-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Skills Training

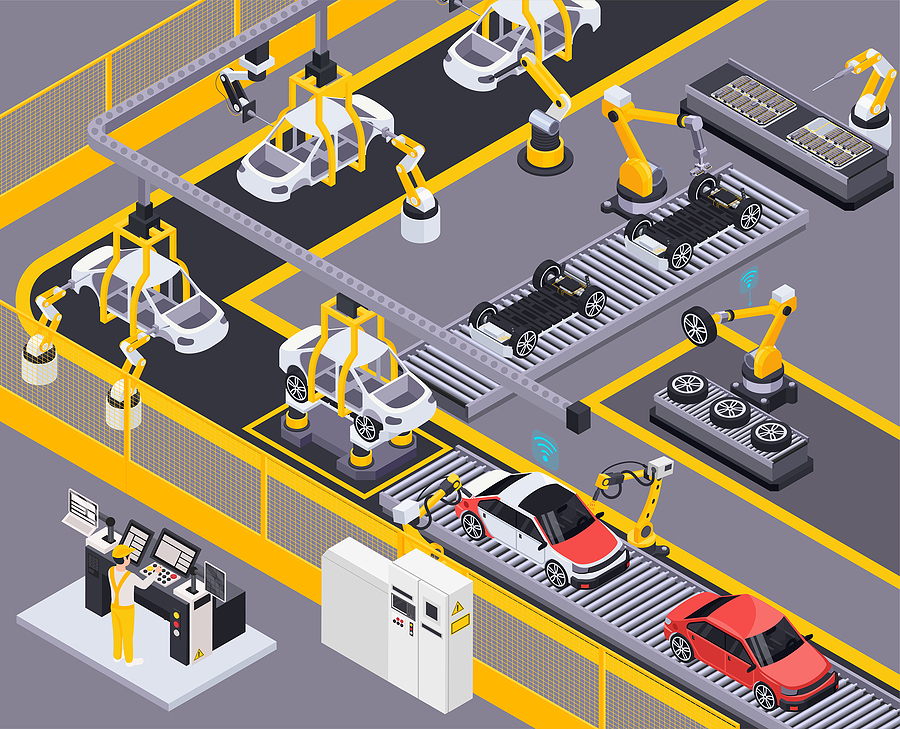

The automotive manufacturing industry has been traveling a strange and bumpy road over the past couple of years. The pandemic created a traffic jam in the supply chain. At the same time, demand for new cars dried up. Who was driving? Everyone was at home during the lockdown. And on the heels of that, interest in electric vehicles began to surge. According to research by the International Energy Association, the demand for EVs is expected to rise 35% by the end of 2023 after a record-breaking 2022.

What did it all mean for auto manufacturers? Demand for traditional vehicles lowered as demand for electric vehicles grew, forcing auto manufacturers to do a delicate dance of balancing the type of production they’ve always done with the new processes and systems needed to produce EVs. The moving target of demand coupled with shaky supply brought about inventory uncertainty — how much was enough, but not too much? And then, there was (and continues to be) the labor shortage, with seasoned workers retiring and younger ones not exactly flooding through the doors.

Improving processes is paramount for the automotive manufacturing industry now. Here are a few ways you can do that:

Lean Six Sigma. If there ever was a need for auto manufacturing process improvements like the ones Lean Six Sigma can produce, it’s now. LSS is the blending of two efficiency methodologies, Lean and Six Sigma. It’s a bit ironic, because the Lean methodology, which focuses on efficiency and eliminating waste, was developed back in the day by Henry Ford… or at Toyota, depending on who you ask. It got its start on the auto manufacturing line, with the intent of eliminating the “seven deadly wastes”: overproduction, waiting, transporting, processing, inventory, excess motion and defects. At USC Consulting Group, we’ve added an eighth waste. People. Specifically, not using them to their fullest, not seeing untapped potential in great workers, and not training and developing people to rise through the ranks. Lean is about eliminating waste to produce more product quickly and efficiently.

Six Sigma, the other side of the Lean coin, is about quality control. Minimizing flaws and defects. But it’s deeper than that, rooted in data. The goal is to improve cycle time while eliminating or reducing defects.

SIOP. It’s difficult to achieve careful, accurate planning for the future when the road ahead contains so many bumps. That’s why we take the usual sales and operations planning (S&OP) process to a different level by adding inventory to the mix. The goal is to look ahead, anticipating the inventory you need while also coordinating with sales, marketing, and finance to involve the entire organization in this process. A key to SIOP is using inventory as a strategic tool to help offset variation in either demand or production issues.

Predictive Maintenance. Yes, it sounds extremely basic, but we find that heading off trouble before it starts can eliminate the risk of bogging down your entire production line to fix what’s broken.

Skills Training. Investing in training is playing the long game, but in light of your best people on the line retiring and fewer people to take their place, it’s paramount. Training has advantages in addition to the obvious — your people being more skilled on the job. It also demonstrates in a very tangible way that you are committed to the growth and success of your employees. You gain loyal workers and create a pipeline for advancement. It’s a win-win.

Technology Investments. USC Consulting Group is not about coming in and asking manufacturers to invest in the latest and greatest technology in order to become more efficient. No, efficiency takes harder work than just installing a new machine. However, in some cases, it’s necessary to level up. Legacy technologies don’t have the same features and capabilities as newer models. And in the auto manufacturing industry, you’re dealing with producing an entirely new product with electric vehicles. It may be time to look at your technology and decide if it can take you into the future or keep you in the past.

Doing business in the automotive manufacturing industry is like driving a manual transmission. You are constantly shifting gears to keep pace with traffic – in this case, the consistent change of consumer demand. Operations consulting helps companies improve their processes and be prepared for what’s coming down the road. We help manufacturers become more efficient and profitable in this or any economy.

Is working with operations consultants an untraveled road for you? Please get in touch. We’d love to talk with you about it.

Knowledge is power, right? The problem? Most working professionals learn the majority of what they will ever know about their chosen profession between the ages of 18-22. They’re kids still, at that age, not even legally allowed to rent a car.

Sure, they’ll learn more on the job. Arguably, they’ll learn everything that really matters at work. But those pedagogical skills. The theory and tech that goes into professional life — that’s typically learned in the more formal classroom setting.

Without upskilling, your staff can wind up in professional limbo. Fortunately, there are many ways to continue developing professionally, even after school is out.

In this article, we take a look at how upskilling your employees can help create a stronger organization.

What is Upskilling?

As the name suggests, upskilling is simply the process of teaching your staff new skills. They learn more about how things work around your organization and perhaps gain the capacity to fulfill other responsibilities somewhere along the line. Kind of like a professional cross-fit program.

Instead of an inordinate amount of leg days, you have team members learning about new technologies or embracing business concepts that might otherwise be outside their job description.

Usually, upskilling is framed as being optional — professional development opportunities that, while not compulsory, may improve the employee’s overall standing within the organization somewhere down the line.

Not everyone will be interested in upskilling, but those who are will learn valuable skills.

Identifying the Go-getters

One of the most obvious benefits of upskilling your employees is that it helps to identify the go-getters. With this, you find out quickly who is interested in growing professionally, and who is more or less coasting on the job. When it comes time to decide who winds up taking on leadership roles, your upskilled staff will often be a great first place to look.

Filling Gaps

Upskilled professionals may also be better equipped to fill gaps within your organization. This is a problem that business leaders all over the world are still dealing with. They have jobs to fill, but they can’t quite find the people willing or qualified to take them on.

You definitely don’t want to rely on your best employees to pick up all the slack, but you can use them here and there to handle additional responsibilities when the moment requires it. Just make sure you reward them accordingly. Short-staffed businesses often experience very high levels of turnover because the work becomes more stressful for the people who remain.

You certainly don’t want to drive away you’re A-team, so call in the favors sparingly and make sure that your incentives are on point.

Avoid Efficiency Lags

As staff members age they inevitably fall out of touch with the most modern business practices. How could they not? Things change constantly, both in terms of what is considered best practices, and based on things like what technology is being used now.

If you’re twenty years out of college, you might not have your finger on the pulse of the latest industry trends. Upskilling is a great way to stay refreshed on what is going on in your chosen profession.

A Downside to Upskilling?

There are downsides and risks associated with upskilling your employees. Perhaps the most straightforward of these is that it takes time, and, by extension, money to teach people new things. Depending on your current resources, that might not be in the cards.

There’s also just the risk of alienating your staff. People work hard. They don’t really like being asked to work harder. You can edge around that particular issue by making professional development optional, but even then you run a bit of a risk. Yeah, you don’t have to do it but…you have to do it, right?

Read the room. There are times to upskill, and times to leave things be. As a decision-maker, it’s your responsibility to take an analytic view of the situation and go from there.

It’s also important to keep in mind that upskilling, or any other form of professional development is not a one-time thing. Technology will continue to change. Strategies will change along with it, and it will be time to refresh your staff’s knowledge all over again.

Learning and progress are important elements of growth, but remember that slow and steady can win the race here. You want to encourage your staff and help them grow. Not bombard them with new responsibilities.

*This article is written by Andrew Deen. Andrew has been a consultant for startups in almost every industry from retail to medical devices and everything in between. He implements lean methodology and is currently writing a book about scaling up business. You can follow him on Twitter @AndrewDeen14.