-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- July 2025 (1)

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Down Days

Truly innovative asset management covers all aspects of monitoring, analyzing, and maintaining capital equipment. Does your business have all its bases covered?

Now recovering from economic instability over the last decade, companies in asset-intensive industries have begun to invest in new and recommissioned equipment. In turn, these decisions ignite a fervent interest in improving uptime quality through optimized workflows, reliability-centered maintenance, and proactive decision-making.

Download our latest e-book “Asset Management: The Rise of Reliability” to discover asset management best practices from our team of experienced operational experts. Here are the seven points examined and discussed therein.

1. Work management

A work order is more than just a slip of paper. Its life cycle extends further than most businesses realize and should include information valuable to future successes in asset management.

2. Downtime tracking

If you fail to understand the nuance of downtime tracking, you will fail to sustainably decrease it.

3. Preventive and predictive maintenance

Reward awaits those facilities that understand what these two cutting-edge maintenance methodologies entail and how to execute on them properly to achieve new heights.

4. Asset criticality review

Are you allocating your resources to the machinery that matters most to your business? Align your goals with your actual asset management processes with a comprehensive ACR.

5. Equipment history capture and analysis

Those who ignore history are doomed to repeat it. Do you know what sorts of data you should capture about your assets today in order to make informed decisions tomorrow?

6. Root cause failure analysis

Assets fail for any number of reasons, but they boil down to three basic types of failure. Learn these as well as tips for digging below the surface when failures strike.

7. Operator equipment care

Line operators can work wonders for an innovative asset management program – if only their leaders know how best to utilize them.

Comprehensive preventive maintenance and asset management ensure both the functionality, and efficiency of high-value equipment at a given business throughout its lifecycle. Yet, without an equally comprehensive auditing and optimization strategy for the ancillary processes around enterprise assets, businesses may accidentally overextend their operating budgets in unnecessary, preventable ways.

How can manufacturers, process industries, energy providers and other asset-intensive sectors optimize their preventive maintenance programs without hurting their productivity?

Reduce preventive maintenance schedule variance

When it comes to preventive maintenance, no matter how beneficial it may be to enhancing the performance of enterprise assets, it is possible to have too much of a good thing.

Is your maintenance schedule overbooked, underbooked, or just right?

Uneven scheduled downtime, for instance, could hike up operational costs in one of three ways:

- When preventive maintenance occurs too frequently, maintenance labor costs outweigh the threat posed by machine deficiency or outright failure. Balancing these costs is crucial to getting everything a business needs from its PM, but not overpaying for superfluous maintenance.

- Spacing scheduled preventive maintenance too far apart has its obvious consequences, like unintentionally allowing a small deficiency to exacerbate unnoticed.

- Choppy preventive maintenance schedules that vary hinder managers from planning strategically over the long term, both in an operational sense and financially.

Moreover, as The Maintenance Phoenix pointed out, scheduling variance could be the result of uncalibrated enterprise asset management software like computerized maintenance management systems (CMMS). Variance could also occur when maintenance professionals assigned repairs don’t carry out work orders within a tight timeframe. To cut down on preventive maintenance variance, businesses should assess their operational data, determine whether their maintenance programs suffer from any of these issues and take the needed corrective steps.

Minimize spare parts inventory management and costs

Traditionally, spare parts management follows along the same vein as asset management. In fact, there is considerable overlap between the two. Both preserve asset availability and mitigate the impact of downtime when it strikes.

That said, businesses must constantly work toward honing their spare parts inventory as much as possible without compromising the insurance these components provide asset uptime. Accomplishing this involves a two-pronged approach to spares: analysis and adjustment.

When a particular component within an asset breaks, an inventory of spare parts on hand accelerates the repair process. However, spare part inventory growth inexorably leads to cost increases, sometimes to the tune of as much as 20 percent or more of company expenditures, according to Life Cycle Engineering. Instead of adding a new batch of spares to the pile whenever assets appear to require them, it might be more cost-beneficial to perform root cause analysis on the “bad actor.”

For example, if a manufacturer spends $2,000 per month stocking fan belts for an asset integral to production, perhaps spending a little more on a one-time RCA cost may uncover why the asset churns through fan belts in the first place. A successful RCA, followed by corrective maintenance, could effectively eliminate the recurring cost entirely.

After tackling spare parts inventory, businesses should then be sure to adjust procurement plans accordingly so they represent the new optimized operations precisely and cut costs.

Process industries, perhaps more so than any other, need a strong risk management approach since they experience and interact with risk on a daily basis. Due to the continual nature of a process-focused enterprise, these companies ostensibly subject themselves to the highest level of risk because they’re continually operating without stop.

As such, the most production-minded companies who pride themselves on efficient, timely output require a stellar and comprehensive risk management strategy. But risk is multifaceted, and in many ways, proper risk management deployment can positively impact and maximize lean processes.

“Everyone working at a processing plant assesses and manages risk.”

How does risk management apply to lean processes?

Lean processes boil down to the elimination of waste. While some experts may argue honing operations has more to it than, the mission of an average company seeking to increase value potential is to “trim the fat” and reduce areas of excess. According to Lean Manufacturing Tools, some of these areas include overproduction, overprocessing and extraneous movement.

However, promoting a true lean mindset shouldn’t hinge myopically on the problem, but the factor or process that yields the problem. This is where risk management comes in. In one way or another, everyone working at a processing plant assesses and manages risk. For example, when an employee applies his occupational knowledge by safely operating heavy machinery, he’s leveraging the risk of injury with his expertise. That said, risk management doesn’t exclusively pertain to preventing injuries in the workplace. That same employee prevents value loss by processing material properly.

Managers and supervisors seeking to flesh out their risk management simultaneously enhance their lean capabilities. BASF explained risk matrices as a very simple math problem: Risk equals probability times severity. This means equal weight is given to small issues that occur frequently and huge ones that only happen once in awhile. Lean process oversight follows similar guidelines: Waste production can be glaring or ingrained in the system, but either way, it’s unwanted at a business seeking efficiency.

Proper risk management avoids processes that could take down the whole operation.

Why risk management and lean operations complement each other without redundancy

In fact, many common areas typically attributed to managing risk are practically blood-related to lean opeations. For instance, since the advent of the digital age, data curation has wedged itself into every industry. Regardless as to what companies do, these days, they all do it with data. In process industries, apart from customer data, information gleaned from machinery and integral technologies can provide managers with valuable insight toward both eliminating inefficiencies and removing risk from the equation.

For example, if a piece of smart equipment reports to a company’s operational risk management system that it’s running too hot, this procedure blends liability control with lean best practices. Not only do these alerts reduce the chances of worker injury, but they also give supervisors an advanced opportunity to address the issue on their own terms, rather than having to deal with a crippled production line completely out of the blue. A Mälardalen University study found downtime can consume almost a quarter of a manufacturer’s total cost ratio. Thankfully, intelligent data deployment and management can resolve those risks and many more.

The biggest mistake a person looking to optimize their production can make is cutting corners. Lean processes aren’t made by throwing the baby out with the bathwater, but by utilizing the resources available with the most innovative and effective methods. operational risk management keeps workers safe, but it’s just as important as a deterrent for expensive downtime, compromise products and surprise repairs.

In process industries, investment in new technology does not always mean that operations will be more efficient. In most situations, technology needs to be paired with the right processes. Automation does not lead to operational improvement by itself. When it comes to improving facility operations, timing is essential. Whether it is to implement a maintenance schedule, adjust equipment settings or administer training, determining the right schedule and sticking to it is paramount.

“Efficient changeovers increase production flexibility.”

The key to successful changeovers is in the planning

Facilities that produce two or more product types know that time can often be lost when switching gears. It takes significant time and effort to alter equipment from one group of settings to another. Accordingly, when implementing changeovers, preventing accrual of downtime is a major consideration. This is accomplished by analyzing the production schedule and determining the best time to make a switch. It may be that a switch from product “A” to “C” is more efficient than a switch from product “A” to “B.” Figuring out these small differences, facility operators can create the right changeover schedule and stick to it. The improvements add up over time and the company is able to save time and money while producing more at the same time. A Lean Journey mentioned that efficient changeovers increase production flexibility, reduce inventory costs and lower defect rates.

Another area of scheduling that is important with regard to changeovers is the staging area. Not only is it important to know when to perform changeovers, but it is also essential that facility technicians take care of the job as quickly as possible. The best way to do this is to make sure that staff members are ready to do the work when the time comes. Having fully stocked staging areas, maintenance staff on standby and process documents in hand can help companies save even more time when performing changeovers.

Scheduling changeovers at the right time can improve operations

Maintenance is not meant to be reactionary

All plant assets require regular maintenance. Some facility operators only do maintenance work when something breaks, but the better strategy is to implement a reliability centered maintenance program. This involves checking and fixing equipment on a regular basis. Reliability Web advised companies to schedule inspections at regular intervals, to discard items before some specified time limit and pay attention to hidden-function items that can lead to functional failures.

The right scheduling can improve facility operations.

Maintenance work is not meant to be reactionary. Alternatively, having a proactive approach ensures that equipment will run longer and more efficiently without interruption. To implement a RCM program, facility operators must designate specific times when the work will be done. The best time may depend on each individual asset and should definitely not interfere with the production schedule. Facility operators can think of RCM as taking insurance out against having to do more significant repair work down the road.

Training is not an option

Because process industries involve lots of equipment, software and technical issues, instituting an ongoing training program is a good idea. Training is one of the main tools employed in the Continuous Improvement methodology. There are many benefits that come with managing a culture of education. Staff will always be updated on best practices in the facility. Furthermore, ongoing training ensures that valuable tribal knowledge accumulated in a facility does not dissipate as aging experienced workers retire. IndustryWeek pointed out that in the manufacturing industry, filling skilled production jobs is already difficult. Regular training can help alleviate this problem because younger workers can learn to take the place of their managers and companies will not have to work so hard trying to hire from the outside

Chemical processing and other batch manufacturing operations are becoming increasingly complex. Manufacturers today need to have a fast response time when quality issues arise and when equipment requires maintenance. Combining real-time analysis with reliability-centered maintenance is a great way to raise efficiency in chemical processing. A constant stream of data coupled with a proactive maintenance plan can ensure that production quality remains high and that plant assets operate in prime condition.

Real-Time Analysis Improves Product Quality

Chemical Processing explained that in batch manufacturing operations, identifying product quality deviations is not an easy thing to do. Additionally, if production continues, and quality issues are not spotted, the cost of wasted time, materials, and energy adds up quickly. This is why it is beneficial to use predictive control techniques so that product quality remains consistent.

According to Chemical Processing, product quality checks should be done with high frequency and accuracy. Automated feedback control can help manufacturers keep track of operations. However, measurements need to be taken without interrupting processes or increasing risk of contamination. Off-line, at-line, and on-line automated devices can allow measurements to be taken close to the process without slowing down the pace of production. Manufacturers can leverage these technology solutions to minimize or even eliminate time delays, if they are able to use the steady stream of accurate and reliable information.

“Product quality checks should be done with high frequency and accuracy.”

Analyzers will provide measurements in real-time or near-real time to manufacturers, but they must be able to respond quickly. For that to happen, KPIs from the analyzers should be worked into the management operating system so that plant managers know how to respond to spikes or dips in the numbers. Data is only useful if companies know how to use it. This is why manufacturing industry experts pride themselves on having a hands-on approach, because giving consulting advice from the boardroom is not always helpful.

Use technology to provide real-time analysis to monitor quality

Data Helps Manufacturers Stay Competitive

Chem.info explained that big data is changing the chemical industry in a profound way. Companies can real-time analysis data from production centers to increase margins, improve product quality and shape business processes. Once manufacturers put the systems in place that collect the data, they should then identify the best ways to use the data to reduce costs, manage assets, generate revenue, and make smarter decisions going forward. Plant managers who can effectively interpret the data and respond accordingly will see noticeable improvements in their business. For example, data analysis can help manufacturers make variants of existing products and either lower production cost per unit or produce a higher quality substitute with higher profit margins.

One practical way to use data from real-time analysis is to link it with reliability-centered maintenance. Demonstrating vigilance in monitoring quality and production levels, as well as keeping assets in optimal condition, can lower overheads and raise efficiency. As previously mentioned, the chemical manufacturing process is complex, but properly leveraging data makes things simpler, allowing companies to better manage production assets and throughput processes simultaneously.

It is important to mention, however, that smart technology alone will not provide the desired benefits. Data collection and analysis is only a means by which better decisions and actions are taken. Companies that understand this last point know that educating staff on how to interpret and proactively respond to KPIs is equally as important as investing in new technology. As the manufacturing field continues to be influenced by evolving technology, management skills must evolve as well.

Having a proper asset maintenance plan in place is essential for every manufacturing plant. However, sometimes a major impediment to getting maintenance done is that production is ongoing 90% of the time. It is always better to be proactive about asset maintenance instead of having it be a reactionary activity, but in all situations, finding the time to assess and improve asset condition is the most important consideration. This post aims to help you identify ways to work on equipment without incurring extra unnecessary downtime.

Operators and maintenance staff must work together

Plant Engineering suggested that one of the most important times to do asset maintenance work is during changeovers. If your plant needs to switch from one product to another, or change the dimensions of production, the specific time it takes to do a changeover may be different, but with proper scheduling and flexibility, you will be able to create a window of opportunity to get in there and do the work. One way to free up staff and allow for the needed flexibility is to create a partnership between the operators and maintenance groups, yet have each group focus solely on their job and avoid overlap. Sometimes, maintenance staff find themselves performing operations tasks, which can affect overall productivity. Making sure operations work goes to the operators will free up maintenance staff do their job when those windows of opportunity open up.

“Preventative maintenance is never meant to hinder operations.”

Maintenance staff and operators must also work together, because if they don’t, downtime windows become sporadic and asset maintenance is delayed, which in turn affects production negatively. If the two groups work in partnership, operators will utilize equipment based on established procedures, complete their work efficiently, and honor their production scheduled downtimes without delay. While it may seem obvious, maintenance and operators must get their work done correctly. A plant will only be able to ensure timely operations when every aspect of the job is accounted for, such as resources and supplies being available at the asset location when it is time to do the work.

Preventative maintenance is meant to add-value, not detract

According to Plant Engineering, preventative asset maintenance, which involves maintaining equipment before failure occurs, is never meant to hinder operations. It falls under the responsibility of the maintenance department to ensure that equipment is not shut down unnecessarily for preventative maintenance work. Approximately 40% of preventative tasks do not uncover asset failures, so planning them at the wrong time is really a no value-added activity. That is not to say that preventative work could not save an operations from unexpected delays and shutdowns, but smart planning goes a long way.

Asset maintenance should be prioritized into the production schedule

A proven method for limiting downtime related to asset maintenance work is to conduct inspections that do not require assets to be powered down, otherwise known as predictive maintenance. Vibration and infrared analysis, as well as flow, pressure, temperature, and statistical analysis from the quality department can provide maintenance staff with a good idea about the condition of assets without having to stop everything. ReliablePlant explained that predictive maintenance must be done while the equipment is in normal operation, and that it helps find defects that would normally not be found through previously tried inspections methods. Manufacturers use new technologies to accurately examine the condition of assets and determine the presence of defects. Vibration analysis is the most common example of these condition-monitoring predictive technologies.

Preventive and preventative asset maintenance are all about avoiding hindering operations. That is why being proactive is so important. Reactionary maintenance slows down or delays production, and reduces windows of opportunity to fix and optimize assets. Alternatively, if an organization is proactive about its maintenance work, things run a lot more smoothly. Using labor effectively means that everyone gets to do their scheduled work.

Ultimately, the best opportunities for asset maintenance work are the result of planning, scheduling, and coordination. Instead of waiting for downtime windows to appear, supervisors have the responsibility of scheduling jobs carefully so that when downtime appears, it is expected and used the right way.

All manufacturers invariably understand the importance of keeping changeover time to a minimum, as increased downtime means a drop in productivity, and ultimately, revenue. To effectively lower changeover time, they must first be measured accurately. According to Lean Production, one standard calculation that manufacturers can apply across multiple assets is to measure changeover time from the creation of the last good product in the current run to the first good product in the next production run. This article explains one popular methodology for promoting faster changeovers – SMED – and provides 4 suggestions manufacturers should consider when aiming to limit downtime.

The basics of improving changeover times

Lean Production noted that improving changeover times is typically done through standardizing processes, maintaining up-to-date information on equipment settings, and keeping track of real-time metrics. Successful manufacturers will facilitate work in these areas through automation, but will not attempt to use automation alone to reduce times. Plant managers must update processes, establish plans, and adhere to efficient schedules before they can expect an investment in new technology to yield the desired results.

When standardizing processes, plant managers should focus on human improvements. This involves defining roles and establishing accountability. If necessary, manufacturers should coach their teams on the best ways to do their jobs. Regardless of position, operators and technicians must follow processes as they are laid out. Doing so will mean retrieving parts before the changeover time begins, regularly marking down equipment settings, and eliminating idle time. On the technical side, installing quick release mechanisms and modularizing equipment can also prove beneficial.

“Plant managers should focus on human improvements.”

Single Minute Exchange of Dies

It is important to point out that changeover time can vary drastically from one industry to another. Packagers may only spend a few minutes doing a changeover, whereas automobile manufacturers could spend days or weeks adjusting equipment for new models. However, regardless of industry, keeping downtime to a minimum is essential. A LEAN Journey mentioned that one technique for reducing changeover time is Single Minute Exchange of Dies, or SMED, which enables manufacturers to perform more frequent changeovers. This approach is based on managing production in a more flexible manner, allowing for smaller batch sizes, while still maintaining high output.

Lean Production explained how SMED can help manufacturers achieve a significant reduction in changeover time. The methodology is based on separating the changeover process into a series of sequenced events called ‘elements.’ The main goal is to manage as many elements as possible while the equipment is still running, thereby lessening downtime indirectly. SMED takes elements that are not involved in the current production run, moves them externally to the process, and streamlines their use by completing them faster. For example, if a smaller piece of equipment must be calibrated before it fits into a larger framework as part of changeover, the smaller piece ought to be managed independently of the process. SMED is particularly helpful in an iterative process.

Smart manufacturers understand that automation alone does not raise efficiency

Actionable items for faster changeovers

Whether using SMED or focusing on faster changeovers, the approach is the same. As previously mentioned, successfully reducing changeover time comes down to thinking, not tinkering. Accordingly, here are four suggestions to help you reduce your changeover times:

- Separate internal and external setup activities

If you have certain processes that can be performed without having to shut down equipment, do them while production is still active. This will limit the amount of downtime you accrue. - Laterally remove idle time from equipment and workers’ schedules

Some manufacturers believe that machines can be idle as long as workers are still doing their job, but the best way to raise efficiency is to maximize productivity across the board. Equipment does not need to be offline as long as you may think. - Maintain fully stocked staging areas with all necessary parts and tools

You can rely on a Kanban system of inventory management, or keep track of parts using other methods, but make sure workers have the necessary tools at the right times. Not doing so results in more time spent wandering around, and less time on value-added activities. - Maintain a schedule of changeover times and continue to beat your record

You can display changeover times near plant equipment so that staff is always kept aware of operational goals. The only way to know if changeover times are reduced is to continually measure them over time.

Reliable Plant mentioned that improving changeover times will likely lead to the establishment and documentation of new work processes. As such, operators will have to be trained in best practices on an ongoing basis. However, as an organization becomes more efficient after each improvement, eventually it will achieve a lean manufacturing environment. The road toward efficiency and reduced changeover time can be painful at times, but it will most certainly pay off in the long run.

With worldwide prices for many commodities like precious metals, chemicals, and even food products continuing to fluctuate, many industries are struggling to match their production with market demand. In addition to the havoc this causes with labor requirements and planning, it has a huge impact the availability of major production-related assets.

Advances in technology continue to change industrial processes therefore reducing the amount of work done by a skilled labor force; given that, a strong Asset Maintenance Program is a necessity.

Here’s why:

1) The increased need for major capital-intensive assets like earth-moving equipment, cranes, tankers, drill rigs, etc. has become essential to boosting production, so the need to leverage these fixed assets has never been more critical. Consider that the value generated from increased asset utilization has a multiplier effect. Just a 1% improvement can have an exponential impact on the bottom line.

2) While the above point may seem obvious, the caveat is that it is often not fully realized…Why? Because while these assets may be necessary, they have become harder to maintain and operate, which has decreased the value of the production increases they generate. As a result preventive asset maintenance with a reliability-centered maintenance (RCM) approach is critical to keeping these assets performing at or near their optimal level.

This approach applies to not just movable equipment, but to entire facilities like power generation plants, chemical, oil & gas refineries, and manufacturing facilities. The turnaround time for shutdowns and planned outages can be greatly reduced with a strong Asset Maintenance plan.

3) Better leveraging fixed assets by keeping operating costs low should be one goal for any company involved in production, processing, or any heavy industry. Revenue-generating assets can represent billions in capital investment. Appropriate preventive maintenance requires a robust Asset Maintenance program and will keep your assets well maintained and capable of meeting present and future production demands

Maximizing the utilization of revenue producing heavy assets is a key driver for financial performance!

Having excellent On-Stream Time is the bread and butter of any processing plant or other facility that produces chemicals, power, pulp, etc. Effective maintenance practices minimize downtime by focusing and coordinating preventive and corrective maintenance activities. There is however another entire category of downtime; that is the downtime driven by Turnarounds. Paul Harker, Senior Operations Manager with USCCG, explains the best approach to Turnarounds below.

The objective of a Turnaround (TA) is to complete all essential maintenance work required to ensure that the area runs reliably for an entire production campaign. This must be done while keeping the TA duration as short as possible to minimize the loss of production.

Turnarounds exist for two reasons:

- There are some maintenance activities that can only take place completely and safely when the plant is down.

- A correctly scoped Turnaround, executed in the minimum time required, prevents unplanned down events that ultimately cause greater total downtime.

Without a comprehensive approach to turnarounds, an organization exposes itself to a number of issues:

- There may be no annual Turnaround Plan:

- The timing to conduct a TA is determined by an individual

- There are no future Turnarounds scheduled

- The work scope of any given TA may be focused on the problem asset(s), but is easily and artificially inflated by, ‘What can we get done while it is down?’ Rather than by, ‘What must be done to ensure reliability?’

- The ability to report & manage TA costs and duration is cumbersome and incomplete. In some situations, the final cost is only known weeks or months later when all the invoices are in.

- Costs and duration over-runs are frequent.

- There is often an intense scrambling to get everything done in the last few hours or days, whereas in a well-managed outage the final stages are typically calmer. This is because most of the work is already completed, with only a few critical activities left.

Due to the complex mix of parts, equipment, and contractors involved there is a great deal of scrambling required to execute the event. Some common stumbling blocks include:

- The TA planning process is not launched and stabilized early enough to be effective.

- The essential work scope is not formally defined and agreed, resulting in some important work being left out, in favor of less significant work that is clearly defined and ready to go.

- The critical path is determined and managed subjectively.

- An individual must manually coordinate the timeline of internal and outside resources.

- There is frequent interference or disconnects between crafts, and in some situations the crafts even have their own plans developed in isolation.

- Significant time is lost waiting for shared equipment to become available.

- The benefit of Key Activities being completed early is invariably lost due to the inability to reschedule with simplicity. As a result, all delays to critical activities translate directly to outage duration increases.

- Float is not readily visible in the schedule resulting in a less effective focus of attention and resources.

- Informal documents are used to pre-identify and track the status of the parts that need to be purchased for a TA.

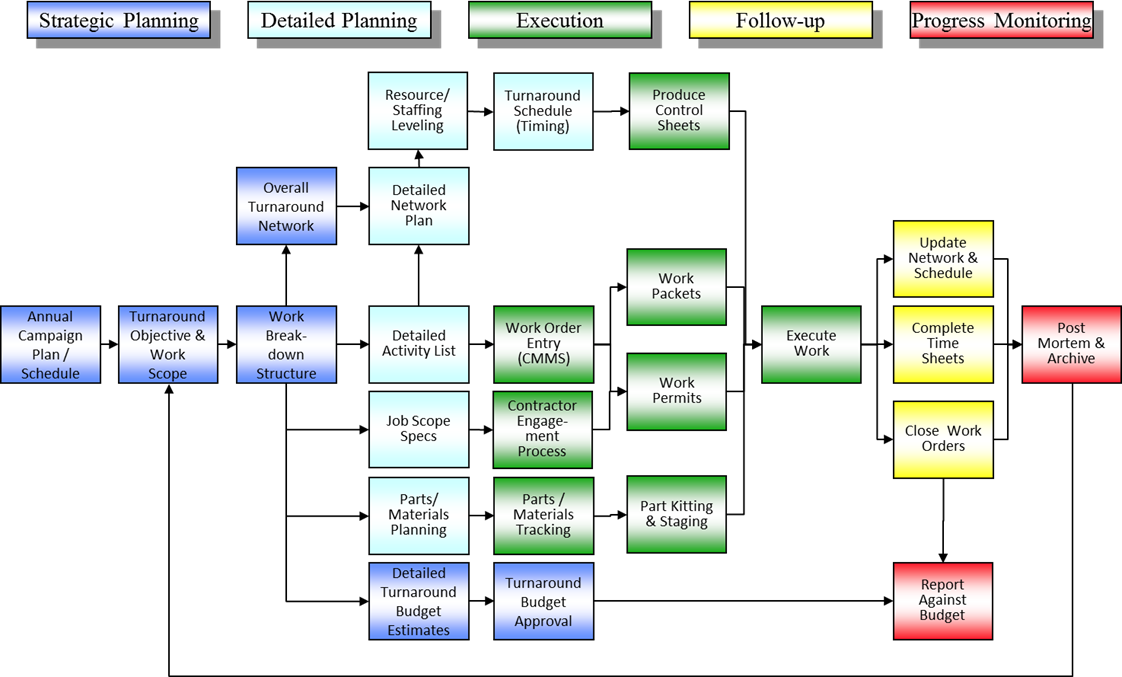

To avoid these issues and to actively manage the balance between speed and effectiveness, a comprehensive system must define a closed loop. The loop needs to contain tools & techniques that fit into the following categories: Strategic Planning, Detailed Planning, Follow-Up, Execution, and Progress Monitoring.

The illustration below depicts the Stages for managing Turnarounds. Each of the categories has been given a color code to make it easier to visualize which elements of the system fit into each category.

(Click image to enlarge)

1. Strategic Planning

The strategic elements of planning for Turnarounds exist to ensure that its activities will drive results. The results need to be consistent with the organization’s production and financial objectives. It is surprising how quickly complex activities like Turnarounds can develop a life of their own and stray from what the organization intended.

The Strategic Planning elements include:

- Annual Campaign Plan

- Define the Turnaround Objective and Essential Work Scope

- Work Breakdown Structure (WBS)

- Overall Turnaround Network

- Detailed Turnaround Budget Estimates & Budget Approval

2. Detailed Planning

This is where the bulk of the planning activities take place. In order to make effective use of the tools and techniques to implemented, there must be resources put in place that have the authority to draw together the needed information and to call the appropriate planning and updating sessions. If these resources and the processes they are pursuing are not given the full support of the management team, you will find that the Turnaround will miss one or more of its reliability, schedule, or cost objectives.

The Detailed Planning elements include:

- Detailed Activities List

- Detailed Network Plan

- Resource/Staffing Level

- Turnaround Schedule (Timing)

- Job Scope Specifications

- Parts/Materials Planning

3. Execution

Execution is where the rubber hits the road in any operating system. For Turnarounds, that includes: ramping down the operation, getting the maintenance work completed, and ramping back up. It also involves follow through on all of the detailed plans by getting work orders written, contractors aligned, work packets put together, materials acquired & staged, etc.

Managing the elements within the Execution category include:

- Produce Control Sheets

- Work Order Entry

- Contractor Engagement Process

- Work Packets

- Work Permits

- Parts/Material Tracking

- Part Kitting & Staging

- Execute Work (Operations, Maintenance, Engineering/HSE&S)

4. Follow-Up

Close Follow-Up is the key to the successful completion of the TA activities. It is also a basic management skill that cannot be over-emphasized. Follow-Up is the periodic review of the status of a work assignment to determine if we remain on-schedule or if some execution problem has arisen. It is essential to give good assignments with specific expectations for follow-up to be effective. This is as equally true for contractors as it is for our own people.

The Follow-Up elements include:

- Update Network & Schedule

- Complete Time Sheets

- Close Work Orders

5. Progress Monitoring

Progress Monitoring is the last of the system categories. It differs from Follow-Up in that we are monitoring the progress to improve our turnarounds, as opposed to executing the current TA. The elements here are designed to capture how successful we were against our cost, schedule, and reliability objectives. Are we getting better at these over time?

The Progress Monitoring elements include:

- Report Against Budget

- Post-Mortem & Archive

The tools and processes outlined above are designed to actively manage the balance between the speed and the effectiveness of Turnarounds.

“Trade Value for Value– If you are not putting in more than you’re taking out, you are either a thief or a mooch. I don’t want to be either.” –Paul Harker

Paul Harker is a Senior Operations Manager at USCCG and has been with the firm since 1988. He has been among the leaders within USCCG in developing our Inventory Management and Sales & Operations Planning processes. Paul has conducted approximately 160 implementations in projects for over 75 clients located in the US, Canada, Mexico, Denmark, Italy, Germany, Taiwan, and China. Despite his busy schedule, he was kind enough to let me ask a few questions about his recent work with clients in the chemical industry, and I’m excited to share Paul’s insights with all of you.

Chemicals is a broad industry, what types of clients do you work with most often?

In terms of process types, our work has been with Continuous and Batch Processing facilities. The Continuous Processing facilities conduct production campaigns, often lasting many months on a single product. The Batch Processing facilities manufacture discrete batches of various products in self-contained loops of vessels.

The product types range from pharmaceuticals, surfactants, and amines to petrochemicals. Their uses range from industrial applications to additives enhancing our medicines, our food, and even our beer.

How is this industry different from other business sectors?

Chemical manufacturing is extremely capital intensive and frequently requires high research and development costs. This industry is stringently regulated on product specifications, sanitation, environmental impact, and employee and public safety. The high cost of entry makes the competitive landscape relatively stable and the operating margins can be quite attractive.

What kinds of issues are your current clients facing?

Because of the capital invested and the margin opportunities, it is critically important that the On-Stream Time of their plants remains very high. Obviously, if they are not producing, they are not making any money. The percentage of On-Stream Time typically needs to be in the mid to high 90% range.

In addition to being On-Stream, the processes within the facilities need to be operating at or near their Rated Capacity. It does our clients little good if they have 98% On-Stream Time, but are only running at 10% of their Rated Capacity. Both indices need to be impacted in order to elevate the output of the plant.

For some clients, the largest erosion of On-Stream Time takes place during their planned Turnarounds (sometimes referred to as Shutdowns). These are periods when the plant is taken down in order to complete maintenance tasks or process improvements that cannot take place while the facility is running. These Turnarounds may occur annually and require two or more weeks to complete. Keeping these as effective and as short as possible are of huge value.

Other clients may have their Turnarounds well managed, but have smaller bites taken out of their On-Stream Time by thinly managed Down Days. A Down Day is a generic term for when a plant goes down due to an unplanned event, or for a planned maintenance or construction task. The duration may be a few hours or a day or two, but are still referred to as Down Days. Although smaller bites, these also need to be well managed in order to get the maximum value in the shortest amount of time

These facilities are tremendously complex and, even with state of the art Distributed Control Systems (DCS), there are typically thousands of steps required to start-up, run, and ramp-down the plant. Well defined and linked procedures are necessary to safely and effectively operate. This is particularly important as the industry expands and the experienced work force approaches retirement.

Virtually all of these clients face an ever-increasing number of regulations and regulatory bodies. The amount of data required concerning the process, equipment configuration and condition, and maintenance task definition and recording has been growing exponentially. This places more requirements on all levels of the organization as well as on the Information Technology infrastructure and support.

What kinds of solutions and benefits can you bring to your clients?

We can have an impact on On-Stream Time by managing Turnaround (TA) events and Down Days (DD) differently. To knock a few days off of an annual TA we have developed a Turnaround Management Operating System that is a comprehensive, closed-loop system that contains the tools, procedures, and practices to manage the balance between the speed and the effectiveness of TAs. We can get more out of DDs by enhancing the use of the Computerized Maintenance Management Operating System (CMMS), overlaying additional planning steps, and restructuring the responsibilities within the planning and materials groups.

We can also have an impact on the Rated Capacity through shifting the maintenance organizations from a Response Centric approach to a Reliability Centric approach. A plant that runs reliably spends more time at or near the rated capacity. This often means building a Reliability Function with dedicated planners and crafts persons. Within that function, we place inspections, lubrication routes, and Preventive Maintenance tasks as well as Down Day and Turnaround events. Additionally, this often requires conducting Failure Mode and Effect Analysis (FMEA) in order to define the correct work plan and frequency for each piece of equipment. Through the years, we have developed a number of templates that dramatically speed up this otherwise daunting task.

Are there any other industries that could benefit from some of the solutions implemented at your clients’ sites?

Any continuous flow manufacturing facility could benefit from these approach elements. Food processing, pharmaceuticals, pulp and paper, petrochemical production and transmission, waste water treatment, and power plants all come to mind.