-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2025 (1)

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Supply Chain Optimization

When managing your supply chain, it’s crucial to be aware of the latest technologies and how to integrate them with your existing systems. Doing so will optimize the efficiency of your operations and boost transparency. To benefit from updated technology, you may first encounter some obstacles during implementation.

This article explores common barriers to adopting technology and provides strategic insights into overcoming these obstacles so your organization can maximize the benefits of technology advancements.

Common Barriers to Tech Adoption and How to Overcome Them

As you participate in the global supply chain systems, you may encounter a variety of common barriers to adopting technology effectively. Common barriers include:

Integration complexities

If you’ve been in business for a significant amount of time, your team will likely have legacy systems that are challenging to integrate with emerging technologies. It’s best to integrate new technologies slowly and methodically.

Prudent managers will create change management strategies to ensure the process goes more smoothly. Companies can work with supply chain integration services, which cover strategic decision-making and setting up integration teams when working with new technology solutions.

Budgetary limitations

One common objection in management to deploying modern technology is the expense of investment and maintenance. But you have to spend money to make money and avoid the opportunity cost that would result from failing to adopt a promising technology.

A strategic move would be to demonstrate the return on investment in Software as a Service, or SaaS, and how adopting new technologies will provide you with significant long-term savings.

For example, you can calculate how much money your organization could save if you migrated data and software services to a cloud computing solution, which would have a dedicated staff of IT experts keeping watch over your information. This will be less expensive than maintaining your own data servers and trying to predict how much capacity you’ll require.

Cloud computing lets your supply chain stakeholders connect to data from any location safely and securely, fostering greater collaboration using mobile devices when they’re not near a desktop computer.

Data security concerns

As you adopt new technology, you must understand the security implications of its use. Criminal hackers may try to invade the privacy of employees who maintain your supply chain.

They may attempt to breach your network with malware — which can lead to theft of intellectual property or lock down data during a ransomware attack — and threaten to not restore access to crucial information until you pay the ransom. You’ll want to implement advanced protocols to ensure optimized cybersecurity. It’s prudent to make sure you comply with global data privacy restrictions.

Workforce training needs

You may have been facing a shortage of skilled workers who can help you deploy and manage new supply chain technologies. Accordingly, you’ll need to invest in development and training.

Often, it’s best to partner with external consultants, whether you’re improving your onboarding process or overhauling the ongoing training you provide to long-standing members of your team.

You want to engage your employees so they can work to their maximum potential within the supply chain. For example, give them wearable mixed reality devices to provide them with additional content to enhance how they carry out complex tasks and work more safely.

Without the Latest Technology for Supply Chain Integration, You May Fall Behind the Competition

Owners and managers of businesses with significant reliance on the global supply chain cannot keep their heads in the sand regarding technology. It pays to hire supply chain experts with a background in technology to pave the way toward optimized integration.

Companies without in-house expertise can partner with firms that specialize in supply chain integration services. Doing so will help you maintain a competitive edge and work more efficiently and transparently.

*This article is written by Gary Brooks. Gary is the CMO of ketteQ and has more than 25 years of experience leading marketing for top software companies. Brooks has been featured in major publications such as Forbes, VentureBeat, ZDNET, Equipment World, Nikkei, Manufacturing Business Technology, Supply & Demand Chain Executive, and Field Service News, among others. Brooks holds a BS from Northeastern University and an MS, Management from Lesley University. He also is the co-founder of the Brooks Family Foundation.

Factors ranging from the weather to celebrities’ social media posts can spur the public’s demand for particular products. Those spikes can cause supply chain constraints company leaders aim to avoid. It is better when corporate teams can predict what people will want and get those products far enough in advance to cater to everyone wishing to buy them. To achieve this, businesses are using AI to strengthen their supply chains. Here’s how…

Managing Demand While Selling Diverse Product Assortments

Demand planning is especially complicated when retailers sell huge varieties of goods within a large category. Such was the case with one of Canada’s largest electronics retailers. People go there to purchase everything from phone chargers to televisions.

However, the demand for those two examples is very different. Many consumers buy several phone chargers per year, such as if they want one for each main room in a home or have forgotten to pack the item before going on a trip. However, most TVs last several years, and people only buy them once the ones they have break or otherwise no longer meet their needs. Plus, many shoppers are more likely to buy those big-ticket items during the holiday season than at other times.

The Canadian retailer uses AI and machine learning technologies to get data-driven demand insights that shape inventory and supply-chain-related decisions. Its leaders have already noticed several benefits. For example, demand planning has become more automated, and those involved can receive detailed reports highlighting potential business risks and impacts.

Additionally, supply chain employees can address slow-moving inventory, plan more enticing promotional offers and reduce stockouts. Another aspect of the AI solution evaluates various supply chain scenarios and gives prescriptive recommendations to prevent unwanted consequences. These examples show how AI can support workers in their roles and increase productivity.

A common misconception about AI is that it will replace human staff. One study found job loss from automation and other advanced technologies was a worry for 42% of respondents. However, besides assisting them with the tasks they already know, artificial intelligence can expand their skills, encouraging them to use new platforms and tools that make demand planning easier.

Streamlining Demand Planning Processes for Better Productivity

Demand planning processes vary depending on what the brand sells, the size of its supplier network, its budget and more. However, no matter how organizations handle them currently, AI can pinpoint opportunities to streamline the work for better overall outcomes.

One example comes from a multinational consumer goods enterprise offering diapers, detergent, personal grooming products and other household staples. Leaders hoped to improve current demand planning by bringing artificial intelligence into the workflow. Initial data inputs for the project included bill-of-materials information for 5,000 products and 22,000 components. Additionally, users imported various types of supporting supply chain details into the system, including specifics about vendors, warehouses and manufacturing plants.

The technology then compiles all that information to give real-time or trend-based insights. Besides providing live inventory data, the AI product can generate supply projection reports that indicate future needs while highlighting possible supply chain disruptions. Knowing about potential issues sooner gives employees the information to act confidently and prevent or mitigate those problems.

The tool was also a significant productivity booster for the consumer goods firm. For example, supply chain queries used to take more than two hours to complete but now occur immediately. Additionally, although it formerly needed more than 10 people to verify the data, the technology can do that without human oversight. Such improvements substantiate studies showing AI can make people 20%-45% more productive depending on various factors.

Running Supply Chain Simulations Before Key Events

Even though some periods of increased demand are impossible to predict, most supply chain managers can anticipate others with near certainty. For example, Black Friday is one of the biggest shopping days of the year in the United States. Additionally, late summer drives sales of bedding sets, reasonably priced furniture and school supplies as students prepare for college.

Demand planning is essential for giving supply chain professionals the necessary information to source and move the products customers will want most during those hectic periods. Since artificial intelligence can process large quantities of information quickly, users could feed details such as social media mentions, customer service email or chat data, and sales figures into tools to determine which factors make some products more or less desirable.

The leaders of one multinational American retailer used AI to determine what customers would want before Black Friday arrived. The goal was to learn those details before shoppers even consciously expressed a desire to buy specific items. While using the artificial intelligence platform, retail staff entered data about shopping and customer trends, seasonal factors and more. The resulting output steered supply chain decisions and helped address issues that might ordinarily cause Black Friday disruptions.

The retailer has also added AI to its daily supply chain workflows, relying on the technology to anticipate demand cycles and unexpected traffic peaks. Some businesses use complementing technologies such as digital twins to get similar results. These tools enable people to predict bottlenecks and investigate potential actions before pursuing them in real life.

Making Demand Planning More Manageable

Demand planning is tricky and requires a thoughtful approach from people who combine their expertise with trustworthy data. However, these examples show how purposeful AI applications can assist with this all-important aspect of supply chain operations, increasing the likelihood of satisfied customers and profit.

*This article is written by Jack Shaw. Jack is a seasoned automotive industry writer with over six years of experience. As the senior writer for Modded, he combines his passion for vehicles, manufacturing and technology with his expertise to deliver engaging content that resonates with enthusiasts worldwide.

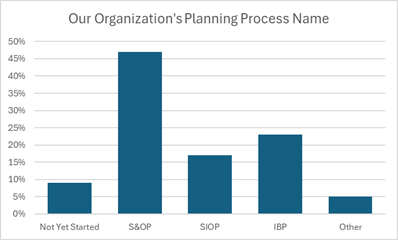

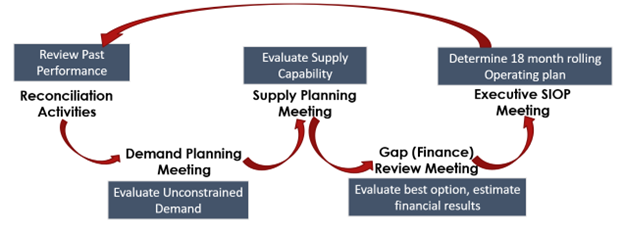

There are a lot of terms used by organizations to describe their mid to long range strategic planning discipline. Whether your organization calls it Integrated Business Planning (IBP), Sales and Operations Planning (S&OP), Sales, Inventory and Operations Planning (SIOP) or something else, the key message is that abbreviations are not important – results are. Strong strategic planning discipline orchestrates sales plans, operations constraints, and financial objectives while giving guidance to short-term scheduling for execution. At USC, we call this discipline SIOP due to the strategic importance of inventory to smooth supply and demand fluctuations to maintain customer service levels.

Survey Says!

Businesses find S&OP beneficial because it helps balance supply and demand, it improves communication between sales and other departments, leads to better decision-making with everyone on the same page, and it ultimately results in better efficiency. Most organizations refer to their planning process as S&OP, but we think it’s incomplete. Inventory needs to be part of this process to unlock greater levels of operational efficiency and customer service rates.

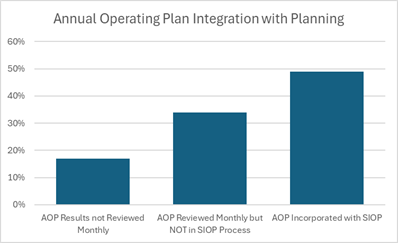

Most companies have less than five years of experience utilizing a SIOP discipline and significantly, fewer than 50% of all companies integrate financial objectives into their monthly planning process. The result is the organization’s annual plans are disconnected from the monthly “replanning” SIOP process. Managers are typically held accountable to their annual plans which are increasingly out of date as the year progresses and better plans are known resulting in sub-optimal decision making based on old assumptions.

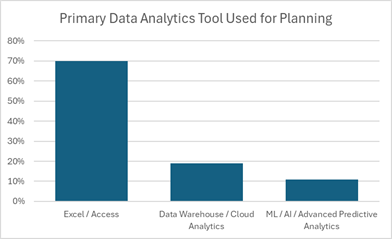

Furthermore, since most companies rely on static models such as Excel and Access to as their primary analytical tools, the planning process can be labor intensive, time consuming and more prone to human error. Integrating decision support systems with operations data, procurement data, inventory data, and customer demand improves simulation and scenario analysis capabilities. Integrating with advanced predictive analytics can further augment planning knowledge.

Sales, Inventory and Operations Planning

We tell our clients that SIOP is making sure you’re having the right conversations about the right things at the right time.

Sales, Inventory, and Operations Planning is a holistic process that integrates customer-focused demand plans with production, sourcing and inventory plans and results in improved tactical and long-term business decision making capability.

Keys to Implementing a Successful SIOP Process

- Everyone is on board. It’s simply not going to work if it’s not interdepartmental. You need everyone – Sales & Marketing, Operations, Procurement and Logistics, Planning, Product Development, Finance, IT, and the C-Suite working in lock step from the same plan.

- Planning cycles should be monthly. This isn’t a one-and-done process. Once you get on the SIOP treadmill, you don’t ever get off. We advise a rolling 18-month period, updated monthly. This ensures the re-planning process is looking out beyond the current budget year and for strategic planning.

- People and Process Discipline is a must. A good SIOP process includes a SIOP monthly process schedule/calendar of key events, RACIs, mutually agreed upon KPIs, actual vs forecasted reporting scorecards, assumptions and occurrences reporting, decisions made with action item follow up.

But Why the Added Focus on Inventory?

Inventory tells a story about a business’ operational efficiency. Inventory accounts pool the collective decisions and market forces affecting the company, telling stories of sales forecasting accuracy, manufacturing efficiency, planning effectiveness, supply chain disruptions, and quality control. Lean inventories reveal robust planning systems and culture, integrated ERP systems, and good governance. Excess inventories can be a short-term benefit to sustain high customer service levels during times of uncertainty, however they come with high obsolescence and carrying costs. Inventory is a strategic lever to smooth operations, procurement, and sales fluctuations. The right level of inventory is different for each company, and changes based on current consumer demand, supply chain disruptions, and strategic decisions.

Benefits of SIOP

- Gets departments in sync. The SIOP process helps to determine whether

your original financial expectations / budget, and your current sales plan and operations plan are in sync with each other. Updating your forecast monthly will show you where problems lie and provide action plans to address shortfalls. - Ensures that the plans are realistic. The key stakeholders from each department participate in formulating the SIOP plan. Since all assumptions are transparent throughout the process, each department has more time to evaluate its resources and capabilities in the context of the most recent company-wide plan. The result is a solid set of department plans that are based on latest expectations and known capabilities.

- Effectively manages change. Many industries have faced significant planning challenges in recent years. Having an agile and timely planning process helps decision makers roll with the punches. With SIOP, your business can make holistic, controlled responses to changes instead of making knee-jerk, departmental centric reactions.

- Measures performance. Our customized approach to KPIs ensures that success measurements identify where the organization is challenged and where to focus on improvement.

- Builds teamwork. SIOP gives each department an opportunity to participate in the overall planning process.

Interested to learn more about how adding inventory to your planning can make you more efficient? For more information on how SIOP can help your business read our eBook, “Sales, Inventory and Operations Planning: It’s About Time.”

*This article is written by USC Consulting Group’s Supply Chain Practice Leader, David Newman.

How’s your supply chain running these days? If you’re like most manufacturers, you’re still experiencing challenges. Big challenges. The pandemic threw the worldwide supply chain into chaos and it hasn’t yet recovered, but the truth is, there have always been supply chain issues bedeviling the industry. The pandemic just exacerbated what already had the potential to go wrong and uncovered new problems lurking just below the surface.

Just-in-time strategies, which were (and continue to be) popular methods of having just the right amount of inventory on hand at any given time, left manufacturers vulnerable to supply chain disruptions. The increasing complexity of global supply chains didn’t help the situation, nor did the pervasive lack of visibility into supply chains themselves.

What are manufacturers facing this year in terms of their supply chain? Let’s take a look at these issues, and examine some ways USC can help.

Manufacturers supply chain challenges for 2024

Materials shortages. Global instability, the lingering effects of the pandemic and other factors are leading to shortages of raw materials and components. Production delays, increased costs and unhappy customers are the result. And speaking of costs…

Rising freight costs. As fuel prices ride the same roller coaster we’re all seeing at the gas pump, and labor shortages and ongoing congestion at ports collide, it means costs to get those components and materials are going up, eating into your profits. And speaking of labor shortages…

Labor shortages. This problem is ongoing, and we have to say, it’s one thing that wasn’t caused by the pandemic. Manufacturing workers are aging and retiring, and there isn’t a large pipeline of younger people with the skills to replace them. It means reduced output and productivity, dwindling motivation and drive, and the loss of institutional knowledge.

DRIP. It stands for data rich, information poor. When you’re talking about the supply chain, it means you need to use data to its fullest. Outdated inventory systems won’t cut it.

Tactics that can help

Diversifying supply chains. Having too many eggs in one basket has proven costly when that basket falls apart. Reliance on any one supplier, especially if that supplier is overseas, is becoming yesterday’s strategy that is just not working in today’s market.

Reshoring. Supply chain disruption, ongoing global instability, higher costs (including higher labor costs in China), increased lead times and more hassles are leading companies to reconsider foreign sources. Many are already doing it. Yahoo Finance reported in June 2023 that 80% of manufacturers are now considering or acting on reshoring some or all of their production. A couple of quick examples: General Motors invested $7 billion in production facilities in Michigan to not just manufacture electric vehicles but the batteries that power them. Intel invested $20 billion in a new semiconductor manufacturing plant in Ohio, and is investing $30 billion for a similar facility in Arizona. Some manufacturers are “nearshoring,” bringing production closer to home, from China to Mexico, say. Not only will this reduce lead times, improve quality control and leave companies less vulnerable to global unrest, it will also create jobs here at home.

SIOP. We laud this tactic often because it really does improve efficiency, but in the age of supply chain disruption, it’s crucial. Sales, Inventory and Operations Planning (SIOP) is a collaborative process that aligns all departments. It involves using inventory as a strategic tool, demand management and supply planning, giving you the ability to capture, analyze, integrate and interpret data to give you a strategic advantage.

Learn more about SIOP in our free eBook, Sales, Inventory and Operations Planning: It’s About Time.

Solid training. The labor shortage isn’t going away, and we’re finding that many manufacturers are investing in training, ensuring that everyone is doing the job the same way, with rock-solid operating procedures. It’s a powerful way to keep institutional knowledge within your facilities, instead of losing it when people retire.

At USC Consulting Group, we have over 55 years of experience helping manufacturers ramp up their efficiency, production and operations. It’s especially crucial to be firing on all cylinders during challenging times… and we’re in them, right now. Give us a call and let’s talk about how we can help.

If your company is looking for process improvements, greater efficiency, operations upgrades and generally a greasing of the gears in order to function at a higher level, that’s great! Now the question becomes: Do you hire an operations management consulting firm or rely on your internal improvement team?

Here’s a look at both options:

Internal improvement teams

What are internal improvement teams, exactly? In general, they’re full-time employees within an organization, usually (but not always) within the HR function. They act as advisors, change agents, process improvement experts, coaches or trainers. But it doesn’t have to be as formal as having a dedicated “internal consultant team.” Oftentimes, companies looking to improve processes pull together a team of people from different departments within the organization to tackle a problem or challenge that is impeding productivity.

Some other aspects, including pros and cons, of internal teams:

Cost. On the surface, using an internal team may seem cheaper than hiring an outside firm because the company is not paying an outside consulting fee. But figuring in salaries, benefits and all of the other expenses involved with full-time employees that are dedicated to process improvement, those savings can dry up. Also, if you’re using an internal team made up of people from different departments, there is the issue of time away from their usual job functions and the loss of productivity that can result from that.

Company knowledge. Internal people have an immediate understanding of the organization. No learning curve needed. There’s already a deep knowledge of the culture, the processes and the “unspoken rules.”

Accountability. Some external consultants “fix it and forget it.” In other words, they swoop in, offer recommendations for change and swoop out, leaving the company to implement the changes and deal with what comes next. (Note: We do NOT do that at USC Consulting Group) Internal people are there, onsite, through it all, and after it all.

Internal politics. This is one of the big “cons” of using an internal team. In many workplaces, you’ve got internal politics and drama running through everything. Who takes recommendations and advice from whom can become an impediment to progress. Certain people may want to be the one to come up with whatever fix is needed, and if they aren’t, they can put up roadblocks or sow seeds of negativity. The internal pecking order can rule the roost. Not ideal when you’re talking about making process improvements, which typically involve changing the way “we’ve always done it.” That’s a delicate endeavor, even for outside consultants. When you have Phil from HR telling a 30-year veteran on the line there’s a better way to do his job, it doesn’t go over very well.

Internal view. Internal teams have a great view of their organization, but not what’s going on out there in the industry at large. They are also not necessarily on top of the latest developments in process improvements, and certainly aren’t experts in things like Lean Six Sigma.

Operations management consultants

Operations consulting, simply put, is a discipline designed to improve your company’s internal operations and processes, making them more efficient, streamlined and ultimately, profitable. At USC Consulting Group, we’ve been dedicated to that since 1968.

Operations consultants will first look at your current operations model, systems and day-to-day processes of getting the job done. They talk with front-line workers, executives and everyone in between. Listening is a big part of the job. They employ methodologies like Lean Six Sigma, the Fishbone, the Five Ms and other tactics to uncover what’s bedeviling your operation and create ways to solve those problems.

Some operations consultants are advisory consultants, or “boardroom consultants,” who perform a two- to three-week study and provide a book of recommendations to help you out, and then hand it to you and go on their way. Implementing consultants, like USC, roll up their sleeves and work with a company’s internal teams to help implement the changes, and ensure the sustainability of those improvements.

Other features of outside consultants include:

Above the fray. This is a main reason execs hire outside consultants. An outside firm is not subject to internal politics and company red tape. They can make the changes necessary for improvements to get results without stepping on anyone’s toes. Oftentimes, recommendations for change go down easier when delivered by someone outside the organization.

A fresh set of eyes. You know what they say about the forest for the trees. Sometimes, when you’re too close to a problem or challenge, you can’t see the big picture of how to solve it. Operations consultants are outside experts who can look at your operations with a fresh set of eyes.

Horsepower. In many cases, operations management firms actually augment the efforts of internal teams and provide “horsepower” to improvement initiatives and help achieve results quicker.

Cost. Outside firms are hired for limited engagements and are not full-time employees. Therefore, a company does not need to provide salaries, benefits and other costs for full-time employees who are part of their internal teams. Yes, the upfront investment for an outside firm is more than you would pay your internal employees. However, once the project engagement is complete, those consulting costs are removed from the ledger, but the benefits are realized for years after.

Industry expertise. Another facet of bringing fresh eyes to a challenge is the fact that those eyes have seen a thing or two. Consultants like USC Consulting Group have worked in the industry for decades and have seen how similar companies have solved similar problems and challenges. While every situation is unique, the decades-long expertise in operational improvements is impossible to duplicate in-house.

Process improvement expertise. It’s a fair bet that companies don’t have many black belts in Lean Six Sigma on staff. LSS is focused on eliminating waste and improving throughput, and it takes years to become an expert in it. External consultants like USC bring that expertise, and even train your staff to implement these tools.

A final thought: Sure, we’re biased. We’re a consulting firm with 55+ years of experience helping companies improve their efficiency and ultimately boost their bottom lines. However, there is a stigma about consulting that seems to be rumored. To clear up this misconception, read our blog “Debunking Myths About Operations Management Consulting.”

Which option should you choose?

Bottom line is you need to make a decision that is best for your business. Whether utilizing your own internal improvement teams or employing an outside consultant, the main focus is reducing your operating costs and improving your productivity and efficiency.

If you would like to talk with one of our subject matter experts to see if USC would be the right fit for your improvement project, give us a call.

In many industries, globalization has resulted in the consolidation of suppliers and increasingly interdependent Supply Chains. Globalization has increased efficiencies and economies of scale, but it has led to decreased diversity of sourcing and supply options.

Increasing geopolitical tensions, pandemic related lockdowns, and ideological polarizations have increased supply chain disruptions for many products and materials.

Supply Chain Risk Management System

An active Supply Chain Risk Management System cannot ensure continuity of supply, however, it can provide a playbook with options when sources of supply are threatened.

Download our free eBook “The Supply Chain Risk Management Playbook: Navigating Through an Uncertain Supply Chain Future” as we advise how to identify and respond to the unique risks that affect your business.

This Playbook details the various concepts that will secure your operations, including:

- Planning the Risk Management assessment

- Conducting the Risk Management assessment

- Checking your findings

- Acting on your findings

Planning the Risk Management Assessment

During the planning stage you will define the project charter and assess your organization’s Risk Tolerance.

Conducting the Risk Management Assessment

Once management has defined success and risk tolerances, it’s time to take action and conduct the assessment.

Check your findings

This step must be tailored to the risk being assessed. Here you will build the risk models and validate the assumptions with your stakeholders.

Act on your findings

Once all appropriate stakeholders have agreed to the change, put the risk mitigation strategy into action.

For full details on each of these critical stages, download the complete Playbook below:

Installing a well-functioning Supply Chain Risk Management Operating System is a journey, not an event.

Enhancing responsiveness to risk provides competitive advantages, especially in industries where competition for key vendors, access to resources, and logistics constraints are prevalent.

USC Consulting Group’s Supply Chain experts have over 50 years of industry experience with the latest risk management practices and can help you with your unique challenges. Contact us to remove the risks and start driving operational improvements in your business.

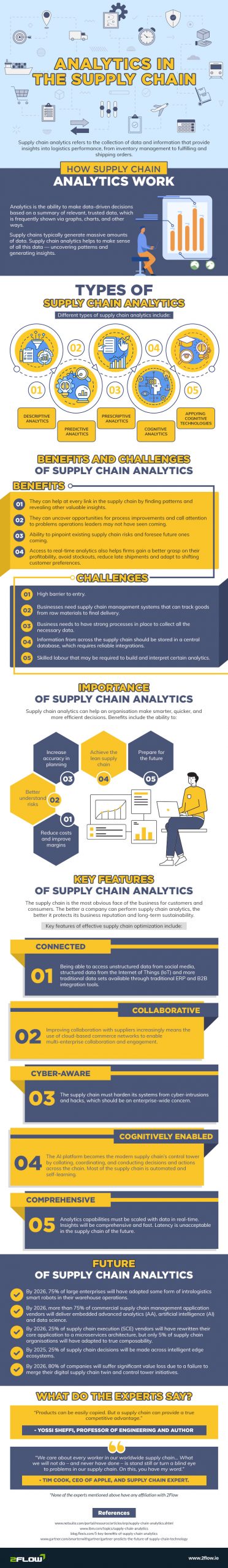

Supply chain analytics refers to the collection of data and information that provide insights into logistics performance, from inventory management to fulfilling and shipping orders.

How Data Analytics is Changing the Supply Chain Landscape

The ever-increasing reliance on big data is altering the landscape of supply chains as we know them. Historically, the majority of supply chain management was dependent on intuition and experience. However, with the introduction of powerful data analytics technologies, supply chains are now guided by data-driven decision making.

The ever-increasing availability of data is driving this transition. Previously, data was dispersed across numerous silos inside a business, making it difficult to provide a comprehensive perspective of the supply chain. Organizations, on the other hand, may collect and store data from all areas of the supply chain in one central location owing to data warehouses and data lakes. This enables supply chain managers to see the entire picture and make data-driven decisions to increase efficiencies and performance.

The rising availability of strong data analytics tools is another factor pushing the change to data-driven decision making. To examine data in the past, supply chain managers had to rely on manual procedures or limited software tools. However, a wide range of powerful data analytics technologies is now available to assist managers in making sense of massive data sets and uncovering hidden patterns and trends. The transition to data-driven decision making is reshaping the supply chain landscape and has far reaching implications for how businesses function.

Organizations may improve the efficiency and performance of their supply chains by leveraging the power of data, providing them with a competitive advantage in the marketplace.

The Advantages of Data Analytics in Supply Chain Management

Data analytics can aid in the smooth and effective operation of supply chains. Supply chains can uncover patterns and trends in past shipments by examining data from previous shipments. This can help them minimize disruptions and stock-outs while also improving inventory management. Furthermore, data analytics can assist supply chains in optimizing their routes and schedules, as well as tracking their success over time.

Here are some of the primary advantages of employing data analytics in supply chain management:

- Reduced Inventory Costs

- Optimized Production Plans

- More Efficient Cargo Shipments

- Reduced Risks

- Cross-Functional Cooperation

Check out the following infographic by 2Flow which takes a deep dive into ‘Analytics In The Supply Chain’.

Supply chain analytics are guiding managers into the future with data-driven decision making. If you need assistance properly analyzing your data and setting up your supply chain management for success, contact USC Consulting Group today.

Supply chain executives dealt with a variety of headaches over the past two years. Disruptions, delays, workarounds and all-out stoppages became all too familiar as COVID brought the fragility of the world’s supply chains into full view. Even consumers are now experts in supply chain woes. As 2022 draws to a close and 2023 waits just around the corner, what can supply chain executives expect from the coming year?

Unfortunately, challenges still lie on the road ahead. Disruption is still with us. Those headaches haven’t gone away. But, hang in there. We see reasons for optimism, too.

Supply chain trends for 2023

Here are some of the trends we’re seeing, and challenges supply chain executives will likely be experiencing in 2023.

Backlogs and logjams

Shortages and congestion at ports worldwide are expected to continue into 2023. If you didn’t see this coming, you’re not alone. In October 2021, economists said supply-chain bottlenecks would be the “biggest threat to growth” for the next 12 to 18 months, but predicted those bottlenecks would ease up during mid-2022, according to the Wall Street Journal.

That didn’t happen. Shortages will continue to make product more difficult to get. Similarly, port congestion remains an issue, but not due to the COVID restrictions that kept cargo ships floating in the harbor, unable to dock. With the exception of China and its zero-tolerance COVID policy, this time, the cause of that congestion will be the lack of trucks to take that cargo where it needs to go.

Lack of skilled workers

Speaking of the shortage of truck drivers … all industries are experiencing problems recruiting, hiring and retaining employees, and jobs all along the supply chain are no exception. Unemployment rates are at historic lows, but talk to any hiring manager and they’ll tell you they can’t get people in the door. The U.S. trucking industry estimates it is down some 60,000 drivers. Warehouses and manufacturing facilities are experiencing labor shortages, too, as a result of an aging workforce and high turnover rates. All of this directly impacts the supply chain, causing manufacturing and delivery delays and creating a ripple effect that extends all the way out to the end user.

Unsteady global relationships

The war in Ukraine doesn’t show any signs of resolving soon, and its impact on the supply chain will continue until the situation there improves. According to Consultancy.eu, the continued war will have an “impact on the costs of raw materials, energy, logistics and digital services.” The report further stated that oil and gas prices in Europe have skyrocketed, due to the high dependence on imports from Russia.

But the war in Ukraine isn’t the only geopolitical cause of disruption to the supply chain. China is continuing with its zero-tolerance COVID lockdowns. If you saw reports of the recent closure of Shanghai Disney, with thousands of guests trapped inside and unable to leave for days until they showed a negative COVID test, you’re aware of this ongoing situation in China. It will undoubtedly affect the manufacturing industry there, even potentially shutting down factories and ports.

Extreme weather events

Are you noticing that we seem to be having a “100-year flood” or the worst hurricane on record or extreme droughts and wildfires regularly? All of these can contribute to a situational supply chain backup, affecting not only manufacturers and truckers in areas that are hit by extreme weather, but those relying on that delayed supply down the line. Climate woes in the U.S. are also contributing to issues like historic low water levels. In October 2022, the water level was so low in the Mississippi River, it resulted in a jam of more than 2,000 barges carrying corn and soybeans.

Inflation

There is a kind of chicken-and-egg scenario with inflation and supply chain disruption. Prices spiked because of supply chain disruption, helping to increase inflation, which in turn feeds price hikes … which in turn affect the supply chain. According to U.S. Bank, the cost of living in the U.S., as measured by the Consumer Price Index, rose by more than 9% from June 2021 to June 2022. The November 2022 rate hike by the Fed, the sixth this year, is intended to mitigate inflation in an effort to help solve the problem.

Bottom line: Hang in there

While these challenges persist, signs point to an easing in supply chain woes in 2023, especially in the area of port congestion. Sea-Intelligence reported in October 2022 that 50% of congestion issues have been or are being resolved. The report predicts the industry being back at “normal” capacity in early 2023. When the logistics industry can get product to where it needs to be on time, that’s half the battle.

At USC Consulting Group, we’ve been helping our clients up their efficiency, deal with supply chain disruption and create more profitable operations for more than 50 years. We’re here to help. Give us a call today.

The global supply chain is a delicate framework in which every participating business needs to stay nimble and adaptable — because, as we saw during the pandemic, one singular event can throw a wrench into the entire system. Innovation and optimization need to be top of mind.

But what qualifies as effective optimization? Given the complexity of the flow of goods, cash and information between multiple producing, storage, delivery and consuming partners, companies can easily neglect key areas, or focus too hard on others. Disruption anywhere along the supply chain line can (and does) create major headaches, stifle throughput and force manufacturers into a dance of optimizing supply and demand.

We can help with that. At USC Consulting Group, we’ve been helping companies optimize their operations for more than half a century. We’ve learned a few things along the way. Here are some important do’s and don’ts for optimizing your supply chain. It’s about helping your business through the ongoing disruption and preparing it for unforeseen events in the future.

Don’t: Use outdated systems

There’s a tendency for many businesses to take an “if it ain’t broke, don’t fix it” approach. However, just because something is working in real time doesn’t mean there aren’t improvements to be made. In today’s data-rich environment, one of those improvements involves data analytics.

Outdated inventory systems, suboptimal communications and disconnected information are some of the biggest areas that hold an organization back. The limitations of legacy technologies thwart the goal of end-to-end transparency along the line and impede rapid-response decision making. Before you know it, you can end up in a data-rich, intelligence-poor environment. It’s so common a scenario now, there’s even an acronym for it: DRIP. Aptly named, because the potential power of all of that data is dripping down the drain if you’re not equipped to use and interpret it.

Do: Use SIOP

Sales, Inventory, and Operations Planning (SIOP) is a method we use here at USC Consulting Group that emphasizes inventory as a strategic tool to allow businesses to get a better look at their operations and formulate superior strategy decisions.

SIOP takes advantage of the wealth of digital data available to business owners to gain a strategic advantage. Having the ability to capture, analyze, integrate and interpret high-quality data is the key to staying ahead of the market. The aim is to achieve process automation and glean predictive analytics, which allow you a clearer look at your operations to make better-informed decisions.

Don’t: Segregate internal planning and communications

Silos! How often do we hear about the dangers of silos in businesses? It’s the concept of departments working separately, having poor communication and perhaps duplicating or negating each other’s efforts. We like to identify it as “the left hand doesn’t know what the right hand is doing.” Any way you refer to it, segregating internal planning and decision-makers leads to trouble in your supply chain.

These systems separate workers into independent subsections with little to no visibility between external partners. These separate groups work in their own ecosystem, unable to effectively communicate with other departments or relevant groups. This not only slows an operation down, but extinguishes any potential spark of collaboration or innovation that may arise from working in conjunction with each other.

Do: Increase information flow

Uncertainty in the supply chain is caused by disconnected information. A truly effective and innovative workplace allows all relevant personnel to communicate with each other.

Internally, abandoning legacy email and phone methods of communication in favor of end-to-end, 3-way knowledge sharing and open social platforms speeds up collaboration and enhances efficiency. Externally, keeping a concurrent, continuous and completely open demand plan is essential for maintaining healthy, profitable business relationships.

Enhancing communication and information flow internally and externally is another key for staying ahead of the curve and fostering innovation for supply chain businesses.

Don’t: Test out a new system on a limited basis

There can be hesitation for a business to roll out a new system, opting instead to test it out in certain departments or methods of communication. This can be a mistake.

Without full implementation, a business never sees the full power and potential of a new system and will be quick to abandon it in favor of the legacy methods they have been operating with for years. The right system can revolutionize operations on all fronts, from internal communication to vendor relationships to future workplace innovations. Without every aspect of a business running on a new method, a business owner may never see the full payoff.

Do: Find a trusted method and go all in

While there certainly are challenges with implementing a new system, it’s important to find a trusted method and go all-in. For example, let’s look back at our SIOP system.

Different areas of a business have different roles and objectives. Sales is eternally optimistic, operations wants to know precisely what is going to be produced and shipped, purchasing makes conservative commitments to suppliers, and finance has to predict performance and cash flow. Getting everyone pushing in the same direction for a system change can be a daunting task.

We have found that SIOP works optimally if your entire enterprise uses it. If you allow a facility, business unit or a customer team to continue to operate outside of the SIOP process it will undermine your efforts. That is why it’s so important to get everyone on board for a new process to truly see the difference it can make.

At USC Consulting Group, we’re dedicated to helping our clients weather any storm, including the kind of supply chain tsunami we’ve all experienced recently. Give us a call today to talk about how we can put our expertise to work for you.

Are you always putting out fires? Not in the literal sense, of course. We’re talking about operational problems that pop up at the most inconvenient times. Once you take care of one issue, two more seem to appear in its place. Issues such as:

- Machines break down

- Workers calling in sick

- Human errors

- Backups and bottlenecks

- Inventory uncertainty

If you’re busy troubleshooting today, it’s hard to focus on improving tomorrow. Opportunities for growth can be missed.

Get ahead of problems before they catch fire by watching this video:

At USC Consulting Group, we’ve been helping clients for over 50 years to implement strong Management Operating Systems that assist them with breaking that firefighter mentality.

The best management operating systems center around four main components:

- Processes

- Systems

- Roles

- Structures

A well-designed MOS will have your company operating like a well-oiled machine, making your bottom line stronger and your operations more efficient.

So put down the fire extinguisher and enhance your management operating system today by contacting USC Consulting Group.

Phone: +1-800-888-8872

Email: info@usccg.com

Learn more about the benefits of an effective MOS in our article How Can A Management Operating System Help Your Organization?