-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- September 2025 (1)

- August 2025 (2)

- July 2025 (2)

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Inventory Management

One of USC Consulting Group’s partners, AICA, has developed a groundbreaking Agentic AI Classification Tool that automates UNSPSC classification, leveraging advanced AI solutions to transform product data management, procurement optimization, inventory management, spend analysis, compliance auditing, and overall operational efficiency.

This innovative tool represents a significant leap forward in data classification technology and has already begun to reshape how organizations approach the classification of products and services.

What is Agentic AI?

Agentic AI refers to advanced artificial intelligence systems that operate autonomously, executing tasks with minimal or no human intervention. Unlike traditional AI models that require constant oversight, agentic AI adapts to predefined goals and delivers results independently, maintaining high levels of accuracy and efficiency.

This approach reduces reliance on manual processes and human input, enabling faster execution, lower costs, and fewer errors.

Why This Tool is Transformative

The Agentic AI Classification Tool is a breakthrough in automating the classification of products and services using the United Nations Standard Products and Services Code (UNSPSC). Here’s why this technology stands out:

- Fully Automated Classification: The tool autonomously handles the entire UNSPSC classification process, eliminating the need for manual intervention and significantly reducing time and labor requirements.

- Exceptional Accuracy and Speed: With unparalleled precision, the tool processes data faster than traditional methods, ensuring reliable and actionable results.

- Cost-Effectiveness: By minimizing the need for manual classification, businesses can achieve substantial cost savings.

- Versatility Across Systems: While designed for UNSPSC, the tool’s adaptable architecture can support other classification systems, extending its application across industries.

- Built-In Quality Assurance: Quality scoring features allow businesses to identify areas where human verification may be beneficial, ensuring data integrity.

Key Features

The Agentic AI Classification Tool includes several advanced features:

- Autonomous Classification: Fully automates classification tasks, streamlining workflows.

- API Integration: Seamlessly integrates with enterprise systems and can be implemented in weeks.

- Scalability: Efficiently processes large datasets, making it ideal for high-volume data management.

- Customizable Applications: Capable of adapting to various classification systems to meet industry-specific needs.

- Quality Feedback Loop: Provides quality scores to monitor and maintain accuracy.

Use Cases

The technology offers solutions across a variety of business functions, including:

Procurement Optimization: Improved supplier management and purchasing efficiency through accurate product classifications.

Inventory Management: Enhanced stock control by reducing categorization errors.

Spend Analysis: More accurate financial reporting and budgeting through precise spend data classification.

Compliance and Auditing: Support for regulatory requirements with standardized and auditable product classifications.

A Transformative Impact on Data Management

This Agentic AI tool enables businesses to reduce classification times, cut labor costs, and achieve higher levels of accuracy and reliability than traditional manual methods. It also supports organizations in scaling their operations to handle increasing data volumes effortlessly.

Looking Ahead

As one of USC Consulting Group’s trusted partners, AICA continues to lead the way in AI-powered solutions for data classification. Their Agentic AI technology exemplifies how innovation can drive efficiency and improve outcomes for businesses managing complex data systems.

By leveraging tools like this, organizations can focus their resources on strategic goals, leaving routine and labor-intensive tasks to advanced AI solutions.

Exploring the dynamics of effective warehouse management reveals a myriad of strategies that significantly enhance operational efficiency and productivity. Focusing on best practices within the warehouse setting not only streamlines operations but also cultivates an environment poised for growth and adaptability. This article delves into essential techniques that are pivotal for modern warehouses aiming to thrive in an increasingly competitive landscape.

Streamline Your Space

You can achieve optimal performance by maximizing the layout and space utilization in your warehouse. By carefully planning and organizing the floor space to minimize movement, you ensure that your most frequently accessed goods are easily reachable. Vertical stacking and the use of adjustable shelving systems can significantly increase your storage capacity. Incorporating these practices creates an organized, efficient workspace that enhances overall productivity. Smart layout adjustments can also contribute to safer work conditions and reduce the risk of inventory damage.

Prioritize Safety Always

Ensuring a steadfast commitment to safety measures is essential for avoiding mishaps in your warehouse. Schedule and execute continuous safety training throughout the calendar to maintain awareness and adherence to crucial safety guidelines. Such consistent updates help embed these practices deeply into everyday activities, securing a safe working environment for all staff. Enhanced safety awareness not only diminishes the likelihood of incidents but also minimizes operational interruptions.

Harness Technology

Leveraging technology and automation in your warehouse can transform mundane tasks into high-efficiency operations. Consider implementing robotic systems for repetitive tasks such as packing and sorting, and use conveyor belts to minimize manual handling. Advanced technology like drones for inventory checks can save you time and labor. Integrating these innovations ensures your warehouse stays competitive in a rapidly evolving market. Furthermore, automation can significantly lower human error rates, leading to more reliable operations.

Master Inventory Management

An effective inventory management system is essential for maintaining the flow of goods in and out of your warehouse efficiently. Utilize modern software that offers real-time tracking and data analytics to keep tabs on inventory levels, order status, and logistical information. This integration allows you to forecast demand more accurately and manage stock levels to prevent both surplus and shortages, ensuring a smooth operation. Proper management systems enhance both speed and accuracy in order fulfillment. Streamlined inventory processes also help in reducing carrying costs and improving customer satisfaction.

Cultivate Clear Communication

Clear and efficient communication is the backbone of successful warehouse operations. Ensure that all team members are equipped with handheld devices that allow for real-time updates and communication. Establish a centralized digital notice system where updates and operational changes can be disseminated quickly. A well-structured communication process minimizes confusion and improves overall efficiency. Effective communication protocols facilitate quicker decision-making and response times in critical situations.

Commit to Continuous Training

Regular training sessions are crucial for maintaining high standards of operation in your warehouse. By continuously educating your staff on the latest operational practices and technology, you empower them to perform their roles more effectively. Regular training fosters a knowledgeable workforce that can adapt to new challenges and technologies as they arise. Investing in training improves both employee performance and job satisfaction. Ongoing education also promotes a culture of safety and efficiency, crucial for long-term operational success.

Embrace Regular Audits

Performing regular audits helps you identify areas for improvement in your warehouse operations. Use these audits to assess and refine workflow, inventory management, and efficiency. Continuous improvement initiatives should be a part of your operational strategy, aiming to enhance quality, reduce waste, and optimize overall performance. Regular feedback from these audits paves the way for incremental enhancements that lead to significant benefits. Audits also ensure compliance with industry standards and regulations, safeguarding your business against legal and financial penalties.

Refining warehouse operations through best practices is an ongoing journey that demands attention to detail and a proactive approach to management. As industries evolve and new technologies emerge, warehouses that prioritize efficiency, adaptability, and continuous improvement will stand out as leaders in their field, ready to meet the challenges and opportunities of the future.

*This article was written by Dean Burgess. Dean runs Excitepreneur, which celebrates the achievements of entrepreneurs. He understands that there are many types of entrepreneurs, and strives to provide helpful information to assist them in achieving their particular idea or goal.

Spend analysis is essential, yet complex and most organizations are unaware that spend analysis can be simplified and accelerated by implementing a structured system like the United Nations Standard Products and Services Code (UNSPSC).

In today’s competitive landscape, accurate and insightful spend analysis is critical for organizations to manage procurement efficiently, identify savings opportunities, and drive strategic purchasing decisions. However, many companies struggle with inconsistent data classification, making it challenging to gain meaningful insights. This is where UNSPSC classification can make a significant difference.

Understanding UNSPSC

The United Nations Standard Products and Services Code (UNSPSC) is a globally recognized system designed to classify goods and services. Its hierarchical structure includes segments, families, classes, and commodities, allowing for a granular approach to categorizing products and services across regions, suppliers, and industries.

By applying UNSPSC codes to procurement data, companies can standardize and streamline their spend analysis, enabling more efficient procurement processes and better decision-making.

The Impact of UNSPSC on Spend Analysis

Standardization of Data

One of the most significant challenges in spend analysis is dealing with inconsistent data across departments, suppliers, or geographic locations. Without a standardized classification system, companies often struggle to compare or consolidate spend data meaningfully. UNSPSC addresses this by providing a consistent framework that ensures all products and services are classified uniformly. Whether your business operates in multiple countries or deals with various suppliers, UNSPSC enables a cohesive and structured view of your procurement activities.

Improved Visibility into Spend Categories

The granularity provided by UNSPSC allows businesses to break down their spending into specific categories, such as office supplies, IT equipment, or professional services. This level of detail helps organizations pinpoint their most significant spending areas and uncover opportunities to optimize procurement. For example, a company can monitor category-specific trends, enabling them to identify potential savings in areas like facility maintenance or software subscriptions.

Difficulties in Spend Analysis Without UNSPSC

Without a robust classification system like UNSPSC, companies often face a range of challenges in their spend analysis efforts. First, manual classification of data is time-consuming and prone to error, making it difficult to achieve consistent categorization across departments. Moreover, inconsistencies in spend data make it harder to track, monitor, and report on procurement activities, leading to a lack of visibility into spending patterns and hindering efforts to benchmark suppliers effectively.

When spend data isn’t accurately categorized, organizations may miss opportunities for cost savings, such as consolidated purchases or volume discounts. Additionally, they may struggle with regulatory compliance, as inconsistent classification complicates audit processes and increases the likelihood of reporting errors.

Enhancing Spend Analysis with UNSPSC

To fully unlock the potential of spend analysis, companies can implement UNSPSC in several ways:

- Standardized Spend Categories

Implementing UNSPSC in spend analytics ensures that all procurement data is classified using the same system. This improves visibility across different departments and regions by creating a uniform view of spend data, making comparisons and consolidations easier. For example, a global company can standardize procurement data from various offices, enabling centralized analysis that supports strategic purchasing decisions. - Improved Spend Visibility

With UNSPSC, companies can break down spending into highly detailed categories. This granular visibility allows procurement teams to monitor specific spend areas, such as IT services or logistics, and identify opportunities for cost reductions. By isolating spend patterns, companies can reduce redundant purchases and optimize their procurement strategies. - Supplier Benchmarking

UNSPSC provides a consistent way to categorize suppliers, allowing organizations to benchmark costs for similar goods or services from different vendors. This enables companies to compare suppliers more effectively, helping them identify opportunities for cost savings or improved performance within specific categories. - Spend Control and Compliance

By categorizing spend data with UNSPSC, companies can more easily identify areas where spending exceeds budget thresholds. This system helps organizations gain better control over their procurement activities, enabling more targeted cost reduction efforts. Moreover, using standardized classifications simplifies compliance with industry-specific regulations, improving audit readiness and ensuring that procurement activities meet necessary reporting requirements. - Automated Spend Classification

When combined with AI-driven analytics platforms, UNSPSC can enable automated spend classification, reducing the need for manual efforts. AI algorithms can map purchases to the correct UNSPSC codes, ensuring real-time categorization of new transactions. This automation allows procurement teams to focus on strategic initiatives rather than getting bogged down in manual data management tasks. - Enhanced Predictive Analytics

By using UNSPSC to organize historical spend data, companies can apply predictive analytics to anticipate future procurement needs. For example, trends in past spending across categories like consulting or software licenses can inform contract negotiations or help manage inventory levels more effectively, providing a proactive approach to procurement.

How AICA Can Help Optimize UNSPSC Classification and Spend Analysis

We recognize that implementing and maintaining UNSPSC classification can be a daunting task for many organizations. That’s why AICA’s advanced AI-driven solutions are designed to support businesses in classifying their data according to the latest version of UNSPSC.

Here’s what makes AICA’s classification service unique:

- Speed and Accuracy

AICA’s AI solutions are up to 90% faster than traditional manual methods, allowing you to implement UNSPSC classifications quickly and efficiently. Our specialized algorithms ensure a classification accuracy of over 80%, far surpassing what can be achieved through manual data entry or general AI models. - Cost-Effective Data Maintenance

Maintaining an accurate and up-to-date classification system is crucial for long-term spend analysis success. AICA’s solutions automate much of the classification and data enrichment process, reducing operational costs and freeing up procurement teams to focus on higher-value tasks. - Customized Solutions

Every company’s procurement system is unique, and AICA provides customizable services to ensure that your UNSPSC implementation aligns with your specific needs. Whether you require one-time data classification or ongoing support, AICA can help you streamline your procurement activities and maximize the value of your spend analysis.

Conclusion

UNSPSC classification is more than just a tool for organizing procurement data; it’s a strategic approach to enhancing spend analytics. By implementing this system, companies can gain better visibility into their spending, improve supplier benchmarking, and control costs more effectively. AICA’s advanced AI-driven solutions can help you leverage UNSPSC classification to its full potential, ensuring that your spend data is clean, consistent, and actionable.

*This article is written by USC Consulting Group’s strategic partner in data cleansing and management, AICA. For more information how AICA can cleanse and enrich your product and services data with AI, visit their website.

Efficient warehouse management is crucial for the success of any business. However, numerous challenges can hinder operations and impact overall profitability. Understanding these obstacles and implementing effective solutions is essential for optimizing warehouse performance.

Common Warehousing Challenges

Ineffective warehouse management practices, such as inadequate order and inventory management, can lead to significant inefficiencies and losses. Inaccurate data, inconsistent tracking, and insufficient space further exacerbate these issues. Additionally, erratic changes in demand and economic fluctuations can disrupt operations and make it difficult to maintain optimal inventory levels. Packaging wastefulness and design shortcomings can also contribute to increased costs and environmental concerns.

Optimizing Inventory Management

To address inventory management challenges, businesses should invest in advanced technologies and streamline processes. Implementing cloud-based inventory management platforms with demand forecasting tools and automated reordering systems can help optimize stock levels and reduce carrying costs. Utilizing mobile productivity tools allows for real-time inventory tracking and control, improving efficiency and accuracy.

Enhancing Warehouse Layout and Space Utilization

Maximizing warehouse space utilization is crucial for optimizing operations and reducing costs. Implementing a well-designed warehouse layout, incorporating storage solutions that maximize vertical space, and utilizing advanced warehouse management systems can help streamline workflows and improve productivity.

Leveraging Technology and Data

Technology plays a vital role in modern warehousing. Implementing barcode technology and system-directed pick/put-away procedures can significantly improve order fulfillment accuracy and speed. Digitizing documentation and utilizing data analytics can provide valuable insights into inventory levels, customer demand, and operational performance.

Addressing Packaging and Sustainability

Packaging waste and design shortcomings can impact both costs and environmental sustainability. Collaborating with pharma packaging machine manufacturers to optimize packaging design can help reduce waste and improve efficiency. Additionally, implementing recycling programs and using sustainable packaging materials can contribute to environmental responsibility.

Overcoming warehousing challenges requires a combination of strategic planning, technological advancements, and efficient processes. By addressing issues such as inventory management, space utilization, and packaging optimization, businesses can improve operational efficiency, reduce costs, and enhance customer satisfaction. The resource below provides a visual overview of common warehousing challenges and potential solutions.

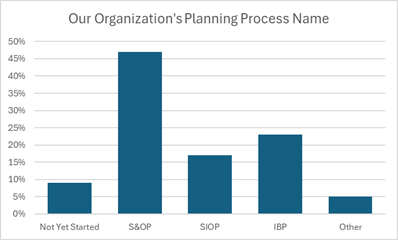

There are a lot of terms used by organizations to describe their mid to long range strategic planning discipline. Whether your organization calls it Integrated Business Planning (IBP), Sales and Operations Planning (S&OP), Sales, Inventory and Operations Planning (SIOP) or something else, the key message is that abbreviations are not important – results are. Strong strategic planning discipline orchestrates sales plans, operations constraints, and financial objectives while giving guidance to short-term scheduling for execution. At USC, we call this discipline SIOP due to the strategic importance of inventory to smooth supply and demand fluctuations to maintain customer service levels.

Survey Says!

Businesses find S&OP beneficial because it helps balance supply and demand, it improves communication between sales and other departments, leads to better decision-making with everyone on the same page, and it ultimately results in better efficiency. Most organizations refer to their planning process as S&OP, but we think it’s incomplete. Inventory needs to be part of this process to unlock greater levels of operational efficiency and customer service rates.

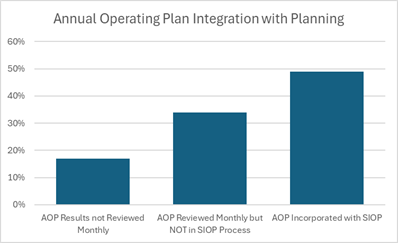

Most companies have less than five years of experience utilizing a SIOP discipline and significantly, fewer than 50% of all companies integrate financial objectives into their monthly planning process. The result is the organization’s annual plans are disconnected from the monthly “replanning” SIOP process. Managers are typically held accountable to their annual plans which are increasingly out of date as the year progresses and better plans are known resulting in sub-optimal decision making based on old assumptions.

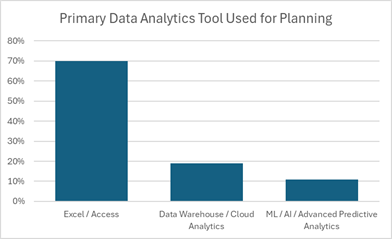

Furthermore, since most companies rely on static models such as Excel and Access to as their primary analytical tools, the planning process can be labor intensive, time consuming and more prone to human error. Integrating decision support systems with operations data, procurement data, inventory data, and customer demand improves simulation and scenario analysis capabilities. Integrating with advanced predictive analytics can further augment planning knowledge.

Sales, Inventory and Operations Planning

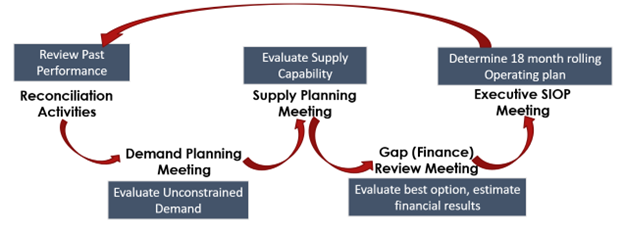

We tell our clients that SIOP is making sure you’re having the right conversations about the right things at the right time.

Sales, Inventory, and Operations Planning is a holistic process that integrates customer-focused demand plans with production, sourcing and inventory plans and results in improved tactical and long-term business decision making capability.

Keys to Implementing a Successful SIOP Process

- Everyone is on board. It’s simply not going to work if it’s not interdepartmental. You need everyone – Sales & Marketing, Operations, Procurement and Logistics, Planning, Product Development, Finance, IT, and the C-Suite working in lock step from the same plan.

- Planning cycles should be monthly. This isn’t a one-and-done process. Once you get on the SIOP treadmill, you don’t ever get off. We advise a rolling 18-month period, updated monthly. This ensures the re-planning process is looking out beyond the current budget year and for strategic planning.

- People and Process Discipline is a must. A good SIOP process includes a SIOP monthly process schedule/calendar of key events, RACIs, mutually agreed upon KPIs, actual vs forecasted reporting scorecards, assumptions and occurrences reporting, decisions made with action item follow up.

But Why the Added Focus on Inventory?

Inventory tells a story about a business’ operational efficiency. Inventory accounts pool the collective decisions and market forces affecting the company, telling stories of sales forecasting accuracy, manufacturing efficiency, planning effectiveness, supply chain disruptions, and quality control. Lean inventories reveal robust planning systems and culture, integrated ERP systems, and good governance. Excess inventories can be a short-term benefit to sustain high customer service levels during times of uncertainty, however they come with high obsolescence and carrying costs. Inventory is a strategic lever to smooth operations, procurement, and sales fluctuations. The right level of inventory is different for each company, and changes based on current consumer demand, supply chain disruptions, and strategic decisions.

Benefits of SIOP

- Gets departments in sync. The SIOP process helps to determine whether

your original financial expectations / budget, and your current sales plan and operations plan are in sync with each other. Updating your forecast monthly will show you where problems lie and provide action plans to address shortfalls. - Ensures that the plans are realistic. The key stakeholders from each department participate in formulating the SIOP plan. Since all assumptions are transparent throughout the process, each department has more time to evaluate its resources and capabilities in the context of the most recent company-wide plan. The result is a solid set of department plans that are based on latest expectations and known capabilities.

- Effectively manages change. Many industries have faced significant planning challenges in recent years. Having an agile and timely planning process helps decision makers roll with the punches. With SIOP, your business can make holistic, controlled responses to changes instead of making knee-jerk, departmental centric reactions.

- Measures performance. Our customized approach to KPIs ensures that success measurements identify where the organization is challenged and where to focus on improvement.

- Builds teamwork. SIOP gives each department an opportunity to participate in the overall planning process.

Interested to learn more about how adding inventory to your planning can make you more efficient? For more information on how SIOP can help your business read our eBook, “Sales, Inventory and Operations Planning: It’s About Time.”

*This article is written by USC Consulting Group’s Supply Chain Practice Leader, David Newman.

Effective inventory management is often a challenging task for businesses to undertake. While some factors may be similar across organizations, predicting inventory demand can vary significantly depending on the industry or business model. One of the most common problems affecting various industries is a lack of inventory visibility.

Inventory visibility issues have become increasingly prevalent with the rise of online shopping. The additional steps and expediency demands of this now preferred process can make tracking an item even more complicated. This often results in invisible inventory, where materials or products are unaccounted for in the system.

To address these issues, many companies are turning to supply chain visibility (SCV) technologies to remain competitive. These advanced systems provide real-time tracking, monitoring, and notification of each item in the supply chain. By utilizing responsive supply chains, a company can increase transparency within its inbound/outbound processes and other daily activities.

Another innovative solution is cloud-based POS systems and e-commerce management software. This technology integrates every aspect of a business for greater efficiency and offers a range of benefits. Companies can use it to track sales and customers, exercise better point of sale control, automate inventory replenishment, and generate reports with detailed analysis of gross margin ROI.

By utilizing modern technology to improve inventory visibility, businesses can stay ahead of the competition and provide better customer satisfaction. To discover strategies for staying ahead in inventory management, we encourage you to explore the resource provided below. It offers valuable insights to help you tackle this crucial aspect of your business operations.

Invisible Inventory from Celerant, a bike shop pos system company

If you need assistance with your inventory management, contact USC Consulting Group today.

Supply chain technology has come a long way in the past few years. Improvements in AI technology and deep learning programs can help supply chain managers accurately predict shortages, adapt to current conditions, and operate more efficiently.

Supply chain technology can also be used to improve the customer journey. Effective supply chain management leverages the Internet of Things (IoT) to give consumers greater control over their orders. Emerging technology can also be used to reduce human error, increase operational efficiency, and improve security.

These breakthroughs in technology improve the customer experience and ensure that consumers get the products they want when they need them.

CX and SCM

At first glance, consumer experience (CX) and supply chain management (SCM) seem unrelated. However, as senior sales executive Sven Esser points out “the relationship between CX and SCM is symbiotic.”

Esser goes on to explain that effectively mapping the customer journey is an important facet of effective CX and SCM. Predicting consumer behavior ensures that supply chains are operating as efficiently as possible and that consumers have accurate information about shipping and order fulfillment before they check out.

Esser advocates for a model of SCM that gets to know consumers and uses AI analytics to accurately map and predict the typical consumer journey. This will help businesses connect with consumers’ personal needs and help supply chain managers shift to a more “customer-focused effort.”

Businesses can use AI analytics to map the consumer journey and improve their SCM through Google Analytics (GA4). GA4 is typically used by marketers who want to improve the materials. However, GA4 can also be used to track users from the referral page to the conversion or exit page.

Supply chain managers can work with marketing to get a better picture of the consumer journey and typical behavior. GA4 can be particularly useful for businesses that use the IoT to place orders or improve CX.

The IoT

The Internet of Things (IoT) is revolutionizing industries around the world. Consumers and businesses can use the IoT to link devices and create “smart” networks between products and machines.

The IoT can also improve the efficiency of supply chains by giving businesses an up-to-date assessment of inventory and potential problems. For example, a business that runs an IoT-integrated warehouse will be aware of issues like faulty equipment and disrupted supply lines earlier than competitors who do not leverage the IoT.

IoT-integrated supply chains can improve the consumer journey directly, too. IoT technology makes it easier for customers to place and edit orders. For example, folks who utilize smart home devices like Google Nest or Amazon’s Alexa can place and edit orders with a simple voice command.

Human Error

Emerging technology like AI software and the IoT is designed to improve operational efficiency and streamline the consumer journey. However, human error still threatens to derail business operations and supply chains.

Supply chain managers can reduce the risk of human error in the workplace by automating relevant processes. This is particularly important in warehouse management, where human error may result in injury due to repetitive motions or dangerous working conditions. Automated machines in smart factories and warehouses can take humans out of the firing line and ensure that customers have their orders fulfilled with minimal delays.

Supply chain technology can also improve post-sale communication with consumers. Consumers who have ordered expensive goods want regular updates on the status of their products. Businesses can send out automated emails when the customer’s product has passed production phases and is ready for shipping. Automated communication improves the customer journey by alleviating worries about order fulfillment without derailing operational efficiency.

Operational Efficiency

Operational efficiency is at the heart of a successful customer journey. Customers can tell when all departments are working in unison and will benefit from quicker order fulfillment due to higher efficiency in the workplace.

Maximizing operational efficiency is particularly important for businesses that use Just-in-time (JIT) inventory management. JIT inventory management relies on accurate consumer forecasts and robust supply chain management to ensure that businesses get the inventory they need just when they need it. This can result in major savings, which can be passed onto the consumer or used to otherwise improve the customer journey.

However, for inventory management methods like JIT to work, businesses need to hyperautomate their operations. Hyperautomation allows businesses to “rapidly identify, vet, and automate as many business and IT processes as possible.” Hyperautomation relies on deep learning programs that can successfully capture and utilize massive data sets. This will improve the customer journey, too, as the same data sets can be used to present personalized adverts and products to consumers.

Conclusion

Emerging technology like the IoT can have a direct impact on the customer journey. Consumers today can place, edit, and receive orders using a network of machines and devices that are connected by AI algorithms. Recent upgrades to supply chain technology can also improve operational efficiency and reduce the risk of human error in factories and warehouses. This ensures that consumers receive their orders with minimal delay and at a lower cost.

*This article is written by Ainsley Lawrence. View more of Ainsley’s articles here.

The COVID-era supply chain disruptions are slowly but surely easing up for manufacturers around the globe. While the worldwide market is not yet fully recovered, signs point to a strong resurgence in 2023, with a return to normalcy by 2024. Even though good news is on the horizon for manufacturers, there are still a number of challenges to be aware of that will impact day-to-day operations. Here’s an overview of a few of the top manufacturing challenges for 2023, and how to handle them.

Challenge: Legacy technologies

Many manufacturers operate with legacy technologies — outdated hardware or software systems. These outdated systems can cause disruption for an organization in a few key areas.

The first problem: Legacy technologies can cause efficiency issues. Since these systems can be years (and sometimes decades) old, they simply don’t have the same features and capabilities of newer software on the market. Additionally, these legacy systems can pose a security risk. Older technology doesn’t have the same safeguards as newer systems, and cybercriminals have a much easier time infiltrating outdated software than one that is up-to-date.

Despite these problems, manufacturers can be hesitant to change systems due to familiarity, not wanting to enact a full system overhaul, or a mix of the two.

Strategy: Invest in new technologies and smart warehouses

Investing in emerging technologies should be a priority for manufacturers heading into the new year.

It’s a wise strategy, not only to become more efficient and protect systems from infiltration, but newer technologies can increase safety in the workplace and free up employees to handle more productive tasks. A recent survey from Deloitte found that 85% of manufacturing executives think that some form of robotics on the production line could increase employee safety, and 78% agree that updated technology can minimize repetitive work, empowering employees to focus on more productive and impactful tasks.

Challenge: Inflation

Starting in mid-2022, inflation across all essential goods prompted public backlash, not to mention squeezing the wallets of consumers and businesses alike. Bearing the brunt of the blame was the global supply chain, and the bottlenecks and scarcity it caused in markets across the world. Although those pressures are easing headed into the new year, inflation will still be a factor in 2023.

Strategy: Re-evaluate costs during design

For manufacturers, inflation means more careful planning to ensure operations remain lean, mean and profitable.

One way of doing this is by implementing Design to Cost — a method in which a manufacturer combines cost management with decision-making during the design stage of a product. Rather than the normal method of thinking about costs after a rough design of a product is made, the unit and material costs are fully integrated during planning to ensure products are profitable.

This type of thinking seems to be the reality for manufacturers in 2023, as a recent Forbes survey found that 87% of manufacturing CEOs plan to increase prices in the new year. Therefore, it’s important for all manufactures to think ahead, and integrate material costs into their design process as soon as possible.

Challenge: Inventory uncertainty

Inventory uncertainty remains one of the manufacturing challenges in 2023. Despite the healing global supply chain, manufacturers still need to strike a proper balance between stockpiling inventory and buying just-in-time. Striking that balance can be tricky. Not getting it right can cause businesses to become over- or under-leveraged at a moment’s notice — affecting the bottom line in the process.

Strategy: SIOP

Sales, Inventory & Operations Planning, SIOP, takes the normal sales and operations planning process and makes inventory just as important of a variable and a strategic tool. Following this methodology helps manufacturers eliminate waste, increase efficiencies and achieve an optimal level between not enough and too much.

We recommend that the SIOP horizon be a minimum rolling 14-month period that gets updated monthly. The aim is to look ahead multiple quarters to make sure inventory is available exactly when you need it. Involving a wide range of departments such as sales, marketing, engineering and finance, SIOP is a system that involves the entire organization to ensure yearly goals and objectives are met.

If you would like to learn more about SIOP, download our (free) eBook, “Sales, Inventory & Operations Planning: It’s About Time.”

Keep moving forward

There will be manufacturing challenges in 2023 and beyond. By addressing your legacy technologies, adjusting to inflation fluxes, and taking the uncertainty out of your inventory management, you will be able to fine-tune your operations for optimal performance.

If your business could use some horsepower to power up your team on improvement initiatives, contact USC Consulting Group and we will put our over 50 years of experience to work for you.

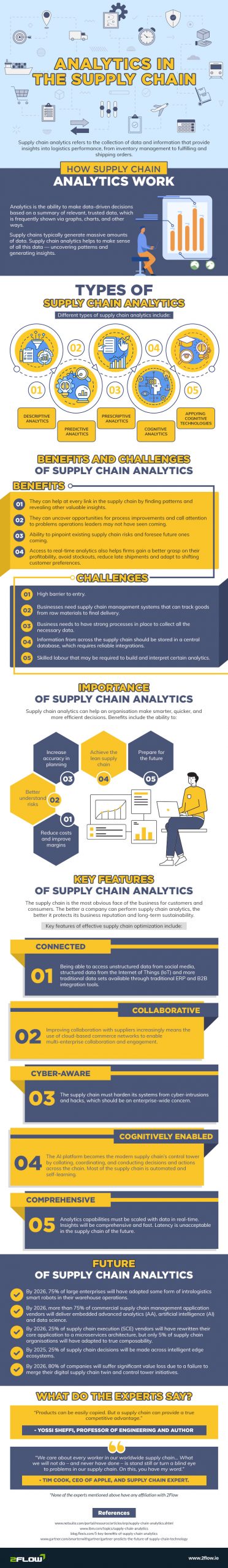

Supply chain analytics refers to the collection of data and information that provide insights into logistics performance, from inventory management to fulfilling and shipping orders.

How Data Analytics is Changing the Supply Chain Landscape

The ever-increasing reliance on big data is altering the landscape of supply chains as we know them. Historically, the majority of supply chain management was dependent on intuition and experience. However, with the introduction of powerful data analytics technologies, supply chains are now guided by data-driven decision making.

The ever-increasing availability of data is driving this transition. Previously, data was dispersed across numerous silos inside a business, making it difficult to provide a comprehensive perspective of the supply chain. Organizations, on the other hand, may collect and store data from all areas of the supply chain in one central location owing to data warehouses and data lakes. This enables supply chain managers to see the entire picture and make data-driven decisions to increase efficiencies and performance.

The rising availability of strong data analytics tools is another factor pushing the change to data-driven decision making. To examine data in the past, supply chain managers had to rely on manual procedures or limited software tools. However, a wide range of powerful data analytics technologies is now available to assist managers in making sense of massive data sets and uncovering hidden patterns and trends. The transition to data-driven decision making is reshaping the supply chain landscape and has far reaching implications for how businesses function.

Organizations may improve the efficiency and performance of their supply chains by leveraging the power of data, providing them with a competitive advantage in the marketplace.

The Advantages of Data Analytics in Supply Chain Management

Data analytics can aid in the smooth and effective operation of supply chains. Supply chains can uncover patterns and trends in past shipments by examining data from previous shipments. This can help them minimize disruptions and stock-outs while also improving inventory management. Furthermore, data analytics can assist supply chains in optimizing their routes and schedules, as well as tracking their success over time.

Here are some of the primary advantages of employing data analytics in supply chain management:

- Reduced Inventory Costs

- Optimized Production Plans

- More Efficient Cargo Shipments

- Reduced Risks

- Cross-Functional Cooperation

Check out the following infographic by 2Flow which takes a deep dive into ‘Analytics In The Supply Chain’.

Supply chain analytics are guiding managers into the future with data-driven decision making. If you need assistance properly analyzing your data and setting up your supply chain management for success, contact USC Consulting Group today.

Yes, it’s that time again. The holiday season is around the corner and it is time for manufacturers to start preparing now.

Most holiday sales will come from online shopping, adding stress to supply chains and the warehousing industry. With proper management, it’s possible to plan to sustain efficient operations despite volume increases and demand.

Managers can analyze the warehouse itself and equip employees and equipment with the necessary tools to make it through the season. What techniques work and what should warehouse managers prioritize among their already lengthy to-do lists?

Preparing Warehouses for Increased Inventory

It’s time to walk the warehouse and analyze the state of everything. Is it already almost bursting with regular inventory, or is there clutter in the walkways? How much space could the warehouse reappropriate for enhanced storage solutions? What maintenance should be conducted to help bear the load of surplus inventory, spatially and financially?

Work with your logistics team on this walkthrough, which should happen long before the holidays hit, to allocate enough time to make renovations or install new structures. Rethinking the floor plan can reveal space optimizations and efficiency modifications, such as more efficient routes for workers and automated machines to pack expediently.

Countless systems and programs can help automate and streamline previously complicated inquiries and tasks, including:

- Implementing scheduling software to help employees trade shifts or sign up for overtime.

- Setting up cameras and other monitoring systems to check everything from maintenance to productivity.

- Choosing the optimal warehouse management system to keep tabs on inventory.

- Collaborating with relevant members of the supply chain with cloud-based blockchain tech, keeping communications open in case of delays or changes.

Your tech stack – the tech that synergizes to make your company run seamlessly – should receive adequate maintenance to ensure technology isn’t the reason for outages or stops in production. Suppose your warehouse does not have any or just a few of these technologies. In that case, this may be a time to invest, because they are long-term solutions that will continually provide benefits outside of the holiday season.

This is the prime time to reflect on the strategies that worked in the previous holiday seasons and what could be improved. Interview the workers to gather perspectives from those who were in the fray last time inventory demand was at its peak.

Readying Workers for Increased Demand

The topmost priority is ensuring the warehouse has enough staff to handle the holidays. It’s helpful to analyze analytics and demand forecasts from the past to make accurate assessments of staffing needs. This will ensure incoming and tenured staff feels supported by the company if they know management gives proper attention to employee well-being and workload distribution.

This doesn’t only include floor staff – extra hands in payroll and human resources to help with scheduling will probably be necessary. They must be equipped with the right resources to adjust for fluctuating employee numbers throughout the holiday season.

Do not resort to increasing hours to adjust for long days, as this will cause turnover and burnout, potentially leaving the success of your holiday season – and after – in jeopardy. It’s vital to prioritize retention during this time, as seasoned staff members can assist with helping seasonal entrants acclimate more quickly to the working environment.

Providing training beforehand will instill accurate expectations for work hours – which could extend past the holiday season due to potential returns – and holiday wages.

On top of having adequate staff is training existing and upcoming staff to mentally and physically prepare them for volume. This combines with informing staff of any changes made to the warehouse, including program updates and organizational shifts that will help efficiency. For mental preparation, ensure employees have access to resources to manage stress to help keep productivity level.

Equipping Shipping Fleets for Holiday Weather and Traffic

Safety is paramount when it comes to holiday shipping. Fleets must be ready to take on the climate shifts in the region while making deliveries on time.

There are plenty of ways to ensure the warehouse’s fleet can withstand holiday conditions. Vehicle maintenance will not only save money by keeping vehicles healthier, longer, but also save on potential injuries in the workplace by keeping employees safer. With hundreds of thousands of fleet vehicles preparing to travel for peak season, it’s also about keeping everyone else on the road safe.

Checking brake pads, tires, and windshield wipers are inexpensive and basic improvements on top of more complex modifications like stronger batteries.

Provide employees with training to know what precautions to take on the road. They must receive as much training as warehouse staff to communicate about and acclimate to unexpected holiday situations. Are they aware of alternate travel routes or how to react in a severe storm?

Warehouses must prep the fleet with insurance and real-time locating system (RTLS) technologies. Especially since the holidays provide the most intensive time crunch of the year, knowing how well your current shipping system is meeting expectations can help you make adjustments along the way to improve efficiency.

It also provides the warehouse and customers with peace of mind, knowing their packages will safely make it to their houses.

Warehouses Prepare for the Holiday Season

Though the holidays can feel overwhelming for anyone in consumer industries, it’s possible to deal with the work gracefully. These timeless strategies allow warehouse managers to find improvements and discover the tactics that genuinely make a difference.

Making necessary adjustments to your warehouses, training employees, and creating safe shipping environments will also reinforce strategies to use in subsequent seasons.

* This article is written by Devin Partida. Devin is a tech writer with an interest in the IIoT and manufacturing. She is also the Editor-in-Chief of ReHack.com.