-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- October 2024 (4)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Warehouse Safety

Exploring the dynamics of effective warehouse management reveals a myriad of strategies that significantly enhance operational efficiency and productivity. Focusing on best practices within the warehouse setting not only streamlines operations but also cultivates an environment poised for growth and adaptability. This article delves into essential techniques that are pivotal for modern warehouses aiming to thrive in an increasingly competitive landscape.

Streamline Your Space

You can achieve optimal performance by maximizing the layout and space utilization in your warehouse. By carefully planning and organizing the floor space to minimize movement, you ensure that your most frequently accessed goods are easily reachable. Vertical stacking and the use of adjustable shelving systems can significantly increase your storage capacity. Incorporating these practices creates an organized, efficient workspace that enhances overall productivity. Smart layout adjustments can also contribute to safer work conditions and reduce the risk of inventory damage.

Prioritize Safety Always

Ensuring a steadfast commitment to safety measures is essential for avoiding mishaps in your warehouse. Schedule and execute continuous safety training throughout the calendar to maintain awareness and adherence to crucial safety guidelines. Such consistent updates help embed these practices deeply into everyday activities, securing a safe working environment for all staff. Enhanced safety awareness not only diminishes the likelihood of incidents but also minimizes operational interruptions.

Harness Technology

Leveraging technology and automation in your warehouse can transform mundane tasks into high-efficiency operations. Consider implementing robotic systems for repetitive tasks such as packing and sorting, and use conveyor belts to minimize manual handling. Advanced technology like drones for inventory checks can save you time and labor. Integrating these innovations ensures your warehouse stays competitive in a rapidly evolving market. Furthermore, automation can significantly lower human error rates, leading to more reliable operations.

Master Inventory Management

An effective inventory management system is essential for maintaining the flow of goods in and out of your warehouse efficiently. Utilize modern software that offers real-time tracking and data analytics to keep tabs on inventory levels, order status, and logistical information. This integration allows you to forecast demand more accurately and manage stock levels to prevent both surplus and shortages, ensuring a smooth operation. Proper management systems enhance both speed and accuracy in order fulfillment. Streamlined inventory processes also help in reducing carrying costs and improving customer satisfaction.

Cultivate Clear Communication

Clear and efficient communication is the backbone of successful warehouse operations. Ensure that all team members are equipped with handheld devices that allow for real-time updates and communication. Establish a centralized digital notice system where updates and operational changes can be disseminated quickly. A well-structured communication process minimizes confusion and improves overall efficiency. Effective communication protocols facilitate quicker decision-making and response times in critical situations.

Commit to Continuous Training

Regular training sessions are crucial for maintaining high standards of operation in your warehouse. By continuously educating your staff on the latest operational practices and technology, you empower them to perform their roles more effectively. Regular training fosters a knowledgeable workforce that can adapt to new challenges and technologies as they arise. Investing in training improves both employee performance and job satisfaction. Ongoing education also promotes a culture of safety and efficiency, crucial for long-term operational success.

Embrace Regular Audits

Performing regular audits helps you identify areas for improvement in your warehouse operations. Use these audits to assess and refine workflow, inventory management, and efficiency. Continuous improvement initiatives should be a part of your operational strategy, aiming to enhance quality, reduce waste, and optimize overall performance. Regular feedback from these audits paves the way for incremental enhancements that lead to significant benefits. Audits also ensure compliance with industry standards and regulations, safeguarding your business against legal and financial penalties.

Refining warehouse operations through best practices is an ongoing journey that demands attention to detail and a proactive approach to management. As industries evolve and new technologies emerge, warehouses that prioritize efficiency, adaptability, and continuous improvement will stand out as leaders in their field, ready to meet the challenges and opportunities of the future.

*This article was written by Dean Burgess. Dean runs Excitepreneur, which celebrates the achievements of entrepreneurs. He understands that there are many types of entrepreneurs, and strives to provide helpful information to assist them in achieving their particular idea or goal.

Warehouses are bustling hubs of activity where precision and speed are key to meeting customer demands. While efficiency has always been a top priority in these environments, safety should not be overlooked. In fact, the relationship between efficiency and safety is tightly intertwined. Implementing safety procedures not only protects your workforce but also ensures your warehouse operates at optimal efficiency. Let’s explore how safety measures are pivotal in shaping warehouse operations.

The relationship between efficiency and safety

Although there is great emphasis on efficient operational practices, ensuring good health and safety practices goes hand in hand with these, too. This is especially relevant in the following areas.

Fewer Items Going Missing

One of the immediate benefits of a safety-conscious environment is a reduction in missing items. When your warehouse is organized and secure, it becomes much harder for equipment, products, or tools to disappear. This means fewer disruptions in operations caused by the frantic search for lost items.

Improved Awareness of Storage

Safety procedures often include guidelines for organizing and labelling storage areas. This enhanced organization ensures that employees are more aware of where items are stored, reducing the time wasted searching for goods. When everything has its place, it’s easier to locate, access, and move products efficiently. Good safety practices also mean that emergency items and personal protective equipment can be easily accessed when needed. This level of organization also helps to improve the overall operational efficiency in warehouses.

Neater Space Equals More Efficiency

A clean and orderly workspace is not just aesthetically pleasing; it also leads to greater efficiency. Cluttered or disorganized spaces can slow down operations, increase the risk of accidents, and impede the smooth flow of goods. A safe, tidy warehouse promotes productivity and minimizes disruptions.

Enhanced Inventory Practices

Efficiency in warehouse operations hinges on accurate inventory management. Safety policies often necessitate tracking and documenting the usage of certain items, like fuel for warehouse vehicles. By implementing these practices, you not only ensure that you never run out of critical supplies, but you also prevent unexpected delays due to equipment shortages.

The importance of safe equipment handling

Staff Safety

The safety of your warehouse staff should always be the top priority. Training employees in safe equipment handling not only reduces the risk of accidents but also promotes a culture of vigilance and responsibility. When workers know how to use equipment correctly, the chances of something going wrong decrease significantly, reducing the need for costly maintenance and repairs.

Correct Use of Specialized Equipment

Warehouses often rely on specialized equipment, such as forklifts, for various operations. Different types of forklifts are designed for specific tasks, and using them correctly is essential for safety and efficiency. Employees should receive training and regular refresher courses on warehouse safety handling to ensure they can operate equipment safely and effectively. Take forklifts, for example. There are many different kinds of forklifts on the market, each fulfilling a specific purpose. The incorrect use of equipment such as these can be costly for repairs and hinder the efficiency level at which certain operations happen.

Implementing safety policies for warehouses

One of the best ways that safety and efficiency can be ensured is through effective policy writing and implementation. Policies are essential for consistency in warehouse operations and provide a platform for the health and safety standards you want to maintain.

Components of a Warehouse Equipment Safety Policy

- Equipment Usage Guidelines: Clearly define how each piece of equipment should be used, including safety procedures, maintenance requirements, and any special precautions.

- Training Programs: Establish comprehensive training programs that cover equipment handling, safety protocols, and emergency procedures.

- Maintenance and Inspection Procedures: Specify regular maintenance schedules and inspection routines to ensure equipment remains in optimal condition.

Ensuring Adherence to Safety Policies

To guarantee that safety policies are adhered to, you can:

- Conduct regular safety audits and inspections.

- Encourage open communication channels for employees to report safety concerns.

- Recognize and reward safe practices to promote a safety-oriented culture.

- Ensure that all staff are trained in the use of warehouse equipment

- Ensure staff are up to date with the current policy and any changes that may follow

Regular Updates to Safety Policies

Safety policies should evolve with changing technologies and regulations. Regularly review and update your safe equipment handling policy to stay current with best practices and legal requirements. It’s, therefore, imperative that safety policies are updated regularly and that the state of warehouse equipment is assessed as often as necessary.

Consistency in all warehouse operations

Stringent safety policies are essential for maintaining consistency in warehouse operations. They have a profound impact on various aspects:

Inventory Reporting

Accurate inventory reporting is essential for meeting customer demands. Safety policies help ensure that inventory is stored, handled, and recorded correctly, reducing discrepancies and errors in reporting.

Safety Standards Maintenance

By implementing safety policies consistently, you ensure that safety standards are maintained across all aspects of your warehouse operations. This consistency minimizes the risk of accidents and injuries.

Legal Compliance

Compliance with safety regulations is not just a moral imperative; it’s also a legal requirement. Consistently following safety policies helps your warehouse meet legal obligations, protecting your business from potential liabilities.

The supplier’s role in safe equipment handling

Suppliers play a crucial role in ensuring safe equipment handling in your warehouse:

- Equipment Guidance: Suppliers can advise on how to use equipment correctly, recommend upgrades when necessary, and provide maintenance plans to extend the lifespan of your machinery.

- Renting Safely: Companies like Alto Handling ensure safety when renting out forklifts to customers. They perform thorough inspections, maintenance, and safety checks to guarantee that the equipment they supply is in optimal condition.

Efficiency and safety go hand in hand in warehouse operations. By prioritizing safety through policies, training, and equipment handling, you not only protect your workforce but also optimize the efficiency of your warehouse. Consistency and supplier collaboration further enhance safety, ensuring a smooth and secure warehouse environment. Equipment leased from suppliers like Alto Handling has a comprehensive training and equipment maintenance guide, helping you operate as efficiently as possible and ensuring best practices.

Given that powerful equipment and trucks frequently operate close to one another, warehousing is one of the riskier industries. Rapid growth in e-commerce is driving an ever-increasing demand for the delivery of products in shorter time frames. Industrial and commercial warehouses must meet this demand while maintaining the present standards for safety.

There are thousands of reports of injuries, illnesses, and deaths in the warehousing industry annually. Many of those are the result of industrial mishaps such as slips and falls, exposure to dangerous products, and defective equipment. Warehouse safety should be the employers’ utmost priority to keep employees safe, ensure efficient operation, maximize productivity, and minimize injury or damage.

Best Practices for an Efficient Warehouse

Preventive Maintenance

The majority of occupational dangers can be avoided by taking the following precautions:

- Recruitment & Training

- Safety Equipment & Precautions

- Hygiene & Pest Control

Planned Maintenance

Periodic maintenance can minimize equipment downtime and reduce maintenance costs. The fundamental maintenance advice listed below should be adhered to in order to maintain your warehouse operating at maximum capacity:

- Have A Maintenance Plan

- Stay Vigilant

- Ask Employees For Their Opinion

By regularly monitoring your warehouse equipment, spares, and procedures, and promoting the well-being of your personnel, you’ll not only increase the productivity of your warehouse, but you’ll also cut your losses if there’s an emergency or an accident. Make sure your warehouse is as secure as it can be by working with your staff.

The infographic below by 2Flow takes a look at ‘Creating A Safe & Efficient Warehouse’.

[click to enlarge]

If you need help with creating a safe and efficient warehouse in your facility, contact us today.

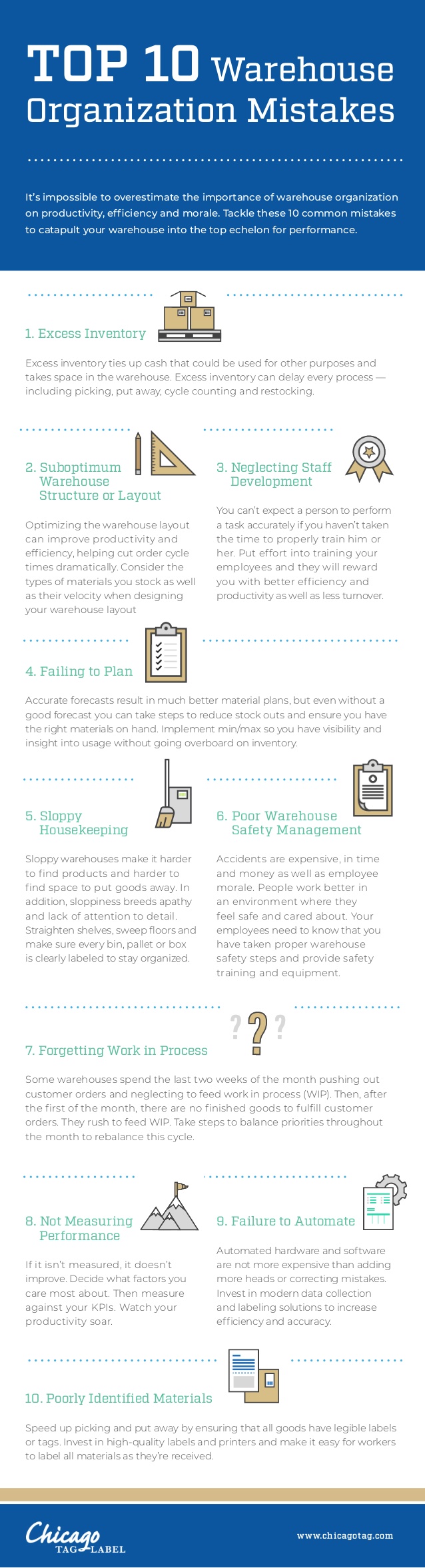

The supply chain is a business’s lifeblood. Unfortunately, much like our own bodies, it’s possible for this system to become sluggish and lethargic through neglect. Just as a lack of exercise and a poor diet can cause our blood to become clogged with cholesterol and fat, inefficient warehouse management can lead to serious issues for your operation. This is why it’s so important to understand how to avoid bad habits that can lead to problems in your warehouse operation.

For example, one of the most common mistakes made in these environments is having too much inventory. A glut of products means the money spent producing them is just sitting on the shelf providing no return on investment. A strict SKU rationalization plan can ensure that nothing goes to waste, and that only those items that are sure to sell enter the supply chain.

Another frequent misstep is made when inventory management doesn’t include metrics. Without a clear idea of how well a facility is performing, it can become nearly impossible to make improvements. Measuring all the factors that matter to your operations is essential if you want to streamline them. Too many warehouse managers also forget about work in process as they rush to push end-of-month orders out the door. When there are no finished goods to fill orders at the start of the month, they’re always playing catch-up.

Taking care of your body is crucial if you want to live a longer, healthier life — and the same principle applies to your warehouse management. For more tips on how to avoid poor habits that can hurt your business, see the accompanying infographic.

Author bio: Don Amato is Vice President of Sales for Chicago Tag & Label, which manufactures form labels, labels and tags that deliver solutions to a broad range of industries including retail, industrial, manufacturing, distribution and medical environments.