-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: WBS

Having excellent On-Stream Time is the bread and butter of any processing plant or other facility that produces chemicals, power, pulp, etc. Effective maintenance practices minimize downtime by focusing and coordinating preventive and corrective maintenance activities. There is however another entire category of downtime; that is the downtime driven by Turnarounds. Paul Harker, Senior Operations Manager with USCCG, explains the best approach to Turnarounds below.

The objective of a Turnaround (TA) is to complete all essential maintenance work required to ensure that the area runs reliably for an entire production campaign. This must be done while keeping the TA duration as short as possible to minimize the loss of production.

Turnarounds exist for two reasons:

- There are some maintenance activities that can only take place completely and safely when the plant is down.

- A correctly scoped Turnaround, executed in the minimum time required, prevents unplanned down events that ultimately cause greater total downtime.

Without a comprehensive approach to turnarounds, an organization exposes itself to a number of issues:

- There may be no annual Turnaround Plan:

- The timing to conduct a TA is determined by an individual

- There are no future Turnarounds scheduled

- The work scope of any given TA may be focused on the problem asset(s), but is easily and artificially inflated by, ‘What can we get done while it is down?’ Rather than by, ‘What must be done to ensure reliability?’

- The ability to report & manage TA costs and duration is cumbersome and incomplete. In some situations, the final cost is only known weeks or months later when all the invoices are in.

- Costs and duration over-runs are frequent.

- There is often an intense scrambling to get everything done in the last few hours or days, whereas in a well-managed outage the final stages are typically calmer. This is because most of the work is already completed, with only a few critical activities left.

Due to the complex mix of parts, equipment, and contractors involved there is a great deal of scrambling required to execute the event. Some common stumbling blocks include:

- The TA planning process is not launched and stabilized early enough to be effective.

- The essential work scope is not formally defined and agreed, resulting in some important work being left out, in favor of less significant work that is clearly defined and ready to go.

- The critical path is determined and managed subjectively.

- An individual must manually coordinate the timeline of internal and outside resources.

- There is frequent interference or disconnects between crafts, and in some situations the crafts even have their own plans developed in isolation.

- Significant time is lost waiting for shared equipment to become available.

- The benefit of Key Activities being completed early is invariably lost due to the inability to reschedule with simplicity. As a result, all delays to critical activities translate directly to outage duration increases.

- Float is not readily visible in the schedule resulting in a less effective focus of attention and resources.

- Informal documents are used to pre-identify and track the status of the parts that need to be purchased for a TA.

To avoid these issues and to actively manage the balance between speed and effectiveness, a comprehensive system must define a closed loop. The loop needs to contain tools & techniques that fit into the following categories: Strategic Planning, Detailed Planning, Follow-Up, Execution, and Progress Monitoring.

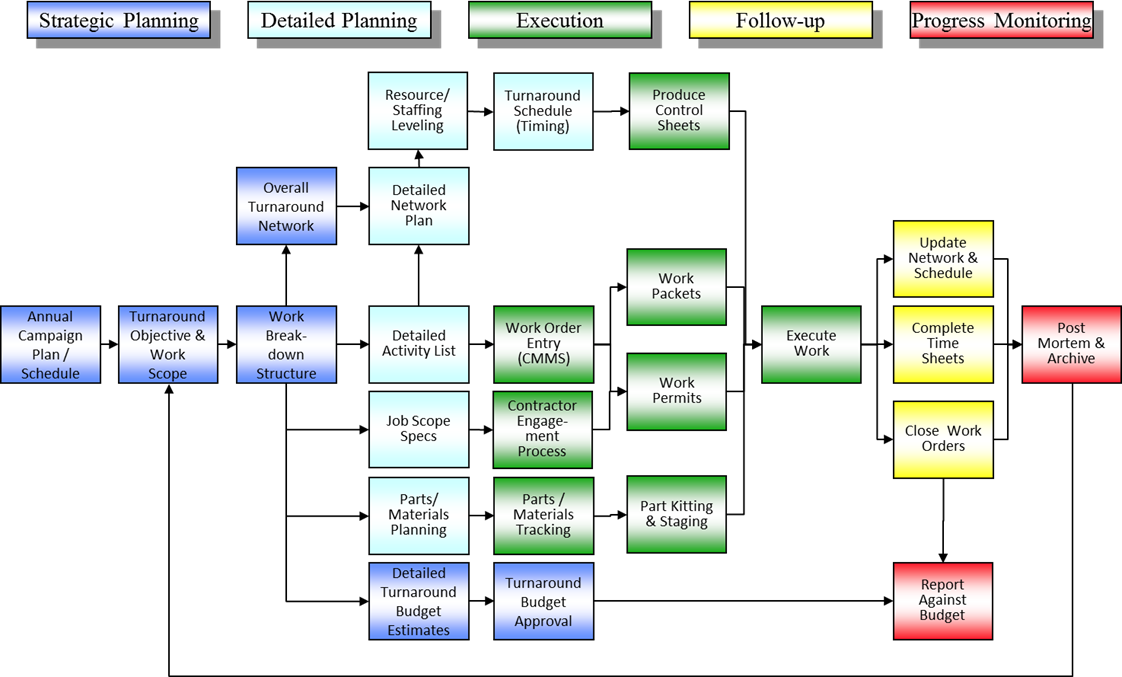

The illustration below depicts the Stages for managing Turnarounds. Each of the categories has been given a color code to make it easier to visualize which elements of the system fit into each category.

(Click image to enlarge)

1. Strategic Planning

The strategic elements of planning for Turnarounds exist to ensure that its activities will drive results. The results need to be consistent with the organization’s production and financial objectives. It is surprising how quickly complex activities like Turnarounds can develop a life of their own and stray from what the organization intended.

The Strategic Planning elements include:

- Annual Campaign Plan

- Define the Turnaround Objective and Essential Work Scope

- Work Breakdown Structure (WBS)

- Overall Turnaround Network

- Detailed Turnaround Budget Estimates & Budget Approval

2. Detailed Planning

This is where the bulk of the planning activities take place. In order to make effective use of the tools and techniques to implemented, there must be resources put in place that have the authority to draw together the needed information and to call the appropriate planning and updating sessions. If these resources and the processes they are pursuing are not given the full support of the management team, you will find that the Turnaround will miss one or more of its reliability, schedule, or cost objectives.

The Detailed Planning elements include:

- Detailed Activities List

- Detailed Network Plan

- Resource/Staffing Level

- Turnaround Schedule (Timing)

- Job Scope Specifications

- Parts/Materials Planning

3. Execution

Execution is where the rubber hits the road in any operating system. For Turnarounds, that includes: ramping down the operation, getting the maintenance work completed, and ramping back up. It also involves follow through on all of the detailed plans by getting work orders written, contractors aligned, work packets put together, materials acquired & staged, etc.

Managing the elements within the Execution category include:

- Produce Control Sheets

- Work Order Entry

- Contractor Engagement Process

- Work Packets

- Work Permits

- Parts/Material Tracking

- Part Kitting & Staging

- Execute Work (Operations, Maintenance, Engineering/HSE&S)

4. Follow-Up

Close Follow-Up is the key to the successful completion of the TA activities. It is also a basic management skill that cannot be over-emphasized. Follow-Up is the periodic review of the status of a work assignment to determine if we remain on-schedule or if some execution problem has arisen. It is essential to give good assignments with specific expectations for follow-up to be effective. This is as equally true for contractors as it is for our own people.

The Follow-Up elements include:

- Update Network & Schedule

- Complete Time Sheets

- Close Work Orders

5. Progress Monitoring

Progress Monitoring is the last of the system categories. It differs from Follow-Up in that we are monitoring the progress to improve our turnarounds, as opposed to executing the current TA. The elements here are designed to capture how successful we were against our cost, schedule, and reliability objectives. Are we getting better at these over time?

The Progress Monitoring elements include:

- Report Against Budget

- Post-Mortem & Archive

The tools and processes outlined above are designed to actively manage the balance between the speed and the effectiveness of Turnarounds.