-

Subscribe to Blog:

SEARCH THE BLOG

CATEGORIES

- Aerospace

- Asset Maintenance

- Automotive

- Blog

- Building Products

- Case Studies

- Chemical Processing

- Consulting

- Food & Beverage

- Forestry Products

- Hospitals & Healthcare

- Knowledge Transfer

- Lean Manufacturing

- Life Sciences

- Logistics

- Manufacturing

- Material Utilization

- Metals

- Mining

- News

- Office Politics

- Oil & Gas

- Plastics

- Private Equity

- Process Improvement

- Project Management

- Spend Management

- Supply Chain

- Uncategorized

- Utilities

- Whitepapers

BLOG ARCHIVES

- June 2025 (4)

- May 2025 (1)

- April 2025 (1)

- March 2025 (1)

- February 2025 (4)

- January 2025 (4)

- December 2024 (4)

- November 2024 (2)

- October 2024 (6)

- September 2024 (5)

- August 2024 (5)

- July 2024 (6)

- June 2024 (3)

- May 2024 (3)

- April 2024 (4)

- March 2024 (3)

- February 2024 (4)

- January 2024 (5)

- December 2023 (2)

- November 2023 (1)

- October 2023 (6)

- September 2023 (3)

- August 2023 (4)

- July 2023 (2)

- June 2023 (3)

- May 2023 (7)

- April 2023 (3)

- March 2023 (3)

- February 2023 (5)

- January 2023 (6)

- December 2022 (2)

- November 2022 (5)

- October 2022 (5)

- September 2022 (5)

- August 2022 (6)

- July 2022 (3)

- June 2022 (4)

- May 2022 (5)

- April 2022 (3)

- March 2022 (5)

- February 2022 (4)

- January 2022 (7)

- December 2021 (3)

- November 2021 (5)

- October 2021 (3)

- September 2021 (2)

- August 2021 (6)

- July 2021 (2)

- June 2021 (10)

- May 2021 (4)

- April 2021 (5)

- March 2021 (5)

- February 2021 (3)

- January 2021 (4)

- December 2020 (3)

- November 2020 (3)

- October 2020 (3)

- September 2020 (3)

- August 2020 (4)

- July 2020 (3)

- June 2020 (5)

- May 2020 (3)

- April 2020 (3)

- March 2020 (4)

- February 2020 (4)

- January 2020 (4)

- December 2019 (3)

- November 2019 (2)

- October 2019 (4)

- September 2019 (2)

- August 2019 (4)

- July 2019 (3)

- June 2019 (4)

- May 2019 (2)

- April 2019 (4)

- March 2019 (4)

- February 2019 (5)

- January 2019 (5)

- December 2018 (2)

- November 2018 (2)

- October 2018 (5)

- September 2018 (4)

- August 2018 (3)

- July 2018 (2)

- June 2018 (4)

- May 2018 (3)

- April 2018 (3)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- December 2017 (1)

- November 2017 (2)

- October 2017 (2)

- September 2017 (1)

- August 2017 (2)

- July 2017 (2)

- June 2017 (1)

- April 2017 (3)

- March 2017 (3)

- February 2017 (2)

- January 2017 (2)

- December 2016 (2)

- November 2016 (4)

- October 2016 (4)

- September 2016 (3)

- August 2016 (6)

- July 2016 (4)

- June 2016 (4)

- May 2016 (1)

- April 2016 (3)

- March 2016 (4)

- February 2016 (2)

- January 2016 (4)

- December 2015 (3)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (4)

- July 2015 (6)

- June 2015 (4)

- May 2015 (7)

- April 2015 (6)

- March 2015 (6)

- February 2015 (4)

- January 2015 (3)

CONNECT WITH US

Tag Archives: Client Interactions

The way that small manufacturers operate holds valuable lessons for the industry as a whole. Armed with quick and flexible production schedules, as well as strong quality control standards, small manufacturers are able to compete with larger companies in a sophisticated market. While small manufacturers don’t produce the same type or quantity of products as their larger peers, the way that they operate is indicative of a tight and efficient management style that adheres to the lean manufacturing philosophy. These niche facilities are able to steer clear of common problems such as overproduction, over-processing and product defects.

Small manufacturers make big moves

In the U.S., the manufacturing industry has evolved through many iterations. Today, according to Manufacturing Global, there is a growing number of small manufacturers, indicating that the outsourcing trend may be reversing slightly. In 2015, there were more than 270,000 small manufacturers across the country. Many of these facilities have less than 50 employees, however, these companies are also responsible for 60 percent of U.S. exports. Contributing approximately 12 percent to U.S. Gross Domestic Product, it is clear that these entities are doing something right.

Small manufacturers adhere to slightly different management philosophies than larger companies when it comes to production. These facilities are able to achieve product customization by maintaining fast and agile production schedules. Employing the same methods that a larger facility would for achieving more efficient changeovers, smaller manufacturers understand that planning and scheduling make a big difference on output and the bottom line. Manufacturing Global pointed out that small manufacturers keep production costs low by following made-to-order production plans. The benefits of this approach include lower inventory levels, no overstock situations, and quality production. Inherent in this type of operation is a strict adherence to following procedures and doing things by the book – something that sometimes larger facilities let slip.

It is important to point out that supply chain costs increase substantially when companies either do not follow standard operating procedures or do not have the best processes in place. Product defects, idle time, and bottlenecks can occur when standards are loose, and these situations are best avoided through careful planning and execution. Small manufacturers are able to avoid common manufacturing pitfalls because production is based on continuously meeting sales goals. Additionally, small manufacturers emphasize the necessity for rigorous quality control standards, which leads to fewer manufacturing defects.

A more careful and diligent management style

According to IndustryWeek, the manufacturing industry is going through a business transformation. In response to shifting consumer expectations, global competition, and advances in technology, facilities are accelerating their production cycles to meet market demand. Similarly to small manufacturers, larger facilities must now exert greater control over the supply chain and adjust business models to meet customer expectations and keep the bottom line healthy.

When it comes to flexible production styles, quality control is key. Accordingly, if you want to make sure your organization is committed to quality, focus on these 3 points:

- Make quality a part of your culture

Strong leadership is essential for achieving a culture of quality. Management cannot just give directions to plant staff, they must make quality management education a regular item on the agenda. Today, at many organizations, executives think of quality as a department, not a company wide priority. Since the majority of facility employees do not work in the quality department, the responsibility of fostering a culture of quality falls initially upon the executive management team. When each person in a facility acts like a stakeholder in the production process, defects and deficiencies are significantly reduced. - Align your KPIs inline with your end goals

At your facility, you should be able to monitor the success of any process at any point in time. Without effective organizational metrics, executives will not be able to track progress, set goals, or achieve results. Whether measuring costs, quality, or equipment effectiveness, having KPIs in the right places is paramount. - Unite disparate systems

Quite commonly, facilities manage disparate systems – likely as a result of sporadic technology investment throughout the years. The best way to address a lack of uniformity in plant equipment is to make sure you have an effective management operating system. With one central resource standardizing processes and reports across departments, you will be able to operate in a more streamlined manner. Using the right system, manufacturers are able to manage fractured manufacturing operations, mitigate nonconformances, and take corrective and preventative actions when necessary.

What makes small manufacturers able to accurately meet their budgeting goals is avoiding costly production mistakes. Larger facility operators should follow this example and make quality an integral part of processes, culture, training, and management.

Tribal knowledge is ascertained through years of hard work and experience. Most plants and manufacturing sites tend to have seasoned workers that have worked on most facility assets and have seen it all. You may think that their skill and experience is an advantage to you, but tribal knowledge can be a dubious thing. If you do not formally preserve their knowledge, it is possible that senior workers will retire without ever passing that information on to others. Additionally, it is important to keep in mind that tribal knowledge is not meant to be guarded and kept hidden, nor is it something to rely on independent of process documents. It is important to record all tips and techniques learned over years of experience into management system procedures, so that tribal knowledge can benefit the organization at large.

“11 million manufacturing workers employed in the U.S. are 55 years of age or older”

Consult with your gurus and soak up the knowledge

Manufacturing Business and Technology explained that since most organizations employ field service people who have worked on all assets of their plant, these individuals tend to have valuable insight with regard to things like best practices, maintenance schedules, and production idiosyncrasies. Manufacturers should always talk with these information gurus and learn what they have to say. Leveraging their tribal knowledge, you can witness considerable improvements in operations and raise efficiency at your plant. Digabit mentioned that when management employs a bottom-up approach and listens to the ones on the frontlines, they are able to incorporate better and more effective processes into standard operational guidelines.

Proper documentation can preserve tribal knowledge

According to Digabit, one of the best ways to make tribal knowledge work for you is to document everything and compile valuable information into management operating systems. Maintaining one central repository of information takes tribal knowledge out of the hands of a select few and makes it available across an organization. After consulting these industry veterans, the information learned should be reflected in process documents, training materials, and safety manuals. By doing this, a facility will increase opportunities for talent sharing and guarantee knowledge is transferred, whether there is high employee turnover or not.

Continually train staff to avoid organizational ‘brain drain’

Manufacturing Business and Technology pointed out that, according to some experts, 25% of the 11 million manufacturing workers employed in the U.S. are 55 years of age or older. For most organizations this means that regardless of high turnover, at some point, if they do not preserve the knowledge of senior workers, they are likely to experience a significant ‘brain drain’ when these people retire. Digabit advised manufacturers to make training of new hires a serious and dedicated commitment. By incorporating regular training sessions into plant schedules, organizations can insure themselves against losing tribal knowledge. Keeping tribal knowledge alive in an organization contributes to innovation and fosters competitiveness. Even the most seemingly insignificant details can pay off in the future and raise efficiency at your plant.

Ultimately, tribal knowledge alone does not make a good plant. However, leveraging the skill and experience of seasoned workers at your plant, management will be able to encourage a culture of learning, improve production processes, and make sure that new hires are always trained with the best practices. The best knowledge is the type that is tested and tried at your facility.

Have you ever sent someone to the grocery store with a list of items to buy along with the money necessary, then had them return home after spending more than you gave them/budgeted? And that they bought flank steak instead of ground beef and both hard and soft shells for your taco dinner?

When asked why they bought and spent what they did, the answer is something like this:

“Your list just said taco shells, so I didn’t know what kind to get (brand or texture) and I prefer to use flank steak when I make tacos as its quality and taste are significantly better than ground beef.”

Essentially, there wasn’t a clearly defined spec that someone other than you could follow when shopping and there wasn’t alignment between you and the shopper on the recipe or quality that was to be followed in preparing the meal, therefore there was no cost management. The net result of these disconnects: an increase in cost and probably longer cooking (processing) time.

The household example above is simplistic and didn’t break the bank or result in dinner being on the table too much later than originally planned, but when similar situations happen in business the impacts can be far greater and include: significant cost overruns and reduced profitability, missed available to ship dates, and angst between functional areas and/or a company and its suppliers, thus the importance of cost management and a well-defined spec.

Proper Use of Cost Management Principles Can Prevent Costly Budget Overruns

We recently encountered a situation with one of our Spend Management clients where there were significant disconnects between functional areas as to the scope of work and specifications that a supplier was working to. The result was a major change in cost from the supplier ($10,000 – $15,000 per production unit) which when combined with budgeted internal expenses, ended up creating a negative impact on margin. To make matters worse, the supplier was still not covering costs with what they were invoicing and decided that each unit they would handle would need to be quoted separately. The cost overrun on the next production unit was expected to be close to $25,000 further impacting margin in the wrong direction.

How did these disconnects occur?

For starters, the initial spec that the supplier bid on was not complete. The client’s Purchasing Organization developed a spec that was used in the bid process without involving other functional areas to make sure that the entire scope was captured and ultimately aligned with internal quality end customer expectations. Since then, things have spiraled out of control with three things driving the cost increase:

- Other functional areas that interfaced with the supplier pushed work from the internal manufacturing process down to the supplier which has a cost impact on the supplier and in turn on our client.

- When quality issues arose, the Quality Control group didn’t work with Purchasing to provide timely feedback to the supplier and work to understand the root cause of the problem so corrective action could be taken. Instead, they developed a tighter quality inspection specification which they provided directly to the supplier without consideration for the impact on cost. Furthermore, they didn’t communicate the new spec to Purchasing.

- Sales didn’t understand the spec that work was being performed to and therefore wasn’t appropriately managing the end customer acceptance process. They also weren’t appropriately pricing what they were selling based on COGS.

The new, even higher quote triggered a lot of anger, frustration, and concern throughout our client’s organization and a request to solve the problem immediately. Likewise, the supplier was very frustrated which was evident in conversations with them as we sought to understand and solve the problem.

When the quotes came back, our supplier had sharpened their pencil overall. (Win #1) We then presented the quotes to Quality and Sales and asked them to make the final decision as to what the inspection criteria would be since this drove the difference in cost between the quotes. Quality deferred to Sales. (Win #2 as Sales has to manage the customer, not our internal Quality Group.) Sales decided to go with the lower cost option and agreed that they would manage the end customer to the correlating inspection criteria or charge more for a tighter spec. (Win #3) Lastly we gained alignment internally and externally that all direction to the supplier would flow through purchasing and that the supplier was not to take direction from any other member of the organization. (Win #4)

After gaining an understanding of the situation through conversations with the supplier and numerous people in the client organization, we pulled together a cross functional team of people (the users) to review the current scope of work and inspection guidelines, make adjustments, and ultimately develop a comprehensive scope of work agreed to by all involved internal parties that could be provided to the supplier for a revised quote. We also asked for quotes on several inspection options so the cost vs. quality trade-off could be weighed appropriately. Lastly, we explained the margin situation to the supplier and asked them to sharpen their pencil as much as possible on this quote while we worked to develop a new bid package for them to respond to.

KEY TAKEAWAY: Everything starts with the specification development process. Without the input of a cross functional team, there is high risk of missing parts of the specification/scope of work leading to unrealistic cost expectations and the potential for frustration and poor supplier relations. Furthermore, if the cost isn’t right, you can’t develop the right selling price and present options to customers that maintain margin.

You should care about your online reputation, as it can overshadow the reputation you try to build in person. Anymore, if you’re scheduled to meet someone for the first time for professional reasons, they have probably looked you up online before you walk in and shake their hand. And honestly, you probably did the same to them.

Like it or not, everyone can be found online. Even if you keep it simple and don’t actively participate in any online communities, chances are there is still a decent amount of information about you available for anyone to find. Whether you’re job hunting, meeting a new client, or are simply networking with other business professionals, you should do your best control what other people uncover about you and be aware of how your online presence can impact your real-world experiences.

While you may believe your Facebook, Instagram, Twitter, and other various online profiles are personal and completely separate from your LinkedIn profile, think again. Just because you only post “professional” content on your LinkedIn, doesn’t mean everything else you post everywhere else online has suddenly vanished and your connections won’t see it.

Take a minute right now to search yourself online (just type your name into Google and see what comes up). What did you find? Is your online persona reflective of how you want to be seen professionally? Were the majority of the results actually about you or other people who share your name?

If the results were less than favorable, maybe it’s time to reassess your online activities. I’m not saying you should delete all of your social profiles, but you should take extra care of the privacy settings, be mindful of your friends/followers/connections, and think before you post. You can’t control what is online about other people with your name, but you can control what you put online.

If your Facebook is full of personal content (status updates, pictures, videos, comments, etc.), don’t “friend” your colleagues or clients. Your vacation pictures may be fine for your friends/family to scroll through and comment on, but you may not want upper-management seeing your pictures and the comments.

When your friends reminisce on Thursdays by posting college photos to Instagram and tag you in them, #tbt doesn’t justify your questionable behavior or clothing choices to your new clients, especially if college wasn’t that long ago. Keep track of what you tag and are tagged in, and know who is able to see those pictures.

Tweeting about your long work week, how much you dislike new company policies, or how incompetent your superiors are may be your way of letting off a little steam, but your current employer and potential future employers will not look favorably on those kinds of comments.

By actively cultivating a positive online presence, you can shape what other people discover and the impacts of those discoveries. It’s never too early or too late to take your online presence seriously. Our lives become more public every day, so getting ahead of it and putting your best self forward will prove beneficial in the future.

One of the benefits of working for a consulting firm is the exposure to a wide range of industries and working environments that a majority of the population will never have the opportunity to experience. Most people will never step foot in an underground gold mine, a candy factory, a pulp & paper mill, or a chemical processing plant, let alone work in all of those places in a given year. We are not most people, and we work in all types of places with all types of clients. It’s the variety of situations that draws us in and the need to improve those situations that brings success to our clients.

Why do we love consulting so much? Because…

We are genuine problem solvers. The thrill of taking on a new project with its own set of challenges is why we are in this business. We’re hungry for the chance to apply our unique set of skills to a project and see it through. We like to find the source of each issue and apply the right solution to correct it. It’s not a problem for us to fix, it’s a puzzle for us to solve.

We are driven to improve upon the status quo. We don’t like living with things that are good enough; we want them to be the best. We know that processes can always be improved and small changes can make a huge difference. It’s this need to constantly evolve the way we do things that gives our clients the results they desire.

We have the capacity to see more. From within an organization, it’s hard to see where the disconnects are or imagine doing things differently. When a client opens up their doors and lets us in, we see the potential for what their business is capable of. This outsider’s perspective often reveals more than internal audit. We are not bound by the limitations of how things are, we visualize how they could be.

We get to learn from everyone. The knowledge gained from all of our various work sites is a major asset we can bring to our clients. A seemingly unresolvable issue in one industry may have a solution discovered in another. We get to apply our knowledge from several industries to problems in completely different ones. We can apply solutions from mines to offices or hospitals to manufacturing. By coming in with a different outlook, we can suggest an alternative not previously considered.

As a consultant, the experience gained and the opportunity to make a difference for our clients is unparalleled in any other job. We get to bring our ideas to the table, work to implement those ideas in the real world, and see the results. Every client is different, but the desire to succeed at each project is always there.

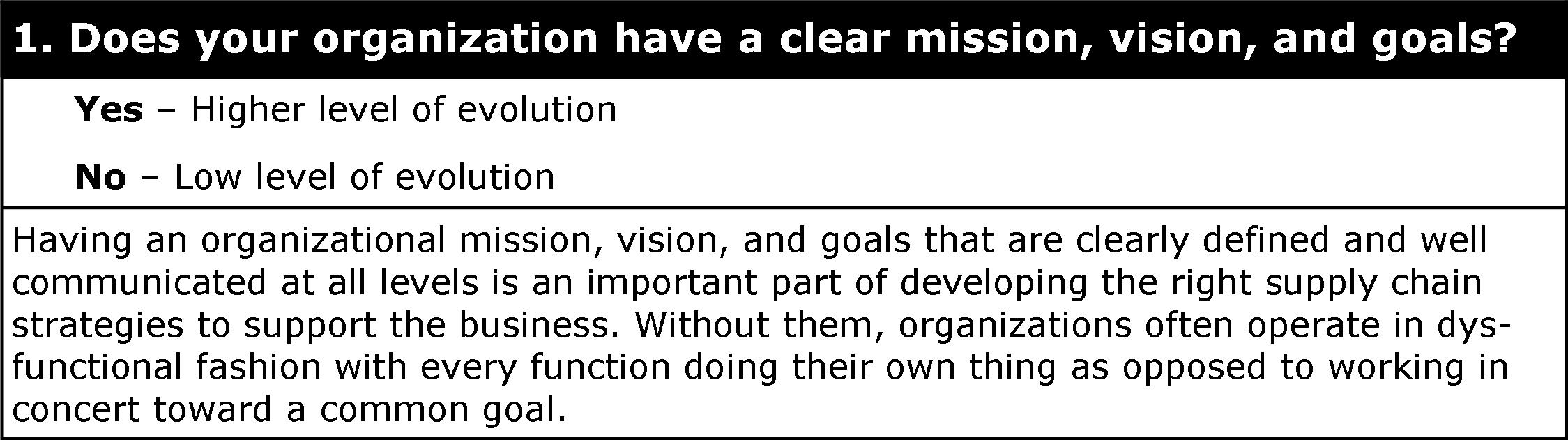

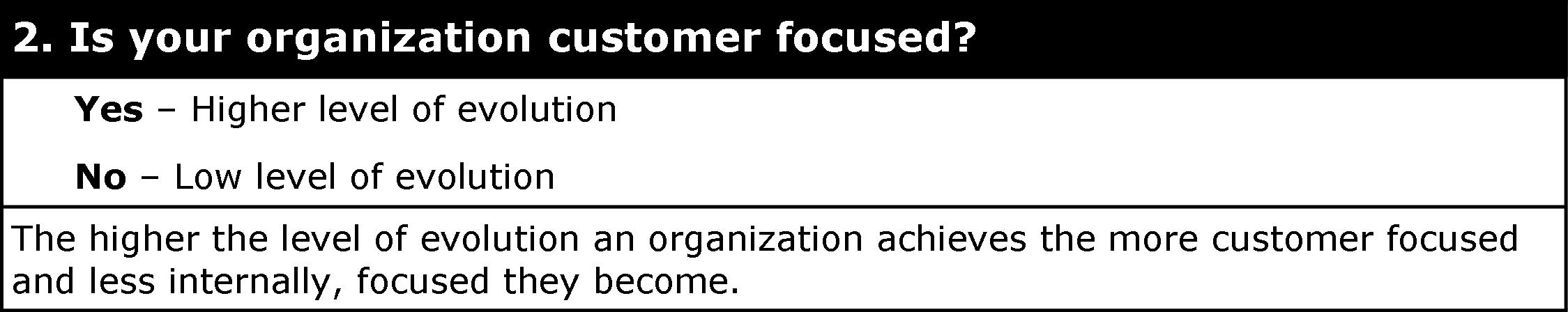

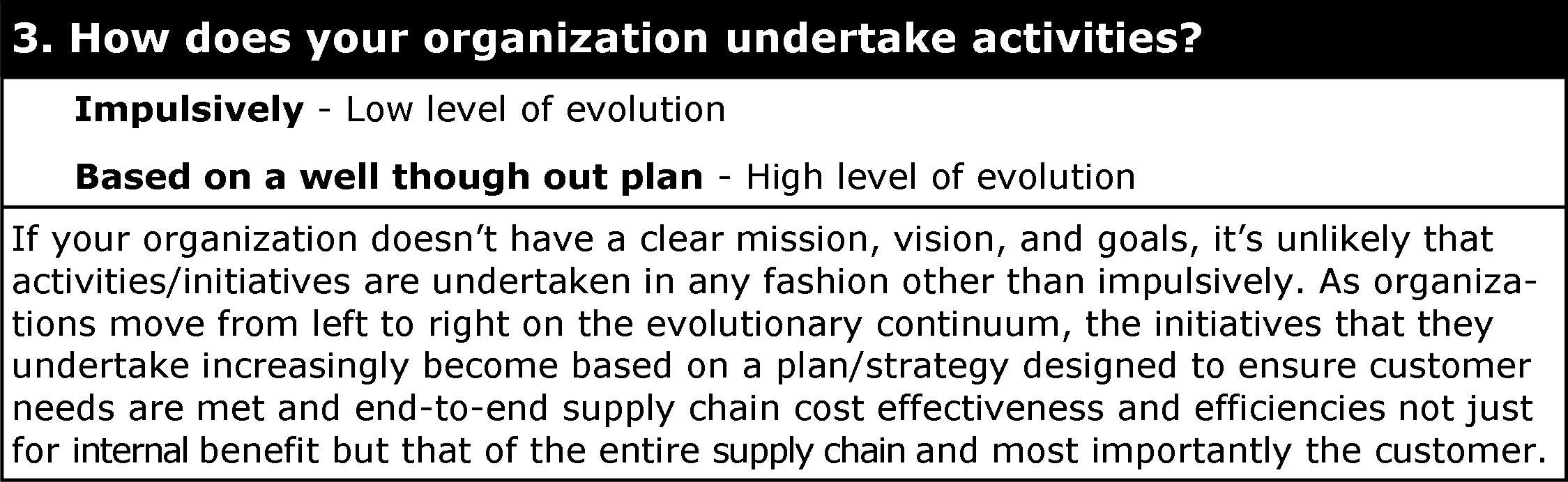

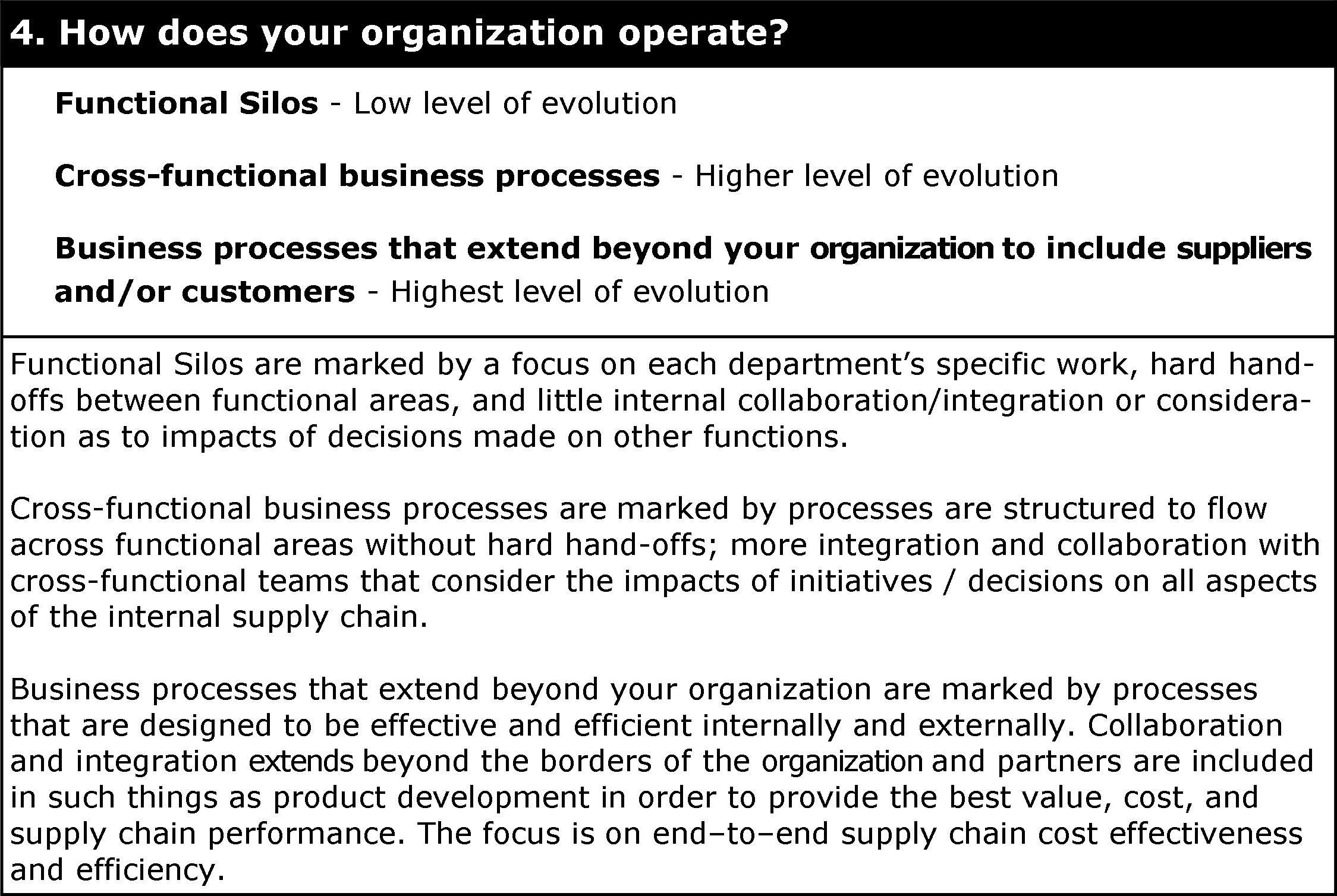

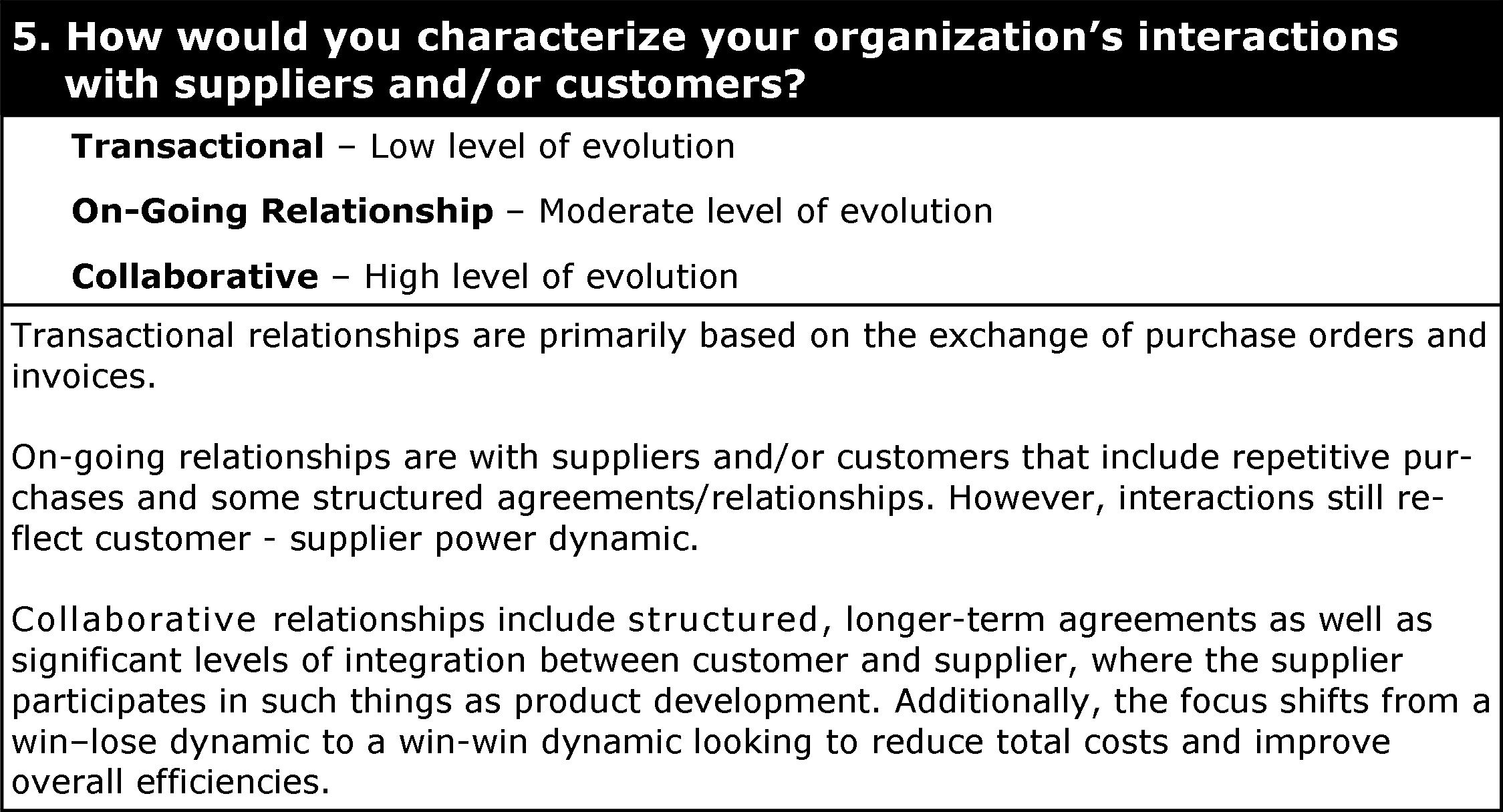

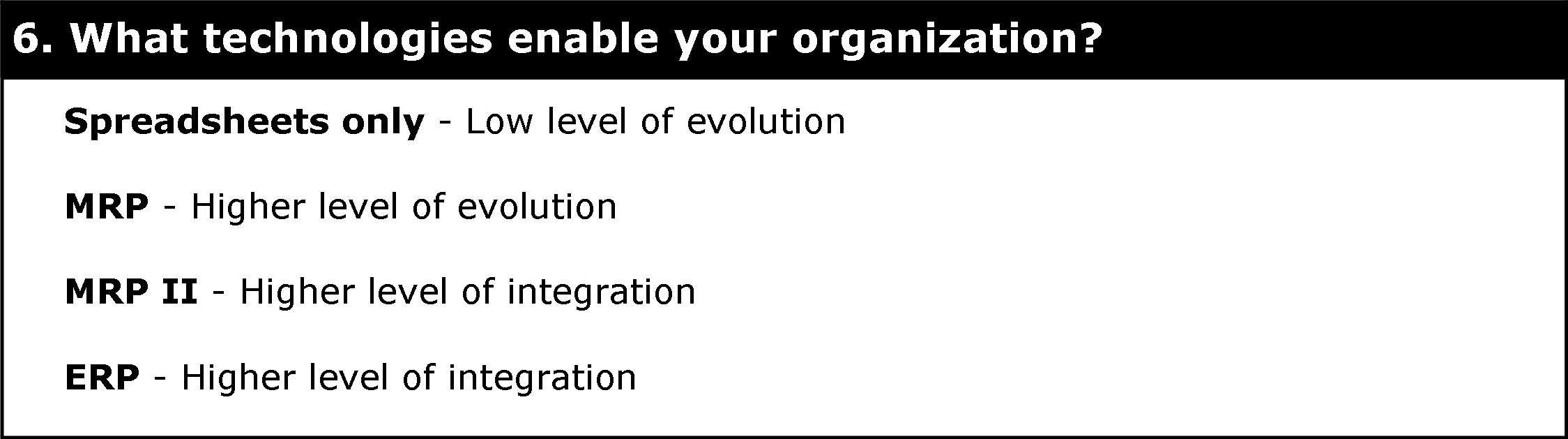

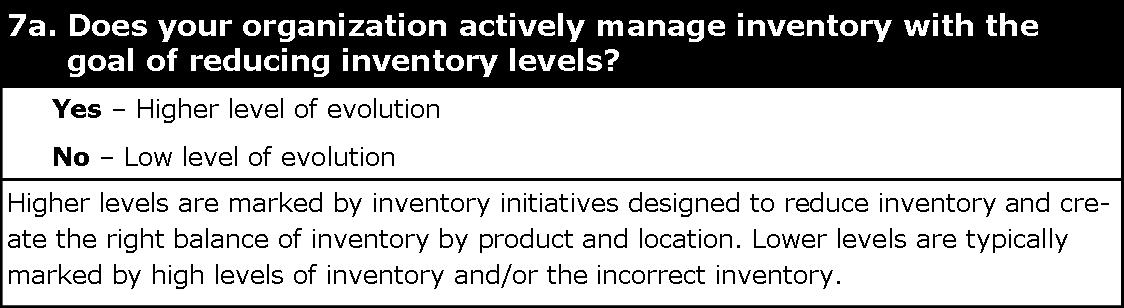

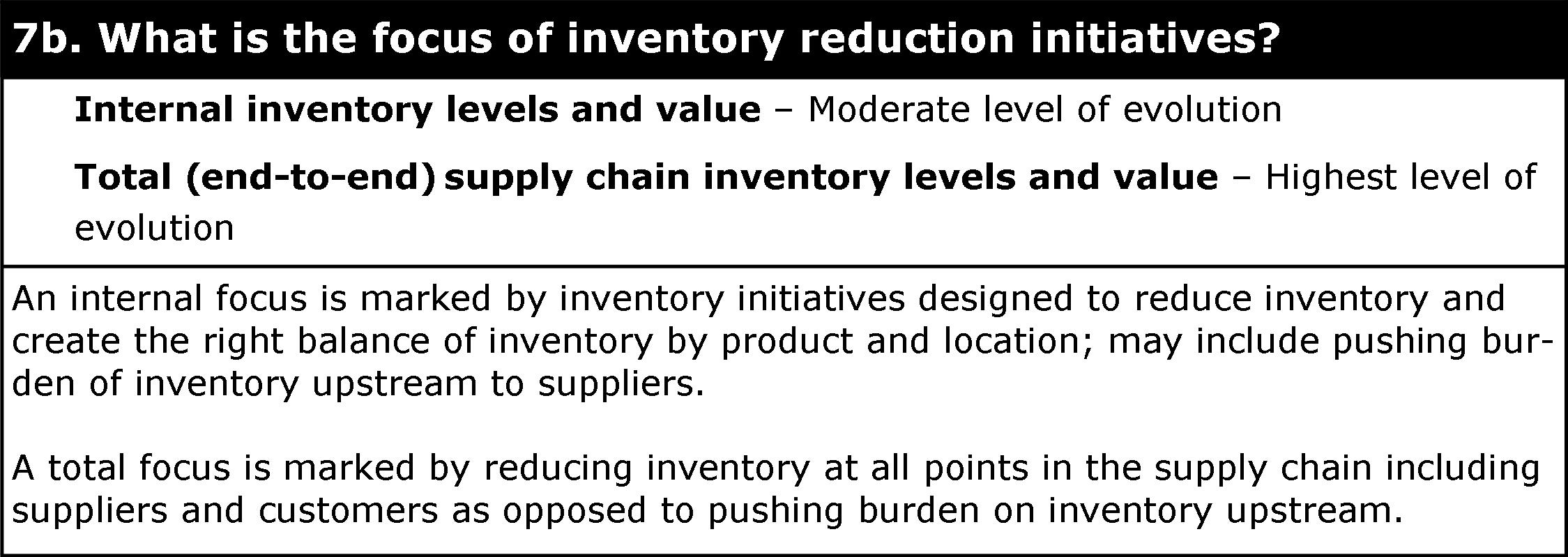

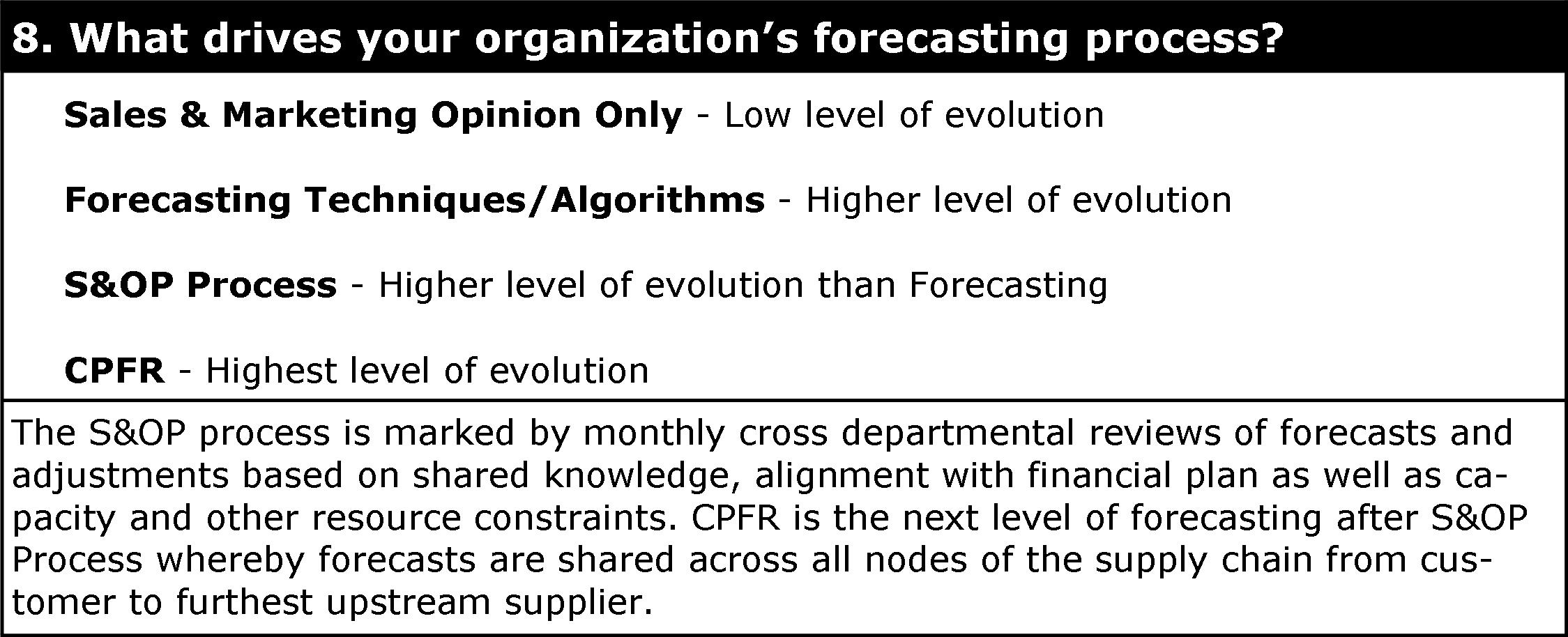

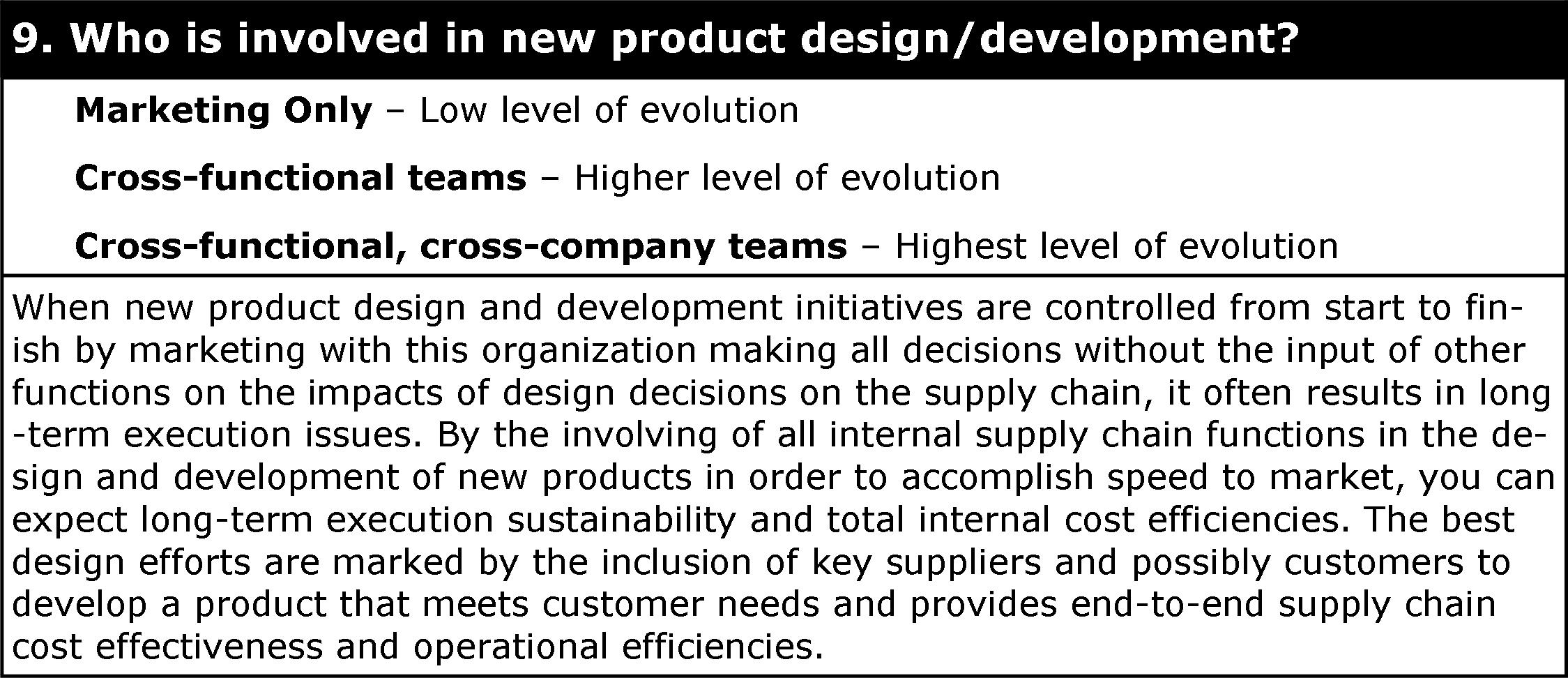

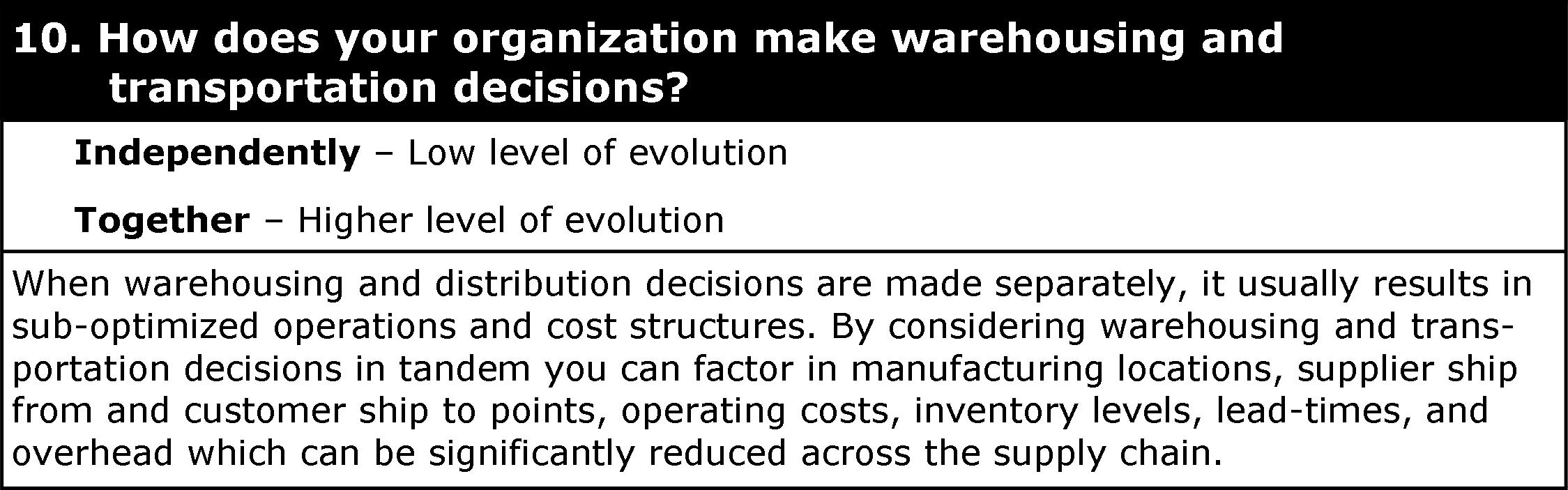

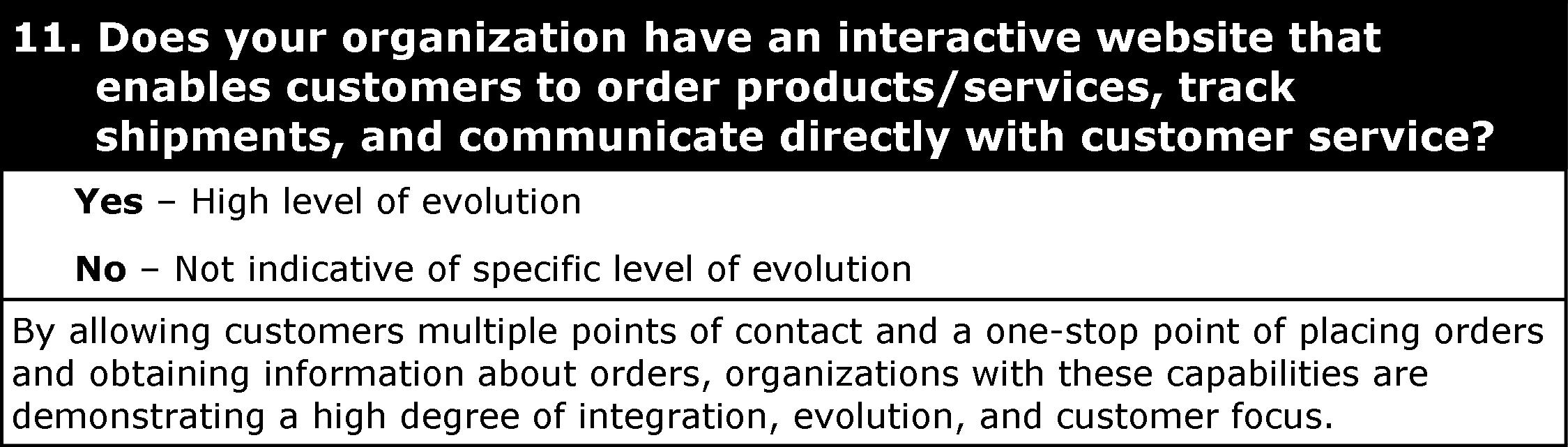

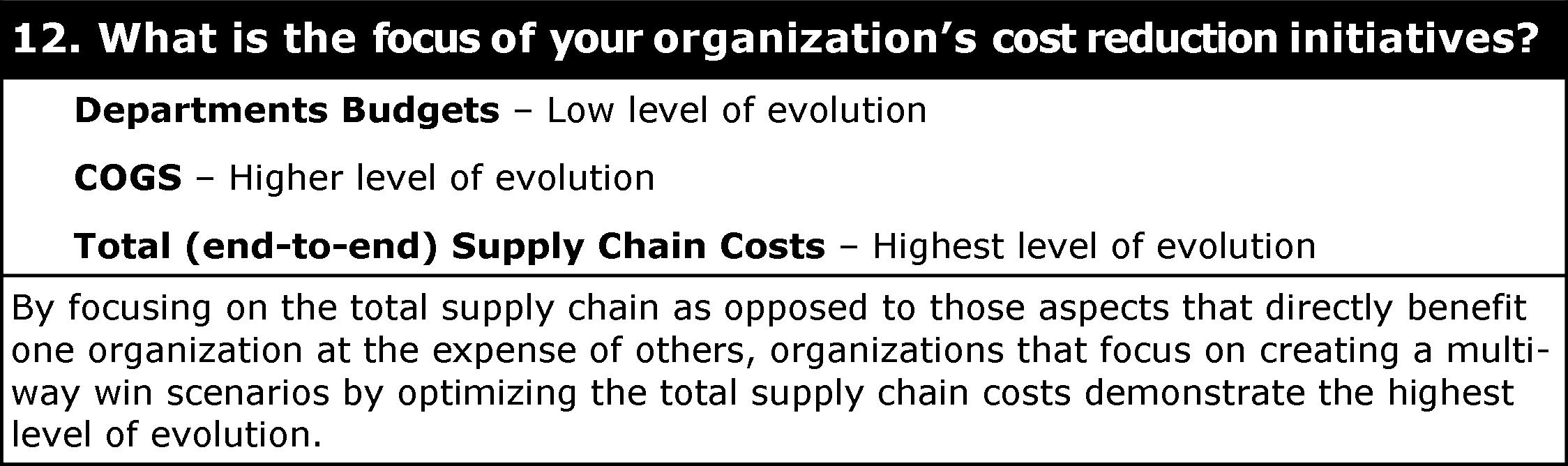

Recently, I have been discussing supply chain evolution. My previous post provided a series of questions for you to assess where your organization is on the supply chain evolution continuum. Hopefully, you took a few minutes to think about the questions and answer them honestly. If not, take a few minutes to look at the assessment and answer the questions before reading on. Now that you have your answers, look below to find out how your organization is evolving.

As you can probably tell, determining your organization’s evolutionary progress and where you are on the continuum isn’t black and white, as your organization might be more advanced in some areas and less so in others; likewise, the supply chains for different brands or product lines might be at different stages of evolution.

APICS offers some additional structure by defining four stages of supply chain evolution on pages 1-18 and 1-19 of their Fundamentals of Supply Chain Management module as follows:

- Stage 1: Multiple Dysfunction. The (potential) nucleus firm [organization] lacks clear internal definitions and goals and has to external links other than transactional ones.

- Stage 2: Semi-Functional Enterprise. The nucleus firm [organization] undertakes initiatives to improve effectiveness, efficiency, and quality within functional areas. While some or all functions engage in initiatives designed to increase efficiency within their departmental walls, there is little or no overlap in decision-making from one department to another.

- Stage 3 – Integrated Enterprise. The firm [organization] break down silo walls and brings functional areas together in processes such as sales and operations planning (S&OP) with a focus on company-wide processes [and cost reductions] rather than individual functions.

- Stage 4 – Extended Enterprise. The firm [organization] integrates its internal network with the internal networks of selected supply chain partners to improve efficiency, product / service quality or both. The starting point is generally one inside / outside partnership that points the way to a completely networked enterprise.

Today, most organizations fall in the middle of the supply chain evolution continuum operating somewhere in or between Stage 2 and Stage 3. While many aspire to achieve Stage 4, few have successfully achieved this level of evolution and built sustainable partnerships with multiple members of their supply and customer base. Regardless of where your organization is on the continuum today, achieving higher levels of evolution in the future is possible. The future depends on…YOU. By ensuring that you think outside the box; integrate and collaborate with suppliers and customers (internal as well as external); and look to create win-win solutions throughout your daily activities, process execution, and interactions you can play an active role in your organization’s supply chain evolution.

In my previous post, I explained how building strong client relationships makes the project process easier and increases overall success. As a company, we pride ourselves on our ability to integrate into our clients’ organizations, find the right solution, and leave them with the capability to continue improving after our project is complete. Part of this comes from our client-centric mentality and constant efforts to be a positive force for our clients. This can at times be difficult for both sides, as it involves a change process that many people are naturally uncomfortable with. The discomfort occurs especially when employees are perfectly content with their positions within the organization. It also involves a large amount of patience from our team. We must explain the process, allow it to sink in, and continue to reinforce all of the main points. Often times a client may develop their own view of the intent of a Management Operating System (MOS) and it is important for our team to remain calm, stay focused, and continue to work with the client to repeatedly direct their attention towards the valuable output of an MOS.

Listening and Understanding

Our first task at every project is understanding our client’s issues, perceived limitations, and goals. We strive to learn their working style, culture, and comfort level. It is during this initial stage of the relationship that we can quickly lay the foundation for success or failure. The quicker we are able to learn our client’s likes and dislikes about their job, the more time we have to build upon that later. This can sometimes be a balancing act between providing impact at a focused level or at an organization level. We recently ran into an example of this at a logistics site office. A site director could not understand why the specific changes he requested were not being completed immediately and were not on the top of the priority list. When dealing with such a decentralized organization, communication and coordination of changes in the management system must be consolidated. This process can sometimes take more time and energy than the client is initially prepared for. The communication of this at the beginning of the engagement is very important so that the client can be prepared for the project as well.

Uncovering Opportunities Together

After we understand the issues, we move forward in discovering the solution, keeping in mind all that we have learned about our clients so far. Their acceptance is important, so we make sure we adequately explain what we plan to do and how we plan to do it. This can be difficult as it requires a certain degree of finesse. It is important that our clients design the answer and we simply facilitate. It is not a game of who is smarter, but rather a training process to view issues as opportunities. We believe that permanent change must always come from within. We will often work through the brainstorming process several times on our own before working through it with a client. This is especially important for the problems that the client feels cannot be solved. One of the first steps we took at a recent project was to train the office staff on identifying issues within the process they were using. This may seem like a straight forward task however, it can be extremely difficult when a “work around” or broken process is part of your day-to-day routine. We worked one-on-one with the office staff to help them review their individual processes by having them decide if each activity is value added or non-value added. We also asked them if they thought there might be a better method of doing each specific activity. Once they began to make this distinction, true exception time (office non-value added time) can be measured and quantified. You can really surprise a client when you help them solve a problem that they truly believed was just the “nature of the business”. One of my first posts described in detail the Root Cause Analysis process; this same process can be applied to any issue or problem, and with the right expertise in the room, will often uncover some interesting solutions to the main issue. While working through this process one client remarked that, “We would never be able to get rid of this problem. It would always occur as it is part of our business.” He was entirely accurate in his statement. However, what if 60% of the issue could be reduced? The business essential 40% would remain, but the capacity from a 60% reduction in major office issues would open up, leaving plenty of room for growth.

Making the Real Change

The implementation of our proposed solutions can be the most challenging phase of a project in regards to our client relationship. Often, this is where other firms will stop and leave the most difficult portion of the change process up to the client. This is the most powerful stage in the process, as it can merit our client’s infinite trust or make us seem like we’re “all talk”. When we actually start changing the way things are done, we are met with more questions and contentions. An immediate overnight change is very unlikely, as real change is a process that takes energy and problem solving. Our clients realize that we have not just shown up with the answer, we’ve begun to provide them with the tools to expose the answer. It is common to experience a significant amount of push-back from direct managers. This is in large part due to the proximity they have with their employees and their day-to-day understanding of their own KPI’s (Key Performance Indicators). At a recent project, one of the managers was questioning the difference between having the numbers on paper coming directly from day-to-day operations and having them in his head from speaking with his people throughout the day. A comment was made that he knew the business and the reports would only confirm what he already knew. There are several issues with having all of this information in one person’s head. Firstly, if he was sick or on vacation there would need to be a suitable replacement that could decipher the same information. In addition, on a day-to-day detailed basis, management may have a good general sense of the state of the business; however, they typically can’t speak to a weekly trend, monthly trend, or correlations between various KPIs. We need to think about the future. What will the requirements be when the business grows? What happens when there is a shift in management reporting structure? What is the true cost of doing business? If all of these questions can be answered accurately, the management team will be ready for growth. If not, they may be able to maintain and sustain, but will have a large degree of difficulty when it comes to change and growth.

Training for Sustainability

After the changes are implemented, we invest time in training the client team to sustain and continue improving their processes. By transferring the ownership over these improvements to their people, we ensure our solutions last. We know as soon as we get to this phase whether or not our client truly understands that value of what we have put in place at their organization. If they understand this, they will gladly take over any and all responsibilities as they will be receiving 100% credit for positive change and have been given to tools to drive it. This is an excellent final gauge to understand if your implementation was initially successful. If you sense hesitation on the client’s part at this point in time, you must quickly identify the frustration source and review the intent with the client. At this point in the process, the client should be seeing the value and wanting more. With each significant change they are getting closer and closer to perfect.

At the End

Our projects are only complete when we are confident that our client is able to sustain the changes we have implemented. By understanding their issues, working with their people, and providing adequate support and training, we know we are leaving our clients in a better place with the tools necessary to succeed. We leave behind a management team prepared to take on the challenges of the business equipped with the tools to do so. This is our commitment to each and every client.

Below is the second half of my interview with our CEOs, George Coffey and Jim Ostrosky. In this section they discuss who we are as a company and how we make a real difference for our clients. Read Part 1 of our interview.

How do you feel USCCG is different from other firms? How are we unique in the market?

George: Many of our clients who have had extensive experience with other firms tell us that we develop a greater depth of understanding of their business and the issues they face which enables us to better design pragmatic solutions to improve performance. Many also feel that we have a more effective approach to engineering change in their organization that fosters ownership by their people. Prospective clients will ask us what we are good at and what makes us different. What we are good at is achieving results. We are able to generate substantial results in a relatively short time while enabling our clients to sustain and accelerate improvements .We strengthen their internal continuous improvement capability with enabling tools, skills, infrastructure, and culture. Generating near term results, while strengthening on-going organizational effectiveness, makes us different from many other approaches.

Jim: I believe a key differentiator between USCCG and our competitors is the depth of experience that our consultants possess in the various industries and domains we service. In this age of specialization, it has become more and more challenging to maintain a cadre of capable resources, but we have been able to do exceptionally well at that over the past 4 ½ decades. We continuously train our people utilizing internal methods as well as memberships in various professional organizations that offer certifications and continuing education credits. Perhaps, more importantly, we have been able to retain our people, which is also a key success factor. In addition, our deployment methodologies have proven to be very effective. We look at the processes by which a client operates, the technology they deploy, and the skills of their people. Real changes are realized when you link all three things together: their People, Processes, and Technology. We feel we do that better than most and that is what makes us different. Another key difference is that we involve ourselves in the implementation. Many consulting firms will analyze a company, and compare current performance to industry norms and benchmarks, create a road map, and leave behind an answer, but it often times that solution will never get implemented. When practical, we prefer to be involved in the implementation of our recommendations, so our clients can realize the value and we can change the processes, the systems and behaviors, so the results last. When we are engaged to work at the process level of a company, we believe that enables us to cause even more fundamental, lasting change. Much of what we are doing in regulated industries, such as Oil & Gas, Energy, and Healthcare, are at the process level. As the government regulatory agencies issue changes and directives, our clients need to verify they are in compliance and understand where they’re lacking. They must put auditable processes in place to keep them in compliance as well as doing so in a cost-effective manner. We have been doing a great deal of work in this area recently.

What makes a successful project, both from our end and the clients’ end?

George:The most critical aspect of a successful project and a successful client relationship is communication. We find when we’re talking to our clients routinely and objectively about how the project is going in a very open and forthright manner, we are able to understand and mitigate issues as they arise over the course of a project. We believe that we are putting the success of the project at risk if too much time passes without meaningful communication with all levels of our client’s organization to get a shared understanding of exactly where we are, what we can do to improve the process, and take corrective action. We typically organize a steering committee protocol to enable efficient communication and decision-making. The steering committee is kept absolutely abreast of where we are with respect to our projected improvement and also to the specific tasks associated with that.

Jim: Communication is a critical component, but to communicate effectively, we need to always do our job at the front end of a project to create a crystal clear shared vision. As we engage with a client, it is imperative that we fully understand what must change and create a clear vision of the end result that is co-owned by USCCG and our clients. It then becomes our job to create a change model to continually reinforce the vision adjusting as we go to make sure that we’re of one mind with all levels of the organization. We believe it to be very important that everybody feels like they’re doing what’s in the best interest of their company as most employees have pride in their company and they want to succeed. Our change model is one where we involve everyone in the organization from the process owner on up to the highest level that we can access on a regular basis. The difference between a good project and a great project: in my experience, it has been the amount of involvement we can gain from our clients especially at the Steering Team Level. We built our change model around a shared vision of employee involvement, combined with the appropriate changes to the processes, the technology, and the skill sets of the process owners and their managers all which serve to make our model very effective.

In what ways have you noticed technology’s impact on our project process and how has that changed what we offer to our clients?

George:One of the more important aspects and benefits of being able to deploy and utilize more technology is the sustainability of our efforts. Good management practice depends on accurate data and timely information. Earlier on, we had to depend on the manual collection of data and the manual preparation of reports. As a result of that, it was very difficult to sustain some of the procedures we would put into place because they were very demanding from a time standpoint. Now, that information comes with a lot less pain, very often automatically. It makes all of our efforts, processes, and procedures easier to sustain. Since we are getting the information more quickly, good management requires timely corrective action when issues are identified. We are able to do more effective problem solving with a greater sense of urgency as a result of having that information more quickly. The whole business intelligence aspect of performance improvement is absolutely critical today.

Jim: With current technology, data has become readily available in various forms and in some cases, in excess. Some of our clients feel as if they have too much data and not nearly enough information. Often our job isn’t to provide clients with more technology, our job is to help them leverage the technology investments they already have made by sorting out the data they currently have and making it actionable. To do this we filter it, slice it and dice it, create meaningful metrics and Key Performance Indicators out of that plethora of information. In many cases, there have been tremendous investments in technology, but sometimes these systems leave out a key part of the organization: the people at the execution level of the process. Management and accounting have better information than ever, but the people who actually execute the process often times don’t receive timely accurate feedback of actionable information. Our job is to make sure we link the data and information from the board room to the process owner, and every step in-between. By sorting out the data, making it relevant, and holding the people accountable at the points of execution we leverage technology to help provide the underpinnings to meaningful lasting change.

What hurdles or objections do we encounter most often with respect to beginning an initiative with a new client or even a new project with an existing client?

George:Sometimes clients feel that they have so many other issues and programs underway, that it’s difficult to add yet another project to everyone’s to-do list, even if it clear that something should be done. There’s never a good time to start these initiatives and there’s never a bad time to start making the kind of dramatic near term and strategic improvement that we can make in business performance. To start, we really have to talk through how many resources we have to bring to bear and get a good solid understanding early on about what the time requirement are going to be for our client’s people. These requirements should be properly assessed, understood, and planned for. There aren’t any businesses or organizations out there that don’t have many different distractions, different initiatives, and different problems. We are very effective at being able to come in and integrate into our client’s organization and be a net increase in their resource capability, not a distraction or a dilution to the already existing initiatives underway.

Jim: One of the questions that comes up often in the early phases of a relationship with a client is, Do you think I have the right organization in place? Or, I don’t feel that I have the right organization in place, therefore now is not the time to begin a project. It can be difficult to see the organization through the client’s eyes, but if the client could see their organization through our eyes, they would understand that it likely is an appropriate time to start. We can optimize their processes, upgrade their skills, implement systems, and technology to help enable their people to become better at what they do. A manager who may not be quite as effective today as a client would like them to be, after having gone through a USCCG deployment will have tools, improved supervisory skills, and will be much more effective than they would have been prior to starting the project. From our perspective, there’s rarely a bad time to start a project as in today’s competitive world improved performance is an imperative to survival. Perceived organizational deficiencies aren’t always a reason not to get started; often they are THE reason to get started.

Last month, USCCG celebrated its 46th anniversary. With a rich history of successful projects and satisfied clients, we know that we must be doing something right. As we begin another year in this business, I felt this was good time to get our CEOs, George Coffey and Jim Ostrosky, to share their thoughts on the company’s evolution and their vision for the future. Below is the first part of our interview:

When did you start with USCCG?

When did you start with USCCG?

George: I started in 1978, as a project consultant in our operating group and progressed through management positions. Ultimately, I moved out to LA to run our projects on the west coast, and then I moved into business development. I became a Business Development Executive, a Regional Manager, Analyst, and ultimately headed up all of Business Development.

Jim: I started in 1979, and entered our operating group at the entry-level; Project Consultant. I spent the majority of my career in Operations, working at every level from a Project Consultant on up to VP-Senior Operations Manager. When the company decided it was time to put a technology practice together, I moved over from directly working in operations to help organize our CTS group. I co-ran Operations and lead the CTS efforts that we now know as LINCS, as well as some of the other client offerings we have.

How do you feel business has changed, back when you started to today?

George: One of the most significant changes is that we had shorter business acquisition cycles back then. Typically, we would meet with a prospective client, determine whether or not there was a compelling value thesis, develop scope, move into feasibility study to more fully develop the business case for moving forward, and get a very quick decision. Today, for a number of reasons, prospective clients are more cautious, the process has slowed, and there is an opportunity cost for these delays in decision-making. More importantly, when I first started, more of our focus was on manufacturing and labor productivity. Today our approach is to address overall EBITDA performance improvement by driving operational excellence across all aspects of our clients’ business, across the entire supply chain including SG&A, Spend Management, Asset Performance Management, Rationalization/Consolidation, Acquisition Integration, Quality, Service, as well as cost reduction. So today, we are much more focused on overall financial performance.

Jim: One thing that is similar is that it’s still a people business. In the 1980’s we would talk about the fact that 80% of our efforts were focused on helping people understand the change process, find out what they are dissatisfied about in their current operation, and help them make that transition; 20% of it was on the technical aspects of what actually had to be changed in order to realize the results. One might argue the ratio 80-20 or 60-40, but ours remains a people business. Other than the people aspect, everything else has changed, the whole world has changed, and we were forced to change our approach as well. Technology entered into the picture and our clients’ expectations certainly changed. Clients are looking for a group to come in make an impact, make it quickly, and drive the value, then move on. Another major difference today is who owns businesses. In the past we dealt with many entrepreneurs, while today, Private Equity has entered the market and has a lot to say about what goes on and that brings different pressures that we have had to adapt to as well. It’s still a people business, but the expectations have certainly changed from the timing of results, the depth of results, and clients who are less patient than ever and expecting more.

How would you describe the way we do business?

George: A cornerstone of our business has always been long-term relationships. In any given year, typically two-thirds of our business, or more, is the result of existing relationships and that’s underwritten by the fact that we’ve done what we’ve said we would do. We make time-bound, realistic projections of what can be accomplished, and then we meet or exceed those projections. Our business is performance improvement. We are not about products, we are about outcomes. We have an extensive array of tools including technology, methodology, and processes that we apply within the context of an intended result. Most importantly we bring to bear a powerful organization of talented subject matter experts (domain, industry methodology) that are highly experienced in designing and implementing performance improvement programs. We can drive improvement in many creative ways and we architect our client relationships based on circumstances and timing.

Jim: I would say, the two R’s: relevance and relationships. We’ve stayed relevant and found a way to deliver value in an ever-changing world. It’s definitely a relationship business in a networked world. We are proud to have worked almost continuously for a couple of clients over the past couple of decades. We recently did a project for a client that we worked for in 1970. The third generation is now running the company, but there was enough staying power to what we implemented and the credibility that we established that when they had a need we were called in to again help with their current challenges. Our goal is always delivering value, and at the end of the day, our clients love us as long as we do what we say. And we definitely do what we say. We feel we’ve always been market driven and client centric, and have had to adapt over the years to survive. Whatever the market or our clients demand, that is what we learn to do. The clients who were the most demanding over time caused us to change and adapt the most, and we are very grateful for those demanding clients. They caused us to really push the envelope for us and for them, but their confidence in us and our ability to do what we say, created great partnerships. By working with them we are able to establish many of the new offerings that we have.

Where do you see USCCG going forward into the future?

George: We’ve always gone to market and organized as a hybrid model, meaning that we have horizontal domain offerings with subject matter experts in areas such as Asset Performance Management, Business Intelligence, Spend Management, and others. We can drive that horizontal domain expertise across different industries. We also have a vertical approach in certain industries because they have significant issues that are specific to those industries such as Mining and Healthcare. We will continue to expand both approaches as we move forward with more offerings, more adjacencies, as well as further develop more industry focus as it relates to our vertical approach.

Jim: Looking ahead to the future, in addition to all the industries we currently serve, we will continue to expand in the areas of healthcare and energy. These are two growth areas with tremendous needs and opportunities for us. In addition, demand for Procurement and Logistics will also continue to grow. The logistics of buying things from the other side of the world and having them delivered to your doorstep creates both challenges and opportunities. As our clients globalize their supply chains, they have those same challenges. How do they get their products procured, inventoried, and delivered in a timely and cost efficient manner? Getting it manufactured cheaply in Indonesia is one thing, but getting it to your customer in an efficient manner is another. Globalization is driving much of our current volume, and is a trend that will likely increase. As we have done for the past 46 years, we will continue to be market and client driven and we will remain focused on our clients’ needs as we develop the value added offerings and solutions they are seeking.

While I’ve spent a significant amount of time working with some of our mining clients, I have recently had the pleasure of working with a client in a much different industry, with a new set of challenges. Joining this project has afforded me the opportunity to get to know a new type of business and work with two individuals who have placed a large emphasis on building a long-lasting relationship with this client. Over the course of this project, they have both given me some valuable insight into the kinds of solutions we can provide for this type of client.

The true strength of this relationship became evident through early discussions with the client during the analysis phase; they clearly already had a great understanding of our process and the effectiveness of our methods. As we explained where we believed the opportunities could be found and what we felt the estimated return would be from capitalizing on these opportunities, they didn’t hesitate for a second. They knew our company, they knew the management, and most importantly, they knew what we were capable of.

A Little Background

Our client is a worldwide logistics organization that has worked with USCCG for several years on multiple projects. It’s been a very interesting portfolio, resulting in a true partnership that perfectly models our “client for life” mentality. They understand that true change is a leadership responsibility; but at the same time, they set high expectations for the organization to deliver for both internal partners and external customers. This client relationship is based on mutual respect, which sometimes means we have to discuss tough, uncomfortable subjects; but they know we hold all aspects of the business in high regard for cost, quality, service, and people.

Our Goal: Streamline Fragmented Logistics Processes

Our Goal: Streamline Fragmented Logistics Processes

The term logistics is often applied to the planning of one or more complex tasks. Traditionally, it has been associated with moving material or people through a process. We like to consider a more broad-based holistic view-point. Logistics is the planning, scheduling, controlling, monitoring, and delivery of goods and/or services from order to cash.

Our process in this arena focuses in large part on the communication loops, either between people or systems, as this is often the greatest area of delay which results in increased costs, decreased service, deterioration of quality, and people’s frustration. The transmission and handling of information behind each customer order is astonishing, especially when you consider the end result of moving a product from A to B. The complexity of this process increases when you consider the multiple business units and multiple modes of transportation, along with the multiple systems being used to manage all of these transactions.

Consider a very practical example: When you look behind your TV at home and see a complete mess of wires running in every direction, you’re not exactly sure how everything functions properly, but it works so you leave it alone. A problem arises when you decide to purchase a new stereo and must remove some cables to plug-in others. You waste an enormous amount of time working through with this tangled mess, and when you’re finished, something isn’t working as it did before.

Our process here began with straightening out each cable one by one. This in itself was a very important exercise to truly understand the current state inner workings of the client before we began. It can at times be the most delicate balance to stay focused through the noise of working with such a large decentralized organization, while at the same time taking in the opinions of each and every employee you meet along the way. Every single opinion or suggestion, regardless of the source, could have an incredible impact on the success of the project. We absorb every piece of information, opinion, and suggestion, and then analyze it until we can draw a conclusion. I can confidently say that we truly leave no rock unturned. Once we have straightened all of the cables out, we began wrapping them up together to create uniform lines of communication.

We’re able to help improve logistical processes by fully understanding the reason for every transaction, reducing/eliminating duplication of effort, engaging enabling technology to improve communication and signals, and having robust business processes for both real-time and long-term decision-making capability. We looked into everything from booking services to dispatching line haul assets to deliver goods.

We didn’t come to the table with a pre-defined solution or software package. By engaging all of the employees in the development of the approach, from C-suite down to hourly, we could truly find a better method and teach the organization how to constantly move towards best. By truly understanding the current state, we could quickly go after gaps and disconnects in the existing processes to drive immediate change. Then, engage the organization in any requisite major changes to better deliver on cost, quality, service, and people issues.

Change is a Process, Not a Destination

Our methodology of discovery, prototyping, and implementation ensures that we have lasting impact and true organizational change. As we like to say, “Change does not take time, it takes energy.” While implementing changes, we always strive to make sure the USCCG project team executes on the deliverables we have committed to, without compromising our client’s values or mission statement.

Our client’s absolute trust in our team has given us the freedom to implement the best solutions possible for their unique situations. Their unfaltering zeal to embrace our recommendations and training has made the change process easier and faster, getting them to a better place in less time. This mutual commitment to support each other’s efforts has been vital to the success of this project and overall client relationship.