-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Muck System

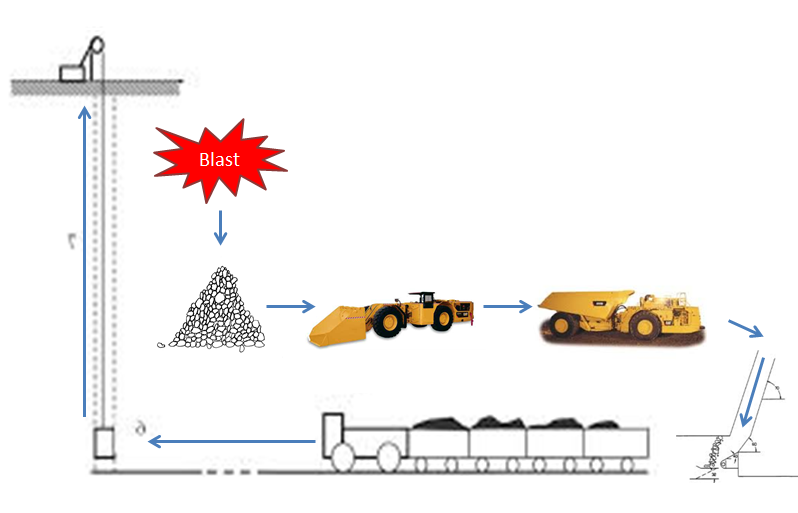

The movement of broken rock or “muck” is critical in an underground mining operation. A large portion of mine design is based around getting the muck from the blast area to the surface. This intricate design involves many different methods including LHD (Load Haul Dump) machines, haul trucks, shaft skips, railcars, conveyors, and gravity fed muck passes. In many cases, all of the mentioned methods may be used in conjunction to form the muck system of an underground mine.

The objective of this muck system is to bring an inherently heavy substance (solid rock/ore), upwards in most cases, with as little effort as possible. Regardless of the methods your underground mine is utilizing to bring the muck to the surface, there are typically a limited number of routes to the surface because of the capital expenditure involved in creating exit points. As a result of this, there is a large impact to operations if one of these routes becomes blocked. A blockage may occur for several reasons: critical equipment failure, path blockage by other equipment, or pure congestion in the area. When this situation occurs, depending on where it occurs in the muck system, the muck will eventually back up to the source or where the mining activity is happening. A critical delay known as being “muck bound” occurs when blasting activities must cease to take place because there is nowhere to put the muck. The miners may be allocated to another location; however, that specific location will remain idle until the blockage is corrected. If this situation occurs in a high-grade area of the mine, it can be very costly to operations. With most other methods of moving muck relying only on proper maintenance and operation, the mobile LHD and haul truck operations provide a variable link between the active mining area and the muck system (below).

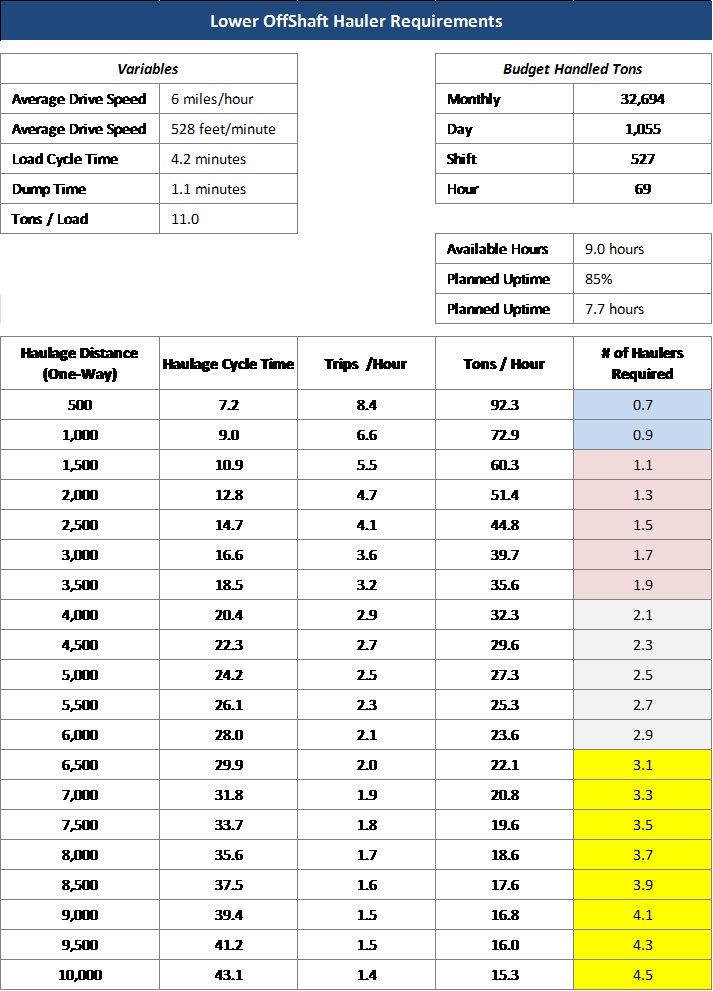

This link in the process can provide a source of opportunity or, if not managed properly, a major source of delay. It is a given that each active mining area will eventually require the assistance of this mobile team to come and take some of their broken rock away and thus, leaving them room to break more. As the breaking (blasting) of rock is arguably the most value added activity in a mine, it is in operations’ best interest to service the mining crew to the highest quality. This is accomplished by providing the miners with as much material as required, when needed, and removing all roadblocks so that the mining cycle can function at an optimal level. Given this great demand on the muck system to keep up with mining activities without allowing a backup of rock anywhere in the process, how does a mine with limited resources deploy these in the most effective manner day in and day out? The challenge of deploying a fixed level of resources effectively with the precision and flexibility to respond quickly to changes in the landscape is amplified greatly in larger mines. Due to the fact that larger operations typically share numerous resources across a vast number of working areas, changing a plan mid-shift can have a significant impact on other areas of the operation. Developing a distance chart could be one of the most valuable tools for your supervisors to use in conjunction with their own level of experience. Here is an example of a distance chart:

For each active mucking area, it outlines the optimal number of trucks that should be deployed to meet the demand of the mining crew. An important element to understand is the concept of optimal in this equation. The first requirement is that we meet the demand of the mining crew. The second requirement is that we meet this demand at the lowest possible cost because these resources could be required elsewhere. Your formula must take into account the following information: Forecasted Demand – How much rock is the mining crew planning to break? Congestion Factor in the Area – How much traffic, aside from mucking activity, is typically present at the location? Distance – What is the one-way distance from the loading location or mining area to the drop point feeding the muck system? Average Truck Cycle Time – Once a truck is loaded, how long will it take to drive to its dump point, dump the rock, and return? Average Truck Load Time – How long does it take for your LHD loader to fill one haul truck? Current Inventory – How much rock has the mining crew broken since last being “mucked” out? With all of these variables known, a distance chart can be created. When planning daily assignments, a distance chart can be very useful to determine the optimal ratio of trucks to LHD machines. This will allow for any excess resources to be allocated to other crews that are short, other areas of the mine, or other job functions. The use of this tool will not tell your crews where to go, but how many resources will be needed once there.

Obtaining the actual Inventory level can be one of the more challenging pieces of information to obtain. This information must be as real-time as possible and accurate. The actual inventory levels along with site priorities will be the guiding force on what locations will require “mucking” assistance. Distance charting, if used properly, can allow the muck system in a mine to rapidly allocate the right amount of resources to the areas that will yield the most benefit. In an industry where the misallocation of such expensive resources can be so costly, the opportunities to gain are equally as considerable. Distance charting is one of the many useful tools that will encourage opportunity seeking decision-making within your company from the front line supervisor level.