5 for 25: The Five Keys to Successful Operations in 2025

Labor shortages, supply chain disruption, and technological change have been cause for concern for executives in the manufacturing industry the last few years. As 2024 draws to a close, business leaders are looking ahead to the coming year. What will manufacturing be facing in 2025?

Here are five trends and challenges we’re expecting for the manufacturing industry in 2025 and advice on how to handle each issue.

1. Digital transformation

It’s not that AI and technology are coming for people’s jobs. It’s about this technology being able to streamline how the job gets done, adding speed, quality, and efficiency to the process. The 2024 Manufacturing and Distribution Pulse Survey Report by Citrin Cooperman found 43% of leaders in manufacturing are currently implementing advanced tech programs and policies in their organizations.

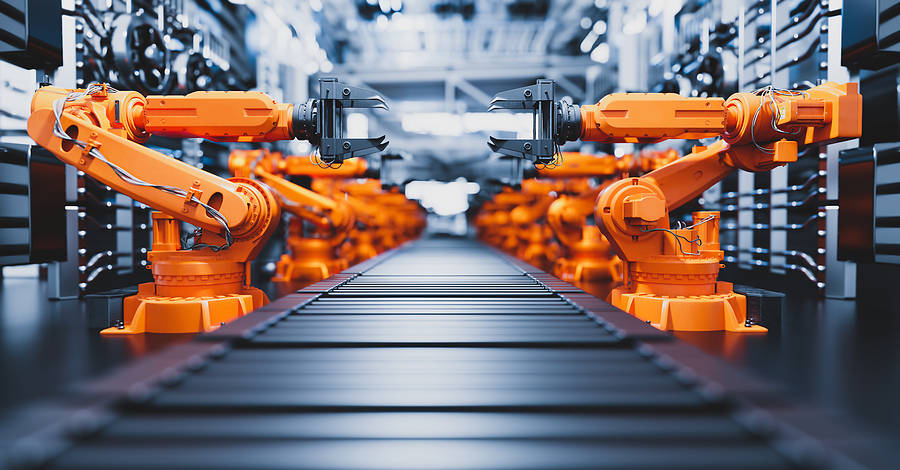

It’s involving AI and Machine Learning to optimize processes and outcomes, the Internet of Things (IoT) which will use smart technology to have machines communicate their own glitches and needs for maintenance, and robotics and automation for tasks like assembly.

The end goal is to increase predictive maintenance, optimize processes, ramp up quality control and provide real-time data for better decision making.

What manufacturing should do:

At USC, we help clients use AI, Machine Learning, and Predictive Analytics to optimize their workflows, processes and demand forecasting. Companies should be using these techniques now, if they’re not already. It’s also crucial to upskill existing employees to be able to work with the new technologies. That’s a win-win for manufacturing companies and their workforce. Higher skilled employees are happier, more effective, and more loyal to the company.

2. Talent

Workforce development, skills gaps and employee retention will be the top issues in regard to talent in 2025. It has been estimated that 1.9 million manufacturing jobs could go unfilled over the next decade if talent challenges aren’t solved. The old guard, long term, experienced employees that executives rely on to get the job done are retiring without a strong pipeline of younger workers to take their place. In addition, the labor force itself is concerned with flexibility, hours, pay, child care and more.

But there’s also the issue of skills. A new study by Deloitte and the Manufacturing Institute found that the need for roles requiring higher-level skills, including technical, digital and soft skills are growing at a rapid rate.

What manufacturing should do:

Working with local trade schools, community colleges and even high schools to offer internships and apprenticeships is a great way to build the talent pipeline.

Also, offering current employees training in digital skills, as well as soft skills like leadership and management training, will provide the company with higher-skilled workforce. This will create a sense of loyalty and pride in the employee knowing the company is investing in them with an eye toward the future.

3. Sustainability

The focus on sustainability is everywhere. Manufacturers are feeling increased pressure to become greener, and as a result are implementing environmental, social and governance strategies.

There is governmental pressure because of tighter environmental standards, but there is also pressure coming from consumers who increasingly want and seek out goods that are manufactured with “clean” methods.

What manufacturing should do:

Continuing to investigate efficient technologies like solar and wind, and making investments in machinery and other assets that are more energy efficient, will be crucial in the coming year and beyond. It will help lower operating costs while satisfying the demand from consumers.

4. Supply chain

Supply chain disruption that plagued just about every business on the planet during the pandemic has eased to a great extent, but challenges are still out there. Lead times for materials is still high, and the cost of transportation and logistics is weighing on companies’ bottom lines.

Shipping delays and uncertainties are a big part of the problem, with headlines nearly every day of yet another cargo ship being attacked at sea.

Then there’s the issue of labor shortages all along the supply chain, both in foreign countries and the U.S., with labor strikes slowing down delivery and labor shortages of truck drivers adding to the snarl.

What manufacturing should do:

It’s extremely challenging for companies to combat labor shortages and shipping delays in their supply chains, but smart demand forecasting and considerations like reshoring supply sources can help. In addition, establishing a strong Sales, Inventory, and Operations Planning (SIOP) program will optimize your supply chain.

5. Tariffs

With a new administration may come new global trade policies, and it’s not just the U.S. that held elections in 2024. Many countries around the globe are restructuring leadership. Ongoing U.S.-China trade tensions will certainly intensify as a result of the tariffs the new administration is proposing, driving up the cost of materials for manufacturers.

What manufacturing should do:

Many manufacturers are ordering supplies and materials now, before the new administration takes over. Stocking up now, in case of major price hikes later.

This issue goes hand in hand with supply chain disruption and is one more reason to consider reshoring and nearshoring of supplies and materials.

The Outlook

Despite ongoing challenges, 2025 looks bright for manufacturers to grow their businesses. Adapting operations to be sustainable and incorporating advanced technology with an upskilled workforce to manage it, business leaders will enjoy major improvements to productivity, their supply chain, and customer satisfaction.

At USC Consulting Group, we’re here to help manufacturing companies become more productive and profitable with standardized operating procedures, enhanced management operating systems, SIOP improvements, and other strategies to find opportunities for greater efficiencies, increased throughput and bottom line results. Contact us today to have your operations humming in 2025.