-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Planned Outages

As a typical rule of thumb in maintenance, planned work will consume roughly one third of the resources (labor cost, materials cost, and costs associated with equipment down-time) as unplanned work will consume. Therefore, the first objective of any maintenance program can be simplified as maximizing the percentage of time and resources spent on planned maintenance, and reducing the amount of unplanned maintenance or repair work resulting from unexpected breakdowns.

Understanding the Types of Work

Planned work can be broken down into two main categories: preventative maintenance and planned repairs. Preventative maintenance includes all the work done not in response to a failure, but to prevent future failures from occurring. This work is typically outlined by the manufacturer in terms of frequency and work that must be performed (oil change, lube, and filter). If the fleet size remains constant, so will the level of preventative maintenance. Planned repairs are work that must be done as a result of wear and tear in which the equipment has not yet failed and can still run reliably until the maintenance department is set up with the required materials, labor, and shop space to adequately address these repairs. For exemplary purposes in this article, we will consider maintenance needed for an underground mine as a model. Due to the travel time in underground mining and the requirement in most cases to have repairs done in the shop after a wash, these two types of planned work are best done together to minimize the mechanic’s trips to and from the equipment.

Given that the level of preventative maintenance will remain considerably flat, as both the materials required and time required can be predicted and cyclical, the only way to effectively increase planned work as a proportion of total work is to increase the level of planned repairs. The first task is to shift the balance of planned maintenance and unplanned maintenance. That is, to convert as much of the resources spent on unplanned work as possible into resources spent on planned work.

Converting Unplanned Work into Planned Maintenance

The first step is to create a backlog, a master list of all known repairs that must be made to each piece of equipment. It consists of repairs necessary to components that are in a partial state of failure, but have not yet failed. The size of a backlog and how well it is managed will provide some valuable insight as to the over-all health of your assets. A complete detailed backlog will also provide other benefits to management when taking a closer look at each type of equipment and analyzing which components require more attention than others. If repairs to equipment must be done before the equipment actually fails, the ability to identify or predict failures before they actually occur will be crucial. Coordination can then be made for the replacement of these components before failure occurs. This can be a very difficult and daunting task when considering a large fleet with complex equipment.

The first element to be considered when creating and managing a backlog is where the backlog work will be sourced from. Where will the maintenance planners get the information to create backlog list? Each time the equipment is inspected, an opportunity is provided to gather backlog. In an underground mining environment, some of these touch points include the preventative maintenance services, planned repairs, and operator circle checks.

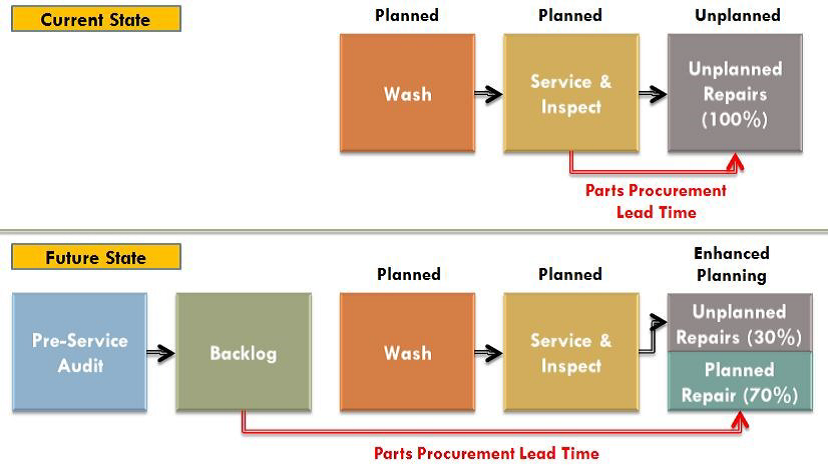

An additional inspection can be strategically added to generate a greater and more detailed amount of backlog. Figure 1 below depicts the impact on parts procurement time of an inspection conducted by a mechanic in a predetermined time frame before the equipment is scheduled to come into the shop for a preventative maintenance service.

Figure 1—Current State vs. Future State with Backlog

Once the backlog list has been developed, the repairs can then be strategically scheduled alongside the preventative maintenance services while the equipment is already in the shop with shop space and labor assigned to it. Additionally, once these repairs have been scheduled, parts and materials can be ordered, packaged, and delivered to the shop where the repairs will be completed.

The supply benefits of planning repairs before failure are amplified in underground mining as the remote locations can be difficult for suppliers to deliver to. Even once on site, the materials must go through a complex supply delivery system to make their way underground. Planning these repairs ahead of time allows the equipment to run for the duration of this prolonged lead time. If the equipment is run until failure, it will remain down for the entire duration of this lead time until the needed parts can be delivered.

In generating and completing the backlog list against each piece of equipment, failures and breakdowns that would normally occur can now be discovered before failure and repaired on average much quicker than if the equipment would have broken down. The backlog system is working towards converting unplanned maintenance work into planned maintenance work, and therefore consuming one third of the resources on each repair converted as would normally be expended.

Planned maintenance leads to significant cost savings with improved productivity. For 50 plus years USC Consulting Group has helped organizations develop planned maintenance programs to increase their uptime. Contact us today to start converting your maintenance practices and keep your operations running as much as possible.

Heavy production assets are ubiquitous across numerous industries, from residential construction to mining. Keeping this mission-critical equipment up and running is among the top priorities for modern industrial organizations. It is why the average firm devotes almost 10 percent of its facilities budget to maintenance activities, according to researchers from Plant Engineering.

Virtually all of these entities leverage either predictive or preventive maintenance methodologies, both of which materialized in recent years due to widespread enterprise digitization. But how exactly are businesses deploying these strategies to ensure heavy production assets maintain peak performance? Here is an industry-agnostic look into the state of predictive and preventive maintenance best practices for heavy asset optimization:

Unpacking the preventive approach

An estimated 80 percent of maintenance teams employ preventive maintenance techniques, per survey data from Advanced Technology Services and Plan Engineering. The proactive approach centers on one operational goal: reducing production downtime. There are several associated best practices that guide preventive maintenance implementation and management.

Relinquishing the reactive approach to asset maintenance is the most impactful of these exercises. Unfortunately, it is also the hardest to adopt, Modern Materials Handling reported. Maintenance specialists that have traditionally listened for the cacophony of mechanical collapse and responded in turn must change their mindsets and instead focus on implementing piecemeal adjustments to mitigate the wear and tear that causes asset failure.

Making this cultural switch is no easy task – neither is reassessing all production and maintenance policies and procedures, and drafting new ones to comport with key performance indicators and company goals. However, four-fifths of maintenance teams have managed to execute these and the other preventive best practices on the way to transformation, including groups responsible for overseeing heavy assets.

Industrial organizations that excel at heavy machinery maintenance and effectively address small mechanical errors before they devolve into downtime-causing kinks focus on developing and sustaining routine asset optimization schedules, according to Reliable Plant. Through consistent check-ups and slight tweaks, maintenance teams responsible for bulky equipment can ensure these key production tools are always in good condition and ready to perform. Usage monitoring is also key, as heavy assets that are misused, either intentionally or unintentionally, typically break down the fastest.

How does usage monitoring unfold within an actual production workflow? A construction company preparing to excavate a new worksite might assess the climate and the soil to determine which backhoe digging attachment is not only best suited for the task at hand, but also the least likely to cause mechanical stress. These and other techniques make preventive maintenance possible, even with heavy assets in play.

Unpacking the predictive approach

When investments in heavy machinery began climbing dramatically more than a half decade ago, equipment manufacturers advised industrial companies to adopt asset tracking solutions to ensure that the multimillion-dollar tools they were deploying were actually required, The Wall Street Journal reported. At the same time, an innovative approach to maintenance, which also happened to be based on data analytics, was emerging.

This methodology, called predictive maintenance, would allow organizations to harness the power of advanced information technology to monitor mission-critical machinery in real-time, calculate the potential for future downtime and make improvements to avoid shutdown. In the years since this strategy materialized, many businesses have embraced it. In fact, 47 percent of industrial firms attest to deploying predictive maintenance processes and tools, per Advanced Technology Services and Plan Engineering.

Perhaps the most well-publicized and successful predictive maintenance programs have unfolded within organizations leveraging larger production assets. For example, construction equipment giant Caterpillar was among the first asset producers to manufacture products meant for use in predictive maintenance workflows, Forbes Magazine reported. The company began building bulldozers, dump trucks, excavators and other common equipment with pre-installed wireless sensors designed to transmit usable performance insights to maintenance leaders. Caterpillar customers have seen significant efficiency gains and cost reductions as a consequence of this forward-thinking equipment and the accompanying software.

Harley-Davidson is another early adopter that propelled predictive maintenance to new heights. Starting back in 2010, the automotive giant began outfitting the decades-old equipment in its York, Pennsylvania plant with wireless sensors configured to monitor mechanical operations and measure physical variables such as component vibration to assess asset performance, The Journal reported. These tools and the predictive maintenance program they facilitated led to drastic shop floor improvement, as Harley-Davidson watched production throughput times and costs decrease.

While impressive, these outcomes merely represent the initial stages of the predictive maintenance approach, according to PricewaterhouseCoopers. The rise of deployable enterprise artificial intelligence technology is expected to have an immense impact on this strategy, lending industrial firms the ability to monitor more data points across larger pools of equipment, including heavy assets.

That said, there is ample ground to cover before AI-propelled predictive maintenance workflows become industry standard. Most organizations inhabit the second position on the predictive maturity scale, per PwC, and therefore still depend on instrument inspections and other manual means. However, a significant number have entered stage three and now leverage real-time condition monitoring tools. Far fewer are in stage four, where expansive data-driven workflows capable of handling massive amounts of asset information are the norm.

In any case, predictive maintenance holds immense potential for teams assigned to heavy assets and, as the survey data from Advanced Technology Services and Plan Engineering indicates, a good number of the teams overseeing large machinery today have at least embraced some processes and tools associated with the strategy.

Implementing preventive and predictive maintenance strategies centered on heavy equipment can seem like an overwhelming task, especially for smaller industrial firms or those with particularly intense production demands. For businesses in these positions, external assistance could be all but necessary. USC Consulting Group has been helping organizations optimize their maintenance operations for decades, leveraging proven techniques and tools that accelerate change and lay the foundation for sustainable growth.

Connect with us today to learn more about our work and how we can help your company reduce heavy asset-related downtime.