-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2025 (1)

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Throughput

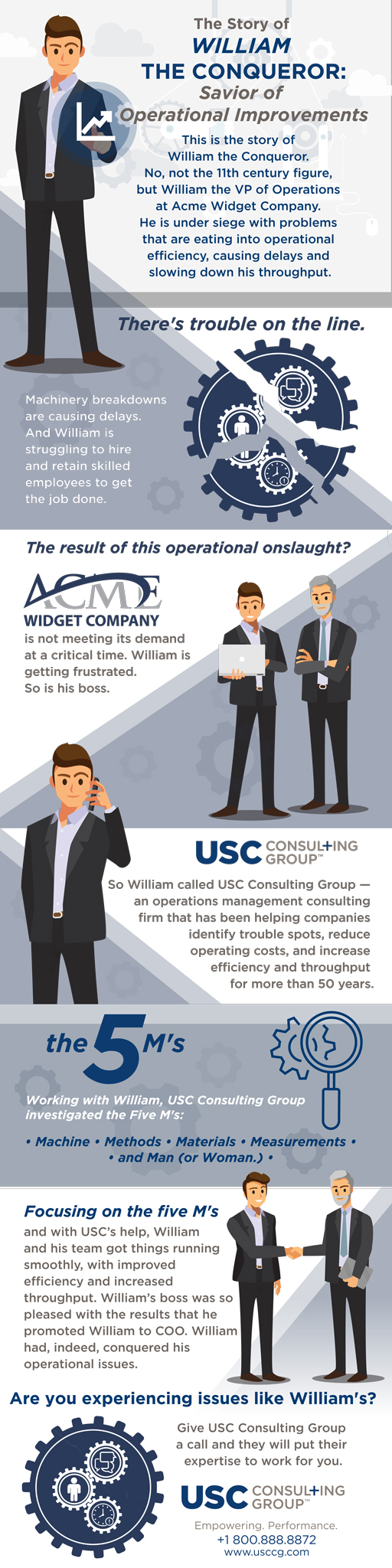

Everyday we set out to conquer life in various ways. We conquer fears, objections, and challenges. It is how we overcome these obstacles that defines are character and successes.

There was a famous historical figure with the moniker William the Conqueror who set out on a conquest which changed the face of history. While we are not conquering nations in the name of our country, we do find victories everyday for ourselves and our companies.

The following is a story illustrating one such victory overcoming operational issues that many others can also achieve themselves…

This is the story of William the Conqueror. No, not the 11th century figure, but William the VP of Operations at Acme Widget Company. He is under siege with problems that are eating into operational efficiency, causing delays and slowing down his throughput.

There’s trouble on the line. Machinery breakdowns are causing delays. And William is struggling to hire and retain skilled employees to get the job done.

The result of this operational onslaught? Acme Widget Company is not meeting its demand at a critical time. William is getting frustrated. So is his boss.

So William called USC Consulting Group — an operations management consulting firm that has been helping companies identify trouble spots, reduce operating costs, and increase efficiency and throughput for more than 50 years.

Working with William, USC Consulting Group investigated the Five M’s:

1. Machine (Does it need maintenance?)

2. Methods (Can you make processes more efficient?)

3. Materials (Supply chain bottlenecks?)

4. Measurements (Are we measuring the right things?)

5. Man or Woman power (Are your people skilled and trained?)

Focusing on the Five M’s and with USC’s help, William and his team got things running smoothly, with improved efficiency and increased throughput. William’s boss was so pleased with the results that he promoted William to COO*. William had, indeed, conquered his operational issues.

If you are experiencing operational issues like William, give USC Consulting Group a call today and we will put our expertise to work for you, too. *You may not be promoted to COO, but you will increase your operation’s efficiency.

This is the story of William the Conqueror.

No, not the 11th century figure, but William the Vice President of Operations at Acme Widget Company who becomes the Savior of Operational Improvements. William is under siege with problems that are eating into operational efficiency, causing delays and slowing down his throughput. There’s trouble on the line. Machinery breakdowns are causing delays. William’s supervisors aren’t communicating issues during shift changes. And William is struggling to hire and retain skilled employees to get the job done.

The result of this operational onslaught? Acme Widget Company is not meeting its demand at a critical time. William is getting frustrated with the delays, breakdowns and inefficiencies. So is his boss.

That’s when William called USC Consulting Group — an operations management consulting firm that has been helping companies identify trouble spots, reduce operating costs, and increase efficiency and throughput for more than 50 years.

Working with William, USC Consulting Group investigated the Five M’s:

- Machine (Does it need maintenance?)

- Methods (Can you make processes more efficient?)

- Materials (Supply chain bottlenecks?)

- Measurements (Are we measuring the right things?)

- Man or Woman (Are your people skilled and trained?)

Focusing on the five Ms and with USC’s help, William and his team got things running smoothly, with improved efficiency and increased throughput. William’s boss was so pleased with the results that he promoted William to COO*.

William had, indeed, conquered his operational issues.

Moral of the Story: William is not a real person, however, the struggles he and his team were experiencing are a reality for many executives today. Are you experiencing issues like William’s? Would you like to discover operational improvements in your business to increase your throughput and efficiency? Give USC Consulting Group a call at 1-800-888-8872 and we will put our expertise to work for you.

*You may not get promoted to COO, but you will increase your operation’s efficiency.

If you’re in manufacturing, you’ve certainly heard of two process methodologies, Lean and Six Sigma. Lean, which has been around forever and has recently migrated from the manufacturing floor into other industries (they’re even talking about Lean HR methods) and Six Sigma, a newer technique. Two sides of the same coin, Lean looks at making processes more efficient and reducing lead times, while Six Sigma focuses on cutting down on defects. Both are useful goals when aiming to optimize your processes, throughput and ultimately, your bottom line.

Lean vs Six Sigma, which is better? Which should you be investing in if you’re coming up against inefficiencies in your production, and can they be used together?

Let’s take a closer look at both methodologies to see who comes out on top in this operational improvement matchup.

Lean

The whole concept of Lean started with identifying and eliminating waste in manufacturing operations. Pioneered back in the day by Toyota… or by Henry Ford even earlier, depending on who you ask, Lean manufacturing is about cutting costs, eliminating waste in both processes and products, and generally becoming as “lean and mean” as possible to reach optimal efficiency. The heart of the process is identifying and eliminating what Toyota called the “seven deadly wastes.” (We happen to think it’s eight.)

- Overproduction. Making too much leaves you with unused product.

- Waiting. This includes waiting on the shop floor between steps on the line, or waiting on supply or even equipment.

- Transporting. This covers excessive movement of inventory, causing the possibility of damage, or even excessive movement within the manufacturing process itself.

- Processing. Do you have extra, unnecessary steps in the manufacturing process? Are you doing in two or three steps what you can do in one?

- Inventory. Too much stock on hand. During the pandemic, many companies combatted supply chain delays by stocking up on inventory. We think that’s a mistake.

- Excess motion. This means getting from Point A to Point B on the floor, extra walking, lifting, reaching. Can things be configured more efficiently?

- Defects. Defects in product happen to the best of us.

- People. This is the eighth waste, which Toyota didn’t identify. Are you using your people to their fullest potential? Or is there untapped potential for a great manager or supervisor you haven’t noticed?

Examining all of these areas of “wastes” in your operation will help you become more efficient and ultimately more profitable. In other words, lean and mean.

Six Sigma

Six Sigma, at its most basic level, is about quality control. Minimizing flaws and defects. But it’s much deeper than that. Six Sigma is data driven, statistical and aims to improve cycle time while eliminating or reducing defects in manufacturing. It’s about using stats, data analysis and also project management techniques to improve the whole process.

The Six Sigma process is defined by an acronym: DMAIC. Define, Measure, Analyze, Improve and Control. First, you define the problem that you want to improve. Then, the team measures the process and analyzes it by using data analytics to get to the root of the problem. From there, it’s about creating improvements and fixes, and setting up controls to make sure it doesn’t happen again.

Six Sigma requires rigorous training to get the process right, so rigorous that practitioners need a certification in the process. The certifications are ranked with a belt system similar to martial arts, with white belts being familiar with the basic process, up to black belts who become masters of the process and are certified to take on complex problems and projects, and to train others in it.

Lean Six Sigma: Better together?

Should it really be Lean vs Six Sigma? Or rather Lean AND Six Sigma? Can these two powerful methods be used together? Yes indeed. In fact, they’ve joined to become one methodology in some circles: Lean Six Sigma, or LSS, which aims to cut defects and shorten lead times.

But, here’s the tricky part.

Ironically, Lean and Six Sigma can clash if not deployed correctly. Defects can be reduced by slowing processes down — reducing speed. On the other hand, you can increase the defect rate by speeding up processes.

Getting it right, striking that perfect balance is imperative. That’s why it requires training and certification in the techniques. At USCCG, Dr. Frank Esposto is our Lean Six Sigma Master Black Belt and Senior Director of Quality. He is also a certified LSS instructor.

Dr. Esposto states, “When we employ the Lean Six Sigma methodology to help our clients’ operations, we don’t simply come in and do it for them. We train clients in these techniques so they can employ them long after we leave.”

The training course Frank teaches is rigorous and hands-on. When participants complete the course, they are certified. Being certified in Lean Six Sigma is a highly sought-after skill.

To summarize, it is not Lean vs Six Sigma, but rather Lean Six Sigma – two complimentary methodologies that when balanced properly reduce operating costs, increase throughput, and achieve overall improvement to your bottom line.

Are you interested in learning more about how these powerful methodologies can work to optimize your processes? Give us a call today. In the meantime, read much more about LSS in our eBook: “Lean Six Sigma: Do You Really Know These Methodologies?”

If you have noticed — or, in many cases, been run over by — dramatically increasing customer demand for your products, you’re not alone. Now that restrictions have been lifted in many parts of the country, and the world, consumers are spending money again. And spending. And spending. All of that increased customer demand translates to the need for ramped-up production across a wide swath of industries, from manufacturing to mining to agriculture to pulp and paper — and the list goes on. Some pundits are predicting an economic boom the likes of which this country hasn’t seen since the last Roaring ’20s. They’re calling it a “supercharged rebound,” one that may well lead to many years of strong growth. That’s great news!

The problem is the speed at which it’s coming and the capacity of companies to meet that demand.

Download USC Consulting Group’s white paper Strategies for Meeting Increasing Customer Demand today. We’ll look deeper into this issue, the reasons for the disconnect between demand and the ability to meet it, and overcoming challenges such as supply chain disruptions and the hiring crunch.

Why is USC uniquely qualified to help?

We were founded as Universal Scheduling Company in 1968. Back then, it was all about shop floor control and working with employees to find out how to get more work done. We spent years refining our capabilities and analyzing processes. We’re up and down the supply chain now. We do organizational design, spend analysis, strategic sourcing. But the heart and soul of our business has been built on getting more efficiency on the shop floor, helping companies do more with less, and increasing operational efficiencies overall.

We’re not like the consultants who started at the high level and then dabbled with the floor. They don’t get out on the shop floor very often. We built our business from the floor up. We’ve had our (steel-toed) boots on the ground for more than 50 years. We’re most comfortable where they’re most uncomfortable. Getting out on the floor — it’s where we live.

If you’d like to learn more about how we work, or talk with us about strategies you can use to harness your existing assets to meet your growing customer demand, please get in touch today.

After 50+ years in the operations management consulting business, USC has become skilled detectives at finding hidden opportunities in our clients’ operations. Here’s the evidence on how we uncover more throughput and production in your operations:

The key to doing more with your existing assets is uncovering opportunities for efficiency and increased productivity. Things you might not even see that are right under your nose.

- Excessive cycle time

- Excessive machine changeover time

- Operational bottlenecks

That’s where our expertise comes in. We often find them by looking at issues that are accepted in the workplace as “that’s the way we’ve always done it.”

We discover breakthroughs by asking questions.

- Where is the bottleneck?

- Is it technical?

- Is it tactical?

If it’s about technology, or your assets, maybe it’s time to bring in the engineers to improve on your machines’ functions.

If it’s tactical, we analyze your processes to find areas of improvement.

Follow the footsteps in the accompanying infographic as Detective Payne points out the areas of interests you want to focus your magnifying glass on.

If you’d like to catch the “thief” stealing efficiency in your operations, contact us today. We’ll put our expert detective work to use for you.

It’s been a bumpy ride for the automotive industry this past year. Back in November and December when the economy was running full speed ahead, automotive manufacturers had high expectations for robust sales activity in 2020.

Then, COVID-19 happened.

With frightening speed, the economy ground to a halt as states, employers, and officials implemented various measures to slow the spread of the virus, which ultimately resulted in layoffs and reduced buying activity. In a typical year, the number of motor vehicles sold runs between 17 million and 20 million. But the sudden decline in car sales has analysts forecasting an overall light vehicle sales total of 14 million nationwide by this year’s conclusion, CNN reported. Perennial leaders in auto sales — such as General Motors, Ford and Chrysler — witnessed double-digit declines in quarterly sales compared to 2019. In response, automotive manufacturers slowed down output, a consequence of declining demand, assembly worker absences caused by COVID-19, and other supply chain disruptions.

Yet defying the odds, automakers appear to be back in the driver’s seat. As some of the coronavirus lockdowns and restrictions have lifted, the economy is in growth mode, with gross domestic product soaring at an annual rate of over 33% in the third quarter, according to the Bureau of Economic Analysis.

While car sales during this same period were lower than this time last year, they finished far better than experts anticipated, including Cox Automotive Senior Analyst Michelle Krebs.

“It’s coming in better than we thought,” Krebs told CNN.

Here’s the problem: Consumers may be back in a buying mood, but automakers still aren’t operating at peak capacity. As Car and Driver magazine reported this past summer, in response to the effects caused by the pandemic, numerous nameplates pushed the pause button on several all-new or upgraded product reveals. During the average year, the upcoming year’s car models start arriving on dealer lots in the late summer. In 2019, for example, 11% of motor vehicles available for purchase were 2020 models. Today, the latest models represent just 2%.

“Consumers may be back in a buying mood, but some automakers aren’t operating at peak capacity.”

“They’re just sort of behind,” Cox Automotive Senior Economist Charlie Chesbrough told Car and Driver. “The white-collar workers are behind in planning the model-year rollovers; the factories have had a difficult time getting the supply chain up to speed.”

The same is true for used and preowned automobiles. As Edmunds.com’s Jessica Caldwell pointed out in a press release, used vehicle parking lots had few to any buyers in them initially, but now, what was unsold is going fast.

The question becomes, then, what strategies and planning can automotive manufacturers implement to ramp up production so inventory issues don’t show up in 2021? The following recommendations may help:

Keep an ongoing maintenance schedule for equipment

While assembly workers is critical to increasing output, the equipment leveraged are the workhorses of auto manufacturer factories, increasing and streamlining production seamlessly. But when they’re not working or encounter repair issues, everything slows down. That’s why it’s important to adhere to a maintenance schedule so equipment is well lubricated and bolts are properly fastened. From semi-automated lifting machines to die gripper cranes, preventive maintenance is critical to avoiding issues that can prevent assembly teams from reaching their production goals in a timely manner.

Review current systems and processes

When it comes to solving problems, you first have to recognize exactly what those are and why they’re happening. When it comes to output for automakers, it’s really been a confluence of events brought on by the pandemic, economic instability that resulted and how manufacturers responded. However, with slight or significant tweaks on the factory floor, teams may be able to maximize how much they produce. By mapping current production processes, crews may be able to isolate where the problems exist and uncover bottlenecks. This type of review may all help identify potential bottlenecks so they can be resolved before they occur.

Consider developing new protocols to keep teams healthy

One of the issues that automotive manufacturers encountered throughout the pandemic was absenteeism. The virulence and contagiousness of COVID-19, the symptoms of which often are similar to influenza, led to fewer people on assembly lines, leaving others to pick up the slack. While most people fully recover from the illness, a lack of personnel naturally leads to a slowdown. Firms may want to think about installing measures that can help workers avoid the potential for becoming sick. Whether it’s daily health screenings like temperature checks, social distancing measures, personal protective equipment, or more regularly scheduled deep cleanings between shift changes, a healthy workplace is a productive workplace.

Perform investigation into more automation

Automation is already a standard part of many automakers’ production processes, given it helps to maximize output, reduce costs and virtually eliminate mistakes that result from human error. But as technology is in a constant state of advancement, there may be systems out there that are better than what you have now. None of this is to say you should invest in more automation, but smarter machines can not only increase the speed of output but improve quality control and give crews the ability to handle issues that automation can’t solve.

Using automation as a supplement to your personnel can help you identify quality control issues that they may miss. As IndustryWeek points out, numerous quality control studies tracing back to the 1970s show human inspectors find 80% of the defect in manufactured parts. Leveraging automation can pick up the difference to increase efficiency, consistency, and — above all else — productivity.

Diversify suppliers

Just like a major motion picture is more than the actors on screen, an automobile is made up of thousands of pieces, parts, metals and components. A supplier is bound to encounter supply chain issues at some point. Instead of relying on one, aim to diversify them so if one is out of what you need, you can pivot to a supplier that has the items necessary. Strategic sourcing is a discipline that is crucial to ongoing supply chain management.

From throughput to quality improvements or supply chain optimization, USC Consulting Group can help your company resolve issues and rev up your operations using the right methodologies. Contact us today to learn more.

The driving drum beat in the popular rock tune “The Chain” by Fleetwood Mac is reminiscent of production’s TAKT time drum beat set by customer demand. When a company’s demand or supply is disrupted, the disorganized supply chain might sound like a band without a beat. Disruptions such as COVID-19 reinforce that disrupting events occur more frequently, tend to last longer, and result in greater loss than most companies assess during traditional risk assessments. Disruptions make abundantly clear the need for accelerated information for rapid responses, resiliency, and optionality in the supply chain.

If recent global disruptions are affecting your company’s typically steady supply chain drum beat, there are strategies that can help you get back on pace. Pairing over 50 years of experience with analytical data from recent research, USC Consulting Group has compiled the below infographic with five tried-and-true techniques for supply chain optimization to mend your operations and improve your processes to be as efficient as possible.

- Enhance transparency by leveraging intelligent data to more effectively forecast shortages.

- Use strategic sourcing by partnering with multiple suppliers to ensure a consistent flow of products.

- Identify opportunities to automate certain work processes, diminishing cycle time and enhancing throughput.

- Coordinate and collaborate with channel partners to enhance communication.

- Maintain a regularly occurring maintenance schedule to reduce the effects of equipment breakdowns on production.

Supply chain optimization is our specialty at USC Consulting Group. We can make sure your operations Don’t Stop and your Silver Springs are humming like a Songbird. You can Go Your Own Way, but then we may not be able to stop making Fleetwood Mac references and all of your Dreams may not come true. Contact us today to ensure that you’re Never Going Back Again to a broken supply chain and instead keep your driving drum beat steady.

If there’s one certain thing about the food and beverage industry, it’s the fact that nothing is certain – not when it comes to trends, anyway. Take nutrition as a classic example. At one time, low fat was all the rage; now it’s high fat, combined with low carbs. In the late 1990s and early 2000s, the all-protein diet from lean meat sources was popular. Today, plant-based protein is on more and more dinner menus.

But there is one constant in the food and beverage business: consumers’ demand for top quality, originality and convenience. Thus, the heat is always on for manufacturers to deliver on Americans’ high expectations.

The best way to come through is to understand what’s on the menu, in terms of food manufacturing challenges facing producers and developing strategies for how to overcome them. Our ebook “Understanding the Challenges Facing Modern Food and Beverage Producers” details some of the potential obstacles producers face and offers suggestions that can help turn sour situations into sweet solutions.

Download our ebook today to learn more about current food manufacturing challenges and discover solutions to key areas including:

- Product quality

- Leveraging technology

- Product variation

- Formalized workflows

- Throughput rates

- Takt time

Contact us today for help fine-tuning your workflows or improving yield and productivity.