S&OP vs SIOP – What’s In a Name and How Can It Help My Business?

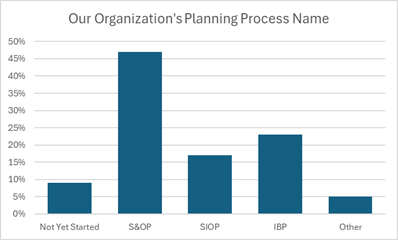

There are a lot of terms used by organizations to describe their mid to long range strategic planning discipline. Whether your organization calls it Integrated Business Planning (IBP), Sales and Operations Planning (S&OP), Sales, Inventory and Operations Planning (SIOP) or something else, the key message is that abbreviations are not important – results are. Strong strategic planning discipline orchestrates sales plans, operations constraints, and financial objectives while giving guidance to short-term scheduling for execution. At USC, we call this discipline SIOP due to the strategic importance of inventory to smooth supply and demand fluctuations to maintain customer service levels.

Survey Says!

Businesses find S&OP beneficial because it helps balance supply and demand, it improves communication between sales and other departments, leads to better decision-making with everyone on the same page, and it ultimately results in better efficiency. Most organizations refer to their planning process as S&OP, but we think it’s incomplete. Inventory needs to be part of this process to unlock greater levels of operational efficiency and customer service rates.

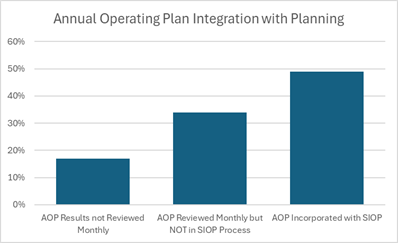

Most companies have less than five years of experience utilizing a SIOP discipline and significantly, fewer than 50% of all companies integrate financial objectives into their monthly planning process. The result is the organization’s annual plans are disconnected from the monthly “replanning” SIOP process. Managers are typically held accountable to their annual plans which are increasingly out of date as the year progresses and better plans are known resulting in sub-optimal decision making based on old assumptions.

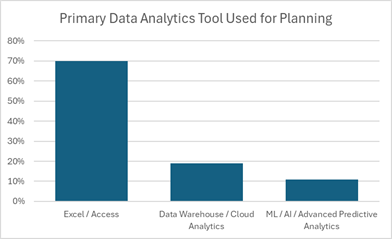

Furthermore, since most companies rely on static models such as Excel and Access to as their primary analytical tools, the planning process can be labor intensive, time consuming and more prone to human error. Integrating decision support systems with operations data, procurement data, inventory data, and customer demand improves simulation and scenario analysis capabilities. Integrating with advanced predictive analytics can further augment planning knowledge.

Sales, Inventory and Operations Planning

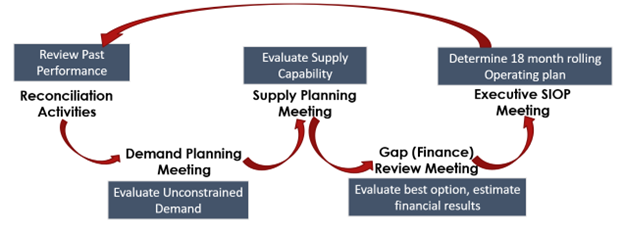

We tell our clients that SIOP is making sure you’re having the right conversations about the right things at the right time.

Sales, Inventory, and Operations Planning is a holistic process that integrates customer-focused demand plans with production, sourcing and inventory plans and results in improved tactical and long-term business decision making capability.

Keys to Implementing a Successful SIOP Process

- Everyone is on board. It’s simply not going to work if it’s not interdepartmental. You need everyone – Sales & Marketing, Operations, Procurement and Logistics, Planning, Product Development, Finance, IT, and the C-Suite working in lock step from the same plan.

- Planning cycles should be monthly. This isn’t a one-and-done process. Once you get on the SIOP treadmill, you don’t ever get off. We advise a rolling 18-month period, updated monthly. This ensures the re-planning process is looking out beyond the current budget year and for strategic planning.

- People and Process Discipline is a must. A good SIOP process includes a SIOP monthly process schedule/calendar of key events, RACIs, mutually agreed upon KPIs, actual vs forecasted reporting scorecards, assumptions and occurrences reporting, decisions made with action item follow up.

But Why the Added Focus on Inventory?

Inventory tells a story about a business’ operational efficiency. Inventory accounts pool the collective decisions and market forces affecting the company, telling stories of sales forecasting accuracy, manufacturing efficiency, planning effectiveness, supply chain disruptions, and quality control. Lean inventories reveal robust planning systems and culture, integrated ERP systems, and good governance. Excess inventories can be a short-term benefit to sustain high customer service levels during times of uncertainty, however they come with high obsolescence and carrying costs. Inventory is a strategic lever to smooth operations, procurement, and sales fluctuations. The right level of inventory is different for each company, and changes based on current consumer demand, supply chain disruptions, and strategic decisions.

Benefits of SIOP

- Gets departments in sync. The SIOP process helps to determine whether

your original financial expectations / budget, and your current sales plan and operations plan are in sync with each other. Updating your forecast monthly will show you where problems lie and provide action plans to address shortfalls. - Ensures that the plans are realistic. The key stakeholders from each department participate in formulating the SIOP plan. Since all assumptions are transparent throughout the process, each department has more time to evaluate its resources and capabilities in the context of the most recent company-wide plan. The result is a solid set of department plans that are based on latest expectations and known capabilities.

- Effectively manages change. Many industries have faced significant planning challenges in recent years. Having an agile and timely planning process helps decision makers roll with the punches. With SIOP, your business can make holistic, controlled responses to changes instead of making knee-jerk, departmental centric reactions.

- Measures performance. Our customized approach to KPIs ensures that success measurements identify where the organization is challenged and where to focus on improvement.

- Builds teamwork. SIOP gives each department an opportunity to participate in the overall planning process.

Interested to learn more about how adding inventory to your planning can make you more efficient? For more information on how SIOP can help your business read our eBook, “Sales, Inventory and Operations Planning: It’s About Time.”

*This article is written by USC Consulting Group’s Supply Chain Practice Leader, David Newman.