-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2025 (1)

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Food Industry

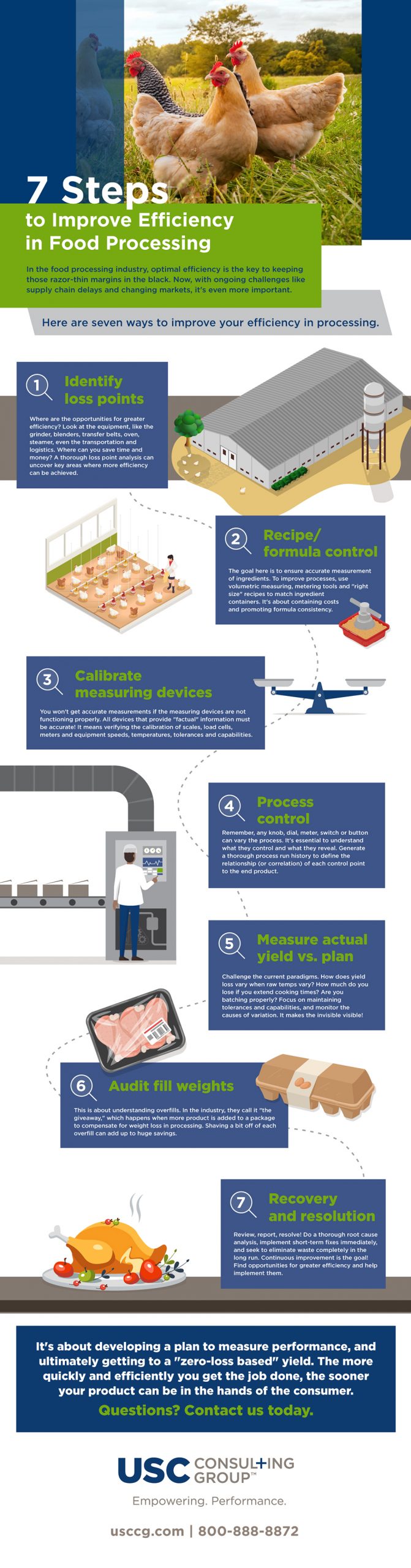

In the food processing industry, optimal efficiency is the key to keeping those razor-thin margins in the black. Now, with ongoing challenges like supply chain delays and changing markets, it’s even more important.

Efficient processes lead to reduced operating costs, improved yield and throughput, and more control over your management systems.

The following graphic provides seven ways to improve your efficiency in food processing:

1. Identify loss points

Where are the opportunities for greater efficiency? Look at the equipment, like the grinder, blenders, transfer belts, oven, steamer, even the transportation and logistics. Where can you save time and money? A thorough loss point analysis can uncover key areas where more efficiency can be achieved.

2. Recipe/formula control

The goal here is to ensure accurate measurement of ingredients. To improve processes, use volumetric measuring, metering tools and “right size” recipes to match ingredient containers. It’s about containing costs and promoting formula consistency.

3. Calibrate measuring devices

You won’t get accurate measurements if the measuring devices are not functioning properly. All devices that provide “factual” information must be accurate! It means verifying the calibration of scales, load cells, meters and equipment speeds, temperatures, tolerances and capabilities.

4. Process control

Remember, any knob, dial, meter, switch or button can vary the process. It’s essential to understand what they control and what they reveal. Generate a thorough process run history to define the relationship (or correlation) of each control point to the end product.

5. Measure actual yield vs. plan

Challenge the current paradigms. How does yield loss vary when raw temps vary? How much do you lose if you extend cooking times? Are you batching properly? Focus on maintaining tolerances and capabilities, and monitor the causes of variation. It makes the invisible visible!

6. Audit fill weights

This is about understanding overfills. In the industry, they call it “the giveaway,” which happens when more product is added to a package to compensate for weight loss in processing. Shaving a bit off of each overfill can add up to huge savings.

7. Recovery and resolution

Review, report, resolve! Do a thorough root cause analysis, implement short-term fixes immediately, and seek to eliminate waste completely in the long run. Continuous improvement is the goal! Find opportunities for greater efficiency and help implement them.

It’s about developing a plan to measure performance, and ultimately getting to a “zero-loss based” yield. The more quickly and efficiently you get the job done, the sooner your product can be in the hands of the consumer. Questions? Contact us today.

For more information about how Food & Beverage consultants can significantly reduce your operating costs and improve productivity, read this eBook:

Fresh or frozen? When it comes to choosing between the two types of food, fresh has held the distinct advantage, uniformly advocated by both health professionals and dietitians.

Yet, given the latter’s success and prosperity before, during, and in the thick of the coronavirus crisis, you would think frozen has had the advantage all along, as manufacturers have not just survived the surge in demand among emergency preparedness-minded consumers, but thrived.

Even prior to COVID-19, frozen food manufacturers of all sizes were in growth mode, quietly gaining significant market share in the food industry as a whole. Indeed, according to the American Frozen Food Institute’s (AFFI) 2019 “Power of Frozen” report, manufacturers have seen sales reach approximately $57 billion on an annual basis over the last few years, Progressive Grocer reported. Some of the industry’s largest movers and shakers — meaning the types of products consumers purchased the most — include ready-to-bake pizza, flash-frozen vegetables, seafood, prepared potatoes, and assorted desserts.

Many food and beverage companies experienced a boost in sales when lockdown orders went into effect across the country, and the frozen food suppliers were no exception. Sales for frozen foods soared 80% during the week of March 15 compared to 12 months earlier, AFFI found in a separate report from this year. The surge in buying activity was even more substantial the following week, up 94% on a year-over-year basis.

Many food and beverage companies experienced a boost in sales when lockdown orders went into effect across the country, and the frozen food suppliers were no exception.

Coronavirus causes conflict for Conagra

One of the nation’s largest frozen food suppliers, Conagra Brands, encountered some production and supply chain disruption issues early on. As Food Business News reported at the time, nearly two dozen workers at one of its Missouri factories contracted COVID-19, which forced the closure of the plant for 10 days, from April 17 to 27.

Putting frozen food production activity on ice temporarily was done out of an abundance of caution, said Conagra spokesperson Daniel Hare.

“The health and safety of our employees is our top priority,” Hare said, according to the website. “In our Marshall facility, we have been using social distancing techniques, screening temperatures and increased sanitization in the facility to prevent the spread of COVID-19.”

Conagra was ultimately able to right the ship and optimize its supply chain through cycle time reduction, productivity improvements and strategic asset utilization. In fact, an uptick in sales, presumably as a result of these efficiency improvements, allowed Conagra to distribute $7 million in cash bonuses to eligible employees, the company said in a press release issued in May.

Innovating and adapting to consumer dietary preferences

Another way the frozen food industry has been able to endure and overcome the hurdles caused by COVID-19 is through better communication with consumers and adapting their product offerings to fit their needs and dietary desires. A classic example is plant-based foods. From frozen pizzas made from cauliflower to Portobello mushroom burger patties, plant-based foods are all the rage these days, as they’re high in fiber and full of vitamins and minerals. As a result, frozen food manufacturers and suppliers have invested in innovative technologies that ensure these foods are handled, prepared, and chilled in the proper manner to lengthen their shelf-life and preserve their nutritional value. This is done by “flash freezing,” in which foods are frozen quickly by leveraging cryogenics.

Darren Seifer, food and beverage industry analyst at The NPD Group, told Progressive Grocer that household name companies like Conagra, Dr. Praeger’s, and Nestle are all offering more plant-based frozen food entrees — and they’re being received by the public quite well thus far.

“New product innovations in plant-based proteins and vegetables are breaking through,” Seifer explained.

These also include an alternative form of flash freezing by using nitrogen. Nitrogen flash freezing leverages the most abundant chemical on the earth so entrees, snacks, vegetables, and other commonly frozen items chill faster and more efficiently.

This is another example of smart asset utilization. Manufacturers must always be looking to see what equipment they currently have in place to produce the goods that their customers want. If they don’t have it, they must actively assess the quality improvements or investments are necessary to reach a better or more desired outcome.

Frozen foods fighting rumor with facts

With infections from COVID-19 still an ongoing problem and concern, there’s speculation the virus may be spreading through the food supply chain. Some have called into question whether this includes frozen foods transmitting COVID-19.

However, the American Frozen Food Institute has been able to nip these rumors in the bud by enlisting the help of disease experts. AFFI reached out to researchers from North Carolina State University to review all the scientific literature related to COVID-19 and what conclusions, if any, suggest SARS-CoV-2 is communicable through food or beverages.

Sanjay Gummalla, senior vice president of scientific affairs at AFFI, said there are no studies that make such a causal link.

“There is just no scientific evidence in the currently available literature to support that SARS-CoV-2 can be spread by foodborne routes,” Gummalla confirmed.

Dr. Lee-Ann Jaykus, a NC State professor in the Department of Food, Bioprocessing and Nutrition, further noted the only known pathway of external contamination is if food were to come into direct contact with a surface that’s been contaminated or physically handled by someone who was infected or presented symptoms. But even here, there would need to be a perfect storm of conditions for transmission to occur. In other words, while it is technically possible, it’s highly unlikely.

Since there have been no known or reported cases of coronavirus spreading through food — frozen or otherwise — it’s confirmation suppliers and manufacturers have put the proper production measures into effect to reduce the chances of cross-contamination through more rigorous cleanliness, product testing, and disinfecting, all of which may be associated with efficiency improvements and supply chain optimization.

If you’re a food manufacturer who is looking to enhance output or refine processes, USC Consulting Group can help you churn out more product without compromising quality. We’ve helped numerous companies over the years enhance their competition position; we’re confident we can do the same for you. Contact us today.