-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Asset Reliability

Over the next five years, mining and metals companies are expected to spend between $25 billion to $30 billion annually to maintain their assets.

Largely driven by efforts to improve operational efficiency, reduce downtime, immediately reduce costs, meet sustainability goals, and manage operational risks in an increasingly volatile market, mining and metals executives are motivated to start their asset management transformation now. Delaying this transformation could result in lost competitive advantages, higher operational costs, and increased regulatory or market pressures.

Over the next five years, the mining and metals industry is projected to invest heavily in the maintenance of fixed and mobile assets. Various reports indicate that the industry is expected to allocate a significant portion of its CAPEX to maintaining and upgrading its assets. A substantial part of this investment will be directed toward maintaining critical assets required to meet global demand for minerals essential for the energy transition. In a recent survey conducted by Global Data, 48% of the companies surveyed indicated they plan to increase investments in technologies like AI and IoT sensors for equipment upkeep over the next two years.

Investment in predictive maintenance is becoming a top priority for many mining operations. Companies are leveraging their EAM’s with advancing technologies like Digital Twins, AI and IoT, along with other reliability and planning applications, and significantly transforming asset management and the asset lifecycle. These advancements in technology are expected to reduce maintenance costs by 20-30%.

Mining and metals companies integrating Enterprise Asset Management (EAM), Computerized Maintenance Management Systems (CMMS), AI, and IoT are experiencing several quantifiable benefits, including:

- Improved Asset Reliability and Uptime: Utilizing a combination of AI, IoT sensors and Digital Twins provides continuous real-time monitoring of equipment health allowing companies to predict potential failures before they occur while reducing the reliance on reactive and scheduled maintenance – reducing unplanned downtime and fewer equipment breakdowns, increasing equipment availability and extending asset lifecycles.

- Cost Reduction: A predictive maintenance capability helps avoid costly emergency repairs and reduces unnecessary scheduled maintenance, saving on labor and spare parts. It also ensures that the right parts are available when needed, minimizing overstock and understock issues, which helps reduce capital expenditure tied to inventory. It optimizes the energy usage of equipment by adjusting operational parameters in real-time, leading to lower energy consumption.

- Scalability and Flexibility: Leveraging these technologies together, allows companies to scale their asset management strategies as they grow, adapting to changes in operational needs without significant disruptions. Maintenance scheduling based on asset condition rather than time-based intervals, ensures that resources are used effectively, reducing downtime and improving workflow efficiency. They provide a holistic view of all assets, enabling better coordination between teams while improving “wrench-time” productivity and the execution of maintenance and operational tasks. It delivers a single platform to access real-time data across the entire asset portfolio, improving visibility and control over operations for optimizing performance and recommendations for future operations.

USC partners with your organization and coaches your people to significantly impact performance outcomes and accelerate Operational Excellence

USC brings a tailored, structured, and disciplined methodology, along with a range of tools and techniques we apply collaboratively with client’s personnel. Whatever your challenge, we are the people who work with our clients to find full potential and unlock the hidden value.

USC help to identify waste, redundancies, and ineffective processes, and then rapidly recover the prioritized opportunities, and convert them to improvements in performance and operating profit. Further, our people embed with client teams to develop, enhance, prototype, validate and implement asset management strategies to drive, sustain and perpetuate improvements in asset lifecycles and equipment reliability, while changing how plans, schedules, and work is executed. In short, USC implements measurable, sustainable changes that drive asset performance and financial improvements.

- Increased Wrench Time (up to 25% improvement) – Reducing non-productive time through improved work-order generation and prioritization, maintenance teams spend less time searching for work-orders, tracking down parts or waiting for approvals.

- Reduction in Travel & Downtime (up to 20% time savings) – Optimizing the routing and scheduling of maintenance tasks and reducing travel time between jobs to maximize “time on tools”.

- Faster Work-order Completion (up to 30% efficiency gains) – Reducing delays in task assignment, approval and completion tracking, technicians can move quickly from one job to the next by ensuring all the necessary tools and parts are available at the work site, eliminating delays caused by missing resources.

- Optimized Spare Parts Management (up to 15% time reduction) – Faster access to parts and accurate spare part forecasting reduce time on sourcing, stocking and searching while ensuring tools & parts are available for tasks.

- Better Data-Driven Decision Making (up to 20% longer asset life spans) – Collecting and analyzing needed information provides actionable insights that support planning and allow for more informed and pro-active decision making, often delaying the need for capital-intensive replacements.

USC clients experience measurable operational and financial results that significantly improve both the efficiency and profitability of their operations. Benefits delivered may include a 10-20% increase in overall equipment availability due to reduced unplanned downtime and optimized maintenance schedules and a 10-15% improvement in equipment utilization as predictive maintenance reduces the time equipment is out of service.

USC Helps You Tackle Key Challenges

- Optimize maintenance strategies and increase equipment availability operational output

- Predict asset integrity and reliability needs and improve time on tools

- Mitigate risks through stronger stakeholder partnerships, while removing redundancies in the supply chain

- Overcoming cultural and communication issues with contractors, while ensuring quality expectations

Do you want to understand how prepared your company is to drive needed asset management performance and reliability improvements and what the key focus areas that will contribute to lower operating costs? Contact us today.

Mining and metals companies are implementing a range of strategies to enhance asset management and equipment reliability.

In today’s market, many senior executives leading natural resource companies hesitate in making additional capital investment and instead focus on what can be done to squeeze higher performance out of current assets. Consequently, companies are increasingly looking for ways to improve performance and returns with existing infrastructure.

The key approach to this challenge lies in upgrading and improving asset management capabilities. Many organizations have failed to deploy optimal asset management practices. This is surprising given that asset spend frequently represents 30% to 50% of the overall operating expenses. Shifting to a best-in-class asset management program will consistently deliver improved plant or equipment performance, lower operating costs, extend asset life, and generate a higher return on capital. Most recently, companies have sought to implement a range of strategies such as:

- Implementing Asset Management Systems: Utilizing robust asset management systems to track equipment performance, maintenance history, and lifecycle costs, allowing for better decision-making regarding repairs, replacements, and upgrades. Digital technologies like IoT sensors, AI-driven analytics, and automation further optimize asset management.

- Enhancing Maintenance Practices: Implementing proactive maintenance strategies like conditioned-based monitoring and reliability-centered maintenance to address issues before they cause failures. Utilizing data-driven insights, mining companies can optimize “time on tools” by identifying patterns and trends in equipment usage, maintenance needs, and performance. This allows for more precise scheduling of maintenance tasks, reducing downtime and maximizing the time equipment is operational.

- Investing in Training: Providing comprehensive training programs for front-line management, maintenance and operations personnel to ensure equipment is used and serviced properly, reducing the likelihood of breakdowns due to human error and that access to equipment is available. Training personnel to utilize data-driven insights enables management to make informed decisions impacting “time on tools” and leading to improved equipment utilization and overall operational performance.

- Improving Supply Chain Management: Ensuring timely access to quality spare parts and materials to minimize downtime caused by equipment breakdowns and repairs. Some are adopting blockchain for transparent supply chain management and better tracking of assets throughout their lifecycle.

The level of performance improvement companies can realize by implementing key strategies such as enhancing proactive maintenance practices, investing in training to improve skills and capabilities, improving supply chain management, and leveraging digital technologies and data-driven insights varies depending upon factors like current operational efficiency, the scale of implementation, and industry conditions. However, many can expect significant improvements in:

- Safety: Proper training programs and proactive maintenance strategies contribute to a safe work environment by reducing risk of accidents and equipment failures.

- Productivity: Proactive maintenance and digital technologies can reduce downtime, increase equipment availability, and optimize process execution, leading to higher productivity levels.

- Cost Reduction: Efficient equipment usage and maintenance practices can lower operational costs by minimizing unplanned downtime, reducing repair and replacement expenses, and optimizing resource utilization.

- Quality: Improving the essential management skills and work place practices result improve the quality of maintenance execution.

Overall, these strategies can result in substantial performance improvements, enhancing competitiveness and profitability for mining and metals companies.

USC Consulting Group partners with your organization and coaches your people to significantly impact performance outcomes and accelerate Asset Management and Reliability Excellence.

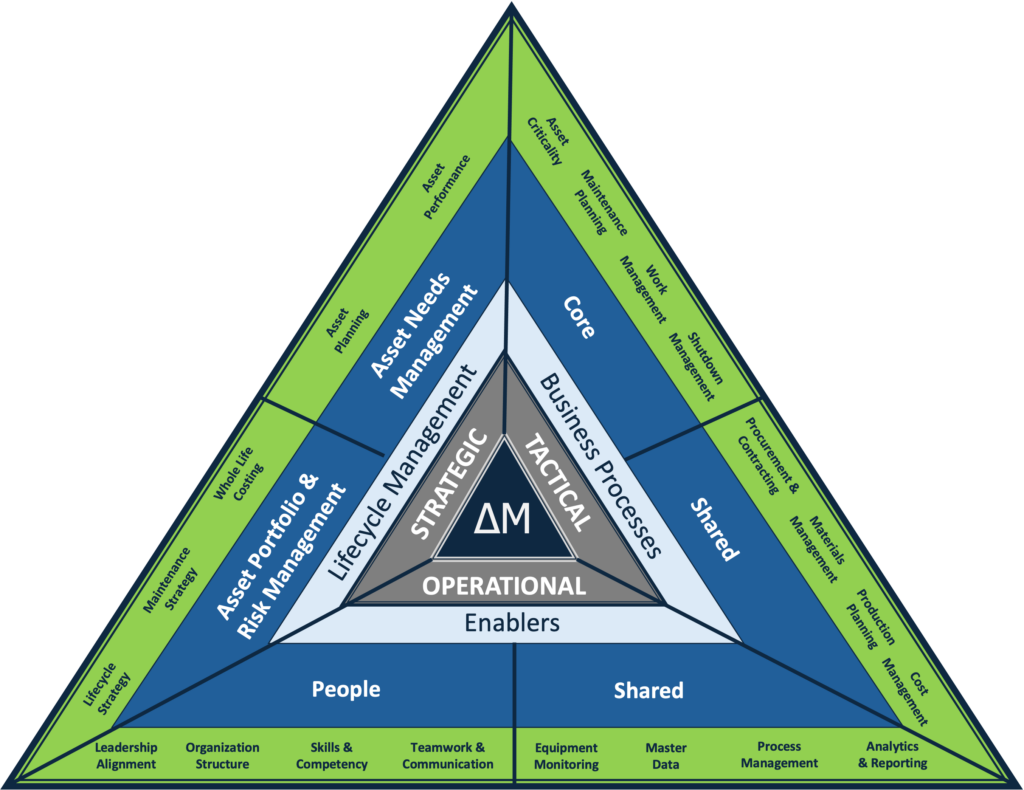

USC’s experience helping clients to shift asset performance by transforming and optimizing asset management capabilities and processes has repeatedly demonstrated the need to focus on the key levers and enablers to asset management and reliability excellence. Our asset management framework is designed to be pragmatic rather than conceptual, thereby leading to accurate, practical decisions about a client’s assets and aspirational outcomes.

The primary goal of USC’s asset management framework is to help our clients to implement and execute of a robust set of integrated processes and tools to manage and maintain their operational assets at the targeted service levels while optimizing life-cycle costs and asset life. This is accomplished by recognizing the needs to:

- Improve safe execution of work

- Increase asset life and reliability

- Improve productivity and cost performance

- Improve operational predictability

- Control material asset risks

- Develop competitive advantage

Our asset management and reliability framework helps clients identify an organization’s asset management maturity level and the areas and gaps that need to be addressed, by evaluating their strategic, tactical and operational levers and the enablers that comprise each.

Strategic (Lifecycle Management): A tailored maintenance program for each piece of equipment translates overall strategic objectives into executable plans for equipment upkeep. Our framework helps to structure and prioritize critical assets while defining a baseline operational ‘plan of action’ by determining strategies for maintaining equipment based on analysis of equipment capabilities, required performance levels, failure frequencies, and cost objectives. Optimal maintenance strategies are frequently a blend of preventative, predictive, operator-maintained, and run-to-fail options.

Tactical (Business Processes): Business processes bridge the gaps between the initial, ideal plan and the reality of ‘day-to-day’ operations, so the maintenance and reliability organization can make adjustments. Historically, many maintenance organizations have been poor utilizers of labor resources that result in low “time on tools” and excessive delays in repairing down or poor performing equipment.

Operational (Enablers): Enablers help to identify needed support to manage assets throughout their lifecycle in alignment with organizational aspirations. Leading asset management teams have also made changes in their organization structures and management practices to foster more action-oriented leadership that focuses on operational excellence, which usually requires a culture shift that must be relentlessly supported by the leadership team over the long-term. A heavy emphasis on management behaviors and company culture can help organizations make this difficult transition.

USC Helps You Tackle Key Challenges

- Optimize maintenance strategies and increase equipment availability operational output

- Predict asset integrity and reliability needs and improve time on tools

- Mitigate risks through stronger stakeholder partnerships, while removing redundancies in the supply chain

- Overcoming cultural and communication issues with contractors, while ensuring quality expectations

Do you want to understand how prepared your company is to drive needed asset performance and reliability improvements and what the key focus areas that will contribute to lower operating costs?

Want to find out more about how USC can help you uncover the hidden value lurking in asset portfolio?

For more information, let’s talk it through with a no obligation video conference call or a meeting with one of our executive team. Email info@usccg.com to arrange a call.

A proper Asset Performance Management (APM) plan ensures that your critical revenue-producing assets operate smoothly, efficiently, and at or near their rated capacity.

Asset Performance Management is the broad, systematic planning and control of a physical resource throughout its operating life. It includes the specification, design, construction, operation, maintenance, modification, and ultimately, disposal. Its principles apply to any industry with mission-critical assets, and is best implemented with support from the top-down and bottom-up. The entire organization should be involved, and supportive to ensure that it is executed properly.

Methodologies used in APM

- Asset Reliability – The process of ensuring that assets continue to do what they are needed to do, when they are needed to do it.

- Reliability-centered Maintenance (RCM) – Used to determine the activities necessary for the asset to operate properly by focusing on maintenance tasks that mitigate against the consequences of failure.

- Maintenance Management – Adherence to a benchmark of world-class maintenance standards and practices.

Key Performance Indicators (KPIs) and Enabling Technology

A vital step in implementing an APM plan is establishing, tracking, and analyzing KPIs. This is what takes a maintenance plan from reactive to proactive. The close management of leading and lagging Key Performance Indicators helps increase the likelihood of driving measureable results without significant capital investment.

Important KPIs include:

- % of planned maintenance work, and completed.

- % of unplanned/emergency maintenance work.

- Proactive work as % of planned maintenance work.

- Actual maintenance hours vs. planning estimate.

- Overall equipment effectiveness.

Having the right technology tools are needed to measure and analyze this data. USC Consulting Group has helped clients optimize their existing tools or install computerized maintenance management systems (CMMS), ERP systems, and USC’s own proprietary Lean Information Control System (LINCS) to ensure that this data is used effectively.

Benefits of Asset Performance Management

In addition to increased uptime, shorter turnaround times, greater throughput and lower maintenance costs, organizations have seen improvements in their EBITDA by 15-25%.

Learn more about how APM can improve the performance of your revenue-producing assets by downloading our eBook Asset Management: The Rise of Reliability.