-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Silver Mine

Recently, our mining team was asked to conduct a study at a silver mine in South America. The goal of this study was to uncover inefficiencies and implement a continuous improvement program within the mining operation and ultimately reduce operating cost per ounce. This was in response to the rapidly dropping price of silver. Therefore, time was of the essence. The recent volatility of this commodity had the management team at the mining company looking for ways to drastically reduce cost in their operation. Our response was to send a team of eight consultants to Argentina for a twenty-day site visit to conduct an analysis of the opportunities.

Discovering what an organization is currently using to manage its business is one of the most interesting parts of a study. You can quickly tell what is working for them and what isn’t. Usually, we are able to find some elements of a Management Operating System (MOS). Sometimes, more often than not, we discover that a functioning/closed-loop MOS is not in place or being used. This is also an early indication that the management team does not have full control of their operation. They may be measuring performance as a lagging indicator, but are unable to provide any leading indicators to performance trends. Without a closed-loop MOS it also becomes very difficult to make continuous improvement changes to impact performance and to actually measure the impact of those changes. Reporting alone will not allow management to do this. This is the first element we focused on at the silver mine.

Based on the initial assessment, our team and the client developed a realistic target for a reduced cost per ounce. In order to obtain the new reduced cost per ounce target, fifty Continuous Improvement Programs were developed. Continuous Improvement Programs vary in size, but all drive towards the same end goal of efficiency. In this case, the Continuous Improvement Programs developed were all intended to impact the utilization of a given level of resources. It is important to understand how much your resources are capable of without road blocks because this will be your “technical limit”. Although a technical limit is often unattainable, this is what the organization and management should be aiming for. Continuous Improvement Programs work to remove all of the road blocks possible in an effort to bring the operation as close to their technical limit as possible.

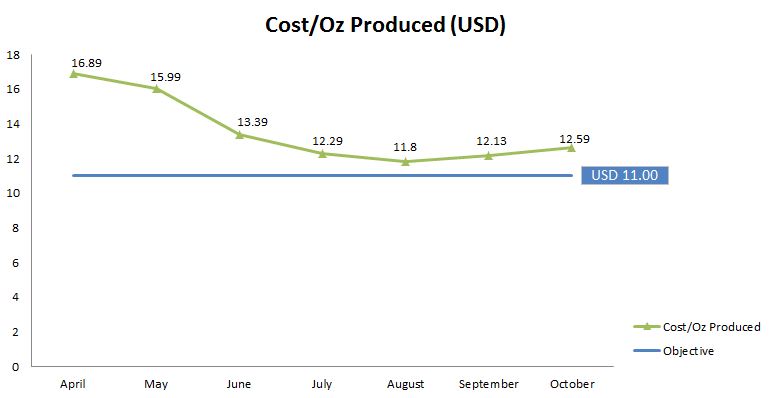

We were onsite to assist in the planning and implementation of each item from start to finish. With such a large number of Continuous Improvement Programs, it was very important to measure the progress towards completing each one and the associated impact they would have on the cost per ounce as they were completed. The financial impact of the changes was measured on a monthly basis.

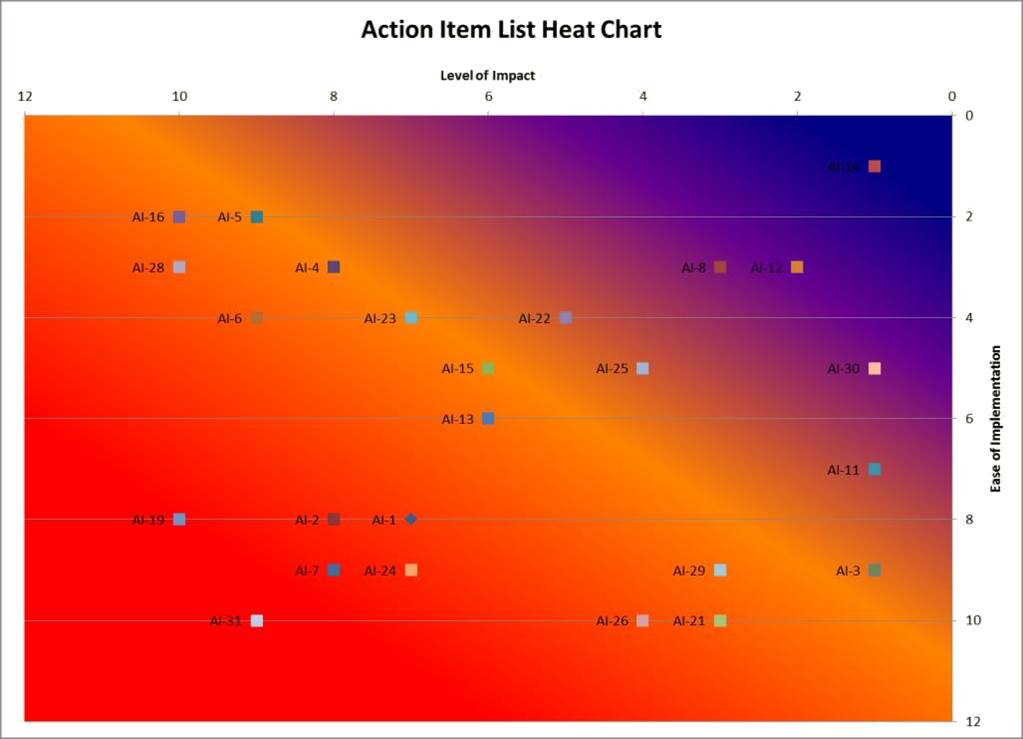

An important tool to use in conjunction with a Pareto chart is a heat map. Plotting action items on a heat map will allow you to prioritize each item based on two or more distinguishing variables. I typically use “ease of implementation” and “level of impact”. If you rank each item on a numerical scale and graph the results, it will provide a strong visual as to which items should take priority over others. From a results standpoint, you would ideally complete the items that will have a high impact and are easy to implement. This will provide the greatest yield with the least investment (time or otherwise).

There are several reasons why using this method can be a very effective way of managing action items. Firstly, process owners or champions typically have the most energy at the front end of the process. They are eager to make an impact and want to be a part of the leading charge. Secondly, it is very likely that as time goes on, new issues will arise and thus, more action items added to the list. There may be some new items that should take priority over older ones because of their importance. By maintaining an up-to-date heat map, each item can be analyzed for its individual importance.

What we have often found with a great deal of our clients is that when we arrive, they are not exactly sure what their organization is capable of. As we begin to show bursts of improvement throughout the project and provide tangible results, they begin to see how attainable continuous improvement really is. In addition to the fact that these results are attainable, they also realize that they are the ones taking ownership of it and to various extents, beginning to walk down the path themselves. The management operating system is theirs and could not function without them. At this stage, the behavioral change process has taken effect and this is what will drive your lasting results. This is the part that will bring your organization savings year over year.