-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Outages

As a typical rule of thumb in maintenance, planned work will consume roughly one third of the resources (labor cost, materials cost, and costs associated with equipment down-time) as unplanned work will consume. Therefore, the first objective of any maintenance program can be simplified as maximizing the percentage of time and resources spent on planned maintenance, and reducing the amount of unplanned maintenance or repair work resulting from unexpected breakdowns.

Understanding the Types of Work

Planned work can be broken down into two main categories: preventative maintenance and planned repairs. Preventative maintenance includes all the work done not in response to a failure, but to prevent future failures from occurring. This work is typically outlined by the manufacturer in terms of frequency and work that must be performed (oil change, lube, and filter). If the fleet size remains constant, so will the level of preventative maintenance. Planned repairs are work that must be done as a result of wear and tear in which the equipment has not yet failed and can still run reliably until the maintenance department is set up with the required materials, labor, and shop space to adequately address these repairs. For exemplary purposes in this article, we will consider maintenance needed for an underground mine as a model. Due to the travel time in underground mining and the requirement in most cases to have repairs done in the shop after a wash, these two types of planned work are best done together to minimize the mechanic’s trips to and from the equipment.

Given that the level of preventative maintenance will remain considerably flat, as both the materials required and time required can be predicted and cyclical, the only way to effectively increase planned work as a proportion of total work is to increase the level of planned repairs. The first task is to shift the balance of planned maintenance and unplanned maintenance. That is, to convert as much of the resources spent on unplanned work as possible into resources spent on planned work.

Converting Unplanned Work into Planned Maintenance

The first step is to create a backlog, a master list of all known repairs that must be made to each piece of equipment. It consists of repairs necessary to components that are in a partial state of failure, but have not yet failed. The size of a backlog and how well it is managed will provide some valuable insight as to the over-all health of your assets. A complete detailed backlog will also provide other benefits to management when taking a closer look at each type of equipment and analyzing which components require more attention than others. If repairs to equipment must be done before the equipment actually fails, the ability to identify or predict failures before they actually occur will be crucial. Coordination can then be made for the replacement of these components before failure occurs. This can be a very difficult and daunting task when considering a large fleet with complex equipment.

The first element to be considered when creating and managing a backlog is where the backlog work will be sourced from. Where will the maintenance planners get the information to create backlog list? Each time the equipment is inspected, an opportunity is provided to gather backlog. In an underground mining environment, some of these touch points include the preventative maintenance services, planned repairs, and operator circle checks.

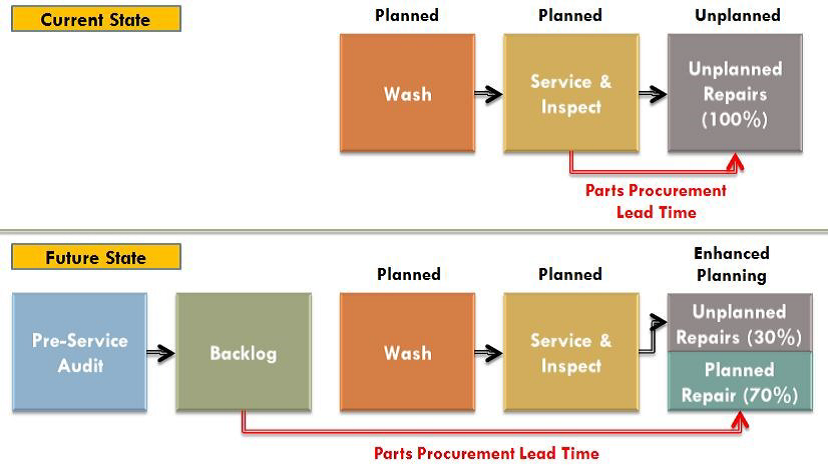

An additional inspection can be strategically added to generate a greater and more detailed amount of backlog. Figure 1 below depicts the impact on parts procurement time of an inspection conducted by a mechanic in a predetermined time frame before the equipment is scheduled to come into the shop for a preventative maintenance service.

Figure 1—Current State vs. Future State with Backlog

Once the backlog list has been developed, the repairs can then be strategically scheduled alongside the preventative maintenance services while the equipment is already in the shop with shop space and labor assigned to it. Additionally, once these repairs have been scheduled, parts and materials can be ordered, packaged, and delivered to the shop where the repairs will be completed.

The supply benefits of planning repairs before failure are amplified in underground mining as the remote locations can be difficult for suppliers to deliver to. Even once on site, the materials must go through a complex supply delivery system to make their way underground. Planning these repairs ahead of time allows the equipment to run for the duration of this prolonged lead time. If the equipment is run until failure, it will remain down for the entire duration of this lead time until the needed parts can be delivered.

In generating and completing the backlog list against each piece of equipment, failures and breakdowns that would normally occur can now be discovered before failure and repaired on average much quicker than if the equipment would have broken down. The backlog system is working towards converting unplanned maintenance work into planned maintenance work, and therefore consuming one third of the resources on each repair converted as would normally be expended.

Planned maintenance leads to significant cost savings with improved productivity. For 50 plus years USC Consulting Group has helped organizations develop planned maintenance programs to increase their uptime. Contact us today to start converting your maintenance practices and keep your operations running as much as possible.

Learn more about project management best practices.

Every organization with major assets has different initiatives or projects it wants to pursue such as shutdowns, turnarounds, outages or other large scale capital projects. However, managing all the details that go into those efforts — from team coordination to stakeholder communication — requires a dedicated strategy. Furthermore, avoiding schedule overrun and staying within or under budget is critical. That’s where project management comes in, which helps leaders better monitor, control and execute projects by emphasizing:

- An established scope of work and delivery schedule.

- Different methodologies for different projects.

- Progress tracking and win sharing.

Want to learn more? Download our eBook “Getting Down to Business: The Essentials of Project Management.”

Planning an upcoming project? Contact us today to speak with our subject matter experts about your initiative.

The project management office (PMO) is a common organizational feature among modern businesses. Eighty-five percent of enterprises have PMOs, according to researchers for the project management software provider PM Solutions. Of those companies that do not have PMOs, 30 percent plan to establish them over the next year.

Organized and well-resourced PMOs can drastically improve operations, allowing companies to execute improvement strategies that are on time and under budget. However, few PMOs perform at this level. A mere 25 percent of PMOs facilitate improvements to productivity, and only one-third consistently deliver under budget. Why? Because many PMOs suffer from functional and structural issues that hinder their performance.

For a deeper look at a Project Management Office and its structure, check out ProjectManager.com as they provide an extensive guide to PMOs.

Now, let’s look at a few common PMO issues and how to address them:

Lack of operational identity

Businesses often form Project Management Offices for one of two reasons:

- Executive leaders have requested the formation of a permanent PM team.

- An operational issue warrants an internal team of problem-solvers.

In either scenario, the resulting PMO can encounter roadblocks as they try to find a clear identity, the Project Management Institute reported. PMOs created at the behest of business leaders often struggle to pinpoint their purpose. At the same time, PMOs established to address one-off problems tend to be slightly more productive, as they at least come into existence with a clear objective in mind. But once they tackle the objective they were created to achieve, finding new purpose can be difficult.

PMOs can avoid this issue by crafting an organizational identity upon formation. For instance, some PMOs use responsive processes and specialize in solving reported problems. Others take a more proactive approach by staffing multiple project managers and technical executors who can actively pinpoint and iron out problem areas. PMOs that work to cultivate actionable identities are more likely to find sustainable success than those that function with seemingly little direction. But organizations should refrain from building PMOs with overly rigid missions. Agility is essential in today’s operational climate, and a PMO that can adapt is far more likely to face new challenges confidently and correctly.

Ineffective performance metrics

In order to achieve success, PMOs must know what excellent performance on the shop floor actually looks like. Metrics are, of course, responsible for painting a full picture.

Unfortunately, few seem to work off such measurements. Analysts for PM Solutions found that more than 40 percent of PMOs struggle to demonstrate their value, which speaks the weakness of their reporting structures. The absence of ironclad performance data can lead to resourcing issues and distrust among executive and operations leaders. This makes it more difficult for PMOs to execute, even without the context data provides.

The root of this problem lies in the actual mechanics of tracking performance. Many PMOs rely on manual reporting practices powered by unwieldy spreadsheets. This variable alone makes it difficult for these offices to collect and analyze actionable data, leaving many to give up on such efforts entirely. Enterprises can overcome this issue by outfitting their PMOs with back-end solutions capable of gathering real-time performance insights that map to specific internal initiatives.

Fear of failure

PMOs pursue long-term performance excellence. As a result, project managers are always searching for projects and cultivating processes meant to maximize the likelihood of success and, ultimately, revenue. But this desire to demonstrate value can actually cause dysfunction within PMOs. PM departments that constantly look for wins may avoid innovative methodologies that could lay the groundwork for operational transformation in favor of more traditional, battle-tested solutions.

Today, according to PMI, 15 percent of the programs managed through PMOs result in failure. This figure indicates that many PMOs put timeliness and budget above overarching business performance by submitting unambitious project plans. Sure, they’re likely to be executed on time and under budget but will have little impact on the operation when all is said and done. PMOs must be empowered to break free from convention and pursue innovative methods for improving their businesses.

In the end, enterprises that overcome these challenges can expect to create powerful PMOs that lead internal initiatives, realize goals, and catalyze real change.

Here at USC Consulting Group, we’ve been working with our partners across various industries for five decades, lending them operational insights that bolster shop-floor functionality and facilitate financial success. Does your PMO lack direction, struggle with its key performance indicators, or feel trapped in a vicious cycle of boilerplate solutions to complex and unique problems? Connect with us today to learn more about our work and how we can help your PMO reach its full potential.