-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2024 (4)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Leadership

“Time is really the only capital that any human being has, and the only thing he can’t afford to lose.” – Thomas Edison

There are many skills a quality leader should have — good communication skills being one of the most important — but perhaps the second most important skill that can help elevate the workplace is time management.

Why Time Management is Such an Important Skill for Leaders in Business

Time management is about learning how to use time wisely and manage your employees effectively. When you push too fast too hard to get things done, it leads to burnout, which is the antithesis of productivity. Once you or anyone on your team starts experiencing burnout, it can be challenging to turn things back in a more positive direction.

Unfortunately, it’s not uncommon for people in the workplace to end up pushing themselves harder when they start experiencing burnout for fear that they aren’t doing a good enough job. This, however, can make things worse and lead to long-term burnout, which can result in severe mental and physical fatigue, a loss of motivation, a weakened immune system, and frequent mood swings.

This is why time management is so crucial a skill to have as a leader — because it helps protect mental bandwidth, which is another word for your executive functioning and cognitive capacity or the ability to exert mental effort. When you’re burnt out because your time is not well managed, it can have a significant impact on your mental bandwidth.

When a leader has mastered time management, however, they lead their team to make smarter decisions, which fosters efficiency and productivity. When your cognitive functioning is working at full capacity, it enables you to better plan out your day so that the right tasks get done at the right time. This is effective time management — not working faster, but working smarter by making smarter decisions.

Tips on How to Master the Art of Time Management

There’s no single right way to develop solid time management skills. It’s a combination of efforts and mindful behaviors that can teach you how to better manage your time and your team.

Set Personal and Professional Goals

Your personal and professional goals can impact your time management ability. For example, if you aren’t enjoying personal time, not getting enough sleep, or not making time for activities or hobbies you love, this can impact how you feel at work.

Part of learning to better manage your time and mental bandwidth is setting both personal and professional goals for growth, such as learning a new software or tool, getting better sleep, and learning to set better boundaries so you have more time for personal activities.

Automate Processes When Possible

One great way to find more time in your day is to go through all the repetitive and redundant tasks you or your team perform every day and see if those tasks can be automated. It might seem like a minor adjustment, but over time, when you don’t have to worry about doing small things, you reserve more of your mental capacity for bigger things that matter.

Delegate Wisely

Learning to delegate tasks to the right people is a key time management skill. If you don’t have enough people to delegate to, it’s potentially a sign that you need to grow your team and hire more people. Additionally, if any staff members are interested in growing into a management position, start delegating certain leadership tasks to them a little at a time to mentor them and help them grow.

Make a To-Do List of Top Priorities Every Morning

Even if you think you remember everything that needs to get done, get in the habit of sitting down each morning and writing everything down. Doing so can be a huge mental relief and help you create a better plan for your day or week. Highlight the top priorities so you know which things need to get done first to avoid wasting time on less important tasks.

Avoid Over-Commitment

Deadlines are important, but be mindful that you are setting and agreeing to realistic deadlines. Pleasing your customers is essential, but not if it means over-committing and burning out yourself and your team. The quality of the work you and your team do will be much better if you allow for the appropriate amount of time to get things done.

Allow for Flexibility

Your list of top priorities should act more as a guide for your day rather than a hard rule set in stone. You will undoubtedly have days where timelines shift and new things pop up that take precedence, and your ability to be flexible can make your day much easier when this happens. It is not the end of the world if something changes and throws a wrench in your plans. Simply go back to your list and move things around.

Allowing for flexibility also means allowing for breaks and space to decompress. This is critical for you and your employees if you want to manage stress in a high-volume work environment. Your days and weeks must allow time for self-care, both at work and at home. If you can tell your team is being pushed too hard, make them take a break. Go outside for a little walk, do some stretching, refuel with a snack — something to just allow the mind to get a little reprieve to avoid mental bandwidth being over-expanded.

Effective Time Management

To remind yourself and your team every day how to be most efficient with time, consider making a list of the “golden” rules of time management and keeping it posted where you can be reminded each day. This might seem silly at first, but writing things down and keeping them where you can easily see them is one of the best ways to remember something often enough that it becomes a habit. At the end of the day, healthier and smarter work habits and behaviors are key to effective time management.

*This article is written by Ainsley Lawrence. View more of Ainsley’s articles here.

Do you ever notice that, right around this time during every presidential election cycle, the candidates always start talking with much urgency about how it’s the “most important election of our lifetime”? We’re not so sure about believing that hype. As far as we can remember, total Armageddon has never occurred after Election Day.

As a wise man once said decades ago, “No matter who wins, I’ll still pack my lunch and go to work in the mines.”

And yet, a recent poll by Investopedia found that 61% of respondents are worried about the impact of the 2024 elections on their investments. That translates to worries for CEOs.

Here are some common concerns CEOs and other top executives at companies of all stripes may be thinking about, and looking for, as we run up to the “most important election of our lifetime.”

Typical concerns as election hype swirls

Uncertainty. A recent survey of CEOs by KPMG found that top executives ranked political uncertainty as their top risk to growth over the next three years. A CNN poll had a similar finding, reporting that 51% of CEOs believe political uncertainty is the top risk to growth.

Another disputed election. This is the last thing anybody wants, CEOs included.

Economic policies. Issues like tax breaks and the tax rate for corporations, a candidate’s stand on trade impacting the supply chain, minimum wage hikes, and other economic policies matter to the heads of large companies. Which candidate will be more favorable to business?

Geopolitical issues. With war and unrest all over the globe, CEOs may be concerned on a personal level, but for business, geopolitical unrest might mean supply chain headaches, price hikes and trade disruption. They are looking for candidates who will work to quell that unrest.

Social issues. There are pressures on companies in all sectors now about things like sustainability, climate change, carbon neutrality. But also, more than ever before, companies are supposed to stand for something larger than the product or service they provide. Which candidates fit best with their brand?

What CEOs may want to see from candidates

Stability. The ancient curse, “May you live in interesting times,” is on the minds of many execs, who prefer boring, old stability and predictability in order to plan, forecast and hit those numbers.

Business-friendly policies: No matter which political party individual execs subscribe to, the bottom line for most is a candidate who is business friendly, promising lower taxes, fewer regulations, and streamlined processes.

Global policies. Many execs have big concerns about supply chain disruption after the past few years, and any politician who can normalize trade and global relations will be a welcome relief.

The good news

Despite the hype surrounding this (and every) election, there is good reason to be optimistic this year. In fact, most CEOs are. According to that CNN poll, “optimism outweighs pessimism among CEOs” for the first time in two years. And just 27% expect economic conditions to worsen, down from 47% in the fourth quarter of 2023.

The bottom line for business during this election year? Focus on efficiency, operational improvements and increasing throughput. That’s the port that will help you weather any political storm.

If history teaches us anything, it’s to heed those long ago words from that miner. Markets tend to rise in presidential election years, no matter who is on the ballot. That same Investopedia article sites the S&P 500 showing positive returns in 20 of the last 24 election years, dating all the way back to 1928.

That’s 83.3% of the time.

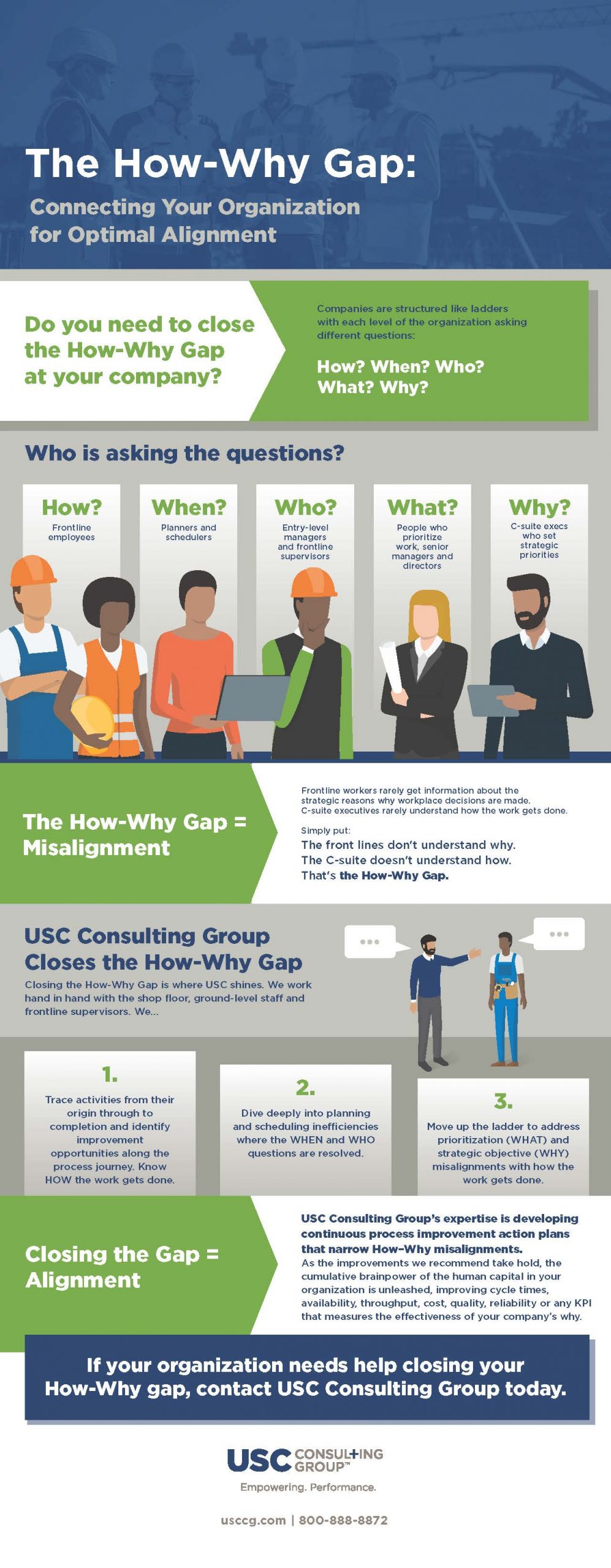

Asking the question, “What’s your why?” has become fashionable to the point of cliché. The intent is to explore purpose and personal meaning. In the workplace, companies are structured like ladders with each organizational layer asking (and ideally solving), “How, When, Who, What and Why” questions. Companies with work execution problems must resolve their “How–Why” gap to achieve organizational alignment.

Breaking Down The How-Why Gap

So what is the How–Why gap? Employees who ask a lot of “how?” questions are most likely working at the ground level – where the work gets done; making journal entries, receiving and shipping goods, or producing widgets. Employees who ask “when?” and “who?” questions, are likely planners / schedulers, front-line supervisors or entry level managers. People who ask “what?” questions are people who prioritize work – Senior Managers and Directors. At the pinnacle of the organization, members of the C-suite often find themselves asking a lot of “why?” questions to set strategic priorities and the purposes of the organization.

“The frontline often does not understand why, and the Executives often don’t understand how.”

When front-line employees venture to ask why questions amongst themselves in the breakroom, they often lack insight into the forces that drive the why strategies. By the same token, it is rare for Executives to understand how the work gets done. Simply put, the frontline often does not understand why, and the Executives often don’t understand how. The greater the misalignment between the why actions taken by the C-Suite and the how execution on the shop floor, the stronger the cultural cognitive dissonance throughout the organization. I call this the “How-Why” gap. Scott Adams, the creator of the workplace cartoon “Dilbert” became famous by satirizing the “How–Why” gap between Dilbert and the Pointy-Haired Boss.

Aligning the How, the Why and everything in between

Reconciling the “How–Why” gap is where USC Consulting Group shines. Many consultants offer Executives ideas on emerging strategies, but few consulting companies get to the how of a company’s point of work execution problems. USC does this by working hand in hand with shop floors, ground level staff and front-line supervisors. We trace activities from their origin through to their completion and identify improvement opportunities along the process journey.

But USC doesn’t stop at understanding how the work gets done, we move up the work ladder to address misalignments with the Who and When, the What and the Why challenges facing the organization. Once insight is gained into the current state, we dive deeply into planning and scheduling inefficiencies where who and when questions are resolved. As one of our senior partners is keen to remind us, USC stands for the “Universal Scheduling Company.” Not only is master scheduling and resource capacity planning our heritage, but it is literally part of our name.

Getting answers to what questions can be among the most challenging because these questions demand prioritization. Managers and Directors who are embroiled in answering what questions are often battling for limited resources (budget and headcount), trying to keep their personal initiatives high on the priority list. This rung of the ladder is where most corporate politics are fought out.

USC Consulting Group’s expertise is developing continuous process improvement action plans that narrow How–Why misalignments. As the improvements we recommend take hold, the cumulative brainpower of the human capital in your organization is unleashed improving cycle times, availability, throughput, cost, quality, reliability, or any KPI that measures the effectiveness of your company’s why. Front line employees can answer “how do we execute our why?” Managers can answer “who will execute our why and when will we do it? Directors can answer, “what initiatives need to be prioritized to execute our why?” and Executives can effectively map the strategic course to answer, “what is our organizational why?”

This detailed infographic illustrates the importance of each role and how to achieve optimal organizational alignment:

If your company needs help with organizational alignment and closing your How-Why gap, please contact us today.

Leo Tolstoy once said: “Everyone thinks of changing the world, but no one thinks of changing himself.”

How true that is. Sure, he was talking about the Russian Revolution, but the words of the author of War and Peace, considered by some to be the greatest novel ever written, are just as applicable in today’s manufacturing workplaces as they were back then. It’s especially true when manufacturers are going through the process of implementing Lean Six Sigma.

When you’re talking about a culture change as big as Lean Six Sigma (LSS), it can feel a bit like your company is going through a revolution. And as Tolstoy so astutely pointed out, changing the “world” — your workplace culture, processes and procedures — is all well and good, but changing oneself and one’s role in it? Is that really necessary? As hard as it is for many managers and top leadership to hear, the answer to that question is “yes.”

It’s hard to hear and even harder to accept because, inherent in the concept of change is the notion that you were doing something wrong. People who have been on the job awhile, from the workers on the front lines to the people in the corner office, are resistant and, dare we say, defensive about that notion. But it’s not about companies doing something wrong. It’s about finding opportunities for greater efficiency, throughput and, frankly, profit.

At USC Consulting Group, we help companies implement LSS. Our Lean Six Sigma Master Black Belt, Dr. Frank Esposto, leads many of these implementations. But as Frank tells companies, LSS isn’t just about a new set of tools and operating procedures. It’s about culture change, too. And managers and top brass embracing that change is crucial to LSS success.

Lean Six Sigma 101

Here’s a quick rundown of Lean Six Sigma.

The whole concept of Lean started with either Henry Ford or Toyota, depending on who you ask. The idea was identifying and eliminating waste in manufacturing operations. Toyota called them the “seven deadly wastes” and that term stuck. At USC, we added an eighth. They include:

- Overproduction. It leaves you with unused product.

- Waiting. Waiting on the shop floor between steps on the line, or waiting on supply or even equipment.

- Transporting. Excessive movement of inventory, causing the possibility of damage, or even excessive movement within the manufacturing process itself.

- Processing. Do you have extra, unnecessary steps in the manufacturing process?

- Inventory. Too much stock on hand.

- Excess motion. Extra walking, lifting, reaching.

- Defects. Defects in product happen to the best of us.

- People. This is the eighth waste. It is about taking a close look at the untapped potential of your people.

The goal is to create greater efficiency on the line.

Six Sigma is a set of techniques aimed at reducing (in a perfect world, eliminating) the probability that an error or defect will occur in the process.

Together, as Lean Six Sigma, the two methodologies pack a punch of efficiency and perfection. LSS enables companies to produce better product faster, increasing throughput and quality.

Learn more about LSS in our eBook – Lean Six Sigma: Do You Really Know These Methodologies?

Why culture change is so important to LSS success

There’s a perception out there that Lean Six Sigma is simply a series of process improvements designed to eliminate waste and increase quality. It is that, for sure. But it also requires the aforementioned culture change. A change in attitudes and behaviors. Everyone, from frontline employees to the corner office, needs to be on board or this change won’t stick. You’ll slide back into your old ways.

It’s vital for the workers performing new processes to embrace those changes. But it’s just as vital for managers and supervisors and the top brass to change, too. Remember, you can’t change the world without changing yourself first.

What managers can do to embrace change

In order for the LSS changes to be sustainable, managers and executives need to demonstrate to employees that they’re on board. And that doesn’t mean sending out a memo of encouragement. It means changing daily work habits, just like employees are expected to do. A few ways to do that:

Walk the floor. This is arguably the most important piece of this puzzle for management. Get out of the office and onto the shop floor. Get into the trenches with your frontline employees. Show them you’re all in.

Ask senior employees for advice and input. You know who we’re talking about. The men and women who have been on your frontlines forever. Shift supervisors. Trusted workers. The people actually doing the job day after day. When you’re in the process of implementing LSS, their input is vital. Not only to the success of the project, but to their buy-in as well.

Roll up your sleeves. If it’s crunch time and you’re shorthanded, take off that suit coat, roll up your sleeves and help out any way you can.

Over the years, we’ve seen how companies that embrace change will succeed in becoming more efficient and profitable. Those that don’t may simply slide back into their old ways.

For leadership teams leading the charge for culture change, we lean on advice from Mahatma Ghandi, “Be the change that you wish to see in the world.”

To help companies reach their highest potential, executives need to understand the challenges that come with owning and operating a business. Whether it’s finding creative solutions for operations management, developing products that can survive a competitive marketplace, or building a team of directors and officers, it’s no surprise that in today’s competitive landscape, executives must always look for ways to improve their company (both internally and externally) if they want to take things to the next level.

That being said, there is more than one roll-up-your-sleeves type of leader who seems to have gotten it right. Of course, their success didn’t come without hardships, obstacles, or lessons learned but it can appear that way on the surface. Not all successful leaders have to be entrepreneurs but there is creative problem solving that goes along with the territory of risking it all for a venture yet to be navigated.

Allow this cohort of self-made billionaire startup founders to inspire you by noting their successes and hiccups. Based on their years of experience in the startup world, Embroker has gathered 13 lessons from these iconic startup leaders to point you in the right direction whether you are seeking a new marketing strategy, launching a new product, or recruiting new team members. Check out the infographic below to learn more about the lessons of the most successful entrepreneurs to overcome executive challenges.

Learning from experience is pivotal to success when facing executive challenges. If you need guidance in operations management, contact USC Consulting Group today and put our 50 plus years of experience to work for you.