational advancement. As mentioned above, Kaizen methodology emphasizes internal collaboration, ideation, and problem solving through formalized sessions. While these gatherings do not generally occur daily, the more consistent and focused cooperation that unfolds, the more likely positive change is to happen.

All Kaizen events have the same goals: getting stakeholders in one place, reviewing existing processes, improving existing processes, and ensuring buy-in. However, these sessions do not share identical frameworks — the strategy allows for variation. Here are some of the most common types of Kaizen events in use now:

- Blitz: Here, personnel completely deconstruct a specific process and reassemble it in an effort to achieve improvement.

- Burst: This event, which happens over the course of three to five days, focuses on rapid process improvement and empowers staff to develop and deploy quick changes with big impact.

- Workshop: During a five-day period, team members conceive production improvements, implement them, and then measure shop floor performance to determine their efficacy.

While there are numerous other Kaizen session types — businesses that have adopted the philosophy over the years have also helped expand it — the collaborative formats mentioned above are typically considered canon.

Coordinating an effective Kaizen event

Kaizen events are immense productions. Internal stakeholders from different departments mingle with external consultants, executive team members depart their corner offices and make appearances, and in the end everyone unites to flip the switch on fresh production processes. With so much involved, impeccable coordination is absolutely essential. Fortunately, there are a good number of formalized event management best practices available to business leaders hosting their first Kaizen sessions. Here are some of the many variables that those involved in Kaizen event planning should address to facilitate success:

- Location: While improvement implementation will obviously unfold on the shop floor, participants must have access to a space within which they can collaborate effectively.

- The agenda: Freewheeling brain storming is not an option within the confines of the Kaizen approach, meaning all events must come with clear-cut agendas.

- The sponsor: Kaizen events typically have high-level internal sponsors who use their clout to green-light operational changes and generally lend support.

- The attendees: Individuals who attend Kaizen events are expected to contribute by mining their specific expertise and experience, a reality that makes attendee selection key.

- The objectives: Kaizen events are meant to spur immediate action that leads to measurable and planned production improvement.

- Information access: The Kaizen approach as a whole emphasizes the use of data during decision-making. Attendees must therefore have access to any internal insights they need.

- Decision-making: Determining how final decisions are made is critical to Kaizen event success.

These are just a handful of the many factors that Kaizen adherents take into account when planning internal events, as continuous improvement often unfolds as a consequence of strong coordination.

Generating ROI the Kaizen way

Kaizen ranks among the most popular strategies for achieving continuous improvement — and for good reason. With roots in Toyota and Japan’s immensely well-respected industrial culture, the strategy easily holds up to scrutiny and can give business leaders the power to transform their companies, should they follow best practices. Of course, even stakeholders who fully embrace Kaizen can encounter difficulties stemming from the significant coordination requirements. Fortunately, these professionals have a place to turn for assistance: USC Consulting Group. We have been helping enterprises of all sizes embrace the agents of continuous change, including the Kaizen methodology.

Connect with USCCG today to learn more about are services and wide breadth of experience.

Executives and shop-floor stakeholders have been pursuing operational excellence for decades, but a fraction of these industrial idealists have actually achieved it. In fact, just 32 percent of supervisors and one-quarter of employees believe that their organizations boast true operational excellence, according to research from Wrike.

Business leaders who have yet to cultivate workflows that adhere to the guiding principles of operational excellence – treating customers and employees with respect, embracing scientific thinking and emphasizing value creation, according to the Shingo Institute – can make progress toward this goal in 2019 by implementing these four workable strategies for achieving operational excellence:

1. Define operational excellence

Analysts for the Institute for Operational Excellence believe that manufacturing firms that have achieved operational excellence make it so that “each and every employee can see the flow of value to the customer, and fix that flow before it breaks down.” This is a tall order, even for larger firms with significant financial resources and manpower. Even so, enterprises in any industry can set themselves up for success by unpacking the idea of operational excellence and mapping out how it might manifest on the shop floor. The IOE recommends leveraging operational flow charts, which help contributors at all levels visualize the progress of value creation. For instance, a chemicals manufacturing firm might dodge procurement issues by building flexibility into its supply chain and developing relationships with multiple raw materials providers, along with shipping and logistics contingencies to match.

2. Establish and monitor KPIs

Achieving sustained operational excellence is impossible without access to baseline performance data from your shop floor. Unfortunately, too many manufacturers either maintain poor data collection and analysis processes or forgo these essential activities altogether. Both actions have the same outcome: dysfunction, a deep lack of understanding, and an inability to strategize intelligently.

Businesses that want to avoid these end results and achieve operational excellence must focus on implementing fast and accurate measures for collecting data and assessing key performance indicators. Automation is important here, as manual methods almost always lead to cumbersome amounts of data entry, errors, and eventually abandonment. Best-in-class manufacturers that have managed to achieve operational excellence leverage automated KPI-collection setups that deliver real-time intelligence to decision-makers, who, in turn, can address production roadblocks and move the operation forward in a timely manner.

3. Empower the employees

Sprinkled in among the more technical best practices included in the Shingo Institute’s guiding principles of operational excellence are some gentler strategies centered on cultivating effective leaders and executors – two key ingredients in an industry-leading manufacturing enterprise.

Principle No. 1, which advises firms to respect workers by empowering them through professional development initiatives, is perhaps the most important. When employees feel empowered and engaged, they take ownership of their work and pursue individual excellence, which contributes to the organization as a whole. However, many businesses struggle in this area. In fact, a mere 34 percent of American workers say they are engaged on the job, according to research from Gallup. Worse yet, the manufacturing sector ranks at the bottom for employee happiness, analysts for TINYpulse found. Companies must overcome these obstacles to achieve operational excellence, which means investing in training programs and other initiatives designed to keep key shop-floor contributors engaged and focused on driving value.

4. Facilitate continuous improvement

Operational excellence is not the end all be all. What matters more is continuing forward with augmentation and understanding that various internal and external variables can easily knock previously rock-solid processes off course, which can cause significant issues that inhibit value creation and drag down the bottom line. Continuous improvement is the engine that drives sustained success. Top performers in the industrial sector facilitate this never-ending search for betterment by deploying risk identification and mitigation methodologies, which make it easier for shop-floor stakeholders to spot burgeoning problems and develop upgraded processes to address them. For example, an automotive manufacturer with access to strong asset management processes – staples of organizations with effective continuous improvement workflows – can identify small mechanical kinks before they devolve into downtime-causing catastrophes that wreck productivity.

Businesses in the manufacturing space can move closer to achieving operational excellence by adopting these impactful best practices. Of course, executing these strategies at scale might prove difficult for some. Here at USC Consulting Group, we have been helping manufacturers optimize their operations for decades, leveraging proven techniques and tools that accelerate change and lay the foundation for growth.

Contact us today to learn more about our work in the manufacturing arena and how we can help your firm pursue operational excellence in 2019.

USC Consulting Group is a world-class operations management firm that for the past 50 years has helped mining companies around the globe improve their business performance by increasing throughput, reducing costs, eliminating waste, increasing productivity, improving quality and leveraging existing assets.

Discovery

Your process improvement experience starts with USC digging in to begin to learn what truly makes your mining operations tick. We conduct detailed diagnostics, at the point of execution, whether underground, in the pit, surface, processing plants and support services to gain an understanding of impediments to increased performance. We’ll handpick a team uniquely qualified to address your specific challenges. We’ll observe how you do things around the clock, shift to shift, engaging directly with the people on the front lines – production, maintenance, engineering, and all support departments. Then we’ll collaborate with you to turn our findings into a detailed, workable plan, complete with tools from our well-rounded toolkit.

Implementation

This is the point when most consultants leave you with a binder and walk out the door. Instead, we’re developing a project plan, organizing work breakdown structure, developing performance goals, determining measurement metrics and making sure our jointly developed strategies get the desired results. Managing data and information in the mining environment is vital for continuous improvement efforts. As part of our implementation process, we will help you enhance how your organization makes use of key data and information. Knowing where the right data and information lives and putting it to value added purposes is essential to managing a successful business. Leveraging enabling technology such as Microsoft Power BI helps to achieve, and then sustain the desired outcomes. Our LINCS® Lean Information Control System will enhance your existing Management Operating System (MOS) by smoothing the change process, providing timely feedback on KPI’s to process owners and actionable business intelligence to key decision makers. We openly share the results of our collaboration to increase and maintain operating excellence, and provide the extra horsepower needed to put ideas (both yours and ours) into action. We help deliver on your goals by empowering your performance. In fact, we’ll help you audit, verify, and sustain results for years to come.

USCCG’s Mining team uses the best of tried-and-proven, and emerging, methodologies to bring about enterprise-wide Lean Transformation, resulting in significant operating and financial gains, all at a very attractive ROI.

Discover more about our work in the Mining industry and contact us today to start your process improvement experience.