Your Workforce is Your Most Valuable Resource Underground

Maximize Your Return on Labor by Focusing on Advance/Man Shift

As one of the most valuable assets in an underground mine, the miners themselves can sometimes be overlooked when analyzing productivity and efficiency. Labor requirements are not always adjusted to suit the labor demands of different mining methods or conditions. The outcome is often over-crewing, resulting in excess labor costs associated with cost/ounce.

While the industry continues to move away from labor intensive mining methods, many jobs that can only be executed through the use of human capital still remain. This is where you may find large gaps between an experienced, highly skilled workforce and a younger, less skilled workforce. When building a crew for a development drive, it is crucial to set realistic expectations based on first hand observations of work-to-time relationships and provide a succinct message that these expectations are simply that. It is also important to clearly outline this message from a safety and employee morale perspective. Between direct observations and a consensus among the workforce, the following model was successfully prototyped at a North American gold mine, increasing productivity (as measured in meters/man shift) by up to 65%.

Firstly, it is imperative to understand how many people are required for each task and what tasks (if any) can be performed at the same time on one single heading. This will provide the basis for your model. In many cases, only one activity can be performed at the same time in the same heading by only one person. The removal of muck would be a good example of this, as only one miner would be needed in this heading for the duration of the task (mucking). Including any additional labor in this heading will not increase productivity or output in any way.

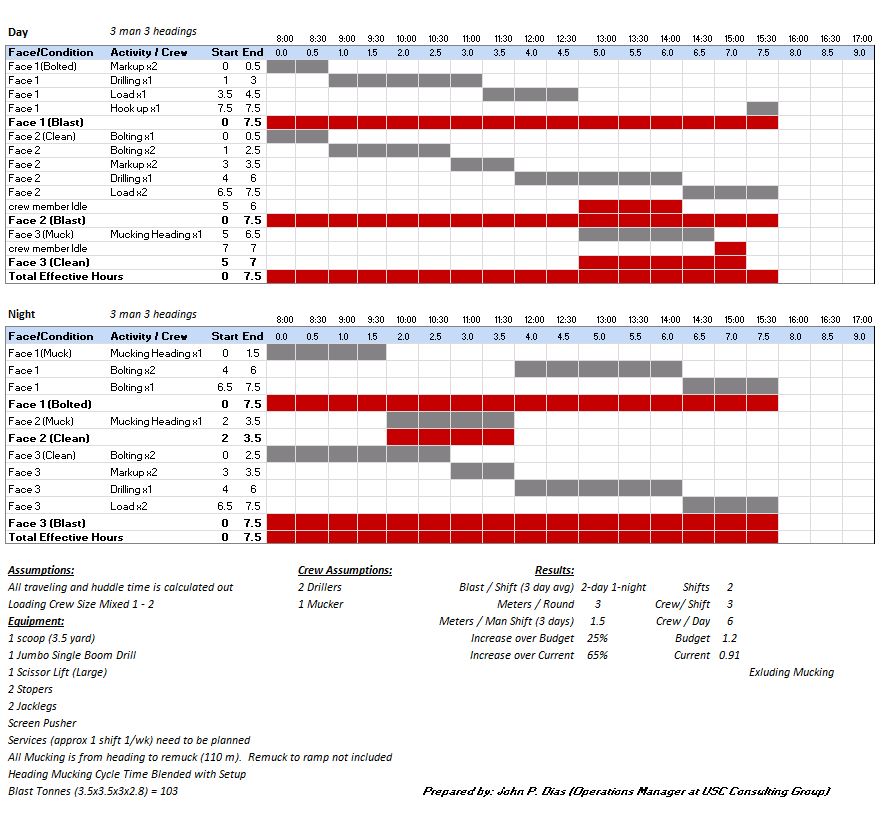

That being said, in the below example there are multiple activities that require the use of two miners, and therefore a crew size of at least two is expected. So how do you effectively allocate your one or two additional miners when a single person activity is being performed on the heading? The key word in that question is effectively. A common response to that question is to have the additional labor observe, clean up, refuel, prep, or assist if possible. In reality, with proper planning, none of those tasks would need to be done and are not an effective method of allocating your valuable underground resource.

The following model will show how effective providing multiple (three) work headings can be with a three person crew. The challenge then, from a planning and engineering perspective, is that they must provide the required number of headings as close in proximity as possible to each other. This ability is assumed in the following model.

With two shifts in each day and approximately eight operating hours available after line-outs and travel, the goal is to alternate between blasting two rounds on one shift and blasting one round on the other. Maintaining this cadence will yield three rounds per day (24 hours). If you are using a Productivity KPI such as meters (advance)/man shift, you will be targeting 1.5 meters/man shift (6 man shifts, 9 meters advanced). In other words, for every development miner you are sending underground, you can expect to advance your standard development headings by 1.5 meters.

In the case of our North American client, this target was achieved several times bringing them up from their current standing of .91 meters/man shift. This translates to a 64% improvement in labor productivity.